Professional Documents

Culture Documents

If-Nt: General Safety Information

Uploaded by

Jackson MeloOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

If-Nt: General Safety Information

Uploaded by

Jackson MeloCopyright:

Available Formats

General Safety Information

WARNING To avoid serious injuries:

The tire outer diameter for wheels which are compatible with the DH-3R30-IF-NT hub dynamo is 492 517 mm. If the hub dynamo is used on a bicycle with a tire outer diameter which is smaller than 492 mm, the braking force may be too great, which could cause the wheels to lock and the bicycle to lose its balance and fall over. The hub of the DH-3R30-IF-NT has a built-in power modulator which controls the braking force to prevent it from being too great. When the braking force reaches a certain level, the power modulator operates to prevent the braking force from going past that level. The recommended operating range for the power modulator is for bicycles with a gross weight (bicycle + rider + luggage) of 65 105 kg {144 232 lb.}. If the gross weight of the bicycle is heavier than the recommended weight range, the braking force may be insufficient, and if it is lighter than the recommended weight range, the braking force may become too great and the wheels may lock and bicycle may fall over. It is essential that you fully understand and test the performance of the power modulator before use. The power modulator is not equipped with a function to prevent the wheel from locking up. Obtain and read the service instructions carefully prior to installing the parts. Loose, worn, or damaged parts may cause serious injury to the rider. We strongly recommend only using genuine Shimano replacement parts. Check that the wheels are fastened securely before riding the bicycle. If the wheels are loose in any way, they may come off the bicycle and serious injury may result. Check that the lamp illuminates normally when riding at nighttime. Read these Technical Service Instructions carefully, and keep them in a safe place for later reference.

Connection of the cables

Connect the cables as shown in the illustration below.

Note:

Scrape away the paint from the lamp's frame connection terminal and the lamp connection terminal when connecting the cables.

Frame connection terminal

Note:

Do not switch over the frame cable and the lamp cable by mistake. If the cables are connected incorrectly, the lamp will not illuminate. Twist the cable wires before connecting them so that they stay together. Recommended wire specifications

Wire Insulation

Lamp connection terminal

Type Wire Insulation

Stranded Size (AWG) 22 Diameter approx. 0.8 mm Diameter 1.8 2 mm

Frame cable Lamp cable

Note: Approx. 16 mm

Approx. 16 mm

Connector cap (gray) Connector cover (black)

Bend the cable wires and run them along the grooves.

Insert

Groove

CAUTION To avoid serious injuries:

The hub dynamo generates an extremely high voltage. Never touch the connection terminal of the hub dynamo directly while riding the bicycle or while the wheel is spinning. Touching the dynamo terminal may cause an electric shock.

Bend

Note:

NOTE:

Set so that it faces the right way.

Do not allow the cable wires to touch each other.

Carefully read the Front Inter-M Brake System Service Instructions for roller brakes in conjunction with these Service Instructions. Check the degree of parallel of the front fork end. If the front fork end is severely out of parallel, deformation of the hub axle may cause noise from an obstruction inside the hub dynamo to be generated. Install the hub dynamo to the front fork so that the side with the connection terminal is on the right when facing toward the front of the bicycle. If the side with the connection terminal is facing toward the left, the hub dynamo may not turn properly while riding. Check that the hub dynamo connection terminal is securely connected before using the hub dynamo. Use a 6 V/ 2.4 W bulb for the front lamp and a 6 V/ 0.6 W bulb for the taillamp. If the bulb of either the front lamp or taillamp blows, excessive voltage will be applied to the remaining lamp and shorten the operating life of the bulb, so any blown bulbs should be replaced as soon as possible. If the lamp is frequently turned on when riding at high speed ranges, it will shorten the operating life of the bulbs. Do not disassemble the internal hub mechanism. Do not apply any lubricant to the inside of the hub, otherwise the grease will come out and it may cause problems with conductivity. The hub dynamo will cause the turning of the wheel to become slightly heavier because of the magnet inside the hub. Parts are not guaranteed against natural wear or deterioration resulting from normal use. Press in until you hear a click.

Hub dynamo connection terminal

Frame connection terminal

Lamp connection terminal

Note:

Secure the cable to the front fork or the basket stay so that it will not get caught in the spokes or any other parts while riding. If the position of the hub dynamo may change with respect to the lamp Connector cover while riding, for example when using a suspension fork, make sure that the cable is connected so that it will not be too loose or too tight at any point within the range of movement. Remove Connect so that the current from the hub dynamo flows through the cable from the lamp connection terminal of the hub dynamo to the frame connection terminal. To disconnect the lamp from the hub dynamo, remove the connector cover. Do not ride the bicycle while the connector cover is removed, otherwise the cable might get caught in the bicycle wheel. When removing the bicycle wheel, first remove the connector cover. If the cables are pulled strongly, it may break the cable wires or cause poor contacts. Furthermore, when installing the wheel, first secure the wheel to the front forks and then connect the connector cover.

SI-0081A-002

DH-3R30-IF-NT

Hub Dynamo

Connector cover

Cable Front fork

Connect

Technical Service Instructions

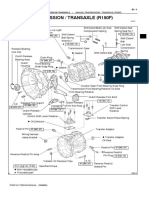

Installation of the front wheel

Install the wheel so that the side with the hub dynamo connection terminal is on the right side when looking toward the front of the bicycle, and so that the hub connection terminal is aligned with the front fork or with the basket stay. Then install by following the procedure shown in the illustration below so that the connection terminal is facing upward. Do not force the connection terminal to turn after the cap nut has been secured. Connection terminal

Basket stay

Checking the lamp illumination

Rotate the front wheel and check that the lamp illuminates.

Connection terminal

Mudguard stay

Front fork

Front fork

Mudguard stay Toothed axle washer

Tightening torque: 20 Nm {174 in. lbs.}

Cap nut (M9)

Basket stay Washer

Note:

These service instructions explain how to use and maintain the Shimano bicycle parts which have been used on your new bicycle. For any questions regarding your bicycle or other matters which are not related to Shimano parts please contact the place of purchase or the bicycle manufacturer.

Please note: Specifications are subject to change for improvement without notice. (English)

Note:

When tightening the cap nuts, tighten the nuts alternately on both sides and do not concentrate all of the effort for tightening and loosening the cap nut on one side of the wheel only, otherwise the hub axle may turn, which could excessively tighten or loosen the lock nuts.

If the cable connected to the ground terminal is not properly grounded, check that the toothed axle washer perforates the paint surface of the front fork. If the toothed axle washer is not perforating the paint surface, the lamp will not illuminate properly, so scrape away a small amount of paint from the front fork. It is recommended that you connect the two wires to ensure that the current flows smoothly.

One Holland, Irvine, California 92618, U.S.A. Phone: +1-949-951-5003 Industrieweg 24, 8071 CT Nunspeet, The Netherlands Phone: +31-341-272222 3-77 Oimatsu-cho, Sakai-ku, Sakai, Osaka 590-8577, Japan

C Nov. 2008 by Shimano Inc. PIT. SZK. Printed in Singapore

You might also like

- Inter BrakeDocument1 pageInter BrakedovlikusNo ratings yet

- Shimano Inter-M BR-IM31-R Brakes Service InstructionsDocument1 pageShimano Inter-M BR-IM31-R Brakes Service InstructionsJon_Bramley_3524No ratings yet

- CB E110 enDocument1 pageCB E110 enandNo ratings yet

- Shimano Tourney Rear and Knob AdjustmentDocument1 pageShimano Tourney Rear and Knob AdjustmentNiraj SuroopjeetNo ratings yet

- Manuale Cambio ShimanoDocument1 pageManuale Cambio ShimanoPaola CapassoNo ratings yet

- SI 6PZRA 003 ENG - v1 - m56577569830677284Document1 pageSI 6PZRA 003 ENG - v1 - m56577569830677284lirch5No ratings yet

- DM FD0001 00 EngDocument29 pagesDM FD0001 00 EngpietouNo ratings yet

- GasBike Bicycle Motor Engine Kit 80cc Installation ManualDocument15 pagesGasBike Bicycle Motor Engine Kit 80cc Installation ManualMichael James Webb100% (1)

- Bicycle Engine Kit Installation Guide - Raw 80ccDocument9 pagesBicycle Engine Kit Installation Guide - Raw 80ccSokitome0% (1)

- ShimanoDocument1 pageShimanoProto Popescu VictorNo ratings yet

- Shimano XTDocument1 pageShimano XTVennia PapadipoulouNo ratings yet

- rd-m592 2Document1 pagerd-m592 2faizgpNo ratings yet

- Shimano AlivioDocument1 pageShimano AlivioBrent MitchellNo ratings yet

- SI 6VJRA 001 00 Eng - v1 - m56577569830769083Document1 pageSI 6VJRA 001 00 Eng - v1 - m56577569830769083chandlerNo ratings yet

- For Left Hand For Right Hand: SHIMANO SLX Mega-9 Rapidfire LeverDocument3 pagesFor Left Hand For Right Hand: SHIMANO SLX Mega-9 Rapidfire Leverlirch5No ratings yet

- Fitting Instructions For A50 and A80: Bicycle Engine KitsDocument16 pagesFitting Instructions For A50 and A80: Bicycle Engine KitsDav BaronaNo ratings yet

- 07 Lefty Speed OMS WebDocument36 pages07 Lefty Speed OMS WebAlejandro Andres Muñoz Mena100% (1)

- MTB Wheel Set: Dealer's ManualDocument39 pagesMTB Wheel Set: Dealer's ManualJONAS OPLASNo ratings yet

- Megatrail Owner S ManualDocument14 pagesMegatrail Owner S ManualDownhillnewsNo ratings yet

- Alivio Front Drive SI-6KFFA - v1 - m56577569830565035Document1 pageAlivio Front Drive SI-6KFFA - v1 - m56577569830565035setze16setze16No ratings yet

- Ecobike: User ManualDocument28 pagesEcobike: User ManualAnonymous AJlmqhTmUqNo ratings yet

- Install 2Document10 pagesInstall 2chimychanga33No ratings yet

- DL RD m760 2 PDFDocument1 pageDL RD m760 2 PDFtudor-72No ratings yet

- 2007 Lefty Speed Dlr2 SL Owners Manual Supplement enDocument36 pages2007 Lefty Speed Dlr2 SL Owners Manual Supplement enWilhelm LuerzerNo ratings yet

- SI-5TK0D-En v1 m56577569830603908Document1 pageSI-5TK0D-En v1 m56577569830603908dcduquNo ratings yet

- Intense Tracer SpecificationsDocument16 pagesIntense Tracer SpecificationsgavincarrieNo ratings yet

- Shimano XTR M980 Shift Lever Set ManualDocument4 pagesShimano XTR M980 Shift Lever Set ManualNick SpeisNo ratings yet

- Electric Bike Soulitions Conversion Kit Owner's ManualDocument13 pagesElectric Bike Soulitions Conversion Kit Owner's ManualIoannis GreenNo ratings yet

- Moulton TSR APB SuspensionDocument5 pagesMoulton TSR APB SuspensionteuapNo ratings yet

- Manitou 2001 Magnum Service ManualDocument12 pagesManitou 2001 Magnum Service ManualEdha AliNo ratings yet

- SH Cset m151 Front Chainwheel FC-M151Document2 pagesSH Cset m151 Front Chainwheel FC-M151Ingrid VantaNo ratings yet

- Manitou 2003 Sherman Service ManualDocument8 pagesManitou 2003 Sherman Service Manualmarcos2808No ratings yet

- 95-4015-023-000 Suspension Fork - Rev D 0 PDFDocument84 pages95-4015-023-000 Suspension Fork - Rev D 0 PDFJuan Manuel AcebedoNo ratings yet

- Suspension Fork: User ManualDocument84 pagesSuspension Fork: User ManualJose GarciaNo ratings yet

- Shimano WH R 600Document1 pageShimano WH R 600AHSetiawanNo ratings yet

- Manitou 2003 Dorado Service ManualDocument6 pagesManitou 2003 Dorado Service ManualAlvin Zaboloteanu100% (2)

- 2014 Fork Owners ManualDocument73 pages2014 Fork Owners ManualYaksá HiperbólicoNo ratings yet

- Rock Shox Judy FilesDocument84 pagesRock Shox Judy FilesIvan PuškadijaNo ratings yet

- Shimano Bottom Bracket SM-BB6700Document1 pageShimano Bottom Bracket SM-BB6700tspinner19No ratings yet

- GasBike Bicycle Motor Engine Kit 80cc Installation ManualDocument16 pagesGasBike Bicycle Motor Engine Kit 80cc Installation ManualPete Melis100% (2)

- Welcomes You To: Please Read All Instructions Before Installation GT50 & GT80 Kit ContentsDocument15 pagesWelcomes You To: Please Read All Instructions Before Installation GT50 & GT80 Kit ContentsKoro MapuNo ratings yet

- Welcomes You To: Please Read All Instructions Before Installation GT50 & GT80 Kit ContentsDocument15 pagesWelcomes You To: Please Read All Instructions Before Installation GT50 & GT80 Kit ContentsKoro MapuNo ratings yet

- 2000 Headshok Lefty Owners Manual Supplement enDocument24 pages2000 Headshok Lefty Owners Manual Supplement encjackall100% (1)

- SI 5VV0B en v1 m56577569830604982Document1 pageSI 5VV0B en v1 m56577569830604982iodinNo ratings yet

- 6.1 Disc BrakesDocument6 pages6.1 Disc BrakesZubair AamirNo ratings yet

- BLACK City Trail OwnersManual FINALDocument14 pagesBLACK City Trail OwnersManual FINALDrAlessanderArmondNo ratings yet

- Shimano 105 5700 Rear Derailleur Installation ManualDocument2 pagesShimano 105 5700 Rear Derailleur Installation ManualjjjNo ratings yet

- SkyHawk Instructions PDFDocument29 pagesSkyHawk Instructions PDFMythrillex AccountNo ratings yet

- Titan-RTR (Ready To Run)Document34 pagesTitan-RTR (Ready To Run)caller10023No ratings yet

- DM Cn0001 00 Eng (Cadena)Document8 pagesDM Cn0001 00 Eng (Cadena)Mauricio Isaias LargaespadaNo ratings yet

- DiaTech Hombre Rear U-Brake InstallDocument3 pagesDiaTech Hombre Rear U-Brake InstallfgfgjlfnglkNo ratings yet

- 01 Rock Shox Judy Owners ManualDocument7 pages01 Rock Shox Judy Owners ManualakjasonNo ratings yet

- Materi Penyuluhan Bahaya MerokokDocument24 pagesMateri Penyuluhan Bahaya MerokokWendy Kusuma100% (1)

- Brompton Manual - Owners ManualDocument16 pagesBrompton Manual - Owners ManualBill FranklinNo ratings yet

- Troll Fork Instructions: Condition 3Document3 pagesTroll Fork Instructions: Condition 3VÍCTOR VINUESA CAÑASNo ratings yet

- Chevy Differentials: How to Rebuild the 10- and 12-BoltFrom EverandChevy Differentials: How to Rebuild the 10- and 12-BoltRating: 5 out of 5 stars5/5 (8)

- Rick Zunigar Resume-BioDocument5 pagesRick Zunigar Resume-BioRick ZunigarNo ratings yet

- Kinematics 1Document6 pagesKinematics 1Shiva Ram Prasad PulagamNo ratings yet

- Dave Tate Westside Barbell Strength Protocols PDF FreeDocument10 pagesDave Tate Westside Barbell Strength Protocols PDF FreeDatiz HuangNo ratings yet

- Trinity Grade 5 QuestionsDocument2 pagesTrinity Grade 5 QuestionsMari Cruz JC100% (2)

- 6.03 Honors AssignmentDocument2 pages6.03 Honors AssignmentMariana JordanNo ratings yet

- Soccer Iq by Dan BlankDocument5 pagesSoccer Iq by Dan BlankSriram50% (2)

- Sport Psychological InterventionDocument30 pagesSport Psychological InterventionRafaelAlejandroCamachoOrtegaNo ratings yet

- Denso A4 EngineDocument18 pagesDenso A4 Enginefarid salmaniNo ratings yet

- Compliance Statement For SCPsDocument2 pagesCompliance Statement For SCPsmengineeringNo ratings yet

- Tipe MobilDocument5 pagesTipe MobilRizalMustaqimNo ratings yet

- Vassily Ivanchuk Best Game - Online ProofDocument927 pagesVassily Ivanchuk Best Game - Online Proofpedjolliny86No ratings yet

- 2017 PPR Pipes PVC PlumbingDocument5 pages2017 PPR Pipes PVC PlumbingRichpaulNo ratings yet

- Certifications: Katrina DangDocument1 pageCertifications: Katrina Dangapi-408421236No ratings yet

- Safety Shoes QuotationDocument10 pagesSafety Shoes QuotationjesusNo ratings yet

- Fantastic MR FoxDocument3 pagesFantastic MR FoxLuca DormánNo ratings yet

- World Championship Games, 1889-1990Document357 pagesWorld Championship Games, 1889-1990donmitsosNo ratings yet

- Oferta de Pret Rulmenti GenOparts GermaniaDocument10 pagesOferta de Pret Rulmenti GenOparts GermaniaPopa CatalinNo ratings yet

- Non Religious FestivalDocument3 pagesNon Religious FestivalRMG REPAIRNo ratings yet

- LOTR RPG - Decipher - The Lord of The Rings Core RulebookDocument308 pagesLOTR RPG - Decipher - The Lord of The Rings Core Rulebooktriruirtiurteuioewhf94% (16)

- V2GEN2 ManualDocument5 pagesV2GEN2 ManualStafa KovářNo ratings yet

- Jose Manuel Pac Cordero: 14 Avenue 8-61 Zone 3 Quetzaltenango GuatemalaDocument2 pagesJose Manuel Pac Cordero: 14 Avenue 8-61 Zone 3 Quetzaltenango Guatemalaapi-271192387No ratings yet

- Operational Information The Two Stroke Crosshead Engine The CrankshaftDocument9 pagesOperational Information The Two Stroke Crosshead Engine The CrankshaftAbhishek Singh ChauhanNo ratings yet

- AISC Sculpture J STPDocument178 pagesAISC Sculpture J STPPrashant DalviNo ratings yet

- Terminals of EcmDocument10 pagesTerminals of Ecmjorge luis guevara martinezNo ratings yet

- Manual Transmission (R150F)Document3 pagesManual Transmission (R150F)daniel_gustavo_2002100% (4)

- Sony Pictures To Acquire TEN Sports From ZEE (Company Update)Document4 pagesSony Pictures To Acquire TEN Sports From ZEE (Company Update)Shyam SunderNo ratings yet

- Alh Turbo RemovalDocument14 pagesAlh Turbo RemovalbamseflorinNo ratings yet

- The Shady Dragon InnDocument40 pagesThe Shady Dragon InnStephen Cameron92% (12)

- E4 EoB MOCKDocument4 pagesE4 EoB MOCKAhmedElhuseiniNo ratings yet

- Prvih10Vlasnika 06112022Document204 pagesPrvih10Vlasnika 06112022Amil DzankovićNo ratings yet