Professional Documents

Culture Documents

DFMaint Tutorial

Uploaded by

pravit08Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DFMaint Tutorial

Uploaded by

pravit08Copyright:

Available Formats

Design for Maintainability

Definition Maintainability is the degree to which a product can be maintained or repaired easily, economically, and efficiently. Design for maintainability (DFMaint) encompasses the measures taken to reduce the time and other resources spent in keeping a product performing well. It benefits the end user by reducing the total ownership costs through less downtime (lost productivity), lower maintenance costs, less inventory, fewer tools, and improved safety. DFMaint can be a differentiating feature for otherwise commodity products. lthough it may increase the costs to manufacture a product, DFMaint can also increase market share and e!tend the product lifecycle. DFMaint is presented in this tutorial as an approach for durable goods. "owever, it can also be adapted appropriately for software, service, operations, and processes. How to Apply Design for Maintainability DFMaint Features #he following features are commonly found in easily maintained products and systems$ %elatively few components in the final assembly &tandard components and fasteners 'onformance to national, international, and industry standards and codes 'omponents that are easily replaced 'omponents that can be easily removed with standard tools 'omponents that are install only one way &pace around or inside the product to perform maintenance activities (ondestructive disassembly &afety precautions protect maintenance workers from ha)ards *wner+s manuals and other appropriate documentation (e.g., wiring diagrams, help facilities, or videos showing how to perform minor repairs) 'onsistent labels to identify parts Installed product re,uired no or minimal ad-ustment &elf.diagnostics, built in tests, or indicators that isolate problems ,uickly and automatically &teamlined testing, calibration, and troubleshooting procedures &imple after.sale processes that ensure service can be received promptly

DFMaint in the Product Development Process #he features of DFMaint products are obvious. /et they can easily be overlooked unless DFMaint is a deliberate consideration in the product development process. Furthermore, DFMaint should be considered early in the product design process when the product concept is fle!ible and change costs are low. #he following closed.loop process outlines this approach$ 0. Form a team that represents design, manufacturing, product maintenance, and customer support functions. 1. 2ather and analy)e data from service technicians, field personnel, customer surveys, and warranty records. (&ee related tutorial on such analysis tools as failure modes and effects analysis 3FM4 5, fault.tree analysis 3F# 5, 6areto analysis, and Ishikawa diagrams at this website.) 7. Identify and prioriti)e maintenance issues. Develop concepts to address the greatest concerns. 8. Incorporate the selected maintenance concepts into the product. (&ee related tutorials on design for manufacturing 3DFM5 and durability at this website.) 9. :. naly)e, test, and improve the product, allowing the design to evolve as maintenance concepts are reviewed and revised. fter product engineers finali)e the design, release the product to manufacturing.

;. 4valuate the performance of the product in the field through customer feedback, warranty information, surveys, and service records. <se this information to inform the design of new products. =. Modify the product as re,uired by critical safety, economics, and performance demands. >. %epeat the DFMaint process with the ne!t generation product. Measuring DFMaint Results Maintenance cost benchmarks are collected by the 6lant Maintenance %esource 'enter (http$??plant.maintenance.com?benchmarking.shtml). #hese benchmarks can help a firm assess its competency in comparison with industry benchmark companies. Maintenance metrics address three factors$ product design attributes, after.sale costs, and product performance. #ypical measures include conformance to specifications fre,uency of repairs repair costs total ownership costs training costs maintenance work orders per year

downtime total maintenance hours number of maintenance personnel

Example In the early 1@@@s, 24+s 4lectro.Motive Division (4MD) was compelled to modify designs for its railway locomotives. (ew 46 re,uirements mandated a significant reduction in (*! emissions produced by locomotives. &ince redesign was unavoidable, the division decided to take the opportunity to improve the maintainability of the e,uipment at the same time. &uch improvements would improve the safety and reduce the re,uired maintenance hours of the e,uipment. Following an interative design process, engineers not only surpassed the mandatory 46 standards, they incorporated several DFMaint features into the new product$ n easily removable hood #rack.level access to the traction motor speed probe &olid.state components to replace more fragile fuses &impler processes for insulation testing %econfiguration and consolidation of electrical wiring and pneumatic piping onto separate sides of the underframe dvanced software to help technicians isolate defective components 'learer messaging on the crew+s cab display screens to accurate convey important maintenance.related information wireless remote monitoring and communications system the provide early alerts of predicted health and maintenance events n ergonomic cab to improve the engineer+s comfort and reduce fatigue

Most importantly, the new design did not alter the basic engine dimensions, nor does it re,uire additional workforce training or tooling. Further Information about Design for Maintainability &ignificant content for this article was found at the website for the %eliability 'enter (% '), an information analysis center affiliated with the <.&. Department of Defense. broad range of ,uality assurance information can be found at their website http$??rac.iitri.org. Additional Sources Markeset, #ore and <day Aumar. Design and development of product support and maintenance concepts for industrial systems. Journal of Quality in Maintenance Engineering Bol. > Iss. 8 (1@@7)$ 7;: C 7>1.

Bantuono, Dilliam '. Design for maintainability. Railway Age Bol. 1@8 (o. ; (Euly 1@@7)$ 70.

You might also like

- Engineering Documentation Control / Configuration Management Standards ManualFrom EverandEngineering Documentation Control / Configuration Management Standards ManualNo ratings yet

- Design For MaintainabilityDocument7 pagesDesign For MaintainabilityEmilian PopaNo ratings yet

- DFMDocument4 pagesDFMMarko BrkicNo ratings yet

- Reliability Program ManagementDocument14 pagesReliability Program Managementloveselvan43No ratings yet

- Basic Concepts in Reverse EngineeringDocument15 pagesBasic Concepts in Reverse EngineeringMohannadNo ratings yet

- Department of Mechanical EngineeringDocument31 pagesDepartment of Mechanical EngineeringnivilogNo ratings yet

- Difference Between Product Development From Past & Present: Assignment 2Document10 pagesDifference Between Product Development From Past & Present: Assignment 2KunalNo ratings yet

- Failure Modes and Effects Analysis (Fmea) : Mechanical Engineering, September 1993Document5 pagesFailure Modes and Effects Analysis (Fmea) : Mechanical Engineering, September 1993JeevanNo ratings yet

- Determine Maintenace StrategyDocument18 pagesDetermine Maintenace StrategyJalel Bejo GudinaNo ratings yet

- Chapter # 04. Operation Management 7 Ed. BY Russell and TaylorDocument45 pagesChapter # 04. Operation Management 7 Ed. BY Russell and TaylorRoman AhmadNo ratings yet

- Group WorkDocument4 pagesGroup WorkfatrupNo ratings yet

- Failure Modes and Effects AnalysisDocument5 pagesFailure Modes and Effects AnalysisBoBo KyawNo ratings yet

- Equipment-Plant Maintenance: September 2000Document536 pagesEquipment-Plant Maintenance: September 2000Emmanuelle IlaganNo ratings yet

- AIAG Cqi 14 Warranty Key TermsDocument13 pagesAIAG Cqi 14 Warranty Key TermsLipeca75% (8)

- KT Plan - Training Sheet (Ebs) Oracle ManufacturingDocument8 pagesKT Plan - Training Sheet (Ebs) Oracle ManufacturingGaurav Srivastava100% (1)

- Chapter 2Document37 pagesChapter 2leuyennhi132002No ratings yet

- Apriso QualityManagementDocument41 pagesApriso QualityManagementrgil252No ratings yet

- Course Mba - 2 Semester Subject Assignment MB0044 - Set 1Document18 pagesCourse Mba - 2 Semester Subject Assignment MB0044 - Set 1kct_thomasNo ratings yet

- Siemens PLM Tecnomatix Digital Manufacturing For Trace Ability WP Tcm73 4931Document10 pagesSiemens PLM Tecnomatix Digital Manufacturing For Trace Ability WP Tcm73 4931adi20019No ratings yet

- Singapore Refinery Document FileDocument6 pagesSingapore Refinery Document FileSubham SharmaNo ratings yet

- 1 Product Development ProcessDocument100 pages1 Product Development Processzaid zainol100% (1)

- Module 4Document13 pagesModule 4joyelpaulNo ratings yet

- The 7 Steps For Rolling Out An Early Equipment Management SystemDocument32 pagesThe 7 Steps For Rolling Out An Early Equipment Management SystemJavier R- Colina M.No ratings yet

- 03-2017 - Maintenance PreventionDocument5 pages03-2017 - Maintenance PreventionmajosehdNo ratings yet

- A Dimensional Engineering Process For ShipbuildingDocument11 pagesA Dimensional Engineering Process For ShipbuildingWJccnNo ratings yet

- Chapter 4 PPT Content UpdatedDocument18 pagesChapter 4 PPT Content UpdatedLD GentelisoNo ratings yet

- Failure Mode and Effect AnalysisDocument9 pagesFailure Mode and Effect AnalysisameliaNo ratings yet

- Proces wp001 - en P PDFDocument16 pagesProces wp001 - en P PDFReinaldo GomezNo ratings yet

- Audit, Develop and ImplementDocument8 pagesAudit, Develop and ImplementVishal MadooNo ratings yet

- Minor Project (Research Report)Document50 pagesMinor Project (Research Report)Atul DahiyaNo ratings yet

- DeCaris2007 RiskBasedEquipQualDocument12 pagesDeCaris2007 RiskBasedEquipQualTim WongNo ratings yet

- Ppce Two MarksDocument21 pagesPpce Two MarksJegan ParamasivamNo ratings yet

- Design For Reliability: Pranit Dhole (PA 09) Manish Jadhav (PA 14) Tejas Shinde (PA 06) Abhishek Birajdar (PA 23)Document14 pagesDesign For Reliability: Pranit Dhole (PA 09) Manish Jadhav (PA 14) Tejas Shinde (PA 06) Abhishek Birajdar (PA 23)Tejas ShindeNo ratings yet

- 4 - Ppt-HciDocument17 pages4 - Ppt-Hcirheena espirituNo ratings yet

- Instrumentation & ControlDocument4 pagesInstrumentation & Controlابزار دقیقNo ratings yet

- Product and Service DesignDocument6 pagesProduct and Service DesignJerome BayocbocNo ratings yet

- Maintenance in MotionDocument8 pagesMaintenance in MotionJaikishan KumaraswamyNo ratings yet

- Design For Manufacturability PDFDocument4 pagesDesign For Manufacturability PDFCarlos Andrés Pérez EstradaNo ratings yet

- Advanced Design EngineeringDocument22 pagesAdvanced Design EngineeringKevin OnyangoNo ratings yet

- Minitab White Paper 5 Techniques For Reliable Product DesignDocument22 pagesMinitab White Paper 5 Techniques For Reliable Product DesignjayaramanNo ratings yet

- Course Mba - 2 Semester Subject Assignment MB0044 - Set 1: Production and Operations ManagementDocument14 pagesCourse Mba - 2 Semester Subject Assignment MB0044 - Set 1: Production and Operations ManagementDantham ConpolwedsonNo ratings yet

- Output Productivity InputDocument13 pagesOutput Productivity InputptwobtwoNo ratings yet

- Development of Quality System For Engine AssemblyDocument55 pagesDevelopment of Quality System For Engine AssemblysvrbchaudhariNo ratings yet

- Remedy 7 Data Model User Guide - v1.1Document32 pagesRemedy 7 Data Model User Guide - v1.1Mohammed Gausul RezaNo ratings yet

- 3 PDFDocument8 pages3 PDFAbdul NadeeNo ratings yet

- Tools and Techniques For TQM: Dr. Ayham Jaaron Second Semester 2010/2011Document51 pagesTools and Techniques For TQM: Dr. Ayham Jaaron Second Semester 2010/2011mushtaque61No ratings yet

- Different Business Face Different Data Management ChallengesDocument7 pagesDifferent Business Face Different Data Management ChallengeslizabuhariNo ratings yet

- Mark V Revitalization Fact SheetDocument2 pagesMark V Revitalization Fact SheetHeryanto SyamNo ratings yet

- 02 Handout 1 (10) Specials TopicDocument14 pages02 Handout 1 (10) Specials TopicAlbert UmaliNo ratings yet

- Operations Management (ME-601) UNIT 2,3: Prof. S. N. VarmaDocument256 pagesOperations Management (ME-601) UNIT 2,3: Prof. S. N. Varmaanimesh650866No ratings yet

- Influence of Modification of Design Out Maintenance & Design Out Information System For Maintenance Cost Control & A Lucrative Business (With Case Study)Document9 pagesInfluence of Modification of Design Out Maintenance & Design Out Information System For Maintenance Cost Control & A Lucrative Business (With Case Study)seventhsensegroupNo ratings yet

- The Purpose of Industrial Plant and Equipment MaintenanceDocument11 pagesThe Purpose of Industrial Plant and Equipment MaintenanceJJ MonroyNo ratings yet

- Design For X: Design and Engineering KTU Module-4Document15 pagesDesign For X: Design and Engineering KTU Module-4Naseel Ibnu AzeezNo ratings yet

- Subject: Production and Operation Management Subject Code: MB0044 Assignment Set - 1Document13 pagesSubject: Production and Operation Management Subject Code: MB0044 Assignment Set - 1amit8214No ratings yet

- CAT Performance Metrics For Mobile Mining Equipment Version 1.1 PDFDocument64 pagesCAT Performance Metrics For Mobile Mining Equipment Version 1.1 PDFPamella Julian100% (9)

- Summary Chapter 5Document4 pagesSummary Chapter 5Benedictus Kevin RNo ratings yet

- Modern Trends in ManufacturingDocument34 pagesModern Trends in Manufacturingalan ShajuNo ratings yet

- MaintenancescorecardsDocument2 pagesMaintenancescorecardsagus setiawanNo ratings yet

- QA Piping Systems FluidFlowDocument15 pagesQA Piping Systems FluidFlowleandroniedbalski100% (1)

- Strategic Management Notes: SM Modules 3, 4 & 5Document61 pagesStrategic Management Notes: SM Modules 3, 4 & 5pravit08No ratings yet

- S4 Corporate Level StrategiesDocument11 pagesS4 Corporate Level Strategiespravit08No ratings yet

- TakttimeDocument1 pageTakttimepravit08No ratings yet

- Prepare A Detail Paper On CSR and Corporate Governance Connecting THM To StrategyDocument1 pagePrepare A Detail Paper On CSR and Corporate Governance Connecting THM To Strategypravit08No ratings yet

- S3 Corporate Level StrategiesDocument15 pagesS3 Corporate Level Strategiespravit08No ratings yet

- Lean Manufacturing Module 2Document20 pagesLean Manufacturing Module 2pravit08No ratings yet

- S1 - 2 Business StrategiesDocument33 pagesS1 - 2 Business Strategiespravit08No ratings yet

- Lean Manufacturing: Module-5 SIX SIGMADocument23 pagesLean Manufacturing: Module-5 SIX SIGMApravit08No ratings yet

- Lean Manufacturing: Module-5 SIX SIGMADocument8 pagesLean Manufacturing: Module-5 SIX SIGMApravit08No ratings yet

- Lean Manufacturing: Module-2 & Module-3Document17 pagesLean Manufacturing: Module-2 & Module-3pravit08No ratings yet

- Lean Manufacturing: Module-1Document36 pagesLean Manufacturing: Module-1pravit08No ratings yet

- Lean Manufacturing: Module-5 SIX SIGMADocument27 pagesLean Manufacturing: Module-5 SIX SIGMApravit08No ratings yet

- Malcolm Baldrige National Quality Award Frequently Asked QuestionsDocument2 pagesMalcolm Baldrige National Quality Award Frequently Asked Questionspravit08No ratings yet

- Synopsis: Name: Pravith P Menon Guide: Anand S. Organisation: Hindustan Coca Cola Beverages PVT LTD (Factory)Document1 pageSynopsis: Name: Pravith P Menon Guide: Anand S. Organisation: Hindustan Coca Cola Beverages PVT LTD (Factory)pravit08No ratings yet

- Leanmanufacturing Module2 ContinuationDocument24 pagesLeanmanufacturing Module2 Continuationpravit08No ratings yet

- Lean Manufacturing: Module-2 ContinuationDocument9 pagesLean Manufacturing: Module-2 Continuationpravit08No ratings yet

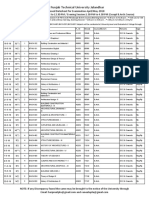

- CC21 - Course Plan - V1Document3 pagesCC21 - Course Plan - V1pravit08No ratings yet

- Scms School of Technology and Management Aluva, Cochin, Kerala - 683106Document2 pagesScms School of Technology and Management Aluva, Cochin, Kerala - 683106pravit08No ratings yet

- (Paper) Computer General Knowledge For Bank Examination (For Bank PO Exam)Document12 pages(Paper) Computer General Knowledge For Bank Examination (For Bank PO Exam)pravit08No ratings yet

- Planned Maintenance EngineeringDocument1 pagePlanned Maintenance Engineeringpravit08No ratings yet

- Sam 82eDocument8 pagesSam 82epravit08No ratings yet

- School Of'Technology and Managembnt: AttnDocument1 pageSchool Of'Technology and Managembnt: Attnpravit08No ratings yet

- Rolled Through Put YieldDocument1 pageRolled Through Put Yieldpravit08No ratings yet

- Ford Production SystemDocument4 pagesFord Production Systempravit08No ratings yet

- 7 Quality of Inferences in Mixed Methods Research - Calling For An Integrative Framework1 PDFDocument31 pages7 Quality of Inferences in Mixed Methods Research - Calling For An Integrative Framework1 PDFAkm EngidaNo ratings yet

- B.Ed. First Year - Sem. 1 Course - 104 Understanding Disciplines and School SubjectsDocument4 pagesB.Ed. First Year - Sem. 1 Course - 104 Understanding Disciplines and School SubjectsMukesh KumarNo ratings yet

- Factors Affecting The English Proficiency of Grade 10 Students at Manggitahan National High School"Document42 pagesFactors Affecting The English Proficiency of Grade 10 Students at Manggitahan National High School"Ben MoradoNo ratings yet

- 3 Types of Nursing Research PDFDocument2 pages3 Types of Nursing Research PDFPxPPxH ChanNo ratings yet

- Lecture 10 Risk 2122BBDocument43 pagesLecture 10 Risk 2122BBCloseup ModelsNo ratings yet

- Stevenchap 1, 2, and 3Document35 pagesStevenchap 1, 2, and 3Portia En Shakespeare IINo ratings yet

- Cash Flow Risk and Capital Structure DecisionsDocument17 pagesCash Flow Risk and Capital Structure DecisionsMuhammad UsmanNo ratings yet

- Correlational Research - Group 2Document9 pagesCorrelational Research - Group 2Elisa HairaniNo ratings yet

- Content Design Portfolio Curious Writer 1643776943Document28 pagesContent Design Portfolio Curious Writer 1643776943AbrilNo ratings yet

- Communicating Authentic Assessment ResultsDocument14 pagesCommunicating Authentic Assessment ResultsGlennson Loyola100% (1)

- APG-Audit Planning PDFDocument4 pagesAPG-Audit Planning PDFdio39saiNo ratings yet

- Work Life Balance PDFDocument12 pagesWork Life Balance PDFNathaniel Nani100% (1)

- Instructional Supervisory Plan Cajidiocan CES 2022Document8 pagesInstructional Supervisory Plan Cajidiocan CES 2022Mariel Romero100% (1)

- Rujukan ARDocument3 pagesRujukan ARcrunx89No ratings yet

- A Study of Public Relations in Cathay PacificDocument45 pagesA Study of Public Relations in Cathay Pacificapi-3842687No ratings yet

- Topic ProposalDocument20 pagesTopic ProposalSophia Marie ReyesNo ratings yet

- Prposed Date Sheet Upload Web SiteDocument154 pagesPrposed Date Sheet Upload Web SiteShaheer ShafatNo ratings yet

- III FinalDocument38 pagesIII FinalSinned1991 SalongNo ratings yet

- Investigation of Pedestrian Safety A CasDocument11 pagesInvestigation of Pedestrian Safety A CasElijah Jane RiveraNo ratings yet

- Chapter 1 Teaching Science As InquiryDocument17 pagesChapter 1 Teaching Science As InquiryPenny GarciaNo ratings yet

- PRISMA StatementDocument7 pagesPRISMA StatementJuan Camilo MontenegroNo ratings yet

- Syllabus - IM31202 - Statistical Learning With ApplicationsDocument3 pagesSyllabus - IM31202 - Statistical Learning With Applicationsrohan kalidindiNo ratings yet

- Flow Assurance Programme v15Document9 pagesFlow Assurance Programme v15Raj Ranjan SinghNo ratings yet

- Ahmad Ruslan Mohd RidzuanDocument5 pagesAhmad Ruslan Mohd RidzuanaminNo ratings yet

- 1 Defining Social Sciences PDFDocument2 pages1 Defining Social Sciences PDFCarla villalva100% (2)

- Computerized Teacher Evaluation System ThesisDocument6 pagesComputerized Teacher Evaluation System ThesisAsia Smith100% (2)

- N Sleeva Yamini Narisetty Mobile NoDocument3 pagesN Sleeva Yamini Narisetty Mobile NoApoorva NarisettyNo ratings yet

- Plan Canada - Because I Am A GirlDocument10 pagesPlan Canada - Because I Am A GirlDora MorhanNo ratings yet

- Critical Quarterly Volume 50 Issue 1-2 2008 (Doi 10.1111/j.1467-8705.2008.00811.x) SIMON FRITH - Why Music MattersDocument15 pagesCritical Quarterly Volume 50 Issue 1-2 2008 (Doi 10.1111/j.1467-8705.2008.00811.x) SIMON FRITH - Why Music MatterssebastianmunoztNo ratings yet

- 1976 - Roll-Hansen - Critical Teleology Immanuel Kant and Claude Bernard On The Limitations of Experimental BiologyDocument33 pages1976 - Roll-Hansen - Critical Teleology Immanuel Kant and Claude Bernard On The Limitations of Experimental BiologyOmar RoblesNo ratings yet