Professional Documents

Culture Documents

Cable Ladder Catalogue

Uploaded by

123peniscolaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cable Ladder Catalogue

Uploaded by

123peniscolaCopyright:

Available Formats

1

Cable

Ladders

INTRODUCTION

Cable Ladder of SFSP is an economical wire management system designed to support and protect electrical wires and cables. Cable Ladder is permitted in a variety of indoor and outdoor applications. Cable ladder systems can provide significant advantages in cable fill over other wiring methods. This can provide savings in the size or number of raceways required thereby reducing both material and labor costs. Cable Ladder permits much greater spacing between support hangers than for most other systems, providing savings in support costs and labor installation. SFSP's Cable Ladder is available in a variety of finishes, and in varying width and load depth for many applications including primary service entrance, main power feeders, branch wiring, instrument and communications cable.

Quality Assurance

Cable

Ladders

INDEX - TABLE OF CONTENTS

Index

Cable Ladders Runs Fittings - Bend 45 - Bend 90 - Tee Branch - Intersection - Vertical 90 Inside Riser - Vertical 90 Outside Riser - Central Reducer - Right Side Reducer - Left Side Reducer Accessories Cable Ladder Covers General Information Engineering Information Materials & Finishes

5 5 6 7 7 8 9 9 10 11 13 14 15 16 3

Cable ladder consists of two longitudinal side rails connected by rungs. SFSPs ladder designs are very popular due to their versatility and lower costs. They also provide: maximum ventilation for conductor cooling, smooth edges on side rails and rungs to protect cables, and slots for easy cable fastening when required. Various rung spacings are available to provide support for most cables, from small flexible cables to the most rigid interlocked armor power cable. Rungs are of two types: plain and slotted, and can be mounted upwards or downwards (see drawing on page 4). The 30 cm rung spacing is the most popular since it provides support for the widest range of cable sizes.

Cable

Ladders

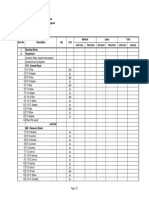

HCL Cable Ladders

Steel Thicknesses: Side rail: 2 mm Rung: 1.5 mm Lengths: 2440 / 3000 mm

Width

100 150 200 300 400 450

HCL - Z

HCL - C

HCL - R

HCLZ 1010 075 100 4 HCLC 1110 075 100 4 HCLR 1210 075 100 4 HCLZ 1010 075 150 4 HCLC 1110 075 150 4 HCLR 1210 075 150 4 HCLZ 1010 075 200 4 HCLC 1110 075 200 4 HCLR 1210 075 200 4 HCLZ 1010 075 300 4 HCLC 1110 075 300 4 HCLR 1210 075 300 4 HCLZ 1010 075 400 4 HCLC 1110 075 400 4 HCLR 1210 075 400 4 HCLZ 1010 075 450 4 HCLC 1110 075 450 4 HCLR 1210 075 450 4

Z - Type

* Heavy Duty Cable Ladder

VCL Cable Ladders

Steel Thicknesses: Side rail: 2 mm Rung: 2 mm Lengths: 2440 / 3000 mm

Width

500 600 700 800 900 1000 1100 1200

VCL - Z

VCLZ 1010 075 500 5 VCLZ 1010 075 600 5 VCLZ 1010 075 700 5 VCLZ 1010 075 800 5 VCLZ 1010 075 900 5

VCL - C

VCL - R

C - Type

VCLC 1110 075 500 5 VCLR 1210 075 500 5 VCLC 1110 075 600 5 VCLR 1210 075 600 5 VCLC 1110 075 700 5 VCLR 1210 075 700 5 VCLC 1110 075 800 5 VCLR 1210 075 800 5 VCLC 1110 075 900 5 VCLR 1210 075 900 5

VCLZ 1010 075 1000 5 VCLC 1110 075 1000 5 VCLR 1210 075 1000 5 VCLZ 1010 075 1100 5 VCLC 1110 075 1100 5 VCLR 1210 075 1100 5 VCLZ 1010 075 1200 5 VCLC 1110 075 1200 5 VCLR 1210 075 1200 5

* Very Heavy Duty Cable Ladder

R - Type

Features Rounded siderail flanges protect cables. All designs permit easy cable dropout with no sharp edges to damage insulation. Slotted rungs allow simple cable fastening.(only upon request ) High strength splices allow random locations between supports (full sections used on all simple beams). Standard straight section length is 3.0 m. Complete line of fittings and accessories.

Cable

Ladders

Rung Type and Dimensions

Rung Thicknesses: 1.5mm - 2.0 mm 50 mm Dimensions: w = 41 mm h = 21 mm Downwards 13 x 30 mm Upwards (slots only upon request )

h w

Side Rails Cable Ladder Length and Rung Spacing

h

Height of rail h = 75 mm, 100 mm, (50 mm upon request )

300 mm

20 mm

Side Rails End Holes

8.5 x 16 mm

h= 75, 100 mm

3000 mm 8.5 x 16 mm

h= 50mm

Ladder Side Rails Types

20 20

Z-Type Top outside Bottom inside

C-Type outside

Inside return flange

20

20 20

C A B L E L A D D E R FITTINGS

Cable ladder fittings are those components which provide for changes in direction or elevation of the cable ladder system. SFSP fittings are available in bending radii of 450 mm to accommodate a wide range of cable sizes and types. The horizontal and vertical elbows are available in 45, and 90 degrees of arc. All illustrations shown herein depict our standard ladder rung. The rung spacing of ladder fittings is generally maintained at the fitting centerline. Cable ladder fittings are usually manufactured in two types; cornered and curved. For a specific type, please mention at the end of the reference code the letters (S) for cornered and (C) for curved.

Cable

Ladders

FITTINGS

Bend 45

Bend 45 2010 Z - Type

Bend 45 Curved Z - Type

HCL

Steel Thicknesses: Side rail: 2 mm Rung: 1.5 mm radius r = 450 mm Width

100 150 200

HCL - Z

HCL - C

HCL - R

HCLZ 2010 075 100 4 HCLC 2110 075 100 4 HCLR 2210 075 100 4 HCLZ 2010 075 150 4 HCLC 2110 075 150 4 HCLR 2210 075 150 4 HCLZ 2010 075 200 4 HCLC 2110 075 200 4 HCLR 2210 075 200 4 HCLZ 2010 075 300 4 HCLC 2110 075 300 4 HCLR 2210 075 300 4 HCLZ 2010 075 400 4 HCLC 2110 075 400 4 HCLR 2210 075 400 4 HCLZ 2010 075 450 4 HCLC 2110 075 450 4 HCLR 2210 075 450 4

Bend 45 2110 C - Type

300 400 450

VCL

radius r = 450 mm Steel Thicknesses: Side rail: 2 mm Rung: 2 mm Width

500 600 700 800 900

Bend 45 2210 R - Type

VCL - Z

VCLZ 2010 075 500 5 VCLZ 2010 075 600 5 VCLZ 2010 075 700 5 VCLZ 2010 075 800 5 VCLZ 2010 075 900 5 VCLZ 2010 075 1000 5 VCLZ 2010 075 1100 5 VCLZ 2010 075 1200 5

VCL - C

VCLC 2110 075 600 5 VCLC 2110 075 700 5 VCLC 2110 075 800 5 VCLC 2110 075 900 5

VCL - R

VCLR 2210 075 600 5 VCLR 2210 075 700 5 VCLR 2210 075 800 5 VCLR 2210 075 900 5

VCLC 2110 075 500 5 VCLR 2210 075 500 5

radius r = 450 mm

1000 1100

1200

VCLC 2110 075 1000 5 VCLR 2210 075 1000 5 VCLC 2110 075 1100 5 VCLR 2210 075 1100 5 VCLC 2110 075 1200 5 VCLR 2210 0751200 5

HCL

Bend 90

Bend 90 2310 Z - Type

Steel Thicknesses: Side rail: 2 mm Rung: 1.5 mm Width

100 150 200 300

HCL - Z

HCL - C

HCL - C

HCLZ 2310 075 100 4 HCLC 2410 075 100 4 HCLC 2510 075 100 4 HCLZ 2310 075 150 4 HCLC 2410 075 150 4 HCLC 2510 075150 4 HCLZ 2310 075 200 4 HCLC 2410 075 200 4 HCLC 2510 075 200 4 HCLZ 2310 075 300 4 HCLC 2410 075 300 4 HCLC 2510 075 300 4 HCLZ 2310 075 400 4 HCLC 2410 075 400 4 HCLC 2510 075 400 4 HCLZ 2310 075 450 4 HCLC 2410 075 450 4 HCLC 2510 075 450 4

radius r = 450 mm

400 450

VCL

Cable

Ladders

Steel Thicknesses: Side rail: 2 mm Rung: 2 mm Width

500 600 700 800

Bend 90 2410 C - Type

VCL - Z

VCLZ 2310 075 500 5 VCLZ 2310 075 600 5 VCLZ 2310 075 700 5 VCLZ 2310 075 800 5 VCLZ 2310 075 900 5

VCL - C

VCLC 2410 075 500 5 VCLC 2410 075 600 5 VCLC 2410 075 700 5 VCLC 2410 075 800 5

VCL - R

VCLR 2510 075 500 5 VCLR 2510 075 600 5 VCLR 2510 075 700 5 VCLR 2510 075 800 5

radius r = 450 mm Bend 90 2510 R - Type

900 1000 1100 1200

VCLC 2410 075 900 5 VCLR 2510 075 900 5

VCLZ 2310 075 1000 5 VCLC 2410 075 1000 5 VCLR 2510 075 1000 5 VCLZ 2310 075 1100 5 VCLC 2410 075 1100 5 VCLR 2510 075 1100 5 VCLZ 2310 075 1200 5 VCLC 2410 075 1200 5 VCLR 2510 075 1200 5

radius r = 450 mm

Bend 90 Curved Z -Type

Tee Branch

Tee Branch 2610 Z - Type

HCL

Steel Thicknesses: Side rail: 2 mm Rung: 1.5 mm Width

100 150 200 300 400 450

HCL - Z

HCL - C

HCL - R

HCLZ 2610 075 100 4 HCLC 2710 075 100 4 HCLR 2810 075 100 4 HCLZ 2610 075 150 4 HCLC 2710 075 150 4 HCLR 2810 075 150 4 HCLZ 2610 075 200 4 HCLC 2710 075 200 4 HCLR 2810 075 200 4 HCLZ 2610 075 300 4 HCLC 2710 075 300 4 HCLR 2810 075 300 4 HCLZ 2610 075 400 4 HCLC 2710 075 400 4 HCLR 2810 075 400 4 HCLZ 2610 075 450 4 HCLC 2710 075 450 4 HCLR 2810 075 450 4

radius r = 450 mm

VCL

Tee Branch 2710 C - Type Steel Thicknesses: Side rail: 2 mm Rung: 2 mm Width

500 600 700

VCL - Z

VCL - C

VCL - R

VCLR 2810 075 500 5 VCLR 2810 075 600 5 VCLR 2810 075 700 5 VCLR 2810 075 800 5 VCLR 2810 075 900 5 VCLR 2810 075 1000 5 VCLR 2810 075 1100 5

VCLZ 2610 075 500 5 VCLC 2710 075 500 5 VCLZ 2610 075 600 5 VCLC 2710 075 600 5 VCLZ 2610 075 700 5 VCLZ 2610 075 800 5 VCLZ 2610 075 900 5 VCLZ 2610 075 1000 5 VCLZ 2610 075 1100 5 VCLC 2710 075 700 5 VCLC 2710 075 800 5 VCLC 2710 075 900 5 VCLC 2710 075 1000 5 VCLC 2710 075 1100 5

radius r = 450 mm Tee Branch 2810 R -Type

800 900 1000 1100 1200

VCLZ 2610 075 1200 5 VCLC 2710 075 1200 5 VCLR 2810 075 1200 5

Tee Branch Curved Z-Type

radius r = 450 mm

Intersection

Intersection 2910 Z - Type

HCL

Steel Thicknesses: Side rail: 2 mm Rung: 1.5 mm Width

100 150 200 300 400 450

Cable

HCL - C

Ladders

HCL - Z

HCL - R

HCLZ 2910 075 150 4 HCLC 3010 075 100 4 HCLR 3110 075 100 4 HCLZ 2910 075 200 4 HCLC 3010 075 150 4 HCLR 3110 075 150 4 HCLZ 2910 075 300 4 HCLC 3010 075 200 4 HCLR 3110 075 200 4 HCLZ 2910 075 400 4 HCLC 3010 075 300 4 HCLR 3110 075 300 4 HCLZ 2910 075 500 4 HCLC 3010 075 400 4 HCLR 3110 075 400 4 HCLZ 2910 075 600 4 HCLC 3010 075 450 4 HCLR 3110 075 450 4

radius r = 450 mm Intersection 3010 C - Type

VCL

Steel Thicknesses: Side rail: 2 mm Rung: 2 mm Width

500 600 700 800 900 1000 1100

VCL - Z

VCLZ 2910 075 500 5 VCLZ 2910 075 600 5 VCLZ 2910 075 700 5 VCLZ 2910 075 800 5 VCLZ 2910 075 900 5

VCL - C

VCLC 3010 075 600 5 VCLC 3010 075 700 5 VCLC 3010 075 800 5 VCLC 3010 075 900 5

VCL - R

VCLR 3110 075 600 5 VCLR 3110 075 700 5 VCLR 3110 075 800 5 VCLR 3110 075 900 5

VCLC 3010 075 500 5 VCLR 3110 075 500 5

VCLZ 2910 075 1000 5 VCLC 3010 075 1000 5 VCLR 3110 075 1000 5 VCLZ 2910 0751100 5 VCLC 3010 075 1100 5 VCLR 3110 075 1100 5

radius r = 450 mm Intersection 3110 R - Type

1200 VCLZ 2910 075 1200 5 VCLC 3010 075 1200 5 VCLR 3110 075 1200 5

Intersection Curved Z - Type

radius r = 450 mm

Vertical 90 Risers

HCL

Vertical 90 Inside Riser 3210 Z - Type radius r = 450 mm Steel Thicknesses: Side rail: 2 mm Rung: 1.5 mm Width

100 150 200 300 400 450

HCL - Z

HCL - C

HCL - R

HCLZ 3210 075 100 4 HCLC 3310 075 100 4 HCLR 3410 075 100 4 HCLZ 3210 075 150 4 HCLC 3310 075 150 4 HCLR 3410 075 150 4 HCLZ 3210 075 200 4 HCLC 3310 075 200 4 HCLR 3410 075 200 4 HCLZ 3210 075 300 4 HCLC 3310 075 300 4 HCLR 3410 075 300 4 HCLZ 3210 075 400 4 HCLC 3310 075 400 4 HCLR 3410 075 400 4 HCLZ 3210 075 450 4 HCLC 3310 075 450 4 HCLR 3410 075 450 4

VCL

Cable

Ladders

Steel Thicknesses: Side rail: 2 mm Rung: 2 mm Width

500 600 700 800 900 1000 1100 1200

Vertical 90 Inside Riser 3310 C - Type radius r = 450 mm

VCL - Z

VCLZ 3210 075 500 5 VCLZ 3210 075 600 5 VCLZ 3210 075 700 5 VCLZ 3210 075 800 5 VCLZ 3210 075 900 5 VCLZ 3210 075 1000 5 VCLZ 3210 075 1100 5 VCLZ 3210 075 1200 5

VCL - C

VCLC 3310 075 600 5 VCLC 3310 075 700 5 VCLC 3310 075 800 5 VCLC 3310 075 900 5 VCLC 3310 075 1000 5 VCLC 3310 075 1100 5 VCLC 3310 075 1200 5

VCL - R

VCLR 3410 075 600 5 VCLR 3410 075 700 5 VCLR 3410 075 800 5 VCLR 3410 075 900 5 VCLR 3410 075 1000 5 VCLR 3410 075 1100 5 VCLR 3410 075 1200 5

VCLC 3310 075 500 5 VCLR 3410 075 500 5

Vertical 90 Inside Riser 3410 R - Type radius r = 450 mm

Vertical 90 Inside Riser Curved Z - Type

HCL

Vertical 90 Outside Riser 3510 Z - Type Steel Thicknesses: Side rail: 2 mm Rung: 1.5 mm Width

100 150 200 300 400 450

HCL - Z

HCL - C

HCL - R

HCLZ 3510 075 100 4 HCLC 3610 075 100 4 HCLR 3710 075 100 4 HCLZ 3510 075 150 4 HCLC 3610 075 150 4 HCLR 3710 075 150 4 HCLZ 3510 075 200 4 HCLC 3610 075 200 4 HCLR 3710 075 200 4 HCLZ 3510 075 300 4 HCLC 3610 075 300 4 HCLR 3710 075 300 4 HCLZ 3510 075 400 4 HCLC 3610 075 400 4 HCLR 3710 075 400 4 HCLZ 3510 075 450 4 HCLC 3610 075 450 4 HCLR 3710 075 450 4

radius r = 450 mm

VCL

Vertical 90 Outside Riser 3610 C - Type Steel Thicknesses: Side rail: 2 mm Rung: 2 mm Width

500 600 700 800 900 1000 1100 1200

VCL - Z

VCLZ 3510 075 500 5 VCLZ 3510 075 600 5 VCLZ 3510 075 700 5 VCLZ 3510 075 800 5 VCLZ 3510 075 900 5

VCL - C

VCLC 3610 075 500 5 VCLC 3610 075 600 5 VCLC 3610 075 700 5 VCLC 3610 075 800 5 VCLC 3610 075 900 5

VCL - R

VCLR 3710 075 500 5 VCLR 3710 075 600 5 VCLR 3710 075 700 5 VCLR 3710 075 800 5 VCLR 3710 075 900 5

radius r = 450 mm

VCLZ 3510 075 1000 5 VCLC 3610 075 1000 5 VCLR 3710 075 1000 5 VCLZ 3510 075 1100 5 VCLC 3610 075 1100 5 VCLR 3710 075 1100 5 VCLZ 3510 075 1200 5 VCLC 3610 075 1200 5 VCLR 3710 075 1200 5

Vertical 90 Outside Riser 3710 R - Type

radius r = 450 mm Vertical 90 Outside Riser Curved Z - Type

Reducers

Central Central Reducer 3810 Z - Type A

Reducing sizes for reducers are usually manufactured in different reducing dimensions. Kindly mention the reducing size desired when ordering, ex: HCLR 3210 050 450/300 4

Cable

HCL

Steel Thicknesses: Side rail: 2 mm Rung: 1.5 mm Width (A)

150 200

Ladders

HCL - Z

HCLZ 3810 075 150 4 HCLZ 3810 075 200 4 HCLZ 3810 075 300 4 HCLZ 3810 075 400 4 HCLZ 3810 075 450 4

HCL - C

HCL - R

HCLC 3910 075 150 4 HCLR 4010 075 150 4 HCLC 3910 075 200 4 HCLR 4010 075 200 4 HCLC 3910 075 300 4 HCLR 4010 075 300 4 HCLC 3910 075 400 4 HCLR 4010 075 400 4 HCLC 3910 075 450 4 HCLR 4010 075 450 4

300 400 450

Central Reducer 3910 C - Type

VCL

A Width (A)

500 600

Steel Thicknesses: Side rail: 2 mm Rung: 2 mm VCL - Z VCL - C VCL - R

VCLZ 3810 075 500 5 VCLC 3910 075 500 5 VCLR 4010 075 500 5 VCLZ 3810 075 600 5 VCLC 3910 075 600 5 VCLR 4010 075 600 5 VCLZ 3810 075 700 5 VCLC 3910 075 700 5 VCLR 4010 075 700 5 VCLZ 3810 075 800 5 VCLC 3910 075 800 5 VCLR 4010 075 800 5 VCLZ 3810 075 900 5 VCLC 3910 075 900 5 VCLR 4010 075 900 5 VCLZ 3810 075 1000 5 VCLC 3910 075 1000 5 VCLR 4010 075 1000 5 VCLZ 3810 075 1100 5 VCLC 3910 075 1100 5 VCLR 4010 075 1100 5 VCLZ 3810 075 1200 5 VCLC 3910 075 1200 5 VCLR 4010 075 1200 5

700 800 900 1000 1100 1200

Central Reducer 4010 R - Type

B Central Reducer Curved Z - Type Right Side Right Side Reducer 4110 Z - type

HCL

A Steel Thicknesses: Side rail: 2 mm Rung: 1.5 mm Width (A)

150

HCL - Z

HCLR 4110 075 150 4 HCLR 4110 075 200 4 HCLR 4110 075 300 4 HCLR 4110 075 400 4 HCLR 4110 075 450 4

HCL - C

HCL - R

HCLS 4210 075 150 4 HCLR 4310 075 150 4 HCLS 4210 075 200 4 HCLR 4310 075 200 4 HCLS 4210 075 300 4 HCLR 4310 075 300 4 HCLS 4210 075 400 4 HCLR 4310 075 400 4 HCLS 4210 075 450 4 HCLR 4310 075 450 4

200 300 400 450

10

VCL

Cable

Ladders

A

Steel Thicknesses: Side rail: 2 mm Rung: 2 mm Width (A)

500 600 700 800 900 1000 1100 1200

Right Side Reducer 4210 C - Type

VCL - Z

VCLZ 4110 075 600 5 VCLZ 4110 075 600 5 VCLZ 4110 075 600 5 VCLZ 4110 075 600 5 VCLZ 4110 075 600 5 VCLZ 4110 075 600 5 VCLZ 4110 075 600 5 VCLZ 4110 075 600 5

VCL - C

VCL - R

VCLC 4210 075 600 5 VCLR 4310 075 600 5 VCLC 4210 075 600 5 VCLR 4310 075 600 5 VCLC 4210 075 600 5 VCLR 4310 075 600 5 VCLC 4210 075 600 5 VCLR 4310 075 600 5 VCLC 4210 075 600 5 VCLR 4310 075 600 5 VCLC 4210 075 600 5 VCLR 4310 075 600 5 VCLC 4210 075 600 5 VCLR 4310 075 600 5 VCLC 4210 075 600 5 VCLR 4310 075 600 5

B Right Side Reducer 4310 R - Type

A Right Side Reducer Curved Z - Type

B Left Side Left Side Reducer 4410 Z - type A

HCL

Steel Thicknesses: Side rail: 2 mm Rung: 1.5 mm Width (A)

150 200 300

HCL - Z

HCL - C

HCL - R

HCLZ 4410 075 150 4 HCLC 4510 075 150 4 HCLR 4610 075 150 4 HCLZ 4410 075 200 4 HCLC 4510 075 200 4 HCLR 4610 075 200 4 HCLZ 4410 075 300 4 HCLC 4510 075 300 4 HCLR 4610 075 300 4 HCLZ 4410 075 400 4 HCLC 4510 075 400 4 HCLR 4610 075 400 4 HCLZ 4410 075 450 4 HCLC 4510 075 450 4 HCLR 4610 075 450 4

400 450

VCL

Left Side Reducer 4510 C - Type A Steel Thicknesses: Side rail: 2 mm Rung: 2 mm Width (A)

500 600 700 800 900 1000

VCL - Z

VCLZ 4410 075 500 5 VCLZ 4410 075 600 5 VCLZ 4410 075 700 5 VCLZ 4410 075 800 5 VCLZ 4410 075 900 5

VCL - C

VCL - R

VCLC 4510 075 500 5 VCLR 4610 075 500 5 VCLC 4510 075 600 5 VCLR 4610 075 600 5 VCLC 4510 075 700 5 VCLR 4610 075 700 5 VCLC 4510 075 800 5 VCLR 4610 075 800 5 VCLC 4510 075 900 5 VCLR 4610 075 900 5

VCLZ 4410 075 1000 5 VCLC 4510 075 1000 5 VCLR 4610 075 1000 5 VCLZ 4410 075 1100 5 VCLC 4510 075 1100 5 VCLR 4610 075 1100 5 VCLZ 4410 075 1200 5 VCLC 4510 075 1200 5 VCLR 4610 075 1200 5

Left Side Reducer 4610 R - Type A

1100 1200

Left Side Reducer Curved Z - Type

11

C A B L E LADDER ACCESSORIES

Cable

Straight Connector

Thickness: 1.5 mm

240

Ladders

Item

Straight Connector Straight Connector Straight Connector

Dimensions

240 x 45 mm 240 x 70 mm 240 x 95 mm

Code

ACL 1000 045 4 ACL 1000 070 4 ACL 1000 095 4

ACCESSORIES

Angle Connector

Thickness: 1.5 mm

240

Item

Angle Connector Angle Connector Angle Connector

Dimensions

Code

240 x 45 x 20 mm ACL 1010 045 4 240 x 70 x 20 mm ACL 1010 070 4 240 x 95 x 20 mm ACL 1010 090 4

h 20

Adjustable Connector

Thickness: 1.5 mm

150

Item

Adjustable Connector Adjustable Connector

150

Dimensions

150 x 20 mm 150 x 40 mm

Code

ACL 1030 020 4 ACL 1040 040 4

Wrap-over Connector

Thickness: 1.5 mm

Item

Wrap-over Connector Wrap-over Connector Wrap-over Connector

Dimensions

45 x 20 mm 70 x 20 mm 95 x 20 mm

Code

ACL 1050 020 4 ACL 1050 020 4 ACL 1050 020 4

Item Barrier Strip

Thickness: 1.5 mm Barrier Strip Barrier Strip Barrier Strip

Dimensions

3000 x 45 x 20 mm 3000 x 70 x 20 mm 3000 x 090 x 20 mm

Code

ACL 1070 045 4 ACL 1070 070 4 ACL 1070 090 4

Barrier strips, also known as dividers or separators, are used to separate cables in a ladder. The barrier may be used to separate cables of varying voltage classes as required. Barriers also divide the ladder into compartments to isolate circuitry such as communications/computer cables from cables for dedicated power etc. Straight section barriers are supplied 3.0 m long with appropriate slots in the bottom leg to accommodate any type of rung or bottom.

12

Cable

Ladders

Item

End Plate End Plate End Plate

End Plate

Thickness: 1.5 mm

Dimensions

w x 50 x 75 mm w x 75 x 75 mm w x 100 x 75 mm

Code

ACL 1100 050 4 ACL 1100 075 4 ACL 1100 100 4

Drop Out Plate

Thickness: 1.5 mm

Item

Drop Out Plate Drop Out Plate Drop Out Plate Drop Out Plate

Dimensions

143 mm

Code

ACL 1110 15 4 ACL 1110 20 4 ACL 1110 30 4 ACL 1110 40 4 ACL 1110 50 4 ACL 1110 60 4 ACL 1110 70 4 ACL 1110 80 4 ACL 1110 90 4 ACL 1110 100 4

193 mm

293 mm 393 mm 493 mm 593 mm 693 mm 793 mm 893 mm 993 mm

=w

Drop Out Plate

idt

ho

Drop Out Plate

f la

dd

Drop Out Plate

er

- 7 mm

Drop Out Plate Drop Out Plate Drop Out Plate

Provides a round radiused surface for cable exit from bottom of ladder.

Item Elematic Cable Ties

Cable Tie Cable Tie Cable Tie Cable Tie Cable Tie Cable Tie Cable Tie Cable Tie Cable Tie

Dimensions

2.5 x 98 mm 2.5 x 160 mm 3.6 x 140 mm 3.6 x 200 mm 4.5 x 160 mm 4.8 x 200 mm 4.8 x 250 mm 3.6 x 370 mm 4.8 x 290 mm 7.8 x 300 mm

Code

EL-1110-C-5203CTS EL-1130-C-5206CTS EL-1150-C-5209CTS EL-1160-C-5214CTS EL-1190-C-5211CTS EL-1210-C-5215CTS EL-1220-C-5216CTS EL-1230-C-5208TS EL-1240-C-5217TS EL-1310-C-5226TS

Provide an easy attachment of cables to ladder rungs

Cable Tie

item Slotted Round Head Screws

Round Head Screw Round Head Screw Round Head Screw Round Head Screw Round Head Screw Round Head Screw Round Head Screw

Dimensions

6 x 15 6 x 20 6 x 30 6 x 40 8 x 30 8 x 40 10 x 30

Code

RB 0615 RB 0620 RB 0630 RB 0640 RB 0830 RB 0840 RB 1030

13

CABLE LADDER Covers

Cable Ladder covers are supplied with or without a 15 mm downturned flange. Straight section covers are furnished 3 meters long. All fitting covers are furnished in solid design only. Steel Thickness: 1.2 mm Cable Ladder Cover Width

150 200 300 400 500 600 700 800 900 1000 1100 1200

Cable

Ladders

HCW

HCW 5000 150 3 HCW 5000 200 3 HCW 5000 300 3 HCW 5000 400 3 HCW 5000 500 3 HCW 5000 600 3 HCW 5000 700 3 HCW 5000 800 3 HCW 5000 900 3 HCW 5000 1000 3 HCW 5000 1100 3 HCW 5000 1200 3

Cable Ladder Cover with Lock Width

150 200 300 400 500 600

HCC

HCC 5500 150 3 HCC 5500 200 3 HCC 5500 300 3 HCC 5500 400 3 HCC 5500 500 3 HCC 5500 600 3 HCC 5500 700 3 HCC 5500 800 3 HCC 5500 900 3 HCC 5500 1000 3 HCC 5500 1100 3 HCC 5500 1200 3

Cover

700 800 900 1000 1100 1200

Lock Ladder

Cable Ladder Cover with Locking Clamp (only upon request ) Locking Clamp Bolt M6x15

Covers Side Height Types Solid without flange Solid with flange

25 x 95 x 2 mm Functions Cable ladder covers should be considered for any of the following purposes: Protection from falling objects or debris, as may occur beneath personnel walkways. Shielding from ultra-violet rays of the sun and to guard against other weathering elements. To minimize accumulation of foreign contaminants such as ash or other industrial deposits. Protection of cables and personnel where a riser ladder penetrates a floor or grating. To assist in EMI/RFI shielding of sensitive circuits installed in solid bottom ladders. Aesthetic considerations in prominent areas of the installation or as deemed necessary by the user.

14

Cable

Ladders

Cable splices are permitted within a cable ladder

system provided that they are accessible and do not project above the top of the tray. Future cables can be added to an existing cable ladder system as easily as the initial cables were installed. Future cable taps and splices can also be made with ease. Installed cables can easily be inspected and cable faults can often be located and repaired without total replacement of the original cable run. Rounded side rail flanges protect cables from damage. Rung designs permit easy cable drop out with no sharp edges to damage cable.

General Information

Advantages of Cable Ladder System Increased cable fill over other wiring methods can save material costs and installation labor. Increased conductor ampacities due to full ventilation can provide significant savings in conductor costs. Cable ladder takes up less space and requires less labor than comparable conduit and wire systems. Increased support spans up to 3 meters save material and labor costs for supports. Metallic cable ladders can be used as an equipment ground conductor. Cables can enter or exit (drop out) at any point in the cable ladder system without expensive boxes or fittings.

Order Number

When Ordering Cable Ladder, the order number will include: - Type of Ladder: HCL (Heavy Duty Cable Ladder) VCL (Very Heavy Duty Cable Ladder) - Type of Side Height: R (Return Flange Inside ) HCL -R 1010 075 150 4

Type Type of Side Height Item Number Side Height

Width of Ladder - Item Number: Items numbers 1010, 1110,1210 stand for raceways Material Thickness of Rung Items number 2000 and higher stands for fittings For Accessories ACL is added to the item number For Covers HCW & HCC are used. WARNING

- Side Height:s 75, 100 mm side heights are available (50 mm upon request) - Width of ladder Widths from 150 mm up to 1200 mm are manufactured - Material Thicknesses Order number 2 for (1.0 mm) Order number 3 for (1.2 mm) Order number 4 for (1.5 mm) Order number 5 for (2.0 mm)

Cable ladder is not to be used as a walkway, ladder, or support for personnel. To be used only as a mechanical support for cables and tubing.

Abbreviations

Materials

Pre Galvanized Hot-dip Galvanized

Code:

: PG : HD Electrolytic Galvanized Powder Coated

Code:

: EG : PC

Side Type

Code:

Thickness

Sheet Sheet Sheet Sheet of of of of 1.00 mm 1.20 mm 1.50 mm 2.00 mm

Code:

: : : : 2 3 4 5

Z-Type: Top Outside / Bottom Inside : Z C-Type: Outside Top & Bottom : C R-Type: Inside Return Flange : R

15

Engineering Information

Cable

Structural Information SFSP cable ladder has been designed to offer maximum strength and load carrying capabilities at the most economical installed costs to the user. The following information is presented to aid the designer/user in the best application of our products to suit his particular requirements. Cable Ladder Loads - Cable Ladder loads are generally uniform loads expressed in Kg per meter. Loads commonly referred to in the cable ladder industry are: Cable Load - Total static weight of the cables to be supported in the ladder. This may include future cable loads if applicable. Live loads- Weather Loads, such as wind, snow, and ice, should be considered in outdoor installations. Working Load - Combination of the cable load and live loads to be applied to your cable ladder system. Allowable Load - Is the destruction load capacity of the cable ladder divided by a safety factor of 1.5. The allowable load capacity should equal or exceed the working load to be applied. Support Spans - A support span is merely the centerline to centerline distance between supports. In actual practice, the support spans of an installed cable ladder system will vary, but the engineer/user should specify the maximum support span. Two support spans commonly referred to are: * Simple BeamA single span with the ends free to rotate. This type span rarely occurs in normal installations, but is used as the most severe case when testing cable ladder to determine load capacity. * Continuous BeamA series of spans connected together and continuous over several supports. This type span more closely approximates an actual installation. Determine the most economical support spacing by reviewing building structure and any existing support structures. In many cases, it can be less expensive to support a stronger ladder system over longer spans by reducing the number of supports. Cable ladder fittings should be supported in accordance with NEMA Standard VE 1, Part 6. In addition, supports should be located on each side, and in close proximity to, expansion splices and vertical and horizontal hinged splices. Support Types - The most common types of support are: - Trapeze hangers consisting of a support angle suspended by all-thread hanger rods; - Wall brackets anchored to walls or columns. NEMA Load Classes - NEMA Standard VE 1, Part 3 outlines load/span class designations to be utilized by the designer/user to specify a tray system to meet his/her structural needs. The designation is of the form 8A, 12A, 20C, etc. The numerical part refers to the support span, in feet. The alpha character in the designation refers to a load category. Current NEMA load/span designations are as follows.

Class Designation

Ladders

8A 8B 8C 12A 12B 12C 16A 16B 16C 20A 20B 20C

Support Span mtr. (ft) 2.4 (8) 2.4 (8) 2.4 (8) 3.6 (12) 3.6 (12) 3.6 (12) 4.8 (16) 4.8 (16) 4.8 (16) 6.0 (20) 6.0 (20) 6.0 (20)

Working (Allowable) Load Kg/m 72.95 109.42 145.90 72.95 109.42 145.90 72.95 109.42 145.90 72.95 109.42 145.90

Load capacities for ladders are determined by test standards outlined in NEMA VE 1, Part 4. Each ladder is supported on a simple beam span and is loaded uniformly to destruction. The total destruction load divided by a safety factor of 1.5 represents the working load of the ladder. Since cable ladder is rarely supported on simple beam spans, the actual installed safety factor of multiple spans is 20 to 60 percent higher (see beam diagrams for comparative bending moments). Deflection - Deflection is the vertical displacement from its original position of a cable ladder when loaded. In general, the maximum deflection occurs at midspan or midway between supports. Deflections shown on the selector chart are for simple beam spans. Deflections for multiple installations are 14 to 12 of those shown (see beam diagrams.) Beam Diagrams M = Bending Moment = Deflection Values shown for bending moments and deflections are expressed as fractions of simple beam span values (assuming equal uniform loads and span lengths).

= 1.00 M = 1.00 Simple Beam

= 0.40 M = 0.56

= 0.40 M = 0.56

M = 1.00 Two Span

= 0.52 M = 0.64

= 0.04 M = 0.20

= 0.52 M = 0.64

M = 0.80 M = 0.80 Three Span

= 0.50 M = 0.62

= 0.37 M = 0.27

= 0.26 M = 0.37

= 0.37 M = 0.27

= 0.50 M = 0.62

M = 0.84

M = 0.63 M = 0.63 Five Span

M = 0.84

16

Cable

Ladders

MATERIAL & FINISHES

SFSP ensures that all of the materials used during the fabrication and finishing of its products conform to the relevant standards.

Basic Material Mild steel classification ASTM A36 or

BS 1449, part 1 or DIN EN 10111/10025/10029 All parts made of steel can be delivered depending on environment and according to the various requirements with different protection methods against corrosion, such as:

Austenitic Stainless Steels.

Steel plate, sheet & strip, ASTM A240M, BS EN 10088 BS 1449 : part 2, DIN 17440, DIN 17441

USA AISI 304 304L 316 316Ti U.K. BSI 304S15 304S11 Germany DIN 17007 X5 CrNi 18 10 X5 CrNi 18 11 Germany W.N 17007 1.4301 1.4306 1.4401 1.4571 France AFNOR Z 6 CN 18-09 Z 2 CN 18-10 Z 6 CND 17-11 Z 6 CNDT 17-12

316S31 X5 CrNi Mo 17 12 2 320S31 X6 CrNiMoTi 17 12 2

Note: After substantial cold working, Grade 304 may exhibit quite strong response to a magnet

Post fabricated components are immersed in a bath of molten zinc (450C or 850F) after cleaning, pickling rinsing and fluxing. This relatively costly process is, however, necessary for installations in highly corrosive environments. Parts galvanized like this not only have an extremely longer endurance compared to those made of mill-galvanized steel sheet - under the same atmospheric influences - but they are, also much better protected against low chemical stress, marine air or urban air. As per standards the average local zinc film thickness per side shall be: - 45 m (315 g/m2) for sheets < 1mm - 50 m (350 g/m2) for sheets 1 to 3 mm The average annual loss value of zinc coats under various atmospheric stresses are: - Rural air 7 - 15 g/m2 0.8 - 1 m/year - Urban air 20 - 40 g/m2 3 - 7 m/year - Marine air 20 - 50 g/m2 3 - 8 m/year - Industrial air 40 - 80 g/m2 5 - 10 m/year White rust Either under a heterogeneous film of water, or under permanent condensation, white rust appears on the surface of the steel sheets. It is a precipitation of basic salts of zinc Zn(OH)2 that combines with CO2 to form a protective layer called Zinc Hydroxycarbonate. White rust has no negative influence on the duration of the zinc protection.

Excellent protection against chemical stress, marine and industrial air. It has also longer useful duration than hot or pre - or electrolytic galvanized steel.

Pre galvanized steel sheets (mill galvanization)

according to ASTM A653M G 90 or BS 2989 Z275 zinc coating 275 g/m2 (36m) on both sides (Sendzimir process Z 275) or BS EN 10142 1991. Parts can be used in dry atmosphere without influence of aggressive particles. The cut edge of these sheets with a thickness of approx. up to 1.5 mm are by experience sufficiently protected by the cathode protection against corrosion in almost dry atmosphere.

crack

Zn (anode) Fe (cathode)

Electrolytic galvanized steel

ASTM B633, BS 1706, BS 3382, part 2, DIN EN 10152/10131 Immersion of clean steel parts in a zinc salt solution and applying an electric current. Coating varies from few microns to 15 m (100 to 175 gr/m2). Attractive appearance when new, as the zinc coating is bright and smooth. Does not provide adequate corrosion resistance and will rarely provide more than 12 months protection in most of the coastal population centers.

Formation of Zinc Hydroxide which fills in the crack.

Zn (anode) Fe (cathode)

Epoxy or Polyester coatings. Adhesion to ASTM D3359-83 on galvanized steel sheets. Zn (anode) Zinc Application: Exterior Polyester, Fe (cathode) Interior Epoxy. salt Zn (anode) Offer good resistance to abrasions and blows, Hot-dip Galvanizing meets the following standards: excellent durability and require little maintenance. Specify the RAL reference for the color. - American Standard: ASTM A123 RAL colors for Epoxy coating - British Standard: BS EN ISO 1461:1999 replacing BS 729 : 1971 (1986) RAL 3020 RAL 8014 RAL 1013 RAL 1003 - German Standard: DIN 50976 - French Standard: NF A91-122 RED BEIGE YELLOW BROWN - International Standard: ISO 1461

Appearance of the outer surface differs from bright shining to dark mat gray, which in all cases does not affect the zinc film / corrosion protection quality.

RAL 9003 WHITE RAL 7004 GREY RAL 5015 BLUE RAL 6005 GREEN

You might also like

- Cable Ladder LeafletDocument8 pagesCable Ladder LeafletMohsan AbbasNo ratings yet

- Cable Ladder CatalogueDocument24 pagesCable Ladder CatalogueMohammad Talib MaqatifNo ratings yet

- TB Cable TrayDocument275 pagesTB Cable Traycrazy devilNo ratings yet

- Legrand Cable TrayDocument56 pagesLegrand Cable Trayaconibet9040No ratings yet

- Schneider Power Control & Protection Products (Contactors) Pricelist 20.12.2013Document35 pagesSchneider Power Control & Protection Products (Contactors) Pricelist 20.12.2013Amit PatelNo ratings yet

- Medium Voltage Cable Construction and SpecificationsDocument34 pagesMedium Voltage Cable Construction and SpecificationsNelson GarvizuNo ratings yet

- Medium Voltage MZDocument86 pagesMedium Voltage MZsujiNo ratings yet

- Crompton LED Price List Nov 2019Document72 pagesCrompton LED Price List Nov 2019Ravish RamNo ratings yet

- Cable Tray CatalogueDocument94 pagesCable Tray Cataloguerzor100% (1)

- Wiring of 13A Switched Socket Outlets in Radial Circuit PDFDocument1 pageWiring of 13A Switched Socket Outlets in Radial Circuit PDFkmleongmyNo ratings yet

- Control Gear Price ListDocument15 pagesControl Gear Price ListShubham GuptaNo ratings yet

- BOQ Format - Electrical PDFDocument7 pagesBOQ Format - Electrical PDFKurama Basket100% (1)

- 15kv Phelps DodgeDocument4 pages15kv Phelps DodgeJuan E Torres M100% (1)

- Oglaend System Smart Cleat 1113Document12 pagesOglaend System Smart Cleat 1113sourcNo ratings yet

- Ip Codes (Reference)Document2 pagesIp Codes (Reference)UNNI VENUGOPALNo ratings yet

- Cable Tray Price ListDocument54 pagesCable Tray Price ListSunil WadekarNo ratings yet

- Insulators MACPSDocument60 pagesInsulators MACPSAshley Julietita AriasNo ratings yet

- General Cable: Price ListDocument48 pagesGeneral Cable: Price Listalfonso.parker100% (1)

- ABC Construction StandardsDocument16 pagesABC Construction StandardswolverinepNo ratings yet

- TD0148 - Creating An AutoCAD Electrical Drawing TemplateDocument5 pagesTD0148 - Creating An AutoCAD Electrical Drawing TemplateMohammad AdrianNo ratings yet

- Electrical DetailsDocument1 pageElectrical Detailscherif yahyaouiNo ratings yet

- Legrand RCCB and MCBDocument78 pagesLegrand RCCB and MCBKelly chatNo ratings yet

- LS Electric Price ListDocument61 pagesLS Electric Price ListMohamed AbdellaNo ratings yet

- Cable Tray Standards - by LegrandDocument4 pagesCable Tray Standards - by Legrandsuresh babuNo ratings yet

- CCTV Single Line Diagram CCTV Single Riser Diagram: Bureau of DesignDocument1 pageCCTV Single Line Diagram CCTV Single Riser Diagram: Bureau of DesignDominador Ladot Heraña Jr.No ratings yet

- Eflex Cable Conduit Work ProcedureDocument8 pagesEflex Cable Conduit Work ProcedureRaden ArmanadiNo ratings yet

- BusAmpacityIEEETransOct94 PDFDocument9 pagesBusAmpacityIEEETransOct94 PDFAnonymous qDCftTW5MNo ratings yet

- Strutfast Cable Trays - LRDocument11 pagesStrutfast Cable Trays - LRzimtonyNo ratings yet

- Voltage drop calculation methods explainedDocument8 pagesVoltage drop calculation methods explainedTerex14253No ratings yet

- VC2182-001-C-001 2 Cable Data SheetDocument78 pagesVC2182-001-C-001 2 Cable Data SheetOoi Wei ShengNo ratings yet

- Installation Instructions EPLAN Education 2023 enDocument16 pagesInstallation Instructions EPLAN Education 2023 enSachin ShikotraNo ratings yet

- CBGS0 Technical SCH-En PresentationDocument33 pagesCBGS0 Technical SCH-En PresentationShah Aizat RazaliNo ratings yet

- A&H Meyer - Low Res PDFDocument36 pagesA&H Meyer - Low Res PDFAnonymous MDkp0hnb3lNo ratings yet

- Brass Cable Glands SpecificationdryDocument10 pagesBrass Cable Glands Specificationdrynirbhay111No ratings yet

- Low Voltage Aerial Bundled Conductors ADVANTAGESDocument1 pageLow Voltage Aerial Bundled Conductors ADVANTAGESCharles HiiNo ratings yet

- Electrical Cable Support System Installation Work (For Cons)Document33 pagesElectrical Cable Support System Installation Work (For Cons)Le Dinh QuangNo ratings yet

- Catalogue Prisma IPM LDocument140 pagesCatalogue Prisma IPM LTrương Quốc Hiệp100% (1)

- Finolex Cable Price List Updated 30th October 2020Document20 pagesFinolex Cable Price List Updated 30th October 2020Sahili SalveNo ratings yet

- Cable GlandsDocument20 pagesCable GlandsBalaji VenkatesanNo ratings yet

- Padmount & Overhead Distribution TransformersDocument18 pagesPadmount & Overhead Distribution TransformersmellymoyoNo ratings yet

- ABB Price List for Electrification ProductsDocument14 pagesABB Price List for Electrification Productspranay prakashNo ratings yet

- Speed Systems CatalogDocument32 pagesSpeed Systems CatalogAdri LozadaNo ratings yet

- Kenwood TH-D72 Users ManualDocument51 pagesKenwood TH-D72 Users ManualrickcobbNo ratings yet

- Cable TrayDocument20 pagesCable TrayChandra Sekaran SaravananNo ratings yet

- Ieee 80-2000 PDFDocument199 pagesIeee 80-2000 PDFKishore KumarNo ratings yet

- Interface A Elbow Connector Technical OverviewDocument2 pagesInterface A Elbow Connector Technical Overviewagust1988100% (1)

- AVEVA Electrical Product Datasheet PDFDocument4 pagesAVEVA Electrical Product Datasheet PDFhahahaNo ratings yet

- Electrical BOQDocument3 pagesElectrical BOQRakesh Mitra100% (1)

- List Cab Let I Pic Power EnglishDocument14 pagesList Cab Let I Pic Power EnglishglenysyaNo ratings yet

- 4e4a 7671 4E4A TABLEDocument1 page4e4a 7671 4E4A TABLEiqkhanukNo ratings yet

- Dialux Training ManualDocument31 pagesDialux Training ManualJugemu JugemuNo ratings yet

- Busduct Catalogue PDFDocument184 pagesBusduct Catalogue PDFJulian RiañoNo ratings yet

- Panasonic Professional Lighting Price List 2019Document19 pagesPanasonic Professional Lighting Price List 2019phillip ray chigogoNo ratings yet

- N EPP-P5-F13 Substation in Basement Agreement-NewDocument3 pagesN EPP-P5-F13 Substation in Basement Agreement-NewSameh سامح MaherNo ratings yet

- Lamda Exothermic Welding ChartDocument93 pagesLamda Exothermic Welding ChartAgus Nur SetiawanNo ratings yet

- 66kV and 132kV HV Catalogue ENSDocument15 pages66kV and 132kV HV Catalogue ENSCristi GrosuNo ratings yet

- Raychem Kit Price ListDocument44 pagesRaychem Kit Price ListAchintya KarmakarNo ratings yet

- Cable Ladder Tray: CatalogueDocument106 pagesCable Ladder Tray: CatalogueJESUS HUAMANINo ratings yet

- Kensteel Cable Tray & LadderDocument48 pagesKensteel Cable Tray & LadderlimresNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- MTR-3 (Uk)Document1 pageMTR-3 (Uk)123peniscolaNo ratings yet

- Mx3ipg2a en TDDocument2 pagesMx3ipg2a en TDRazvan Sasu100% (3)

- Why Using MCCB Instead of Fuses PDFDocument4 pagesWhy Using MCCB Instead of Fuses PDF123peniscolaNo ratings yet

- 5 KV and 10 KV Insulation Resistance TestersDocument3 pages5 KV and 10 KV Insulation Resistance Testers123peniscolaNo ratings yet

- Readme SIPROTEC 4 Upgrade PDFDocument7 pagesReadme SIPROTEC 4 Upgrade PDF123peniscolaNo ratings yet

- Energy Cables Building & Construction: Circular PVC 3C + E SWA, CopperDocument2 pagesEnergy Cables Building & Construction: Circular PVC 3C + E SWA, Copper123peniscolaNo ratings yet

- MV LOAD CABLE SIZINGDocument1 pageMV LOAD CABLE SIZING123peniscolaNo ratings yet

- Catalogue Protective and Measuring Transformers m4 enDocument86 pagesCatalogue Protective and Measuring Transformers m4 enwizardgrt100% (1)

- Mx3ipg2a en TDDocument2 pagesMx3ipg2a en TDRazvan Sasu100% (3)

- Bus Duct - Catalog - GERS ViejoDocument12 pagesBus Duct - Catalog - GERS Viejo123peniscolaNo ratings yet

- Readme Fwup PDFDocument42 pagesReadme Fwup PDF123peniscolaNo ratings yet

- 1.5mm2 PVCDocument2 pages1.5mm2 PVC123peniscolaNo ratings yet

- Doe Handbook: Primer On Lead-Acid Storage BatteriesDocument54 pagesDoe Handbook: Primer On Lead-Acid Storage Batteriesyana_harsana100% (1)

- Energy Cables Building & Construction: Circular PVC 2C + E SWA, CopperDocument2 pagesEnergy Cables Building & Construction: Circular PVC 2C + E SWA, Copper123peniscolaNo ratings yet

- Ex Protection Type ComparisonDocument1 pageEx Protection Type Comparison123peniscolaNo ratings yet

- 241-267 - CT and VT Basics - QuazvinDocument27 pages241-267 - CT and VT Basics - Quazvincarlos vidalNo ratings yet

- Energy Cables Building & Construction: Circular PVC 2C + E SWA, CopperDocument2 pagesEnergy Cables Building & Construction: Circular PVC 2C + E SWA, Copper123peniscolaNo ratings yet

- TBM Main Bearing Life DeterminationDocument12 pagesTBM Main Bearing Life Determination123peniscolaNo ratings yet

- Cooling methods for motorsDocument1 pageCooling methods for motors123peniscolaNo ratings yet

- TP IEC - Routine Motor TestsDocument5 pagesTP IEC - Routine Motor Tests123peniscolaNo ratings yet

- Cooling methods for motorsDocument1 pageCooling methods for motors123peniscolaNo ratings yet

- Motor Enclosure TypesDocument1 pageMotor Enclosure TypesPoncho RmzNo ratings yet

- Current Transformer GuideDocument79 pagesCurrent Transformer Guidesabill arasyid100% (1)

- Why Using MCCB Instead of FusesDocument4 pagesWhy Using MCCB Instead of Fuses123peniscolaNo ratings yet

- ABB ensures on-time success in aluminium manufacturingDocument10 pagesABB ensures on-time success in aluminium manufacturing123peniscolaNo ratings yet

- Domae MCB and C60/C120 Circuit Breakers Reference GuideDocument125 pagesDomae MCB and C60/C120 Circuit Breakers Reference Guide123peniscola80% (5)

- Domae MCB and C60/C120 Circuit Breakers Reference GuideDocument125 pagesDomae MCB and C60/C120 Circuit Breakers Reference Guide123peniscola80% (5)

- Current Transformer GuideDocument79 pagesCurrent Transformer Guidesabill arasyid100% (1)

- Siemens Sirius 3RW30 3RW40 Manual PDFDocument212 pagesSiemens Sirius 3RW30 3RW40 Manual PDFElias Nassif GomezNo ratings yet

- Tkinter Cheat SheetDocument2 pagesTkinter Cheat Sheetphanina01No ratings yet

- Applies To:: How To Disable Logging To The Sqlnet - Log and The Listener - Log (Doc ID 162675.1)Document2 pagesApplies To:: How To Disable Logging To The Sqlnet - Log and The Listener - Log (Doc ID 162675.1)Thiago Marangoni ZerbinatoNo ratings yet

- Secretary's Certificate in Re Board ResolutionsDocument2 pagesSecretary's Certificate in Re Board Resolutionslucky joy domingoNo ratings yet

- 6 Non-Executive-Presidents-In-Parliamentary-Democracies-PrimerDocument34 pages6 Non-Executive-Presidents-In-Parliamentary-Democracies-PrimerWorawut Von SarkhanNo ratings yet

- ABB Surge Arrester POLIM-D PI Outdoor - Data Sheet 1HC0093993 E01 AADocument4 pagesABB Surge Arrester POLIM-D PI Outdoor - Data Sheet 1HC0093993 E01 AAHan HuangNo ratings yet

- Bangalisan V Ca G.R. No. 124678 July 31, 1997 Regalado, J.: FactsDocument1 pageBangalisan V Ca G.R. No. 124678 July 31, 1997 Regalado, J.: FactsKate GaroNo ratings yet

- Profile of FAOADocument5 pagesProfile of FAOAqubrex1No ratings yet

- 06-472 ARM III Disconnect SwitchDocument4 pages06-472 ARM III Disconnect SwitchCarlos YepezNo ratings yet

- XJ550 Parts ManualDocument121 pagesXJ550 Parts Manualjuan2610100% (5)

- Vapor Sensor: Installation GuideDocument12 pagesVapor Sensor: Installation GuideShalvaTavdgiridzeNo ratings yet

- OmniVision OV9716Document2 pagesOmniVision OV9716cuntadinNo ratings yet

- Manila Bay accretion disputeDocument24 pagesManila Bay accretion disputeRoman KushpatrovNo ratings yet

- Electric Bike ReportDocument33 pagesElectric Bike ReportGautham M A100% (1)

- HP MOQ Traditional BPC Mar'21 Pricelist - FTPDocument8 pagesHP MOQ Traditional BPC Mar'21 Pricelist - FTPrachamreddyrNo ratings yet

- Customer and Banker Relationship MCQDocument13 pagesCustomer and Banker Relationship MCQsn n100% (3)

- Centrifugal Pump Hand BookDocument150 pagesCentrifugal Pump Hand Bookbarun1977100% (2)

- International Trade Finance - Nov 2009Document8 pagesInternational Trade Finance - Nov 2009Basilio MaliwangaNo ratings yet

- ACT NO. 4103: (As Amended by Act No. 4225 and Republic Act No. 4203 (June 19, 1965) )Document6 pagesACT NO. 4103: (As Amended by Act No. 4225 and Republic Act No. 4203 (June 19, 1965) )Marvin Alvic Bustaliño LasticaNo ratings yet

- Work Based Career Episodes 3Document3 pagesWork Based Career Episodes 3Ajith JohnsonNo ratings yet

- Quadcopter Project Presentation Using KK 2.1.5 ControllerDocument13 pagesQuadcopter Project Presentation Using KK 2.1.5 ControllerAkshay SinghalNo ratings yet

- Interview Questions For PBDocument3 pagesInterview Questions For PBskrtripathiNo ratings yet

- Commercial Dispatch Eedition 7-10-19Document16 pagesCommercial Dispatch Eedition 7-10-19The DispatchNo ratings yet

- Construction ScheduleDocument3 pagesConstruction Schedulegroup2sd1314100% (1)

- (Studies in Critical Social Sciences) Elizabeth Humphrys - How Labour Built Neoliberalism (2018)Document281 pages(Studies in Critical Social Sciences) Elizabeth Humphrys - How Labour Built Neoliberalism (2018)Angularity AngularityNo ratings yet

- Fluxes For MetallurgyDocument15 pagesFluxes For Metallurgyramau619No ratings yet

- User Manual FADALDocument583 pagesUser Manual FADALAntonio GonçalvesNo ratings yet

- Computer Skills For Page (50) - AboodalmsriDocument112 pagesComputer Skills For Page (50) - Aboodalmsribq4k2wgdjsNo ratings yet

- 7 Principles of Highly Effective Command CentersDocument11 pages7 Principles of Highly Effective Command CentersLuis OlavarrietaNo ratings yet

- Comparison of ROBOT and MIDAS GENDocument2 pagesComparison of ROBOT and MIDAS GENAshish LoyaNo ratings yet

- CS 132 Mathematics For Computer Science: Applications of DerivativesDocument23 pagesCS 132 Mathematics For Computer Science: Applications of DerivativesDhuanne EstradaNo ratings yet