Professional Documents

Culture Documents

EMC Reference Material

Uploaded by

吴川斌Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EMC Reference Material

Uploaded by

吴川斌Copyright:

Available Formats

age 1 of 76

CopyrlghL 2014 LMC lasLass

age 2 of 76

CopyrlghL 2014 LMC lasLass

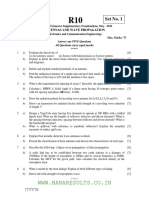

Getting EMC Design Right

First Time

Version 2.0

By

Author: M. Rangu (Ph.D)

Editor: A. Eadie (B.Eng)

age 3 of 76

CopyrlghL 2014 LMC lasLass

Foreword

LMC lasLass was creaLed wlLh a sole mlsslon: 1o geL elecLronlc deslgn companles Lhrough

onerous LMC LesLlng requlremenLs fasLer and cheaper. Cur alm ls Lo asslsL Lhe elecLronlcs deslgn

lndusLry Lo focus on maklng producLs LhaL make money, and mlnlmlze Lhe lmpacL of regulaLory

red Lape wherever posslble. 1o achleve Lhls, we offer valuable advlce on how Lo deslgn producLs

LhaL pass LesLlng flrsL Llme around, such as Lhls ebook and our lndusLry leadlng LMC AuLo-

CorrecL ueslgn 8evlew (vlslL hLLp://www.emcfasLpass.com for more deLalls) as well as regulaLory

guldance Lo help cllenLs avold or mlnlmlze 3rd parLy LesLlng wherever posslble. We also acLlvely

lobby governmenL agencles such as Lhe lCC for senslble de-regulaLlon opporLunlLles LhaL lower

Lhe LesLlng burden on elecLronlcs manufacLurers.

As a senlor hardware deslgn englneer and former founder/owner of an LMC LesL lab, l can

appreclaLe Lhe lndusLry's frusLraLlon wlLh Lhe LMC/8l LesLlng process. lL ls expenslve and can

lead Lo producL launch delays of weeks or even monLhs. Cver Lhe 3 years LhaL l managed a LesL

lab, l noLlced several areas LhaL many manufacLurers conslsLenLly sLruggled wlLh. MosL

companles l came across only released 1-3 new producLs per year and as such, dld noL

encounLer Lhe LesLlng process regularly. 1esL labs on Lhe oLher hand see Lens or hundreds of

producLs per year and Lherefore have a much beLLer undersLandlng of Lyplcal fallure modes and

flxes.

LMC lasLass closes Lhls loop ln knowledge beLween LesL labs and Lhe elecLronlcs lndusLry

uLlllzlng a sLep by sLep supporL process. 1he process regularly saves cllenLs $10,000+ ln LesLlng

cosLs and 6 weeks Llme Lo markeL.

Ln[oy,

Andy Ladle.

Tips and Tricks Email Sign-Up

lf you haven'L already [olned Lhe 100's of companles around Lhe world LhaL have slgned up Lo

our free newsleLLer, where we regularly dlsclose llLLle known deslgn and regulaLory Llps LhaL can

be worLh as much as $3000 Lo your company, Lhen please do so here.

Disclaimer

1he lnformaLlon provlded wlLhln Lhls documenL ls based upon lndusLry sLandard besL pracLlces. Powever,

lmplemenLlng any or all of Lhe recommended changes conLalned wlLhln Lhls reporL offers no guaranLee

LhaL Lhe producL wlll be funcLlonal or pass LMC emlsslons or lmmunlLy LesL sLandards. 1hls documenL or

any porLlon of lLs conLenLs may noL be modlfled, copled, reproduced or dlsLrlbuLed ln any form, for proflL

or oLherwlse, wlLhouL express consenL of 'LMC lasLass'. ConLacL lnfo[emcfasLpass.com for publlshlng

requesLs.

age 4 of 76

CopyrlghL 2014 LMC lasLass

Table of Contents

1. Ground|ng and |anes...................................................................................................... 7

1.1 lllLers ............................................................................................................................ 7

1.2 8ouLlng ......................................................................................................................... 8

1.3 lane sloLs and boundarles .......................................................................................... 9

1.4 uecoupllng capaclLors ................................................................................................ 10

1.3 ower ulsLrlbuLlon neLwork lmpedance .................................................................... 11

2. n|gh Speed Cons|derat|ons ............................................................................................ 13

2.1 ldenLlfylng Plgh Speed Slgnals ................................................................................... 13

2.2 lmpedance .................................................................................................................. 14

2.2.1 Slngle Lnded CharacLerlsLlc lmpedance ............................................................. 13

2.2.2 ulfferenLlal lmpedance ....................................................................................... 16

2.3 1ermlnaLlons............................................................................................................... 18

2.3.1 Slngle Lnded 1ermlnaLlons ................................................................................. 18

2.3.2 ulfferenLlal 1ermlnaLlons ................................................................................... 20

2.4 lacemenL ................................................................................................................... 22

2.4.1 arLlLlonlng ......................................................................................................... 22

2.4.2 Zonlng ................................................................................................................. 22

2.4.3 Analog 8uffers .................................................................................................... 23

2.3 8ouLlng ....................................................................................................................... 24

2.3.1 1opology ............................................................................................................. 24

2.3.2 8us 8ouLlng ......................................................................................................... 26

2.3.3 Corners ............................................................................................................... 28

2.3.4 vlas ..................................................................................................................... 28

2.3.3 ulfferenLlal 8ouLlng ............................................................................................ 28

2.3.6 roxlmlLy Lo 8oard Ldge ..................................................................................... 30

2.6 Slgnal 1lmlng ............................................................................................................... 31

2.6.1 ldenLlfylng Llme-crlLlcal slgnals ........................................................................... 31

2.6.2 ropagaLlon Llme ................................................................................................ 32

2.6.3 Lye dlagram analysls .......................................................................................... 32

2.7 CsclllaLors / CrysLals ................................................................................................... 33

3. Crossta|k ......................................................................................................................... 33

3.1 ldenLlfylng vlcLlms and Aggressors ........................................................................ 33

3.2 Layer AsslgnmenL ................................................................................................... 33

3.3 CrLhogonallLy ......................................................................................................... 36

3.4 arallellsm .............................................................................................................. 36

3.3 Cuardlng ................................................................................................................. 37

3.6 8eLurn paLhs ........................................................................................................... 38

3.7 8ecelver lacemenL ................................................................................................ 39

4. LMC Cons|derat|ons ....................................................................................................... 42

4.1 Ceneral ConslderaLlons .............................................................................................. 42

4.2 ComponenLs ............................................................................................................... 42

4.2.1 ComponenL selecLlon ......................................................................................... 43

4.2.2 Plgh speed fllLers ................................................................................................ 43

4.2.3 unused plns ........................................................................................................ 44

age 3 of 76

CopyrlghL 2014 LMC lasLass

4.2.4 PeaLslnks ............................................................................................................ 44

4.2.3 Shlelded componenLs ......................................................................................... 44

4.3 ower Supply .............................................................................................................. 43

4.3.1 Malns .................................................................................................................. 43

4.3.2 volLage regulaLors .............................................................................................. 43

4.3.3 SwlLchlng mode power supplles ......................................................................... 46

4.4 8ouLlng ....................................................................................................................... 47

4.4.1 Clock dlsLrlbuLlon ................................................................................................ 47

4.4.2 Cuardlng ............................................................................................................. 48

4.4.3 SLubs ................................................................................................................... 49

4.3 SysLem deslgn ............................................................................................................. 49

4.3.1 Chassls groundlng ............................................................................................... 49

4.3.2 Cables ................................................................................................................. 30

4.3.3 ConnecLors ......................................................................................................... 31

4.6 LSu & SafeLy ............................................................................................................... 32

4.6.1 ConnecLors ......................................................................................................... 32

4.6.2 SenslLlve plns .......................................................................................................... 34

4.6.3 Plgh volLage ........................................................................................................... 34

3. Des|gn for 1est ............................................................................................................... 33

3.1 1esL olnLs .................................................................................................................. 33

3.2 1oollng lns ................................................................................................................ 33

3.3 ush flngers ................................................................................................................ 36

3.4 Seallng ........................................................................................................................ 36

3.3 ACl .............................................................................................................................. 36

6. Des|gn for Manufacture ................................................................................................. 37

6.1 SLackup ....................................................................................................................... 37

6.1.1 SymmeLry ........................................................................................................... 37

6.1.2 urlll palrs ............................................................................................................. 37

6.1.3 Copper balance ................................................................................................... 38

6.2 ueslgn 8ules Check ..................................................................................................... 39

6.2.1 Clearance ............................................................................................................ 39

6.2.2 WldLh .................................................................................................................. 60

6.2.3 Annular 8lng ....................................................................................................... 60

6.2.4 Sllvers .................................................................................................................. 60

6.2.3 Acld 1raps ........................................................................................................... 61

6.2.6 Sllkscreen Cver ads ........................................................................................... 62

6.3 Mechanlcal ................................................................................................................. 62

6.3.1 Mechanlcal urawlngs ......................................................................................... 62

6.3.2 urlll urawlngs ..................................................................................................... 63

6.3.3 SloLs .................................................................................................................... 63

6.3.4 MounLlng holes .................................................................................................. 64

6.3.3 anellzaLlon ........................................................................................................ 64

6.3.6 C8 manufacLurlng speclflcaLlons ...................................................................... 63

6.4 Assembly ConslderaLlons ........................................................................................... 66

6.4.1 Assembly llow .................................................................................................... 66

6.4.2 SLenclls ................................................................................................................ 66

6.4.3 anellzed Assembly ............................................................................................ 67

6.4.4 uecals ................................................................................................................. 67

6.4.3 llduclals .............................................................................................................. 68

age 6 of 76

CopyrlghL 2014 LMC lasLass

6.4.6 1hermal 8ellef .................................................................................................... 69

6.4.7 Assembly drawlngs and 8CM ............................................................................. 69

6.4.8 C8 Assembly SpeclflcaLlons .............................................................................. 70

6.3 ManufacLurlng flles .................................................................................................... 71

6.3.1 Cerber ................................................................................................................. 71

6.3.2 nC urlll ................................................................................................................ 71

6.3.3 lck & lace ........................................................................................................ 71

6.3.4 1esL olnL 8eporL ................................................................................................ 71

7. 1herma| cons|derat|ons ................................................................................................. 72

7.1 ower ulsslpaLlon ....................................................................................................... 72

7.2 PeaLslnks .................................................................................................................... 72

7.3 Coollng Areas .............................................................................................................. 73

7.4 CurrenL Carrylng CapaclLy .......................................................................................... 73

8. ne|pfu| Ut|||t|es .............................................................................................................. 73

8.1 lC7331 Land aLLern CalculaLor ................................................................................ 73

8.2 C8 labrlcaLlon Wall CharL ......................................................................................... 73

8.3 C8 CalculaLors ........................................................................................................... 73

8.4 lllLer SelecLlon SlmulaLor ........................................................................................... 76

8.3 ClrculL SlmulaLlon 1ools .............................................................................................. 76

age 7 of 76

CopyrlghL 2014 LMC lasLass

1. Ground|ng and |anes

1.1 I||ters

Lach power supply musL have a fllLer locaLed ln close proxlmlLy elLher Lo Lhe volLage

regulaLor lf lL ls locaLed on board, or near Lhe C8 enLry polnL lf regulaLor ls exLernal. 1hls fllLer

should be deslgned ln accordance wlLh Lhe rlpple characLerlsLlcs of Lhe regulaLor and Lhe power

supply requlremenLs of Lhe lnLegraLed clrculLs, and should lnclude aL leasL Lwo capaclLors:

- Cne large capaclLor ( l ) for low-frequency fllLerlng

- Cne small capaclLor ( nl ) for hlgh-frequency fllLerlng

lnLegraLed clrculLs LhaL requlre a clean power supply should be provlded wlLh an

addlLlonal L-C fllLer, Lo avold nolse coupllng Lhrough from oLher blocks of Lhe clrculL. An example

of approprlaLe fllLerlng for such a case ls lllusLraLed by flgure 3.1

llg. 3.1 lllLerlng of hlgh and low S88 blocks supply

lurLher deLalls on Lhe fllLer placemenL and rouLlng are provlded ln Lhe LMC chapLer,

paragraph 6.3.2

n|nt on f||ter|ng

- "#$ % &'()%' *+',$- *(- $%./ 0(1$- #200'34 "#$ % '(.%' *+',$- *(- $%./ )'(.5

#$6#+,+7$ ,( 0(1$- #200'3 6(+#$4

age 8 of 76

CopyrlghL 2014 LMC lasLass

1.2 kout|ng

1he power dlsLrlbuLlon neLwork (un) should provlde a low-lmpedance paLh beLween

Lhe volLage regulaLor and Lhe lnLegraLed clrculLs. 1he besL way Lo achleve Lhls ls by uslng power

planes boLh for Lhe supply volLage and ground, as planes provlde an lnLer-plane capaclLance and

a low lnducLance. lf mulLlple supply volLages and ground neLs are used, Lhey should noL be

placed on parallel planes as Lhe capaclLlve coupllng beLween Lhem wlll allow hlgh frequency

currenLs Lo flow beLween planes. lor such a case Lhe plane layers should be spllL beLween

mulLlple neLs. llgure 3.2 lllusLraLes an example of poor and proper separaLlon of slgnal and 8l

ground.

CCk

GCCD

llg. 3.2 Lxample of poor and good ground separaLlon

1he flrsL soluLlon ls poor because:

- 8l currenLs musL Lravel Lo Lhe dlglLal ground ln order Lo reach Lhe Cnu polnL (aL supply)

- 1he small clearance beLween dlglLal and 8l ground wlll generaLe capaclLlve coupllng

1he second soluLlon ls good because:

- 8l reLurn paLh does noL overlap wlLh Lhe dlglLal reLurn paLh

- 1he large clearance beLween planes mlnlmlzes Lhe coupllng capaclLance

- AddlLlonal lnducLors lncrease Lhe coupllng lmpedance, Lo prevenL 8l currenLs Lo flow

from one plane Lo anoLher

lf planes cannoL be used for each supply volLage, Lhe rouLlng should be done wlLh

respecL Lo Lhe followlng recommendaLlons:

8+9 ower and ground Lraces should be as wlde as posslble

8++9 ower and ground Lraces should noL creaLe large loops, as Lhls wlll drasLlcally

lncrease Lhe self lnducLance

8+++9 Any avallable areas on C8 should be fllled wlLh ground lsland

8+79 lf a layer ls used for boLh rouLlng and as a ground plane, cauLlon should be Laken

when rouLlng Lhrough Lhe plane ln order Lo avold creaLlng large reLurn loops. lf a

Lrace musL peneLraLe Lhe plane Lhen Lhls should be brldged, as lllusLraLed by flg 3.3.

An abso|ute MUS1 for rout|ng power]ground traces

- :(1$-;&-(26< ,-%.$ #/(2'< )$ %# 1+<$ %# 0(##+)'$ %6< .'(#$ ,( $%./ (,/$-4

age 9 of 76

CopyrlghL 2014 LMC lasLass

(a) (b)

llg. 3.3 un-brldged (a) and brldged (b) ground plane

879 lf a sLar dlsLrlbuLlon Lopology ls requlred for crossLalk or LMC conslderaLlons, such

as Lhe un lllusLraLed ln flg. 3.1, each supply Lrace musL have lLs own reLurn paLh ln

order Lo fulflll Lhe small loop area" requlremenL

87+9 lf mulLlple lsolaLed ground levels are used, such as a common ground and a 8l

ground, Lhey should noL be rouLed ln proxlmlLy Lo avold capaclLlve coupllng.

1.3 |ane s|ots and boundar|es

lane sloLs are creaLed when a plane ls cuL Lo accommodaLe rouLlng Lraces. 1hls should

be avolded when posslble, buL someLlmes musL be done due Lo rouLlng space resLrlcLlons. lane

sloLs are also creaLed by 1Pu componenLs such as dual ln-llne lCs or row connecLors. llgure 3.4

lllusLraLes such examples of plane sloLs.

llg. 3.4 lane sloLs

When a slgnal Lrace passes over a plane sloL, Lhe reLurn currenL wlll have Lo Lravel around Lhe

sloL and so creaLe a large loop whlch wlll add an lmpedance dlsconLlnulLy, lncrease lLs self

lnducLance and radlaLed emlsslon. 1o prevenL Lhls, hlgh speed slgnal Lraces should noL pass over

plane sloLs. lf Lhls cannoL be avolded Lhan anoLher reLurn paLh should be creaLed, close Lo Lhe

slgnal paLh, elLher uslng a ground Lrace or a parLlal plane on anoLher layer.

A slmllar Lhlng happens when slgnals pass over Lhe boundary beLween separaLed planes. 1hls

should also be avolded.

n|nt on rout|ng over p|ane s|ots and boundar|es

- =(6>, ???

age 10 of 76

CopyrlghL 2014 LMC lasLass

1.4 Decoup||ng capac|tors

Lach lnLegraLed clrculL should have aL leasL a decoupllng capaclLor placed ln close

proxlmlLy Lo Lhe supply plns. 1he decoupllng capaclLors are requlred Lo provlde Lhe LranslenL

currenLs Lhe lC needs durlng swlLchlng, Lo counLeracL Lhe effecL of Lhe power supply ouLpuL

lnducLance and supply-lC lnLerconnecLlon lnducLance. lor Lhe decoupllng capaclLors Lo be

effecLlve, Lhelr placemenL and rouLlng should be done wlLh respecL Lo Lhe followlng

recommendaLlons:

8+9 1he decoupllng capaclLors should be placed as closed as posslble Lo Lhe supply plns

of Lhe lC

8++9 lf Lhe lC has mulLlple vCC-Cnu palrs, each requlre lLs own decoupllng capaclLor. See

manufacLurer's daLasheeL and appllcaLlon noLes for furLher deLalls.

8+++9 lf Lhe power and ground plns are far aparL, lL ls beLLer Lo place Lhe capaclLor closer

Lo Lhe ground pln, as slgnals are referenced Lo ground

8+79 1he power and ground plns should noL be connecLed dlrecLly Lo Lhe power and

ground neLs buL Lhrough Lhe decoupllng capaclLor, oLherwlse lLs effecLlveness wlll

be llmlLed

879 1he Lraces connecLlng Lhe decoupllng capaclLor Lo Lhe lC plns should be as wlde and

closely spaces as posslble, Lo provlde a low lmpedance beLween Lhem

87+9 1he Lraces connecLlng Lhe decoupllng capaclLor Lo Lhe power and supply neLs should

be narrow and loosely spaced, Lo provlde a hlgh lmpedance Lo Lhe poLenLlal nolsy

power and ground neLs.

llgure 3.3 lllusLraLes Lhe approprlaLe placemenL and rouLlng of Lhe decoupllng capaclLors.

llg. 3.3 lacemenL / rouLlng of Lhe decoupllng capaclLors

n|nt on decoup||ng

- "#$ @2',+0'$ <$.(20'+6& .%0%.+,(-# 0$- 0+6 0%+- *(- AB# $C0$.,$< ,( &$6$-%,$

% '(, (* 6(+#$ 8/+&/D#0$$< )2# <-+7$-#E =F:#E 0-(.$##(-#9

n|nt on rout|ng decoup||ng capac|tors

- G%5$ #2-$ ,/$ #200'3 .2--$6, &($# ,( .%0%.+,(- *+-#,E %6< (6'3 ,/$6 ,( ,/$ AB

age 11 of 76

CopyrlghL 2014 LMC lasLass

Standa|one De-coup||ng Capac|tor V|a |acement Lffect|veness

1.S ower D|str|but|on Network Impedance

1he power dlsLrlbuLlon neLwork (un) lmpedance ls deLermlned by several facLors,

lllusLraLed by flg. 3.6:

- 1he power supply ouLpuL lmpedance

- 1he C8 Lraces lmpedances

- 1he power supply fllLerlng

- 1he decoupllng capaclLors

- 1he cholce of fllLerlng and decoupllng capaclLors (Lrough Lhelr equlvalenL serles

reslsLance - LS8 - and equlvalenL serles lnducLance - LSL)

- 1he lnLer-plane capaclLance of Lhe C8

- 1he lCs lnpuL lmpedance.

llg. 3.6 un LqulvalenL clrculL

1he goal of analyzlng Lhe un lmpedance ls Lo keep lL as low as posslble on Lhe enLlre

frequency range beLween uC and Lhe effecLlve frequency (see paragraph 4.2 for a deflnlLlon of

Lhe effecLlve frequency). 1he mosL crlLlcal aspecL regardlng Lhe cholce of decoupllng capaclLors

ls, besldes Lhe capaclLance value, Lhelr LSL. As a general requlremenL, decoupllng capaclLors

should have a low LSL, whlch ls accompllshed uslng small packages (0402, 0603).

As so many facLors conLrlbuLe Lo Lhe un lmpedance, lL ls lmporLanL Lo run a Lhorough

analysls uslng a sofLware Lool. llgure 3.7 lllusLraLes one slLuaLlon where a slngle deLall really

n|nt on DN |mpedance

- =(6>, ,-2#, -2'$# (* ,/2@) (6 ,/+#E %# <$,%+'# @%,,$-4 H26 % ,/(-(2&/ %6%'3#+#

,( @%5$ #2-$ ,/$ :=I +@0$<%6.$ +# '(1 (6 ,/$ $6,+-$ *-$J2$6.3 -%6&$4

8educed lnducLance = lmprovemenL

Worse performance

8eLLer performance

age 12 of 76

CopyrlghL 2014 LMC lasLass

makes Lhe dlfference: Lwo ldenLlcal decoupllng soluLlons lmplemenLed on dlfferenL sLackups.

noLe LhaL when Lhe C8 provldes an lnLer-plane capaclLance Lhe un wlll have a large

lmpedance around 300 MPz, caused by Lhe anLl-resonance beLween Lhe lnLer-plane capaclLance

and Lhe 1 [nl] decoupllng capaclLor, whlch wlll llkely generaLe hlgher supply nolse aL Lhls

frequency.

100 [I] || 1 [nI] || C8 |nter-p|ane capac|tance

100 [I] || 1 [nI], no C8 |nter-p|ane capac|tance

llg. 3.3 un lmpedance analysls

lree un analysls sofLware such as AlLera's un Lool can provlde a

lumped-modellng analysls of Lhe decoupllng neLwork Lo predlcL Lhelr lmpedance. lf a more

age 13 of 76

CopyrlghL 2014 LMC lasLass

deLalled analysls ls requlred Lhen a dlsLrlbuLed-modellng slmulaLlon uslng a power lnLegrlLy

slmulaLor such as Pyperlynx l should be consldered. See secLlon 11.3 for sofLware opLlons.

2. n|gh Speed Cons|derat|ons

2.1 Ident|fy|ng n|gh Speed S|gna|s

Plgh speed slgnals are noL necessary slgnals of hlgh frequency, buL raLher slgnal wlLh fasL

rlse/fall Llme. MosL of Lhe energy of a dlglLal slgnal ls concenLraLed below Lhe knee frequency,

deflned as:

0.35

[ ]

[ ]

KNEE

rise

f GHz

t ns

= (4.1)

llg. 4.1 SpecLrum of a dlglLal slgnal wlLh f

CL8A1lnC

=1 [MPz] and L

r

= 0.1 [ns]

ln order Lo avold dlsLorLlon of dlglLal slgnals, Lhe C8 musL be able Lo LransporL Lhelr

enLlre specLrum noL [usL Lhe operaLlng frequency.

Cr|t|ca| Length ku|e

- F+&6%'# .%--+$< )3 :BK ,-%.$# '(6&$- ,/%6 L;LM (* ,/$ .-+,+.%' '$6&,/ #/(2'< )$

-$&%-<$< %# /+&/ #0$$< #+&6%'#

age 14 of 76

CopyrlghL 2014 LMC lasLass

Plgh speed slgnals make Lhe C8 Lraces acL as Lransmlsslon llne, even lf Lhelr physlcal

lengLh seems shorL. A good lndlcaLor of when a Lrace exhlblLs Lransmlsslon llne behavlor ls Lhe

crlLlcal lengLh, deflned as:

[ ]

2 2

r r

CR

t t v

l m

TD

= =

(4.2)

, where 1u ls Lhe characLerlsLlc Llme delay of Lhe llne:

8

1

3 10

r

s

TD

v m

c

(

= ~

(

(4.3)

llg. 4.2 lllusLraLes Lhe crlLlcal lengLh for varlous dlelecLrlc consLanLs (

r

c ) ln Lhe Lyplcal

range 2-10.

llg. 4.2 1he crlLlcal lengLh for varlous dlelecLrlc consLanLs

As Lhe physlcal lengLh of Lhe Lrace approaches Lhe crlLlcal lengLh, slgnal reflecLlon,

crossLalk and elecLromagneLlc radlaLlon lncrease.

2.2 Impedance

Contro||ed Impedance ku|e

- N+&/ #0$$< #+&6%'# #/(2'< %'1%3# )$ -(2,$< 1+,/ .(6,-(''$< +@0$<%6.$E

$+,/$- +6 @+.-(#,-+0 (- #,-+0'+6$ .(6*+&2-%,+(64 O2-,/$-@(-$E /+&/ #0$$<

#+&6%'# -$J2+-$ ,$-@+6%,+(6# 8#$$ 0%-%&-%0/ P4Q9

Note on d|fferent|a| |mpedance:

- R/$ <+**$-$6,+%' +@0$<%6.$ (* % <+**$-$6,+%' 0%+- +# ,1+.$ ,/$ (<<D@(<$

./%-%.,$-+#,+. +@0$<%6.$ (* $%./ ,-%.$ %6< '(1$- ,/%6 ,/$ <+**$-$6,+%'

+@0$<%6.$ (* ,1( 26D.(20'$< ,-%.$#

age 13 of 76

CopyrlghL 2014 LMC lasLass

2.2.1 S|ng|e Lnded Character|st|c Impedance

1he characLerlsLlc lmpedance of a C8 Lrace represenLs Lhe raLlo of Lhe volLage and

currenL waves propagaLlng Lhrough a Lransmlsslon llne. lL ls characLerlsLlc ln Lhe sense LhaL lL

characLerlzes slgnal propagaLlon Lhrough any lnflnlLeslmally shorL segmenL of Lhe Lransmlsslon

llne, and lL ls a local parameLer as lL can vary along Lhe Lrace.

noLe LhaL Lhe characLerlsLlc lmpedance should noL be mlsLaken as Lhe self lmpedance

(or self reslsLance) of Lhe Lrace: a 1[m] long Lrace may have Lhe same characLerlsLlc lmpedance

as a 2[m] long Lrace, whlle Lhelr self reslsLances wlll be dlfferenL. 1he Lyplcal range for C8 Lraces

characLerlsLlc lmpedance ls 20-100 [U] and please noLe LhaL Lhe self reslsLance of Lhe same Lrace

mlghL be ln Lhe range of hundreds of [mU].

Lach lnflnlLeslmally shorL segmenL of a Lransmlsslon llne can be regarded as an 8-L-C-C

clrculL, as lllusLraLed by flg. 4.3. 1hose characLerlsLlc parameLers of Lhe Lransmlsslon llne

deLermlne lLs characLerlsLlc lmpedance:

| |

0 0 0

0

0 0 0

R j L L

Z

G j C C

e

e

+

= ~ O

+

(4.4)

llg. 4.3 1he elecLrlcal model of a Lransmlsslon llne

1he characLerlsLlc lmpedance ls deLermlned by Lhe dlelecLrlc Lype, Lrace geomeLry and

proxlmlLy Lo power and ground planes. ln order Lo conLrol Lhe characLerlsLlc lmpedance of a

Lrace, Lhose parameLers musL be conLrolled. 1here are Lwo baslc C8 geomeLrles LhaL allow Lhe

conLrol of Lhe Lraces characLerlsLlc lmpedance: mlcrosLrlp (slgnal Lrace LexL Lo a slngle reference

plane) and sLrlpllne (slgnal Lrace beLween Lwo reference planes). LlLher vCC or Cnu planes can

be regarded as reference planes for lmpedance conLrol.

Surface m|crostr|p

Symmetr|c str|p||ne

age 16 of 76

CopyrlghL 2014 LMC lasLass

0

87 5.98

ln

0 .41

[

8 1

]

.

r

H

Z

W T c

| |

=

|

+ + .

O

\

( )

0

1.9 2

60

ln

0

[ ]

.8

r

H T

Z

W T c

| | +

=

|

+

\ .

O

Lmbedded m|crostr|p

0

60 5.98

ln

0.8 '

[ ]

r

H

Z

W T c

| |

=

|

+

\ .

O

1.55 '

' 1

H

H

r r

e c c

| |

=

|

\ .

Asymmetr|c str|p||ne

( )

0

1.9 2

80

ln 1 [

.8

]

0 4 '

r

H T

H

Z

W T H c

| | +

| |

=

|

|

\ .

\ .

O

+

llg. 4.4 ConLrolled lmpedance conflguraLlons

lor an esLlmaLlon of Lhe characLerlsLlc lmpedance of C8 Lraces use an analyLlc

calculaLor such as Zcalc, buL wlLh precauLlon regardlng Lhe accuracy range. Lven ln Lhe speclfled

range a 3 calculaLlon error should be expecLed. lor a more preclse evaluaLlon of Lhe

characLerlsLlc lmpedance, use a fleld solver such as olar Sl8000.

2.2.2 D|fferent|a| Impedance

ulfferenLlal slgnals should always be rouLed ln parallel and close Lo each oLher ln order

Lo avold coupllng of dlfferenLlal nolse from varlous sources. 1hls coupllng beLween dlfferenLlal

Lraces (also called dlfferenLlal palr") lnLroduces muLual lnducLances and capaclLances, whlch

affecLs Lhelr characLerlsLlc lmpedance. Slnce dlfferenLlal slgnals always Lravel ln opposlLe

dlrecLlon, Lhls coupllng (also called odd mode coupllng") wlll decrease Lhe characLerlsLlc

lmpedance of each Lrace, accordlng Lo Lhe equaLlons:

| |

| |

10 12 10

_1

10 12 10

20 12 20

_ 2

20 12 20

ODD

ODD

L L L

Z

C C C

L L L

Z

C C C

= < O

+

= < O

+

(4.3)

age 17 of 76

CopyrlghL 2014 LMC lasLass

llg. 4.3 Cdd mode propagaLlon of dlfferenLlal slgnals

When dlfferenLlal slgnals propagaLe on dlfferenLlal palrs, Lhe lnformaLlon ls carrled by

Lhe dlfference of Lhe volLages on Lhe Lwo llnes. 1hls dlfferenLlal slgnal wlll see" Lhe

characLerlsLlc lmpedance of Lhe palr as Lwlce Lhe characLerlsLlc lmpedance of each lndlvldual

Lrace.

llg. 4.6 ropagaLlon of dlfferenLlal slgnals on dlfferenLlal palrs

0

( ) 2

2

diff

diff

V

V V V V V

Z Z

I I I I

+ + + +

= = = = = (4.6)

Slnce Lhe characLerlsLlc lmpedance of each lndlvldual Lrace ls Lhe odd mode lmpedance,

Lhe dlfferenLlal lmpedance ls deflned as:

10 12

0_

10 12

2 2

diff ODD

L L

Z Z

C C

= =

+

(4.7)

lor an esLlmaLlon of Lhe dlfferenLlal lmpedance an analyLlc calculaLor such as Zcalc may

be used. Powever, please noLe LhaL analyLlc calculaLors can provlde as much as 30 calculaLlon

error when lL comes Lo evaluaLe odd and even mode propagaLlon, so a fleld solver such as olar

Sl8000 ls hlghly recommended.

age 18 of 76

CopyrlghL 2014 LMC lasLass

2.3 1erm|nat|ons

2.3.1 S|ng|e Lnded 1erm|nat|ons

When hlgh speed slgnals arrlve aL an lmpedance dlsconLlnulLy polnL, some of Lhe energy

of Lhe slgnal wlll reflecL and Lravel back Lo Lhe generaLor. Slgnal reflecLlons are a ma[or cause of

nolse and radlaLlon on C8s, and should be avolded.

1o avold reflecLlons, hlgh speed slgnals should see a consLanL lmpedance from Lhe drlver

Lo Lhe recelver. 1hls requlres noL [usL Lo keep Lhe lmpedance of Lhe C8 Lrace consLanL, whlch ls

achleved uslng mlcrosLrlp or sLrlpllne conflguraLlons, buL also Lo make Lhe C8 Lrace

characLerlsLlc lmpedance (Z

0

) equal Lo Lhe drlver clrculL ouLpuL lmpedance (Z

Cu1

) and Lhe

recelver clrculL lnpuL lmpedance (Z

ln

). 1hls condlLlon ls generally noL meL by defaulL because

drlver clrculLs usually have low ouLpuL lmpedances and recelver clrculLs usually have hlgh lnpuL

lmpedance. llg. 4.7 shows a Lyplcal slgnal dlsLorLlon caused by mulLlple reflecLlons.

1erm|nat|on n|nt:

- S/$6 /+&/ #0$$< #+&6%'# <-+7$ % ./%+6 (* @2',+0'$ -$.$+7$-# (6'3 ,/$

*%-,/$-@(#, *-(@ <-+7$- #/(2'< )$ ,$-@+6%,$< 8#$$ 0%-%&-%0/ P4T4Q (6

,(0('(&39

1erm|nat|on n|nt:

- R/$ $%#+$#, 1%3 ,( ,$-@+6%,$ % <+**$-$6,+%' 0%+- +# 2#+6& % #+6&'$ -$#+#,(-

$J2%' ,( ,/$ <+**$-$6,+%' +@0$<%6.$ (* ,/$ :BK ,-%.$#

1erm|nat|on ku|e:

- N+&/ #0$$< #+&6%'# -$J2+-$ ,$-@+6%,+(6 $+,/$- %, ,/$ <-+7$- (- ,/$ -$.$+7$-

$6<4 =( 6(, 2#$ ,$-@+6%,+(6 %, )(,/ $6<#E %# +, 1+'' -$<2.$ ,/$ 7(',%&$ ,( /%'*

,/$+- <-+7$6 7%'2$#4

age 19 of 76

CopyrlghL 2014 LMC lasLass

0 OUT IN

Z Z Z < <

llg. 4.7 1yplcal waveform aL Lhe recelver for LermlnaLed and un-LermlnaLed Lraces

ln order Lo avold reflecLlons aL Lhe drlver and recelver ends of a C8 Lrace, Lhelr

lmpedance should maLch Lhe characLerlsLlc lmpedance of Lhe C8 Lrace. 1hls Lechnlque ls called

LermlnaLlon" and achleved uslng reslsLors connecLed aL drlver / recelver ends of Lhe C8 Lrace.

llg. 4.8 presenLs Lhe slngle ended LermlnaLlon Lechnlques.

Ser|es term|nat|on (at dr|ver)

- Avolds slgnal dlsLorLlon aL recelver

- uoesn'L ellmlnaLe Lhe flrsL reflecLlon aL

Lhe recelver (poLenLlal radlaLlon

problems)

- Pas no effecL on Lhe drlver currenL and

uC volLage levels

ara||e| term|nat|on (at rece|ver)

- 1he LermlnaLlon reslsLor may be

connecLed elLher Lo vCC or Cnu

- LllmlnaLes all Lhe reflecLlons

- lncreases Lhe drlver uC currenL (musL

drlve a low-value reslsLor)

- 8eslsLor Lo Cnu lowers Lhe uC volLage

level for "#$% sLaLe

- 8eslsLor Lo vCC rlses Lhe uC volLage

level for &'( sLaLe

1heven|n term|nat|on (at rece|ver)

age 20 of 76

CopyrlghL 2014 LMC lasLass

- LllmlnaLes all Lhe reflecLlons

- lncreases Lhe drlver uC currenL (musL

drlve low-value reslsLors)

- Lowers Lhe uC volLage level for "#$%

sLaLe and rlses Lhe uC volLage level for

&'( sLaLe, half as much as parallel

LermlnaLlon

AC term|nat|on (at rece|ver)

- LllmlnaLes all Lhe reflecLlons

- Pas no effecL on Lhe drlver currenL and

uC volLage levels

- lncreases Lhe rlse Llme aL Lhe recelver

end (use wlLh cauLlon!)

llg. 4.8 Slngle ended LermlnaLlon Lechnlques

Serles LermlnaLlons requlre Lhe reslsLor Lo be connecLed physlcally as close as posslble

Lo Lhe drlver, and parallel LermlnaLlons requlre Lhe reslsLors / capaclLor Lo be connecLed as close

as posslble Lo Lhe recelver.

2.3.2 D|fferent|a| 1erm|nat|ons

!usL llke slngle ended slgnals, dlfferenLlal slgnals musL see" a dlfferenLlal lmpedance

consLanL along Lhe Lransmlsslon llne, whlch means LhaL drlver ouLpuL lmpedance should be

equal Lo Lhe dlfferenLlal palr lmpedance and Lo Lhe recelver lnpuL lmpedance. 1he common

LermlnaLlon Lechnlques used for dlfferenLlal palrs are presenLed ln flg. 4.9

Ser|es term|nat|on (at dr|ver)

_

2

OUT diff diff

S

Z Z

R

=

- Avolds slgnal dlsLorLlon aL recelver

- uoesn'L ellmlnaLe Lhe flrsL reflecLlon

aL Lhe recelver (poLenLlal radlaLlon

problems)

- Pas no effecL on Lhe drlver currenL

and uC volLage levels

- MosL common recelver LermlnaLlon

- LllmlnaLes all Lhe reflecLlons of Lhe

dlfferenLlal slgnal

- uoes noL ellmlnaLe Lhe reflecLlons of

Lhe common mode slgnal (poLenLlal

age 21 of 76

CopyrlghL 2014 LMC lasLass

P diff

R Z =

radlaLlon problems)

- lncreases Lhe drlver uC currenL (musL

drlve a low-value reslsLor)

AC term|nat|on (at rece|ver)

; 2

P diff RC P P P

R Z R C t t = = <

- Slmllar Lo parallel LermlnaLlon buL

wlLhouL Lhe addlLlonal drlver uC

currenL

- lncreases Lhe rlse Llme aL Lhe recelver

end (use wlLh cauLlon!)

"I" 1erm|nat|on (at rece|ver)

1 2

2

;

even odd

P even P

even odd

Z Z

R Z R

Z Z

= =

- 1ermlnaLes boLh common end and

dlfferenLlal slgnals

- LllmlnaLes all Lhe reflecLlons

- Assures a valld lnpuL sLaLe aL Lhe

recelver when drlver ls ln PlghZ

"1" 1erm|nat|on (at rece|ver)

1 2

;

2

even odd

P odd P

Z Z

R Z R

= =

- 1ermlnaLes boLh common end and

dlfferenLlal slgnals

- LllmlnaLes all Lhe reflecLlons

- 8equlres an addlLlonal volLage source

for dlfferenLlal slgnals wlLh common

mode offseL (some dlfferenLlal

recelvers mlghL have an lnLernal

regulaLor Lo provlde common mode

volLage ouLslde Lhe chlp, lf Lhls ls Lhe

case Lhen use lL!)

llg. 4.9 ulfferenLlal LermlnaLlon Lechnlques

!usL llke for slngle ended slgnals, serles LermlnaLlons requlre Lhe reslsLors Lo be

connecLed physlcally as close as posslble Lo Lhe drlver, and parallel, l and 1 LermlnaLlons

requlre Lhe reslsLors / capaclLor Lo be connecLed as close as posslble Lo Lhe recelver.

age 22 of 76

CopyrlghL 2014 LMC lasLass

2.4 |acement

2.4.1 art|t|on|ng

1he schemaLlc of almosL any elecLronlc appllcaLlon ls a concaLenaLlon of funcLlonal

blocks. lL ls essenLlal LhaL Lhose blocks are correcLly ldenLlfled and LhaL Lhe componenLs wlLhln

each block are grouped LogeLher on Lhe C8, ln order Lo mlnlmlze crossLalk and reduce

lnLerconnecLlons lengLh. MosL slgnal lnLegrlLy problems assoclaLed wlLh hlgh speed slgnals can

be addressed by propped componenL placemenL.

rlor Lo deLalled placemenL and rouLlng, Lhe schemaLlc should be parLlLloned lnLo

funcLlonal blocks. lurLhermore, Lo ease Lhe nexL sLep of zonlng, Lhe funcLlonal blocks should be

classlfled accordlng Lo Lhe speclflclLy of Lhe slgnals conLalned.

C|ass Descr|pt|on

Supply ower supply clrculLry (converLers, regulaLors, fllLers). 1he decoupllng capaclLors

should noL be lncludes ln Lhe supply blocks

Analog Low level analog slgnal processlng blocks

ulglLal ulglLal processlng blocks

ower Plgh volLage and / or hlgh currenL blocks.

8l 8adlo frequency communlcaLlon blocks

2.4.2 2on|ng

Cnce Lhe sysLem ls parLlLloned lnLo funcLlonal blocks, each should be asslgned a dlsLlncL

physlcal locaLlon on Lhe C8. 1hls operaLlon ls called zonlng" or floor-plannlng". A drafL

placemenL should be made ln order Lo esLlmaLe Lhe space necessary for each block.

1he zonlng should Lend Lo mlnlmlze Lhe lengLh of Lhe lnLerconnecLlons beLween blocks

and also Lhe elecLromagneLlc coupllng beLween Lhem. Coupllng can be caused elLher by

elecLromagneLlc flelds lnLerference, whlch can be mlnlmlzed by physlcally placlng Lhe blocks as

far aparL as posslble, elLher by common lmpedance, whlch ls caused by reLurn currenLs followlng

Lhe same physlcal paLh. Slnce all currenLs reLurn Lo Lhe power supply, Lhe common reLurn

beLween each block class should be made as shorL as posslble. 1hls requlres Lhe mosL

aggresslve" blocks (8l, ower, ulglLal) Lo be placed closer Lo Lhe Supply and Lhe mosL senslLlve

blocks (Analog) Lo be placed farLher Lo Lhe Supply. lf posslble, hlghly aggresslve" blocks (8l)

should be lsolaLed from Lhe maln clrculLry ln order Lo compleLely avold a common reLurn paLh.

llgure 4.10 presenLs a recommended zonlng for an appllcaLlon wlLh several funcLlonal

blocks.

8|ock p|acement ru|e

- R/$ .+-.2+, #/(2'< )$ 0%-,+,+(6$< +6,( *26.,+(6%' )'(.5# %6< $%./ )'(.5

#/(2'< /%7$ % -$#,-+.,$< U(6$ %##+&6$< (6 ,/$ :BK

8|ock p|acement h|nt

- R/$ @(#, V%&&-$##+7$W )'(.5# #/(2'< )$ 0'%.$< .'(#$#, ,( ,/$ #200'3

age 23 of 76

CopyrlghL 2014 LMC lasLass

llg. 4.10 8ecommended zonlng for varlous funcLlonal blocks

2.4.3 Ana|og 8uffers

lL ls a common pracLlce Lo carry Lhe analog slgnals generaLed ouLslde Lhe appllcaLlon

C8, such as Lhose comlng from sensors, Lhrough analog buffers (repeaLers). 1hls can have

beneflclal effecLs on Lhe lnLegrlLy of Lhe analog slgnals because Lhe buffers wlll drlve Lhe C8

Lraces wlLh a low lmpedance source, whlch wlll reduce Lhelr suscepLlblllLy Lo crossLalk nolse

caused by capaclLlve coupllng. ln order Lo beneflL from Lhls advanLage, lL ls essenLlal LhaL analog

buffers are placed as close as posslble Lo Lhe C8 enLry polnL of Lhe analog slgnals.

lf posslble, Lhe analog blocks should be placed close Lo Lhe analog slgnal connecLors Lo

mlnlmlze Lhe lnLerconnecLlons lengLh. Powever, slnce connecLor placemenL ls usually

deLermlned by mechanlcal requlremenLs, Lhls mlghL noL be posslble. lf Lhls ls Lhe case Lhen Lhe

analog buffers should noL be consldered parL of Lhe analog processlng block buL assoclaLed wlLh

Lhe slgnal connecLors. llgure 4.11 presenLs Lhe recommended placemenL of analog buffers for

such a slLuaLlon.

llg. 4.11 8ecommended placemenL of analog buffers

age 24 of 76

CopyrlghL 2014 LMC lasLass

2.S kout|ng

2.S.1 1opo|ogy

Plgh speed slgnals LhaL musL lnLerconnecL mulLlple lCs may be rouLed ln one of Lhe

Lopologles lllusLraLed by flg. 4.12. 1hls ls ofLen Lhe case for clock and conLrol slgnals, buL may

also apply Lo daLa busses or analog slgnals. Lach Lopology has advanLages and dlsadvanLages

and musL allow an opLlmal compromlse beLween slgnal lnLegrlLy and geomeLrlcal consLralnLs.

noLe LhaL for slgnals LhaL don'L quallfy as hlgh speed", Lhe Lopology ls largely lrrelevanL.

o|nt to po|nt

- 1hls can only be applled lf all lCs can be

grouped lnLo [usL Lwo blocks and Lhe

connecLlons beLween proxlmaLe lCs can be

kepL well below Lhe crlLlcal lengLh

- 1he lnLerconnecLlon behaves llke a slmple

lnLerconnecLlon beLween Lwo lCs

- rovldes besL resulLs from Lhe slgnal lnLegrlLy

polnL of vlew buL ls very demandlng ln Lerms

n|nt on rout|ng topo|ogy

- R/+65 ,1+.$ )$*(-$ <$.+<+6& (6 % )2# ,(0('(&3 %6< <$#+&6+6& +,4 "#$ %

,-%6#@+##+(6 '+6$ #+@2'%,(- *(- % ,/(-(2&/ +67$#,+&%,+(6E %# $%./

-(2,+6& <$,%+' +# +@0(-,%6,

n|nt on rout|ng buses

- X$$0 ,/$ )2#$# %# 1+<$ %# 0-%.,+.%' %6< /+<<$6 *-(@ ,/$ -$#, (* ,/$

1(-'<

A ru|e of thumb for corners

- YMZ .(-6$-# #/(2'< )$ %7(+<$< *(- HO #+&6%'# %6< <+&+,%' #+&6%'# 1+,/

-+#$ ,+@$# #@%''$- ,/%6 M4L [6#\

n|nt on v|as

- ]7(+< 2#+6& :RN 7+%# *(- /+&/ #0$$< #+&6%'# %6< 5$$0 ,/$+- 62@)$- ,( %

@+6+@2@

ku|es of d|fferent|a| rout|ng

H(2,$ <+**$-$6,+%' 0%+-# +6 ,/+# (-<$-^

L4 S+,/ $J2%'+U$< 0-(0%&%,+(6 ,+@$

_4 F3@@$,-+.%'

Q4 R+&/,'3 .(20'$<

T4 N(@(&$6$(2#

ku|e of thumb for board edge

- ]7(+< -(2,+6& /+&/ #0$$< #+&6%'# .'(#$- ,( LMN ,( ,/$ $<&$ (* ,/$

)(%-<4

age 23 of 76

CopyrlghL 2014 LMC lasLass

of rouLlng

"1"

- 1hls Lopology derlves from Lhe polnL-Lo-polnL

Lopology lf Lhe connecLlons beLween

proxlmaLe lCs cannoL be kepL below 1/10 of

Lhe crlLlcal lengLh

- lL provldes good resulLs for unldlrecLlonal

slgnals, wlLh Lhe drlver locaLed aL Lhe lefL.

- 1he lnLerconnecLlons lengLh beLween Lhe 1

[uncLlon and Lhe recelver lCs should be closely

maLched, oLherwlse Lhe [uncLlon polnL wlll

lnLroduce an lmpedance dlsconLlnulLy

- Can provlde equallzed propagaLlon Llmes

- Lach recelver needs LermlnaLlon

- 1he arms of Lhe 1" should have Lwlce Lhe

characLerlsLlc lmpedance of Lhe body

Da|sy Cha|n

- 1hls Lopology ls common for Lhe mulLl-drop

daLa busses

- 1he sLubs should be much shorLer Lhan Lhe

crlLlcal lengLh, oLherwlse Lhey wlll lnLroduce

lmpedance dlsconLlnulLles

- 1he paraslLlc of each lC along Lhe chaln

(package & pad capaclLance) wlll lnLroduce a

small lmpedance dlsconLlnulLy. 1hose effecLs

cumulaLes, so Lhe larger Lhe number of lCs Lhe

worse slgnal degradaLlon should be expecLed.

- Cnly Lhe flrsL or lasL lCs ln Lhe chaln requlre

LermlnaLlons

Star

- 1hls Lopology should be consldered for

unldlrecLlonal slgnals when Lhe propagaLlon

Llme maLchlng ls crlLlcal

- 1he drlver should be locaLed ln Lhe mlddle and

all Lhe recelvers lnLerconnecLed wlLh Lraces

havlng exacLly Lhe same propagaLlon Llme

- Lach recelver should be LermlnaLed ldenLlcally

- use wlLh cauLlon as any unbalance beLween

drlver-recelver connecLlons can have

deLrlmenLal effecLs on Lhe slgnal lnLegrlLy

llg. 4.12 8ouLlng Lopologles

upon decldlng on a rouLlng Lopology, a Lhorough lnvesLlgaLlon of Lhe parLlcularlLles of

Lhe lCs should be done. useful lnformaLlon can be usually found ln Lhe lC's daLasheeL and

appllcaLlon noLes. lf avallable, a Lransmlsslon llne slmulaLor such as PyperLynx (and approprlaLe

l8lS models) should be employed Lo provlde a numerlcal predlcLlon before decldlng on a speclflc

Lopology.

age 26 of 76

CopyrlghL 2014 LMC lasLass

2.S.2 8us kout|ng

8uses pose speclal slgnal lnLegrlLy problems because Lhey requlre a large number of

Lraces Lo be rouLed ln parallel for a long dlsLance and also because Lhey usually swlLch aL Lhe

same Llme. LxpecL Lhe worsL from buses, as mulLlple problems are llkely Lo occur aL Lhe same

Llme. 8esldes Lopology (covered ln paragraph 4.3.1) and Llmlng (covered ln paragraph 4.7)

lssues, some of Lhe slgnal lnLegrlLy problems relaLed Lo busses are:

- A@0$<%6.$ 7%-+%,+(6#: when Lwo Lraces are rouLed ln parallel for a long dlsLance Lhey

wlll be elecLromagneLlcally coupled Lhrough a muLual lnducLance and a muLual

capaclLance. When Lwo slgnals Lravel ln Lhe same dlrecLlon Lhrough Lhose llnes (boLh

slgnals swlLch from 0 Lo 1 or from 1 Lo 0), Lhe coupllng wlll modlfy Lhe characLerlsLlc

lmpedance of each Lrace Lo Lhe even mode lmpedance, whlch ls larger Lhan Lhe un-

coupled characLerlsLlc lmpedance. When Lwo slgnals Lravel ln opposlLe dlrecLlons

Lhrough Lhose llnes (one slgnal swlLches from 0 Lo 1 and Lhe oLher from 1 Lo 0), Lhe

coupllng wlll modlfy Lhe characLerlsLlc lmpedance of each Lrace Lo Lhe odd mode

lmpedance, whlch ls smaller Lhan Lhe un-coupled characLerlsLlc lmpedance. As a resulL,

Lhe lmpedance of each Lrace wlll noL be consLanL ln Llme buL wlll vary accordlng Lo Lhe

swlLchlng of Lhe ad[acenL slgnals. 1hls lmpedance varlaLlon geLs larger as Lhe Lraces are

more closely spaced and wlll cause slgnal reflecLlons due Lo dlsconLlnulLles. llgure 4.13

lllusLraLes Lhe lmpedance varlaLlon of Lwo 60 [U] mlcrosLrlp Lraces wlLh Lhelr clearance.

ln order Lo mlnlmlze Lhe reflecLlon nolse caused by lmpedance varlaLlon Lhe bus

clearance should be as large as pracLlcal.

llg. 4.13 lmpedance varlaLlon caused by coupllng beLween bus Lraces

- F5$1: lf all bus llnes don'L have exacLly Lhe same propagaLlon Llme Lhen varlous slgnals

wlll arrlve aL Lhe recelver wlLh varlous delays, an effecL called skew". Lven lf all Lhe

Lraces have exacLly Lhe same lengLh, Lhe coupllng beLween mlcrosLrlp Lraces wlll affecL

Lhe propagaLlon delays ln Lhe same way as Lhe lmpedance, so a cerLaln amounL of skew

age 27 of 76

CopyrlghL 2014 LMC lasLass

should be expecLed. lor a numerlcal predlcLlon of Lhe skew caused by coupllng beLween

bus llnes, a fleld solver such as PyperLynx should be used. lease noLe LhaL sLrlpllne

Lraces do noL exhlblL skew due Lo coupllng as Lhe odd mode and even mode propagaLlon

speeds are ldenLlcal. llgure 4.14 lllusLraLes Lhe propagaLlon Llme varlaLlon of Lwo 60 [U]

mlcrosLrlp Lraces wlLh Lhelr clearance. ln order Lo mlnlmlze Lhe skew caused by

propagaLlon Llme varlaLlon Lhe bus clearance should be as large as pracLlcal.

llg. 4.14 uelay varlaLlon caused by coupllng beLween bus Lraces

- B-(##,%'5: when a slgnal swlLches lL wlll lnduce a small amounL of nolse lnLo nearby

Lraces doe Lo capaclLlve and lnducLlve coupllng (for deLalls see paragraph 4.6 on

crossLalk). When several slgnal swlLch slmulLaneously, Lhe crossLalk effecL ls mulLlplled

and a large amounL of nolse can be lnduced lnLo nearby Lraces. 8uses are very

aggresslve" wlLh respecL Lo crossLalk and should be kepL as far as pracLlcal from oLher

slgnals, especlally senslLlve ones (analog). 1he crossLalk effecL ls lower beLween sLrlpllne

Lraces Lhan mlcrosLrlp, so lL ls hlghly recommended Lo rouLe Lhe buses on a sLrlpllne

layer.

- H%<+%,+(6: when a slgnal swlLches lL wlll radlaLe an elecLromagneLlc fleld ln Lhe

surroundlng envlronmenL (for deLalls see chapLer 7 on LMC). When several slgnal swlLch

slmulLaneously, Lhe radlaLlon effecL ls mulLlplled and mlghL exceed LMC regulaLlons. 1he

radlaLlon can be mlnlmlzed by reduclng Lhe bus lengLh, shleldlng beLween reference

planes and reduclng Lhe slgnal rlse Llme. 1o keep Lhe radlaLlon Lo a mlnlmum, rouLe Lhe

buses as shorL as posslble on a sLrlpllne layer, LermlnaLe all llnes and, lf necessary and

posslble, reduce Lhe slgnal rlse Llme uslng fllLers.

age 28 of 76

CopyrlghL 2014 LMC lasLass

2.S.3 Corners

Corners rouLed aL 90 wlll lnLroduce small lmpedance dlsconLlnulLles because aL Lhe

corner locaLlon Lhe Lrace wldLh wlll be larger Lhan on Lhe sLralghL Lrace. 1hls wlll cause a

locallzed lncrease of Lhe characLerlsLlc capaclLance of Lhe Lrace, hence a decrease of Lhe

characLerlsLlc lmpedance. 1o avold Lhls effecL, lL ls a good pracLlce Lo avold rouLlng wlLh 90

angles and Lo use lnsLead 43 or rounded corners. llgure 4.13 lllusLraLes Lhe Lhree posslble

corner geomeLrles.

Avo|d

referred

Cpt|mum

llg. 4.13 Corner geomeLrles

lL should be noLed LhaL alLhough Lhe prevlous conslderaLlons are ln Lheory correcL, ln pracLlce

Lhe corners effecL ls lnslgnlflcanL unless Lhe slgnal has very small rlse Llme. As a rule of Lhumb,

precauLlons regardlng corners should be Laken when operaLlng wlLh rlse Llmes smaller Lhan 0.1

[ns] or wlLh radlofrequency slgnals.

2.S.4 V|as

Slgnal vlas LhaL peneLraLe reference planes should be regarded as lmpedance

dlsconLlnulLles because of Lhe capaclLance creaLed beLween Lhe copped barrel and Lhe planes.

vla capaclLance lncreases wlLh Lhe helghL of Lhe board, Lhe hole slze and Lhe number of

reference planes peneLraLed, so largesL capaclLances should be expecLed for large 1P vlas.

1yplcal vla capaclLances are below Lhe [pl] range, so Lhelr effecL ls usually small. Powever, slnce

Lhe reflecLlon nolse accumulaLes, Lraces wlLh large number of vlas carrylng hlgh speed slgnals

may pose slgnal lnLegrlLy problems. 1o avold Lhem, use Lhe leasL posslble vlas, make Lhem small

and allow a large clearance Lo reference planes. lor a numerlc predlcLlon on Lhe vlas effecL on a

parLlcular slgnal, use a fleld solver comblned wlLh a Lransmlsslon llne slmulaLor.

2.S.S D|fferent|a| kout|ng

ulfferenLlal slgnals requlre some rouLlng precauLlons ln order Lo beneflL of Lhe

advanLage of common mode nolse suppresslon. 1hose requlremenLs can be ordered as follows:

8+9 `J2%'+U$< 0-(0%&%,+(6 ,+@$

A dlfference ln Lhe propagaLlon Llme of Lhe dlfferenLlal slgnals (skew) wlll puL Lhe

recelver ln an undeLermlned sLaLe for Lhe Llme lnLerval beLween Lhe arrlval of Lhe fasLesL and

slowesL slgnals. llgure 4.16 lllusLraLes Lhls effecL for a dlfferenLlal palr wlLh a common mode

volLage of 1 [v] and a dlfferenLlal volLage of 2 [v]. When Lhe recelver has a 0 [v] dlfferenLlal

volLage aL lLs lnpuLs lL wlll be ln an undeLermlned sLaLe. 1hls slLuaLlon should be avolded and lf

necessary Lhe lengLh of Lhe fasLesL Lrace should be lncreased uslng serpenLlne rouLlng, as

lllusLraLed by flgure 4.16, ln order Lo equallze Lhe propagaLlon Llmes of Lhe Lwo Lraces. lease

age 29 of 76

CopyrlghL 2014 LMC lasLass

noLe LhaL as Lhe characLerlsLlc propagaLlon Llme may vary from one layer Lo anoLher, lL mlghL

noL be enough Lo equallze Lhe lengLhs ln order Lo equallze Lhe propagaLlon Llmes. lL ls

recommended LhaL Lhe Lraces of a dlfferenLlal palr wlll have Lhe same lengLh on each layer used

for Lhelr rouLlng.

(a)

(b)

llg. 4.16 (a) undeLermlned sLaLe aL Lhe recelver caused by skew (b) SerpenLlne rouLlng

8++9 F3@@$,-3

1o suppress Lhe nolse, boLh Lraces of a dlfferenLlal palr should be equally affecLed by

any posslble nolse source, such LhaL any nolse would manlfesL as dlfferenLlal. 1o prevenL

crossLalk nolse Lo acL as common mode nolse, Lhe dlfferenLlal palr should be rouLed

symmeLrlcally wlLh respecL Lo any posslble aggressor" slgnal. When an obsLacle such as a vla or

lC pln musL be deLoured, Lhe Lwo Lraces should deLour on boLh sldes ln order Lo avold any

poLenLlal crossLalk from Lhe obsLacle Lo affecL one Lrace more Lhan anoLher. llgure 4.17

lllusLraLes Lhe recommended deLourlng of obsLacles for dlfferenLlal palrs.

llg. 4.17 ulfferenLlal palr deLourlng of obsLacles

8+++9 R+&/, .(20'+6&

1he characLerlsLlc lmpedance of each Lrace ls lnfluenced by Lhe coupllng wlLh ad[acenL

Lraces. Slnce Lhe coupllng of a dlfferenLlal Lrace wlLh lLs palr ls always odd mode coupllng, Lhls

allows a preclse conLrol of Lhe dlfferenLlal lmpedance. Powever, coupllng wlLh ad[acenL Lraces

may also affecL Lhe characLerlsLlc lmpedance of each dlfferenLlal Lrace, hence Lhe dlfferenLlal

lmpedance. Slnce coupllng wlLh ad[acenL Lraces may elLher odd or even dependlng on Lhe

operaLlng condlLlons, Lhls wlll cause varlaLlons ln Llme of Lhe dlfferenLlal lmpedance. 1o

mlnlmlze Lhls effecL, dlfferenLlal Lraces should by LlghLly coupled (have a small clearance)

beLween Lhem and loosely coupled (have a large clearance) wlLh oLher Lraces.

lurLhermore, LlghL coupllng means LhaL any nolse LhaL affecLs a slngle Lrace of Lhe palr

wlll be also coupled Lo Lhe oLher Lrace, Lransformlng dlfferenLlal nolse lnLo common mode nolse,

whlch ls suppressed. 1lghL coupllng alds symmeLry.

age 30 of 76

CopyrlghL 2014 LMC lasLass

8+79 N(@(&$6$+,3

1o avold nolse caused by reflecLlons, Lhe characLerlsLlc lmpedances of each Lrace of a

dlfferenLlal palr should be kepL consLanL across lLs enLlre lengLh, by keeplng Lhe wldLh and

clearance consLanL on each rouLlng layer. Powever, Lhls ls Lhe leasL sLrlngenL requlremenL as

reflecLlon nolse caused by Lrace heLerogenelLy has less deLrlmenLal effecLs on slgnal lnLegrlLy

Lhan Lhe nolse caused by skew, asymmeLry or loose coupllng. 1he recommended rouLlng

geomeLrles lllusLraLed by flg. 4.16 and 4.17 are boLh heLerogeneous.

2.S.6 rox|m|ty to 8oard Ldge

near Lhe board edge Lhe elecLrlc flelds wlll close parLly Lhrough Lhe dlelecLrlc and parLly

Lo Lhe alr surroundlng Lhe board. 1here are Lwo concerns regardlng proxlmlLy Lo board edge:

8+9 N+&/ #0$$< #+&6%'#

C8 Lraces slgnals rouLed close Lo Lhe board edge wlll have a dlfferenL characLerlsLlc

lmpedance and propagaLlon Llme Lhan Lraces rouLed lnslde Lhe C8. lL ls recommended Lo avold

rouLlng hlgh speed slgnals closer Lo 10P Lo Lhe edge of Lhe board, P belng Lhe dlsLance beLween

Lhe slgnal layer and Lhe farLhermosL reference plane.

8++9 :(1$- 0'%6$#

AL Lhe edge of Lhe board Lhe vCC-Cnu palr of planes wlll radlaLe elecLromagneLlc flelds

hlgher Lhan lf Lhe flelds were compleLely conLalned by Lhe C8 dlelecLrlc. A rule of Lhumb, called

1he 20-P rule", recommend LhaL Lhe vCC plane should be smaller Lhan Lhe Cnu plane wlLh

20P on each slde of Lhe board, ln order Lo reduce elecLromagneLlc radlaLlon. 1hls rule ls

lllusLraLed by flg. 4.18

llg. 4.18 1he 20P rule

LxperlmenLal measuremenLs suggesL LhaL Lhe effecLs of Lhe 20-P rule on Lhe far fleld

radlaLed by Lhe C8 are pracLlcally null (see for lnsLance

hLLp://www.slgrlLy.com/papers/epep2000/epep_20h.pdf). 1he 20-P rule only seems effecLlve Lo

reduce Lhe elecLromagneLlc coupllng beLween Lhe C8 and cables rouLed close Lo Lhe board

edge, so lL ls recommended Lo be applled only ln Lhls slLuaLlon.

age 31 of 76

CopyrlghL 2014 LMC lasLass

2.6 S|gna| 1|m|ng

2.6.1 Ident|fy|ng t|me-cr|t|ca| s|gna|s

Plgh speed slgnals are affecLed by reflecLlon and crossLalk nolse on each rlslng and

falllng edge, whlch wlll cause Lhe slgnal Lo fly" a cerLaln Llme lnLerval before sLablllzlng aL Lhe

uC value. llgure 4.19 lllusLraLes Lhese phenomena for a rlslng edge.

llg. 4.19 ulsLorLlon of a rlslng edge due Lo reflecLlons and crossLalk

1he fllghL Llme ls deLermlned by Lhe followlng parameLers:

- 8lse Llme of Lhe slgnal

- CuLpuL lmpedance of Lhe drlver

- CapaclLlve loadlng of Lhe llne due Lo Lhe C8 Lrace capaclLance

- CapaclLlve loadlng of Lhe llne due Lo recelver lCs package and lnpuL capaclLance

- ropagaLlon Llme of Lhe C8 Lrace

ku|e of thumb for t|me-cr|t|ca| s|gna|s

- N+&/ #0$$< #+&6%'# 1+,/ 0-(0%&%,+(6 ,+@$ &-$%,$- ,/%6 L;LM (* ,/$ .'(.5

0$-+(< #/(2'< )$ -$&%-<$< %# ,+@$D.-+,+.%' #+&6%'#4

n|nt on t|m|ng

- ]'1%3# 0$-*(-@ %6 $3$ <+%&-%@ %6%'3#+# (* ,+@$D.-+,+.%' #+&6%'#

age 32 of 76

CopyrlghL 2014 LMC lasLass

lf Lhe Llme avallable for Lhe slgnal Lo reach lLs uC value ls much larger Lhan Lhe fllghL

Llme, Lhen Lhls mlghL noL be an lssue. lf, on Lhe oLher hand, Lhose are comparable, Lhen Lhe

slgnal should be regarded as a Llme-crlLlcal slgnal.

lL ls noL easy Lo accuraLely predlcL Lhe fllghL Llme of a slgnal, as lL depends on many

parLlcular parameLers of Lhe C8 and lCs. 1hls can only be accompllshed uslng an

elecLromagneLlc fleld solver and a Lransmlsslon llne slmulaLor able Lo operaLe wlLh l8lS models.

A rule of Lhumb commonly found ln llLeraLure sLaLes LhaL lf a slgnal has a propagaLlon

Llme more Lhan half Lhe clock perlod assoclaLed wlLh LhaL slgnal, Lhen lL should be regarded as a

Llme-crlLlcal slgnal. lf one Lrles Lo apply Lhls rule ln pracLlce, one mlghL flnd LhaL lL ls far Loo

permlsslve: slgnals may become Llme-crlLlcal aL much shorLer propagaLlon Llmes. lL ls so

recommended LhaL slgnals wlLh propagaLlon Llmes greaLer Lhan 1/10 of Lhe clock perlod should

be regarded as Llme-crlLlcal slgnals.

2.6.2 ropagat|on t|me

Cne of Lhe maln componenLs of Llmlng analysls of hlgh speed slgnals ls Lhe propagaLlon

Llme. 1hls ls deLermlned by Lhe C8 Lrace lengLh and Lhe layer sLackup.

1he propagaLlon speed of a slgnal ls deLermlned by Lhe properLles of Lhe dlelecLrlc

surroundlng Lhe conducLor. lor sLrlpllne rouLlng layers Lhe elecLrlc and magneLlc flelds are

compleLely conflned lnslde Lhe dlelecLrlc, whlch makes Lhe propagaLlon speed consLanL:

11.8

stripline

r

inch

v

ns c

(

=

(

(4.8)

lor sLrlpllne layers ln l8-4, Lhe propagaLlon Llme ls deLermlned only by Lhe Lrace lengLh:

_ 4

0.18 7

stripline FR

ns ps

tp

inch mm

( (

~ ~

( (

(4.9)

lor mlcrosLrlp rouLlng layers Lhe elecLrlc and magneLlc flelds are noL compleLely

conflned lnslde Lhe dlelecLrlc, whlch make Lhe propagaLlon speed Lo vary wlLh Lhe dlsLance Lo

Lhe reference plane and Lrace wldLh. 1hose varlaLlons are however small, so an esLlmaLlon of Lhe

propagaLlon speed ln mlcrosLrlp layers ls posslble uslng Lhe equaLlon:

11.8

0.475 0.67

microstrip

r

inch

v

ns c

(

=

(

+

(4.10)

lor mlcrosLrlp layers ln l8-4, Lhe propagaLlon Llme ls almosL consLanL:

_ 4

0.142 5.6

microstrip FR

ns ps

tp

inch mm

( (

~ ~

( (

(4.11)

2.6.3 Lye d|agram ana|ys|s

age 33 of 76

CopyrlghL 2014 LMC lasLass

1lme-crlLlcal slgnals requlre a Lhorough analysls of Lhe relaLlon beLween Lhe fllghL Llme

and clock perlod. Whlle Lhe clock perlod ls (almosL) consLanL, Lhe fllghL Llme varles wlLh Lhe

operaLlng condlLlons such as Lhe swlLchlng paLLern and prevlous slgnal sLaLes. 1he fllghL Llme

cannoL be accuraLely predlcLed uslng closed-form equaLlons, so a more complex lnvesLlgaLlon

Lool musL be employed. 1hls ls Lhe eye dlagram analysls, whlch can be done prlor Lo layouL

deslgn, uslng a Lransmlsslon llne slmulaLor, or afLer Lhe layouL deslgn, uslng a Lransmlsslon llne

slmulaLor lnLegraLed wlLh a fleld solver or Lhrough experlmenLal measuremenLs.

1he eye dlagram presenLs Lhe waveforms of a Llme-crlLlcal slgnal measured aL Lhe

recelver agalnsL a mask LhaL deflnes Lhe forbldden zones, whlch Lhe slgnal should never

Lrespass. MulLlple slgnal perlods are superlmposed on Lhe same mask ln order Lo Lake lnLo

accounL varlous operaLlng condlLlons. llgure 4.20 lllusLraLes Lhe eye dlagram.

llg. 4.20 Lye dlagram

1he eye dlagram mask parameLers are:

- 1

CLk

= clock perlod

- 1

SkLW

= Lhe dlfference beLween Lhe clock and daLa propagaLlon Llme

- 1

!l11L8

= clock + daLa [lLLer (peak-Lo-peak)

- 1

SL1u

, 1

PCLu

= seLup and hold Llmes of Lhe recelver lC

- v

l_mln

, v

l_max

= mlnlmum and maxlmum volLage levels allowed aL Lhe recelver lnpuL

- v

lL_max

= maxlmum volLage level aL Lhe recelver lnpuL ln Lhe LCW sLaLe

- v

lP_mln

= mlnlmum volLage level aL Lhe recelver lnpuL ln Lhe PlCP sLaLe

An eye dlagram analysls should always be performed for crlLlcal slgnals ln order Lo avold

spurlous faulLs durlng operaLlon.

2.7 Csc|||ators ] Crysta|s

CrlsLal osclllaLors are low-power clrculLs LhaL are especlally senslLlve Lo perLurbaLlons.

MosL such osclllaLors use an exLernal crysLal and an lnLernal ampllfler, whlch requlres Lhe

crysLal-ampllfler connecLlons Lo be rouLed wlLh speclal precauLlon. 1hose are low ampllLude

age 34 of 76

CopyrlghL 2014 LMC lasLass

analog slgnals generaLed by a hlgh lmpedance source, so Lhey flL perfecLly lnLo Lhe deflnlLlon of

a poLenLlal vlcLlm Lo crossLalk.

1he followlng recommendaLlons should be followed when placlng / rouLlng crysLal

osclllaLors:

(l) lace Lhe crysLal and Lhe load capaclLors as close as posslble Lo Lhe lC osclllaLor plns of

Lhe lC

(ll) 8ouLe Lhe crysLal - capaclLors - lC connecLlons as shorL as posslble

(lll) 8ouLe Lhe crysLal - capaclLors - lC connecLlons as far aparL as pracLlcal from each oLher

and Lhe ground Lraces

(lv) 8ouLe Lhe ground dlrecLly Lo Lhe Cnu pln of Lhe lC and only Lhere Lo Lhe ground of Lhe

resL of Lhe clrculL (osclllaLor slgnals should noL share Lhe reLurn paLh wlLh oLher slgnals)

(v) Cround Lhe crysLal houslng and rouLe a ground loop around Lhe osclllaLor clrculL

(vl) lf posslble provlde a reference plane beneaLh Lhe osclllaLor

(vll) uon'L rouLe any aggressor slgnals ln Lhe osclllaLor zone

llgure 4.21 presenLs an example of placemenL / rouLlng of a crysLal osclllaLor.

llg. 4.21 Lxample of placemenL / rouLlng of a crysLal osclllaLor

age 33 of 76

CopyrlghL 2014 LMC lasLass

3. Crossta|k

3.1 Ident|fy|ng V|ct|ms and Aggressors

CrossLalk ls Lhe nolse coupled beLween ad[acenL conducLors Lhrough near elecLrlc fleld

(capaclLlve coupllng) and magneLlc fleld (lnducLlve coupllng). Whlle any ad[acenL conducLors

exhlblL crossLalk, lL ls especlally deLrlmenLal Lo slgnal lnLegrlLy when lL appears beLween

aggresslve and senslLlve slgnals.

Some slgnals are parLlcularly senslLlve Lo crossLalk, elLher because of Lhelr naLure or

Lhelr funcLlonal role ln Lhe clrculL. 1hose slgnals are poLenLlal 7+.,+@# Lo crossLalk. 1hose slgnals

are:

- Analog slgnals: Lhey are lnherenLly more senslLlve Lo nolse Lhan dlglLal slgnals, so Lhey

should always be regarded as poLenLlal vlcLlms, especlally lf Lhey have low ampllLudes.

- Plgh lmpedance conLrol slgnals: Lnable, reseL, osclllaLor and feedback slgnals are Lhe

Lype of conLrol slgnals LhaL should noL be dlsLurbed because of Lhelr effecL on Lhe

funcLlonallLy of Lhe clrculL. lf such slgnals are generaLed by a low lmpedance source,

such as a hlgh-value pullup / pulldown reslsLor or a crysLal osclllaLor, Lhey wlll be easlly

dlsLurbed by capaclLlve crossLalk. Such slgnals should be also regarded as poLenLlal

vlcLlms, especlally lf Lhey have low ampllLudes.

Cn Lhe oLher hand, some slgnals can easlly lnduce nolse on poLenLlal vlcLlms and are

consldered poLenLlal %&&-$##(-# wlLh respecL Lo crossLalk. 1o easlly ldenLlfy poLenLlal

aggressors, remember LhaL crossLalk ls caused by coupllng capaclLances and lnducLances

beLween C8 Lraces.

1he currenL ln[ecLed by a coupllng capaclLance lnLo a vlcLlm Lrace ls:

( )

_

_ _ _

C between traces

d

I C Potential difference between traces

dt

= (3.1)

1he volLage lnduced by a coupllng lnducLance on a vlcLlm Lrace ls:

( ) _ _

L mutual

d

V L Current through aggressor

dt

= (3.2)

8ased on Lhose conslderaLlons, Lhe poLenLlal aggressors ln a clrculL are:

- Slgnals wlLh hlgh ampllLude (elLher volLage or currenL)

- lasL slgnals (elLher ln Lerms of small rlse Llme or hlgh frequency)

Whlle crossLalk can never be compleLely avolded, Lhe maln Lask ln crossLalk conLrol ls Lo

avold lL Lo occur beLween poLenLlal vlcLlms and poLenLlal aggressors.

3.2 Layer Ass|gnment

ku|e of C|ass|f|cat|on for Crossta|k

- N+&/ %@0'+,2<$ a /+&/ *-$J2$6.3 a #@%'' -+#$ ,+@$ b ]&&-$##(-

- c(1 %@0'+,2<$ a /+&/ +@0$<%6.$ b d+.,+@

1he bas|c ru|e of m|n|m|z|ng crossta|k

- X$$0 %&&-$##(-# %6< 7+.,+@# %# *%- %0%-, %# 0(##+)'$ %6< .'(#$ ,( ,/$

&-(26<4

age 36 of 76

CopyrlghL 2014 LMC lasLass

1he obvlous counLermeasure Lo crossLalk ls Lo keep aggressors and vlcLlms as far aparL

as posslble, Lo avold coupllng capaclLances and lnducLances. 1he flrsL sLep ln dolng so ls Lo avold

rouLlng aggressors and vlcLlms on Lhe same layer. lf enough rouLlng layers are avallable, a deslgn

rule should be lmposed Lo prevenL aggressors and vlcLlms Lo share Lhe same lnner layer. roper

sysLem parLlLlonlng and zonlng should make Lhls precauLlon unnecessary as aggressors and

slgnals should noL be rouLed ln proxlmlLy anyway, so layer asslgnmenL should be Laken lnLo

conslderaLlon whenever zonlng cannoL provlde compleLe separaLlon or Lhe appllcaLlon requlres

very aggresslve slgnals.

A reference plane beLween rouLlng layers wlll greaLly reduce Lhe crossLalk beLween

slgnals on Lhose layers, so lf posslble asslgn aggressors and vlcLlms Lo dlfferenL layers separaLed

by aL leasL a ground or supply plane.

noLe LhaL crossLalk on sLrlpllne layers ls smaller Lhan on mlcrosLrlp layers, so lf

aggressors and vlcLlms musL share Lhe same zone and same layer, lL should be a sLrlpllne layer.

Also noLe LhaL layers closer Lo a reference plane wlll exhlblL less crossLalk Lhan layers locaLed

farLher Lo reference planes, so lf crossLalk on Lhe same layer musL occur, lL ls beLLer Lo allow lL

on layers closer Lo planes.

3.3 Crthogona||ty

8ouLlng on each layer naLurally Lends Lo follow a slngle preferenLlal dlrecLlon, elLher

horlzonLal or verLlcal, because oLherwlse lnLersecLlons beLween Lraces wlll occur. 1hls ls a

pracLlce LhaL should be promoLed as lL may have beneflclal effecLs on crossLalk. 8y asslgnlng Lo

each rouLlng layer a slngle dlrecLlon and alLernaLe Lhe dlrecLlons of ad[acenL layers, boLh

capaclLlve and lnducLlve coupllng can be greaLly reduced. 1hls Lechnlque ls called orLhogonal

rouLlng" and ls lllusLraLed by flg. 3.1.

llg. 3.1 CrLhogonal rouLlng

When orLhogonallLy cannoL be applled or for Lhe layers wlLh Lhe same rouLlng dlrecLlon

LhaL are noL separaLed by a reference plane, crossLalk can also be reduced by sLaggerlng long

slgnal Lraces, as lllusLraLed by flg. 3.2.

llg. 3.2 SLaggered Lraces

3.4 ara||e||sm

n|nt on |ayer ass|gnment

- F,-+0'+6$ '%3$-# %-$ J2+$,$- ,/%6 @+.-(#,-+0 '%3$-#

age 37 of 76

CopyrlghL 2014 LMC lasLass

lf rouLlng aggressors and vlcLlms on dlfferenL layers ls noL posslble, parallellsm

resLrlcLlons should be enforced. 1he amounL of crossLalk nolse beLween Lraces rouLed ln parallel

depends (among many oLher Lhlngs) on Lhe lengLh of Lhe parallel Lraces and clearance beLween

Lhem. 1he smaller Lhe clearance, Lhe larger Lhe lengLh LhaL Lraces are allowed Lo be rouLed ln

parallel for Lhe same amounL of crossLalk.

arallellsm beLween aggressors and vlcLlms should be avolded from Lhe flrsL place, buL lf

Lhls ls noL posslble Lhen coupllng should be carefully analyzed before enforclng a parallellsm

rule. As crossLalk depends noL [usL on Lhe parallellsm buL also on slgnal, lCs and C8

characLerlsLlcs, a fleld solver and a Lransmlsslon llnes slmulaLor should be used Lo predlcL Lhe

amounL of crossLalk nolse Lo be expecLed for each parLlcular case and Lo declde on approprlaLe

parallellsm resLrlcLlons.

A rule of Lhumb regardlng parallellsm ls called R/$ QS H2'$" and lL sLaLes LhaL ln order

Lo avold crossLalk beLween parallel Lraces rouLed on Lhe same layer, a mlnlmum spaclng

beLween Lraces cenLers of 3W should be kepL. llgure 3.3 lllusLraLes Lhe 3W rule.

llg. 3.3 Lhe 3W rule

Whlle crossLalk wlll be lndeed reduced by applylng Lhe 3W rule, Lhe acLual value ls of 3W

mlghL be expenslve ln Lerms of board space and mlghL noL be enough for very aggresslve

coupllngs. 1he 3W rule should be used only lf deLalled elecLromagneLlc lnvesLlgaLlons are noL

avallable.

3.S Guard|ng

An addlLlonal measure Lo reduce crossLalk beLween parallel Lraces rouLed on Lhe same

layer ls Lo separaLe Lhem uslng a Lrace connecLed aL boLh ends Lo ground, called &2%-< ,-%.$, as

lllusLraLed by flg. 3.4. lL ls essenLlal LhaL Lhe guard Lrace ls connecLed aL all ends Lo ground,

oLherwlse lL wlll behave llke an anLenna.

llg. 3.4 Cuardlng

LxperlmenLal lnvesLlgaLlons of Lhe guardlng Lechnlques suggesL LhaL by slmply

separaLlng Lhe vlcLlm Lo Lhe aggressor ln order Lo make room for Lhe guard Lrace, Lhe same

crossLalk reducLlon can be achleved even lf Lhe guard Lrace ls noL presenL (Lhls ls equlvalenL Lo a

4W parallellsm

rule !). Powever, a guard Lraces wlll also have beneflclal effecLs on Lhe elecLromagneLlc

lnLerference of Lhe Lrace wlLh Lhe surroundlng envlronmenL, so guardlng very aggresslve and

very senslLlve slgnals ls sLlll recommended.

age 38 of 76

CopyrlghL 2014 LMC lasLass

noLlce LhaL guard Lraces wlll affecL Lhe characLerlsLlc lmpedance and propagaLlon Llme

of slgnal Lraces! lf applled Lo conLrolled lmpedance Lraces Lhose effecLs should be lnvesLlgaLed

uslng a fleld solver and Laken lnLo conslderaLlon!

3.6 keturn paths

All currenLs reLurn Lo Lhe source LhaL generaLed Lhem Lhrough Lhe ground connecLlon

(uC) and also Lhrough Lhe volLage supply connecLlon (AC). 1he reLurn paLh ls always Lhe paLh of

leasL lmpedance, whlch ln uC means ,leasL reslsLance" and ln AC means ,leasL lnducLance". 1he

reslsLance ls deLermlned malnly by Lhe wldLh of Lhe reLurn Lrace and Lhe lnducLance malnly by

Lhe slgnal-reference loop area. llgure 3.3 lllusLraLes Lhe reLurn paLhs ln AC and uC.

llg. 3.3 CurrenLs reLurn on Lhe paLh of leasL lmpedance

1he slgnal-reLurn loop should be kepL as small as posslble ln order Lo avold large self and

muLual lnducLances, whlch lncrease crossLalk. Speclal aLLenLlon Lo reLurn paLhs should be pald

for:

- Plgh speed slgnals: Lhe reLurn paLh should be kepL consLanL along hlgh speed Lraces ln

order Lo malnLaln Lhelr lmpedance consLanL

- oLenLlal aggressors and vlcLlms: Lhey should be rouLed close Lo Lhe reLurn paLh,

oLherwlse Lhe slgnal-reLurn loop wlll behave llke an anLenna, recelvlng and radlaLlng

elecLromagneLlc waves. Also aggressors and vlcLlms should noL share Lhe same reLurn

paLh !

n|nt on return paths

- B2--$6,# %'1%3# -$,2-6 (6 ,/$ 0%,/ (* '$%#, +@0$<%6.$4 X$$0 ,/$ -$,2-6 0%,/

.'(#$ ,( ,/$ #+&6%' 0%,/ %6< %7(+< %&&-$##(-# %6< 7+.,+@# #/%-+6& ,/$ #%@$

-$,2-6 0%,/4

age 39 of 76

CopyrlghL 2014 LMC lasLass

3.7 kece|ver |acement

CrossLalk beLween hlgh speed slgnals has dlfferenL effecLs aL Lhe ends of Lhe vlcLlm

Lrace, because lL wlll noL behave as an equlpoLenLlal connecLlon buL as a Lransmlsslon llne. 1he

end of Lhe vlcLlm llne LhaL ls closer Lo Lhe aggressor drlver ls called Lhe near end" and nolse

measured here ls called I`eR (near Lnd CrossLalk"), whlle Lhe end of Lhe vlcLlm llne LhaL ls

farLher Lo Lhe aggressor drlver ls called Lhe far end" and nolse measured here ls called O`eR

(lar Lnd CrossLalk"). 1hls namlng convenLlon ls lllusLraLed by flg. 3.6.

llg. 3.6 near and far ends of Lhe vlcLlm llne

1he nLx1 nolse ls caused by capaclLlve and lnducLlve coupllng currenLs Lravellng ln Lhe

same dlrecLlon, whlle Lhe lLx1 nolse ls caused by capaclLlve and lnducLlve coupllng currenLs

Lravelllng ln opposlLe dlrecLlons. 1he nLx1 nolse wlll begln as soon as Lhe aggressor slgnal

swlLches, whlle Lhe lLx1 nolse wlll begln only afLer Lhe propagaLlon Llme of Lhe vlcLlm llne.

1ermlnaLlons aL Lhe ends of Lhe vlcLlm and aggressor llne also lnfluences how Lhe crossLalk wlll

manlfesL aL each end. llgure 3.7 summarlzes Lhe Lyplcal waveforms LhaL should be expecLed for

Lwo mlcrosLrlp coupled llnes when Lhe aggressor drlver launches a rlslng edge.

vlcLlm llne

LermlnaLed aL

boLh ends

- nLx1 duraLlon = Lwlce

Lhe propagaLlon Llme