Professional Documents

Culture Documents

Si-203en - Id749 Valvula Mariposa

Uploaded by

carlosyanezlagosOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Si-203en - Id749 Valvula Mariposa

Uploaded by

carlosyanezlagosCopyright:

Available Formats

Datasheet

Butterfly valve

Si-203 EN

Edition: 2013-04

Type VSS

Wafer design

Nominal pressure

PN 10 - 25

Nominal size

DN 80 - 1200

Material

Stainless steel

triple

Advanced

eccentric design

for control

Designed

and shut-off

applications

for

Designed

applications up to

350 C (662 F)

class in

Tightness

accordance with EN

60534-4 Class V as

standard

seat made of

Solid

stainless steel

design

Wafer

(Mounted between

flanges) alt. lugged

design

Option

PTFE-seat

temperature

High

applications up to

550 C (1022 F)

SOMAS butterfly valves, type VSS is used as a control, on/off and shut-off valve. The

VSS valve is designed to handle a wide range of liquids, gases and steam within a broad

temperature range.

The valves have an advanced triple eccentric design including a unique shape of the disc

allows the use of a solid stainless steel seat. The solid seat remains unaffected by high

flow velocities and temperatures. A good valve function is achieved even on difficult

applications.

The seat is replaceable in alternative materials.

The VSS valve can be mounted between flanges and is also supplied in lugged design.

The SOMAS valves are delivered ready for installation and operation. The valve

assemblies are delivered factory tested as complete units with actuators, positioners and

accessories.

Edition: 2013-04

Tightness class

The tightness class is related to the chosen material in

the seat ring.

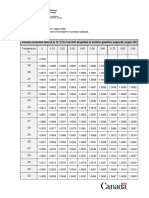

Pipe geometry factor FP

Valve

Pipe

DN

DN

80

100

150

Metal seat Code C alt. D EN 60534-4 V (ASME B16-104 Class V)

PTFE seat Code A

EN 60534-4 VI (ASME B16-104 Class VI)

(Option)

Opening angle

10 20

30

1,0

1.0

1,0

1.0

0,99 0.99

0,99 0.96

0,96 0.93

0,93

0.99

0,99

0.99 0,98

0.98 0,97

0.97 0,92

0.92 0,86

0.86

0,97

0.97 0,94

0.94 0,88

0.88 0,81

0.81

1,0

1.0

1,0

1.0

0,98

0.98

0,99

0.99 0,97

0.97

0,96

0.96

0,97

0.97

0,94

0.94

0,93

0.93

0,93

0.93

0,87

0.87

0,85

0.85

0,88

0.88 0,84

0.84 0,88

0.88

0,80

0.80 0,76

0.76 0,80

0.80

0,77

0.77 0,72

0.72 0,77

0.77

1,0

1.0

1,0

1.0

0,98

0.98

0,99

0.99 0,95

0.95

0,93

0.93

0,95

0.95

0,89

0.89

0,86

0.86

0,91

0.91

0,83

0.83

0,78

0.78

0,91

0.91

0,83

0.83

0,78

0.78

0,88

0.88 0,91

0.91

0,79

0.79 0,83

0.83

0,74

0.74 0,78

0.78

1,0

1.0

1,0

1.0

0,98

0.98

0,99

0.99 0,95

0.95

0,93

0.93

0,95

0.95

0,89

0.89

0,86

0.86

0,91

0.91

0,83

0.83

0,78

0.78

0,91

0.91

0,83

0.83

0,78

0.78

0,88

0.88 0,91

0.91

0,79

0.79 0,83

0.83

0,74

0.74 0,78

0.78

1,0

1.0

1,0

1.0

0,99

0.99 0,98

0.98 0,96

0.96 0,93

0.93

0,99

0.99 0,98

0.98 0,96

0.96 0,92

0.92 0,86

0.86

0,97

0.97 0,94

0.94 0,88

0.88 0,81

0.81

0,99

0.99 0,99

0.99 0,97

0.97 0,95

0.95

0,91

0.91 0,93

0.93

0,83

0.83 0,86

0.86

0,77

0.77 0,81

0.81

0,93

0.93 0,95

0.95

1,0

1.0

1,0

1.0

1,0

1.0

1,0

1.0

200

150

100

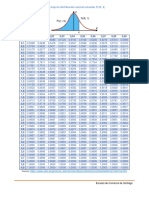

Flow characteristics

100% Flow

Si-203 EN

125

150

200

250

150

200

250

200

250

300

250

200

250

300

350

300

350

400

350

300

350

400

500

400

450

1,0

1.0

1,0

1.0

500

450

400

450

0 80

Opening angle

500

Opening angle

10 20 30 40 50 60 70 80 90

0,88

0,59

0.88 0,86

0.86 0,82

0.82 0,80

0.80 0,74

0.74 0,68

0.68 0,61

0.61 0,60

0.60 0.59

Factor Fl is valid for all sizes

Factor

Flp

Factor Flp is valid for all sizes

600

700

1,0

1.0

600

700

1,0

1.0

1,0

1.0

1,0

1.0

1,0

1.0

50

60

70

80

90

0,91 0.93

0,93

0.91

0,83

0.83 0,86

0.86

0,77

0.77 0,81

0.81

0,99

0.99 0,99

0.99 0,97

0.97 0,93

0.93 0,88

0.88 0,85

0.85

0,98

0.98 0,95

0.95 0,90

0.90 0,83

0.83 0,8

0.8

0,99

0.99 0,99

0.99 0,98

0.98 0,96

0.96 0,95

0.95

0,99

0.99 0,99

0.99 0,98

0.98 0,94

0.94 0,90

0.90 0,87

0.87

0,88

0.88

0,83

0.83

0,96

0.96

0,90

0.90

0,91

0.91 0,85

0.85 0,82

0.82 0,85

0.85

0,97

0.97 0,95

0.95 0,93

0.93 0,95

0.95

0,94

0.94 0,90

0.90 0,87

0.87 0,90

0.90

0,98

0.98 0,96

0.96

0,99

0.99 0,99

0.99

0,99

0.99 0,99

0.99 0,98

0.98

0,98

0.98 0,96

0.96 0,91

0.91 0,85

0.85 0,82

0.82

0,99

0.99 0,99

0.99 0,99

0.99 0,97

0.97 0,97

0.97

0,99

0.99 0,99

0.99 0,98

0.98 0,96

0.96 0,93

0.93 0,91

0.91

0,98

0.98 0,96

0.96 0,91

0.91

0,99

0.99 0,99

0.99 0,99

0.99

0,99

0.99 0,99

0.99 0,97

0.97 0,94

0.94

0,98

0.98 0,95

0.95 0,90

0.90

0,85

0.85

0,97

0.97

0,93

0.93

0,85

0.85 0,82

0.82 0,85

0.85

0,98

0.98 0,97

0.97 0,98

0.98

0,90

0.90 0,87

0.87 0,90

0.90

0,84

0.84 0,80

0.80 0,84

0.84

0,99

0.99 0,99

0.99 0,99

0.99 0,98

0.98 0,98

0.98 0,98

0.98

0,99

0.99 0,98

0.98 0,97

0.97 0,93

0.93 0,88

0.88 0,85

0.85 0,88

0.88

0,98

0.98 0,95

0.95 0,89

0.89 0,83

0.83 0,79

0.79 0,83

0.83

0,99

0.99 0,99

0.99 0,98

0.98 0,96

0.96 0,95

0.95 0,96

0.96

600

800

900

800

1,0

1.0

1,0

1.0

700

900

1000

800

1,0

1.0

1,0

1.0

750

900

1000

900

1,0

1.0

1,0

1.0

800

1000

1200

1,0

1.0

1,0

1.0

0,99

0.99

0,99

0.99 0,99

0.99

0,98

0.98

0,99

0.99

0,98

0.98

0,96

0.96

0,98

0.98

0,94

0.94

0,91

0.91

0,96

0.96

0,90

0.90

0,81

0.81

0,97

0.97

0,93

0.93

0,84

0.84

1,0

1.0

1,0

1.0

0,99

0.99

0,99

0.99 0,99

0.99

0,98

0.98

0,99

0.99

0,98

0.98

0,96

0.96

0,98

0.98 0,97

0.97 0,96

0.96

0,95

0.95 0,91

0.91 0,87

0.87

0,91 0,84

0.91

0.84 0,80

0.80

0,97

0.97

0,91

0.91

Factor FLP

Opening angle

10 20 30 40 50 60 70 80 90

0,88

0,81 0.80

0,78 0,71

0,63 0,53

0,52

0.88 0,86

0.86 0.82

0.74 0.68

0.61 0,50

0.60 0.59

1,0

1.0

800

700

Liquid pressure recovery factor FL

Factor

Fl

500

600

500

40

900

1000

1200

1400

1200

0,99

0.99 0,99

0.99 0,97

0.97 0,94

0.94 0,90

0.90 0,87

0.87 0,90

0.90

0,98

0.98 0,96

0.96 0,91

0.91 0,85

0.85 0,81

0.81 0,85

0.85

0,99

0.99 0,99

0.99 0,98

0.98 0,97

0.97 0,96

0.96 0,96

0.96

0,99

0.99 0,99

0.99 0,98

0.98 0,95

0.95 0,91

0.91 0,89

0.89 0,91

0.91

0,98

0.98 0,96

0.96 0,92

0.92 0,87

0.87 0,83

0.83 0,87

0.87

0,99

0.99 0,99

0.99 0,98

0.98 0,97

0.97 0,96

0.96 0,96

0.96

0,99

0.99 0,99

0.99 0,98

0.98 0,95

0.95 0,91

0.91 0,89

0.89 0,91

0.91

0,98

0.98 0,96

0.96 0,92

0.92 0,87

0.87 0,83

0.83 0,87

0.87

0,97

0.97

0,93

0.93

0,85

0.85

0,84

0.84

0,95

0.95 0,93

0.93 0,95

0.95

0,88

0.88 0,85

0.85 0,88

0.88

0,83

0.83 0,79

0.79 0,83

0.83

1000

1400

1600

1400

1,0

1.0

1,0

1.0

0,99

0.99 0,99

0.99 0,97

0.97

0,99 0.98

0,98 0.97

0,97 0.93

0,93

0.99

0,98 0.95

0,95 0,89

0.98

0.89

1200

1600

1800

1,0

1.0

1,0

1.0

0,99 0.99

0,99 0.98

0,98 0.96

0,96 0.95

0,95 0.96

0,96

0.99

0,99 0.98

0,98 0.98

0,98 0.95

0,95 0.91

0,91 0,88

0,91

0.99

0.88 0.91

0,98 0.96

0,96 0.91

0,91 0,85

0.98

0.85 0,82

0.82 0,85

0.85

Si-203 EN

Edition: 2013-04

Capacity factor Kv and Resistance factor

DN

80

100

125

150

200

250

300

350

400

450

500

600

700

750

800

900

1000

1200

10

14

21

35

50

89

142

207

279

371

482

584

853

1157

1157

1525

1945

2395

3450

20

31

45

75

108

193

307

446

602

800

1039

1258

1839

2494

2494

3289

4190

5160

7440

30

48

70

116

168

299

476

692

934

1242

1618

1951

2851

3867

3867

5100

6495

8005

11540

40

73

107

177

256

457

727

1058

1427

1898

2472

2981

4357

5909

5909

7793

9925

12230

18050

Opening angle

50

60

108

165

158

240

262

400

379

580

675

1030

1076

1650

1566

2400

2111

3230

2809

4300

3661

5630

4413

6760

6448

9880

8746

13400

8746

13400

11534

17670

14690

22500

18100

26500

26095

37940

70

203

324

520

780

1390

2211

3219

4341

5775

7555

9071

13256

17981

17981

23711

30195

37205

53645

80

235

375

605

905

1610

2555

3720

5020

6675

8732

10485

15325

20780

20780

27405

34900

43000

62000

90

205

326

523

784

1397

2222

3235

4362

5805

7594

9117

13223

18071

18071

23830

30345

37390

53910

90

1.18

1,18

1.13

1,13

1.06

1,06

0.98

0,98

0.99

0,99

0.95

0,95

0.93

0,93

0.95

0,95

0.91

0,91

0.90

0,90

0.90

0,90

0.76

0,76

0.77

0,77

0.77

0,77

0.76

0,76

0.80

0,80

0.81

0,81

0.81

0,81

Relation between Kv and Cv: Kv = 0.86 x Cv

Pressure and temperature rating

Use shaft material according to material code A for temperatures up to 150 C.

Use shaft material according to material code B for acids and hot gases above 150 C.

Max. working pressure (bar)

PN

6

10

16

25

0-20 30

6

5,7

5.7

10

9,5

9.5

16 15.5

15,5

25 24.5

24,5

40

5,7

5.7

9,5

9.5

15

24

50

60

5,4

5.4 5,4

5.4

9

9

14,5 14.5

14,5

14.5

22,5

23 22.5

70

5,1

5.1

8,5

8.5

14

22

Temperature ( C)

80

90 100 120 140 160

5,1

4,5 4.5

4,5

5.1 5,1

5.1 4,8

4.8 4,8

4.8 4.5

8,5 8.5

8,5

7,5 7.5

7,5

8.5

8

8

7.5

13,5 13.5

13,5 13 12.5

12,5 12.5

12,5 12

13.5

21,5 21 20.5

20,5 20 19.5

19,5 19

21.5

180 200 250 300 350 400 450 500 550

4,5 4.2

4,2 4.2

4,2 3.9

3,9 3.9

3,9 3.6

3,6 3.6

3,6 3.6

3,6 3.6

3,6

4.5

7,5

6,5 6.5

6,5

7.5

7

7

6.5

6

6

6

6

11,5 11 10.5

10,5 10

9,5 9.5

9,5 9.5

9,5

12 11.5

10

9.5

18,5 18 17.5

17,5 16.5

16,5 16 15.5

15,5 15.5

15,5 15

18.5

15

Max. allowable pressure drops/torque figures

Maximum allowable pressure drops are valid at 20 C (see below).

Max. pressure drop. bar

at opening angle

Torque min.

at P

Torque min.

at P

Torque max. shaft

Valve

DN

80

PN

25

0

25

60

13

80

4,4

4.4

bar

10

Nm

100

bar

> 10

Nm

120

Nm

150

100

125

150

200

250

300

350

400

450

500

600

700

750

800

900

1000

1200

25

25

25

25

25

25

25

25

25

25

25

25

25

25

10

10

6-10

25

25

25

25

25

20

20

20

16

15

10

8

8

8

7

6

4.5

4,5

13

15

9

4.3

4,3

3.6

3,6

3.6

3,6

3.6

3,6

4.7

4,7

3.4

3,4

4.4

4,4

3.9

3,9

2.7

2,7

2.7

2,7

2.6

2,6

2.4

2,4

2.2

2,2

1.8

1,8

4.4

4,4

5.8

5,8

2.7

2,7

1.1

1,1

1.05

1,05

0.93

0,93

1.09

1,09

1.43

1,43

0.95

0,95

1.19

1,19

1.13

1,13

0.75

0,75

0.75

0,75

0.75

0,75

0.65

0,65

0.55

0,55

0.45

0,45

10

10

10

10

10

10

8

8

7

6

5

4

4

4

3

3

3

120

180

200

250

400

500

800

1000

1350

1900

2400

3200

3200

4000

4800

6000

7500

> 10

> 10

> 10

> 10

> 10

> 10

>8

>8

>7

>6

>5

>4

>4

>4

>3

>3

>3

165

220

250

290

500

620

1000

1350

1900

2700

2900

4200

4200

5000

5800

7500

9000

220

220

300

350

600

750

1200

1600

2250

3250

3500

5000

5000

6000

6900

9000

10800

3

Edition: 2013-04

Tu

Ti

G h9

Si-203 EN

de

DN 450 - 1200

D

A

M (HCD)

P

DN

80

100

125

150

200

250

300

350

400

450

500

600

700

750

800

900

1000

1200

A

50

52

56

56

60

68

78

78

102

114

127

154

165

165

190

203

216

254

B

120

120

135

155

180

205

240

320

360

385

415

475

530

545

600

640

705

805

C

150

163

175

195

235

275

290

315

340

370

400

450

515

538

580

645

730

800

Butterfly valve type VSS

d de D

F

G H I

K

L

M (HCD) O

P

70

60

133 270 20 120 5 45 22.5

22,5 M12

90

74 44

90

86 160 283 20 120 5 45 22.5

22,5 M12

90

74 44

116 110 190 295 20 120 5 45 22.5

22,5 M12

90

74 44

140 138 215 315 25 120 5 45

28 M12

90

78 50

187 186 270 355 25 120 5 45

28 M12

90

78 50

236 235 324 410 30 150 5 60

33 M12

120

92 58

285 285 375 425 35 150 5 50

38 M12

120 100 64

331 330 435 450 40 150 5 50

43 M12

120 108 70

382 380 490 550 50 150 10 80 53.5

53,5 M12

120 124 82

429 425 535 580 50 150 10 80 53.5

53,5 M12

120 124 82

479 475 590 610 60 200 10 90 64 M16 160 147 96

579 575 695 675 70 200 10 110 74.5

74,5 M16 160 162 112

74.5 M16 160 162 112

674 675 800 730 70 200 10 110 74,5

74.5 M16 160 162 112

680 675 860 765 70 200 10 110 74,5

774 775 910 825 80 200 10 120 85 M16 160 183 120

900 875 1010 890 80 200 10 120 85 M20 160 183 120

975 975 1110 975 80 250 10 120 85 M20 205 200 200

1175 1175 1300 1055 100 250 10 125 106 M20 205 200 200

A = Face to face dimension according to EN 558 series 20 (valid for DN 100 - 1200)

de = Necessary free diameter for the disc under movement

S

6

6

6

8

8

8

10

12

14

14

18

20

20

20

22

22

22

28

X

40

40

40

40

40

50

50

50

50

50

60

60

60

60

76

76

85

85

Tu

41

52

64

77

100

124

149

172

199

223

249

300

343

343

393

449

498

598

Ti Weight

37

7

48

9

60

11

73

14

96

19

120

30

145

43

167

56

194

85

217 109

242 150

292 221

343 300

343 360

393 420

449 530

488 710

588 1140

Si-203 EN

Edition: 2013-04

H

P

140

130

SWEDEN

SFFLE

SWEDEN

30

SFFLE

87

55

DN

80

80

100

100

125

150

200

250

250

300

300

350

400

400

450

450

500

500

600

600

700

750

800

800

900

1000

1000

1200

1200

Butterfly valve type VSS with actuator type A-DA

K

N

O

P

R

W Weight

Type H

A13 250

275 325 83 106 90

13

A21 255

295 360 94 106 140

17

A21 255

305 370 94 106 140

19

A22 255 260 305 370 94 106

20

A22 255 260 320 385 94 106

22

A22 255 260 340 410 94 106

25

A22 255 260 380 445 94 106

30

A23 305

420 485 117 152 140

47

A31 380

470 560 144 152 215

55

A31 380

485 575 144 152 215

68

A32 380 395 485 575 144 152

74

A32 380 395 525 600 144 152

87

A32 380 395 570 655 144 152

116

A33 470

570 655 185 230 215

123

A34 470 485 600 685 185 230

165

A41 550

645 770 210 230 315

185

A41 550

675 800 210 230 315

230

A42 545 560 675 800 210 230

245

A41 550

725 850 210 230 315

300

A42 545 560 725 850 210 230

315

A42 545 560 790 915 210 230

390

A42 545 560 810 940 210 230

455

A42 545 560 810 1000 280 355

515

A43 680

875 1000 280 355 370

570

A51 745

965 1150 315 355 370

735

A51 745

1050 1235 315 355 370

920

A52 745 760 1050 1235 315 355

955

A51 745

1120 1305 315 355 370 1350

A52 745 760 1120 1305 315 355

1385

DN

Type

80

A23X

100 A24X

125 A24X

150 A24X

200 A24X

250 A33X

300 A33X

350 A34X

400 A43X

450 A43X

500 A44X

600 A44X

700 A44SO

Actuator type A-SC/SO

H

K

N

O

P

415

295 360 117

415

305 370 117

415 420 320 385 117

415 420 340 405 117

415 420 380 445 117

660 470 560 185

660 485 575 185

665 680 525 610 185

920

615 740 280

920 645 770 280

925 935 675 600 280

925 935 725 850 280

925 935 790 915 280

R

152

152

152

152

152

230

230

230

355

355

355

355

355

W Weight

140

24

140

25

38

41

46

215

88

215 101

145

315 250

315 275

370

440

515

X = SC Spring to close

X = SO Spring to open

For units with the positioner type SP405, add 2 kg

For units with the positioner type SPE405, add 3 kg

For units with the positioner type SP405, add 2 kg

For units with the positioner type SPE405, add 3 kg

Edition: 2013-04

AA

CC

DN

80

100

125

150

200

250

300

350

400

450

500

600

700

750

800

900

1000

1200

Butterfly valve type VSS with gear unit

AA

BB

CC

DD

Type

M10/F07

185

380

180

250

M10/F07

185

395

180

250

M10/F07

185

405

180

250

M10/F07

185

425

180

250

M10/F07

185

465

180

250

M12/F12

225

540

220

300

M12/F12

225

555

220

300

M12/F12

225

580

220

300

M14/F14

250

685

265

350

M14/F14

250

715

265

350

M15/F16

365

875

430

610

M15/F16

365

925

430

610

M20/F25

460

905

450

610

M20/F25

460

930

450

610

M30

530

970

485

610

M30

530

1035 485

610

M30

530

1120

485

610

M30

530

1250 485

610

Weight

15

17

19

22

27

42

55

68

106

130

186

285

363

424

426

640

820

1250

DN

80

100

125

CC

BB

BB

DD

AA

Si-203 EN

Butterfly valve type VSS with hand leverr

AA

BB

CC

Type

Weight

HSR20

355

275

245

10

HSR20

355

288

258

12

HSR20

355

300

270

14

Selection table

Double acting

Valve

DN

80

100

125

150

200

250

300

350

400

450

500

600

700

750

800

900

1000

6

1200

Shaft

dia. (mm)

20

20

20

25

25

30

35

40

50

50

60

70

70

70

80

80

80

100

5.5 bar

A13

A21

A22

A22

A22

A23

A31

A32

A32

A41

A41

A41

A42

A42

A42

A51

A51

A51

4 bar

A21

A22

A22

A22

A22

A31

A32

A32

A33

A34

A42

A42

A42

A42

A43

A51

A52

A52

Pneumatic actuators

Spring return

Spring to close

Spring to open

5.5 bar

4 bar

5.5 bar

4 bar

A23-SC

A23-SC

A23-SO

A23-SOL

A24-SC

A24-SC

A24-SO

A24-SOL

A24-SC

A24-SC

A24-SO

A24-SOL

A24-SC

A24-SC

A24-SO

A24-SOL

A24-SC

A24-SC

A24-SO

A24-SOL

A33-SC

A33-SC

A33-SO

A33-SOL

A33-SC

A33-SC

A33-SO

A33-SOL

A34-SC

A34-SC

A34-SO

A34-SOL

A43-SC

A43-SC

A43-SO

A43-SOL

A43-SC

A43-SC

A43-SO

A43-SOL

A44-SC

A44-SC

A44-SO

A44-SOL

A44-SC

A44-SC

A44-SO

A44-SOL

A44-SO

Manual override

Hand lever

HSR020

HSR020

HSR020

Gear unit

M10/F07

M10/F07

M10/F07

M10/F07

M10/F07

M12/F12

M12/F12

M12/F12

M14/F14

M14/F14

M15/F16

M15/F16

M20/F25

M20/F25

M30

M30

M30

M30

Si-203 EN

Edition: 2013-04

Flange standard

Further technical information

SOMAS butterfly valve type VSS in this data sheet

is of wafer type for mounting between flanges PN

10-25.

Technical data for the materials used in the SOMAS

valves, flange standard, steam data, etc. can be

found in section 6 of the SOMAS catalogue.

The valve can also be delivered in lugged design.

See also data sheet Si-205, that shows butterfly valve

type MTV (DN 80500). For valves with pressure

class PN 50, see data sheet Si-204.

The valve can also be drilled for mounting bet ween

flanges according to ASME.

When ordering, please always state the pressure

rating of the counter flanges. See the valve specification system on page 8, code 11.

Seat design

Valves with metal seat (type Y) according to code

D. Valves for Fire Safe have a metal seat (3 pcs)

according to code C.

PTFE and HiNi seat is available as an option.

Also check the valve specification system (code 6)

to find further seat alternatives.

Actuators and accessories

The valves can be fitted with SOMAS manual, on/off

or control actuators in accordance with the selection

table. The valves will then be delivered as tested

units ready for installation.

Check sections 4 and 5 of the SOMAS catalogue,

where positioners, limit switches and solenoid valves

are also presented.

We can also fit other types of actuators and accessories in accordance with your specification.

Supplemental information

Note: Use gaskets with the correct inside diameter to ensure that pressure is applied on the cover plate.

For mounting between flanges according to

PN 10-25, the inside gasket diameter should not

exceed the dimensions specified in the standard

EN 1514-1.

For mounting between flanges according to Class

150 dimensions according to the standard ASME

B 16.21 RF are valid where the following dimensions

refer to the gasket.

Gaskets according to EN 1514-1

Valve

DN

80

100

125

150

200

250

300

350

400

450

500

600

700

800

900

1000

1200

Max. Inside dia.

di (mm)

89

115

141

169

220

273

324

356

407

458

508

610

712

813

915

1016

1220

Outside dia. (dy) (mm)

PN 10

PN 16

PN 25

142

142

142

162

162

168

192

192

194

218

218

224

273

273

284

328

329

340

378

384

400

438

444

457

489

495

514

539

555

564

594

617

624

695

734

731

810

804

833

917

911

942

1017

1011

1042

1124

1128

1154

1341

1342

1364

Gaskets according to ASME B 16.21 RF

Valve

DN

80

100

125

150

200

250

300

350

400

450

500

600

750

Max. Inside dia.

di (mm)

89

114

141

168

219

273

324

356

406

457

508

610

762

Outside dia. (dy) (mm)

Class 150

136

174

196

222

279

340

410

451

515

550

606

720

857

Edition: 2013-04

Variants

Si-203 EN

Temperature range

The standard VSS valve is designed to be mounted

between flanges, but is also available in lugged

design.

Seat

A = PTFE (10 % carbon)

C = 1.4462 (metal seat, 3 pcs.)

Max. temp.

170 C

350 C1

550 C2

350 C1

550 C2

400 C

170 C

D = 1.4470 (metal seat type Y)

E = 1.4547

P = PTFE (fibreglass 15 %)

Shaft

A = 1.4460

B = 1.4460, hard chromed

F = 1.4435

G = 1.4435 (316L), hard chromed

H = 1.4429

J = 1.4547

K = 1.4539

T = Titanium

Max. temp.

150 C

350 C1

550 C2

350 C1

550 C2

150 C

550 C

550 C

400 C

350 C1

150 C

Valve body

A = 2343-12

CF8M

E = CK-3MCuN

Max. temp.

550 C

500 C

400 C

C = 1.4460, HiCo coated

Ordering

State desired valve according to the valve

specification system below as well as type of

actuator, positioner and accessories.

Check with SOMAS for temperatures between 350 and 550 C.

At higher pressures for example steam turbine applications.

2

At lower pressures for example exhaust applications.

1

Valve specification system

VSS - A 5 - A A D - A 1 1 - DN - PN

1

1 Type of valve

10

5 Material disc

Wafer design

VSS

2 Valve body design

A = Wafer design according to EN 558-1, Series 20

Bearing valve body/shaft

A = 2343-121

1 = Without bearing

B = 2343-121, hard chromed

3 = HiCo (High Cobalt alloy)

C = 2343-121, HiCo coated

6 = 1.4547

S = CK-3MCuN

7 = 1.4539

6 Material seat

F = Lugged design

3 Nominal pressure

11

A = PTFE (10 % carbon)

Stuffing box

1 = Graphite

1 = PN 6

C = 1.4462 (metal seat, 3 pcs.)

2 = PN 10

D = 1.4462 (metal seat, type Y)

10 Valve size, DN

5 = PN 25

E = 1.4547

11 Drilling, counter flanges,

6 = PN 50

L = HiNi (High Nickel alloy)

4 Material valve body

2 = PTFE

PN/Class

T = HiCo (High Cobalt alloy)

7 Material shaft

A = 2343-12 (CF8M)

E = CK-3MCuN

A = 1.4460

B = 1.4460, hard chromed

C = 1.4460, HiCo coated

H = 1.4429

J = 1.4547

1.4436 for DN 80-200

Check with SOMAS for further combinations.

SOMAS reserves the right to make improvements without prior notice.

www.somas.se

Box 107

SE-661 23 SFFLE

sweden

Phone: +46 533 167 00

Fax: +46 533 141 36

E-mail: sales@somas.se

You might also like

- 2004 VCF Tables - SGS Implementation (A4)Document1 page2004 VCF Tables - SGS Implementation (A4)Adrian RuizNo ratings yet

- VCF Aviation GasolineDocument5 pagesVCF Aviation GasolineEdgar GuardiaNo ratings yet

- Simo TopDocument62 pagesSimo TopNiculescu MariusNo ratings yet

- B732 N1 Versus EPR TableDocument1 pageB732 N1 Versus EPR TableGuilioNo ratings yet

- LP Banda Agricola 2020 - R1 TOYO POWERDocument9 pagesLP Banda Agricola 2020 - R1 TOYO POWERlefrenchg1No ratings yet

- Table de La Loi Normale Redulte Probabilité D'une Valeur Inférieure À TDocument2 pagesTable de La Loi Normale Redulte Probabilité D'une Valeur Inférieure À TayoubNo ratings yet

- Volume Correction Factors-Liquefied Petroleum Gas or PropaneDocument5 pagesVolume Correction Factors-Liquefied Petroleum Gas or PropaneDadang Ibnu SetyawanNo ratings yet

- Hosr Cell Availability CSSR Hsupa (%) CSSR R99 (%) CSSR Hsdpa (%) CSSR - Spee CH RAB Congestion RRC Congestion CDR Speech (%) CDR Hsupa (%)Document21 pagesHosr Cell Availability CSSR Hsupa (%) CSSR R99 (%) CSSR Hsdpa (%) CSSR - Spee CH RAB Congestion RRC Congestion CDR Speech (%) CDR Hsupa (%)alexanderNo ratings yet

- New Siteid 8-Jun 9-Jun 10-Jun 11-Jun 12-Jun 13-Jun 14-Jun 15-Jun 16-JunDocument6 pagesNew Siteid 8-Jun 9-Jun 10-Jun 11-Jun 12-Jun 13-Jun 14-Jun 15-Jun 16-Junashar sNo ratings yet

- QRV Frequency Distribution ChartDocument21 pagesQRV Frequency Distribution ChartMarco ArceNo ratings yet

- Remedial FIL 002 - NocilladoDocument226 pagesRemedial FIL 002 - NocilladoJC Valerio DelacruzNo ratings yet

- Tabel Pemancar 1 Watt TC9122 OKDocument7 pagesTabel Pemancar 1 Watt TC9122 OKRaymond KondengisNo ratings yet

- SDFGXHCKLDocument34,725 pagesSDFGXHCKLbrintopvNo ratings yet

- Downhole MotorsDocument31 pagesDownhole MotorsRFVNo ratings yet

- Profesor Christian Lorca CruzDocument2 pagesProfesor Christian Lorca CruzkhgcjhkjNo ratings yet

- Equipo 1-2Document99 pagesEquipo 1-2Diego IvanNo ratings yet

- Is 228 (Part 1) : 1987 Methods For Chemical Analysis Of: (Reaffirmed 2008)Document5 pagesIs 228 (Part 1) : 1987 Methods For Chemical Analysis Of: (Reaffirmed 2008)Indira BanerjeeNo ratings yet

- Standard Normal Distribution TableDocument1 pageStandard Normal Distribution TableNam KhanhNo ratings yet

- Table de La Loi Normale Centree Reduite 1Document1 pageTable de La Loi Normale Centree Reduite 1Houho DzNo ratings yet

- N(x) distribution table for negative and positive x valuesDocument1 pageN(x) distribution table for negative and positive x valuesWynn MaiNo ratings yet

- Estado Flujo EfectivoDocument2 pagesEstado Flujo EfectivoByron SincheNo ratings yet

- Metodo de Bolomey: Peso (GR.) Piedra Arena Curva Optima de Bolomey (A 12)Document1 pageMetodo de Bolomey: Peso (GR.) Piedra Arena Curva Optima de Bolomey (A 12)Luis German Aguilar VargasNo ratings yet

- Die LifterDocument2 pagesDie LifterTirtheshwar SinghNo ratings yet

- 3 9 +tabla+zDocument6 pages3 9 +tabla+zHypatia AsimovNo ratings yet

- Inch Socket Head Cap Screws Dimensions and SpecificationsDocument16 pagesInch Socket Head Cap Screws Dimensions and SpecificationsyauctionNo ratings yet

- Tabla Probabilidad NormalDocument1 pageTabla Probabilidad NormalAnonymous M6O8URiNo ratings yet

- STEEL RODSDocument3 pagesSTEEL RODSHamed GeramiNo ratings yet

- Table 9 Alternating-Current Resistance and Reactance For 600-Volt Cables, 3-Phase, 60 HZ, 75°C (167°F) - Three Single Conductors in ConduitDocument1 pageTable 9 Alternating-Current Resistance and Reactance For 600-Volt Cables, 3-Phase, 60 HZ, 75°C (167°F) - Three Single Conductors in ConduitPaul BautistaNo ratings yet

- Power Derate by Temp N Altitude DOOSANDocument2 pagesPower Derate by Temp N Altitude DOOSANComercial 1No ratings yet

- NACA 2412 Data FileDocument4 pagesNACA 2412 Data FilehutkuosliNo ratings yet

- NACA 2412 Data FileDocument4 pagesNACA 2412 Data FileWobber1111No ratings yet

- Catalog Maa-Baa Marelli MotoriDocument24 pagesCatalog Maa-Baa Marelli MotoriHasan KendekNo ratings yet

- Tables-Loi-Normale-Dr FARAH FSTDocument1 pageTables-Loi-Normale-Dr FARAH FSToussamabenjedi2No ratings yet

- Table de La Loi Normale Centree ReduiteDocument1 pageTable de La Loi Normale Centree ReduiteYasmin HafieneNo ratings yet

- Isinma Kesi̇t KontrolDocument503 pagesIsinma Kesi̇t KontrolMustafaNo ratings yet

- Table - Loi NormaleDocument1 pageTable - Loi NormaleFab LBhNo ratings yet

- Auto MonitoringDocument8 pagesAuto MonitoringJohn SalaanNo ratings yet

- Percentage rates documentDocument3 pagesPercentage rates documentIago Rodrigues BlancoNo ratings yet

- 01 - Table de Loi NormaleDocument1 page01 - Table de Loi NormalePascalNo ratings yet

- Normal Distribution TableDocument1 pageNormal Distribution Tablenznnznz sghshNo ratings yet

- 2D Heat Transfer TutorialDocument180 pages2D Heat Transfer Tutorialsanojk_2000No ratings yet

- Everest EverestDocument24 pagesEverest Everestabhi24shekNo ratings yet

- DS-006-5-EN - Exertherm - IR Sensor Gain MatrixDocument2 pagesDS-006-5-EN - Exertherm - IR Sensor Gain MatrixJose Javier Costa LarragaNo ratings yet

- Statistical Tables: Appendix CDocument2 pagesStatistical Tables: Appendix CJenna CoatesNo ratings yet

- 3 Tablas Poisson PDFDocument4 pages3 Tablas Poisson PDFfernandaNo ratings yet

- Función Acumulada de La Distribución de Poisson: K T e T X PDocument4 pagesFunción Acumulada de La Distribución de Poisson: K T e T X PpaolaNo ratings yet

- Exp Hdpe 1Document203 pagesExp Hdpe 1Ignacia CastroNo ratings yet

- Standard Normal Distribution Table For Z 0.00 To 3.59Document4 pagesStandard Normal Distribution Table For Z 0.00 To 3.59Coca CocaNo ratings yet

- 3 9 The-Z-TableDocument7 pages3 9 The-Z-Tablesk ngiamNo ratings yet

- Normal Distribution Table Law Reduced CenterDocument1 pageNormal Distribution Table Law Reduced CenterKissyman Mody KantéNo ratings yet

- DT e X: Distribución NormalDocument1 pageDT e X: Distribución NormalGustavo Ortega y GassetNo ratings yet

- Tabla de La Distribución Normal AcumuladaDocument2 pagesTabla de La Distribución Normal AcumuladaFelipe RubioNo ratings yet

- RTWALLDocument18 pagesRTWALLJomar CerdaNo ratings yet

- I. Táblázat: Standard Normális (N (0,1) ) Eloszlású Változó Eloszlásfüggvényének ÉrtékeiDocument1 pageI. Táblázat: Standard Normális (N (0,1) ) Eloszlású Változó Eloszlásfüggvényének ÉrtékeiGergő BátoriNo ratings yet

- Nominal Capacity Tables Outdoor Unit To Indoor Unit Nominal Capacity TablesDocument122 pagesNominal Capacity Tables Outdoor Unit To Indoor Unit Nominal Capacity Tablesmatt12manyNo ratings yet

- Distribución normal estandar N(0,1) áreas bajo la curvaDocument1 pageDistribución normal estandar N(0,1) áreas bajo la curvaKarla Fernanda Donoso CaceresNo ratings yet

- H+ Teorica Analisis Actual pH Cu2Document75 pagesH+ Teorica Analisis Actual pH Cu2Claudio Pastén CortésNo ratings yet

- VCF JetADocument5 pagesVCF JetAAlexNo ratings yet

- Valve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow ApplicationFrom EverandValve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow ApplicationRating: 4.5 out of 5 stars4.5/5 (21)

- ReadmeDocument1 pageReadmeherberthhpNo ratings yet

- Si-203en - Id749 Valvula MariposaDocument8 pagesSi-203en - Id749 Valvula MariposacarlosyanezlagosNo ratings yet

- Mi-706en - Id162 Valvula BolaDocument40 pagesMi-706en - Id162 Valvula BolacarlosyanezlagosNo ratings yet

- Servicio Técnico STAC100 (Inglés)Document4 pagesServicio Técnico STAC100 (Inglés)carlosyanezlagosNo ratings yet

- Pro Wedge (PW) VM 20 ManualDocument48 pagesPro Wedge (PW) VM 20 ManualcarlosyanezlagosNo ratings yet

- Si-502en Id174 ActuadorDocument4 pagesSi-502en Id174 ActuadorcarlosyanezlagosNo ratings yet

- Si-704en - Id161 Valvula BolaDocument4 pagesSi-704en - Id161 Valvula BolacarlosyanezlagosNo ratings yet

- Programming All Equipment Combined CDocument4 pagesProgramming All Equipment Combined CcarlosyanezlagosNo ratings yet

- (Z0940) STAC100 Manual (Inglés)Document11 pages(Z0940) STAC100 Manual (Inglés)carlosyanezlagosNo ratings yet

- Catalogo Gral CadweldDocument0 pagesCatalogo Gral CadweldcarlosyanezlagosNo ratings yet

- Pro Wedge (PW) VM 20 ManualDocument48 pagesPro Wedge (PW) VM 20 ManualcarlosyanezlagosNo ratings yet

- Ringo - Control ValvesDocument36 pagesRingo - Control ValvescarlosyanezlagosNo ratings yet

- Tensiometro Pro TesterDocument1 pageTensiometro Pro TestercarlosyanezlagosNo ratings yet

- (Z0940) STAC100 Manual (Inglés)Document11 pages(Z0940) STAC100 Manual (Inglés)carlosyanezlagosNo ratings yet