Professional Documents

Culture Documents

SELENOIDE-Valv Solen 8220

Uploaded by

MARACO46Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SELENOIDE-Valv Solen 8220

Uploaded by

MARACO46Copyright:

Available Formats

4

qwer

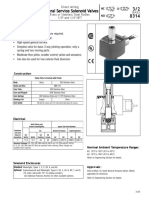

Normally Closed or Normally Open

Steam and Hot Water Valves

Brass or Stainless Steel Bodies

1/8" to 2 1/2" NPT

2/2

NC

SERIES

Hot Water/

Steam

NO

Features

Handle the challenges of high-temperature fluids.

PTFE and EPDM discs, stainless steel seats, plus high-temperature

coils, help provide long, reliable service life.

Wide range of valve constructions, including Straight Through and

Slow Closing, with Normally Closed and Normally Open operation.

Specify these valves for the high-temperature applications found in

laundries, molding, steam atomization, sterilizers, autoclaves, and

many others.

Series 8263: direct acting miniature valves.

Series 8267: direct acting straight through, self-cleaning design.

^

%

)

Series 8210/8220: pilot operated diaphragm valves.

Series 8220: heavy-duty, pilot operated piston valves have

stainless steel pistons.

Series 8221: slow-closing, anti-water hammer design.

Series 8222: pilot operated diaphragm and piston valves.

Y-body floating piston design.

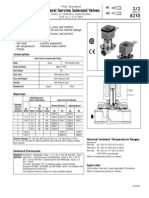

Construction

Valve Parts in Contact with Fluids

Common Parts

Body

Brass

Stainless Steel

Core Tube

305 Stainless Steel

Core and Plugnut

430F Stainless Steel

Springs

302 Stainless Steel

Shading Coil

Copper

Silver

8210HW Series

Seals, Discs, and Diaphragms

EPDM

8263 Series

Seals

PTFE

Disc

EPDM or PTFE

8220/8221 Series

Piston

Stainless Steel

Discs

EPDM or PTFE

Seals

EPDM, PTFE

8222 Series

Seals, Discs, and Diaphragms

EPDM and/or PTFE

Piston

Brass or PTFE

8267 Series

Seals

FKM, PTFE

Disc

Stainless Steel

Seat

Glass-Filled PTFE

8210

Nominal Ambient Temperature Ranges:

Red-Hat II/

Red-Hat AC: 32F to 125F (0C to 52C)

Red-Hat II DC: 32F to 104F (0C to 40C)

Red-Hat DC: 32F to 77F (0C to 25C)

(104F/40C occasionally)

Refer to Engineering Section for details.

Electrical

Approvals:

See individual valve series in General Service Section for details.

Most are UL listed, CSA certified, and meet applicable CE

directives. Contact ASCO for details.

Solenoid Enclosures

Standard: Red-Hat II - Watertight, Types 1, 2, 3, 3S, 4, and 4X; Red-Hat - Type 1.

Optional: Red-Hat II - Explosionproof and Watertight, Types 3, 3S, 4, 4X, 6,

6P, 7, and 9; Red-Hat - Explosionproof and Raintight, Types 3, 7, and 9.

(To order, add prefix "EF" to catalog number.)

See Optional Features Section for other available options.

Important: Explosionproof Catalog Numbers EF8210HW,

EF8220, EF8221, and EF8263 are not UL listed. They are

suitable for Types 4, 7 (C and D), and 9 (E and F) only, and

have a temperature range code of T3A.

7.37 R3

SERIES

Hot Water/

Steam

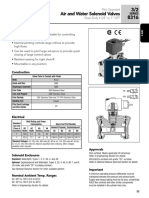

Specifications (English units)

Pipe

Size

(ins.)

Orifice

Size

(ins.)

Cv Flow

Factor

Min.

Operating Pressure

Differential (psi)

Max. Fluid

Temp. F

Hot Water

Hot Water

Max. AC

AC Watt

Rating/

Class of Coil

Insulation

Brass Body

AC

DC

Catalog Number

Constr. Ref.

No.

AC

DC

40

100

40

100

40

100

210

210

210

210

210

210

150

150

150

150

150

150

8210G93HW

8210G1HW

8210G94HW

8210G2HW

8210G95HW

8210G9HW

32

33

32

33

34

35

10.1/F

6.1/F

10.1/F

6.1/F

10.1/F

6.1/F

11.6/F

11.6/F

11.6/F

11.6/F

11.6/F

11.6/F

210

210

210

210

210

210

210

210

8221G1HW

8221G3HW

8221G5HW

8221G7HW

8221G9HW

8221G11HW

8221G13HW

8221G15HW

36

36

36

38

39

40

41

42

6.1/F

6.1/F

6.1/F

6.1/F

6.1/F

6.1/F

6.1/F

6.1/F

210

210

210

210

210

210

210

210

8221G21HW

8221G23HW

8221G25HW

8221G27HW

8221G29HW

8221G31HW

8221G33HW

8221G35HW

43

43

44

45

46

47

48

49

16.1/F

16.1/F

16.1/F

16.1/F

16.1/F

16.1/F

16.1/F

16.1/F

Max. DC

HOT WATER SERVICE ONLY - NORMALLY CLOSED (Closed when de-energized), EPDM Diaphragm

3/8

3/8

1/2

1/2

3/4

3/4

5/8

5/8

5/8

5/8

3/4

3/4

3

3

4

4

5

5

0

5

0

5

0

5

100

125

100

125

100

125

SLOW CLOSING - NORMALLY CLOSED (Closed when de-energized), EPDM Disc

3/8

1/2

3/4

1

1 1/4

1 1/2

2

2 1/2

9/16

9/16

3/4

1

1 1/8

1 1/4

1 3/4

1 3/4

3

3.5

5.5

11.5

13

24

36

38

5

5

5

5

5

5

5

5

150

150

150

150

150

150

150

150

SLOW CLOSING - NORMALLY OPEN (Open when de-energized), EPDM Disc

3/8

1/2

3/4

1

1 1/4

1 1/2

2

2 1/2

9/16

9/16

3/4

1

1 1/8

1 1/4

1 3/4

1 3/4

3

3.5

5.5

11.5

13

24

36

38

5

5

5

5

5

5

5

5

150

150

150

150

150

150

150

150

Operating Pressure Differential (psi)

Max. Fluid

Temp. F

Max.

Brass Body

Pipe

Orifice

Size

Size

Cv Flow

Constr.

Min.

(ins.)

(ins.)

Factor

Ref. No.

Steam

Hot Water

Steam

Hot Water

Catalog Number

DIRECT ACTING - NORMALLY CLOSED (Closed when de-energized), Stainless Steel Seat, EPDM , or PTFE Disc

8263G52

1/8

1/8

.34

0

50

298

1

1/8

1/8

.34

0

90

331

8263G58

1

8263G53

1/4

1/8

.34

0

50

298

2

1/4

1/8

.34

0

90

331

8263G59

2

1/4

5/32

.52

0

110

110

344

210

8263G300

3

1/4

7/32

.72

0

70

316

8263G301

3

1/4

9/32

.85

0

60

307

8263G303

3

3/8

1/8

.36

0

125

125

353

210

8263G304

3

3/8

5/32

.52

0

110

110

344

210

8263G305

3

3/8

7/32

.72

0

70

316

8263G306

3

3/8

9/32

.85

0

60

307

8263G308

3

PILOT OPERATED - NORMALLY CLOSED (Closed when de-energized)

1/4

3/8

1.2

1

80

324

8222G68

4

1/4

3/8

1.2

1

125

353

8222G70

4

3/8

3/8

2.5

1

80

324

8222G64

4

3/8

3/8

2.5

1

125

353

8222G74

4

5

3/8

5/8

3.0

50

150

300

210

8220G1

5

5

3/8

5/8

3.0

125

150

353

210

8220G19

5

3/8

5/8

3.0

0

125

353

8222G1

6

3/8

5/8

3.0

0

50

300

8222G93

7

1/2

3/8

2.5

1

80

324

8222G66

4

1/2

3/8

2.5

1

125

353

8222G76

4

1/2

1/2

3.6

2

125

353

8222G47

9

1/2

5/8

4.0

0

50

300

8222G94

7

1/2

5/8

4.0

0

125

353

8222G2

6

5

1/2

5/8

4.0

50

150

300

210

8220G3

5

5

1/2

5/8

4.0

125

150

353

210

8220G21

5

7.38 R3

Stainless Steel Body

Constr.

Ref. No.

Catalog Number

AC Watt

Rating/

Class of Coil

Insulation

8263G318

8263G319

8263G320

8263G321

31

31

31

31

6.1/F

6.1/F

6.1/F

6.1/F

10.1/H

10.1/H

17.1/H

10.1/H

10.1/H

10.1/H

17.1/H

8222G60

8222G87

-

28

29

-

6.1/F

6.1/H

6.1/F

6.1/H

10.1/F

10.1/H

17.1/H

10.1/F

6.1/F

6.1/H

10.1/H

10.1/F

17.1/H

10.1/F

10.1/H

SERIES

Hot Water/

Steam

Specifications (English units continued)

Pipe

Size

(ins.)

Orifice

Size

(ins.)

Operating Pressure Differential (psi)

Max.

Cv Flow

Factor

Min.

Steam

Hot Water

Max. Fluid

Temp. F

Steam

Hot Water

Brass Body

Catalog Number

Constr.

Ref. No.

Stainless Steel Body

Constr.

Ref. No.

Catalog Number

AC Watt

Rating/

Class of Coil

Insulation

PILOT OPERATED - NORMALLY CLOSED (Closed when de-energized)

3/4

5/8

4.5

0

50

300

8222G62

28

10.1/F

3/4

5/8

4.5

0

125

353

8222G88

29

17.1/H

3/4

3/4

5.0

0

50

300

8222G95

10

10.1/F

5

3/4

3/4

5.0

50

150

300

210

8220G5

8

10.1/F

5

3/4

3/4

5.0

125

150

353

210

8220G23

8

10.1/H

3/4

3/4

5.0

0

125

353

8222G3

11

17.1/H

3/4

1/2

4.6

2

125

353

8222G49

9

10.1/H

3/4

1/2

4.6

5

200

388

8222G5

12

10.1/H

1

1

11.2

5

125

353

8222G89

30

10.1/F

5

1

1

13.5

50

150

300

210

8220G7

14

10.1/F

5

1

1

13.5

125

150

353

210

8220G25

14

10.1/H

1

1

13.5

5

125

353

8222G4

13

10.1/H

1

1

13.0

0

200

388

822299

13

28.2/H

5

1 1/4

1 1/8

15

50

150

300

210

8220G9

15

10.1/F

5

1 1/4

1 1/8

15

125

150

353

210

8220G27

15

10.1/H

5

1 1/2

1 1/4

22.5

50

150

300

210

8220G11

16

10.1/F

5

1 1/2

1 1/4

22.5

125

150

353

210

8220G29

16

10.1/H

5

2

1 3/4

43

50

150

300

210

8220G13

17

10.1/F

5

2

1 3/4

43

125

150

353

210

8220G31

17

10.1/H

5

2 1/2

1 3/4

45

50

150

300

210

8220G15

18

10.1/F

5

2 1/2

1 3/4

45

125

150

353

210

8220G33

18

10.1/H

DIRECT ACTING, STRAIGHT-THROUGH DESIGN - NORMALLY CLOSED (Closed when de-energized)

3/8

1/4

1.5

0

75

320

8267G1

19

16.1/H

3/8

3/8

5.1

0

30

280

8267G3

19

16.1/H

1/2

1/4

1.4

0

75

320

8267G5

19

16.1/H

1/2

3/8

4.5

0

15

250

8267G7

19

16.1/H

3/4

3/8

5.4

0

30

280

8267G17

20

16.1/H

3/4

1/2

9.7

0

15

250

8267G19

20

16.1/H

DIRECT ACTING, STRAIGHT-THROUGH DESIGN - NORMALLY OPEN (Open when de-energized)

3/8

1/4

1.5

0

75

320

8267G9

19

16.1/H

3/8

3/8

5.1

0

30

280

8267G11

19

16.1/H

1/2

1/4

1.4

0

75

320

8267G13

19

16.1/H

1/2

3/8

4.5

0

15

250

8267G15

19

16.1/H

3/4

3/8

5.4

0

25

267

8267G21

20

16.1/H

3/4

1/2

9.7

0

15

250

8267G23

20

16.1/H

PILOT OPERATED - NORMALLY OPEN (Open when de-energized)

3/8

9/16

3

5

50

150

300

210

8220G71

21

16.1/F

3/8

9/16

3

5

125

150

353

210

8220G91

21

16.1/F

1/2

9/16

4

5

50

150

300

210

8220G73

21

16.1/F

1/2

9/16

4

5

125

150

353

210

8220G93

21

16.1/F

3/4

3/4

5

5

50

150

300

210

8220G75

22

16.1/F

3/4

3/4

5

5

125

150

353

210

8220G95

22

16.1/F

1

1

13.5

5

50

150

300

210

8220G77

23

16.1/F

1

1

13.5

5

125

150

353

210

8220G97

23

16.1/H

1 1/4

1 1/8

15

5

50

150

300

210

8220G79

24

16.1/F

1 1/4

1 1/8

15

5

125

150

353

210

8220G99

24

16.1/H

1 1/2

1 1/4

22.5

5

50

150

300

210

8220G81

25

16.1/F

1 1/2

1 1/4

22.5

5

125

150

353

210

8220G101

25

16.1/H

2

1 3/4

43

5

50

150

300

210

8220G83

26

16.1/F

2

1 3/4

43

5

125

150

353

210

8220G103

26

16.1/H

2 1/2

1 3/4

45

5

50

150

300

210

8220G85

27

16.1/F

2 1/2

1 3/4

45

5

125

150

353

210

8220G105

27

16.1/F

Notes: Once opened at higher pressure, valve will remain open to 0 psi at inlet.

Once opened at higher pressure, valve will remain open to 3 psi at inlet.

0 psi on AC construction, 1/4 psi on DC construction.

Series 8220 Normally Closed valves through 3/4" will remain open to 0 psi while energized. Once opened at 5 psi, larger sizes will remain open to 3 psi, as will all Series 8220

Normally Open valves.

EPDM disc.

7.39 R3

SERIES

Hot Water/

Steam

Specifications (Metric units)

Max. Fluid

Temp. C

Operating Pressure Differential (bar)

Pipe

Size

(ins.)

Orifice

Size

(mm)

Hot Water

Kv Flow Factor

(m3/h)

Min.

Max. AC

Hot Water

Watt Rating/

Class of Coil

Insulation

Brass Body

AC

DC

Catalog Number

Constr.

Ref. No.

AC

DC

2.8

6.9

2.8

6.9

2.8

6.9

98

98

98

98

98

98

65

65

65

65

65

65

8210G93HW

8210G1HW

8210G94HW

8210G2HW

8210G95HW

8210G9HW

32

33

32

33

34

35

10.1/F

6.1/F

10.1/F

6.1/F

10.1/F

6.1/F

11.6/F

11.6/F

11.6/F

11.6/F

11.6/F

11.6/F

98

98

98

98

98

98

98

8221G1HW

8221G3HW

8221G7HW

8221G9HW

8221G11HW

8221G13HW

8221G15HW

36

36

38

39

40

41

42

6.1/F

6.1/F

6.1/F

6.1/F

6.1/F

6.1/F

6.1/F

98

98

98

98

98

98

98

98

8221G21HW

8221G23HW

8221G25HW

8221G27HW

8221G29HW

8221G31HW

8221G33HW

8221G35HW

43

43

44

45

46

47

48

49

16.1/F

16.1/F

16.1/F

16.1/F

16.1/F

16.1/F

16.1/F

16.1/F

Max. DC

HOT WATER SERVICE ONLY - NORMALLY CLOSED (Closed when de-energized), EPDM Diaphragm

3/8

3/8

1/2

1/2

3/4

3/4

16

16

16

16

19

19

0

0.3

0

0.3

0

0.03

2.57

2.57

3.43

3.43

4.29

4.29

6.9

8.6

6.9

8.6

6.9

8.6

SLOW CLOSING - NORMALLY CLOSED (Closed when de-energized), EPDM Disc

0.3

3/8

14

2.57

10.3

0.3

1/2

14

3.00

10.3

0.3

1

25

9.86

10.3

0.3

1 1/4

29

11.14

10.3

0.3

1 1/2

32

20.57

10.3

0.3

2

44

30.86

10.3

0.3

2 1/2

44

32.57

10.3

SLOW CLOSING - NORMALLY OPEN (Open when de-energized), EPDM Disc

0.3

3/8

14

2.57

10.3

0.3

1/2

14

3.00

10.3

0.3

3/4

19

4.71

10.3

0.3

1

25

9.86

10.3

0.3

1 1/4

29

11.14

10.3

0.3

1 1/2

32

20.57

10.3

0.3

2

44

30.86

10.3

0.3

2 1/2

44

32.57

10.3

Operating Pressure Differential (bar)

Max. Fluid

Temp. C

Max.

Brass Body

Pipe

Orifice Kv Flow

Size

Size

Factor

Constr.

Min.

(ins.)

(mm)

(m3/h)

Ref. No.

Steam

Hot Water

Steam

Hot Water

Catalog Number

DIRECT ACTING - NORMALLY CLOSED (Closed when de-energized), Stainless Steel Seat EPDM , or PTFE Disc

8263G52

1/8

3

.29

0

3

146

1

1/8

3

.29

0

6

164

8263G58

1

8263G53

1/4

3

.29

0

3

146

2

1/4

3

.29

0

6

164

8263G59

2

1/4

4

.45

0

8

8

172

98

8263G300

3

1/4

6

.62

0

5

156

8263G301

3

1/4

7

.73

0

4

151

8263G303

3

3/8

3

.31

0

9

9

177

98

8263G304

3

3/8

4

.45

0

8

8

172

98

8263G305

3

3/8

6

.62

0

5

156

8263G306

3

3/8

7

.73

0

4

151

8263G308

3

Stainless Steel Body

Constr.

Ref. No.

Catalog Number

AC Watt

Rating/

Class of Coil

Insulation

8263G318

8263G319

8263G320

8263G321

31

31

31

31

6.1/F

6.1/F

6.1/F

6.1/F

10.1/H

10.1/H

17.1/H

10.1/H

10.1/H

10.1/H

17.1/H

8222G60

8222G87

-

28

29

-

6.1/F

6.1/H

6.1/F

6.1/H

10.1/F

10.1/H

17.1/H

10.1/F

6.1/F

6.1/H

10.1/H

10.1/F

17.1/H

10.1/F

10.1/H

PILOT OPERATED - NORMALLY CLOSED (Closed when de-energized)

1/4

1/4

3/8

3/8

3/8

3/8

3/8

3/8

1/2

1/2

1/2

1/2

1/2

1/2

1/2

7.40 R3

10

10

10

10

16

16

16

16

10

10

13

16

16

16

16

1.03

1.03

2.14

2.14

2.57

2.57

2.57

2.57

2.14

2.14

3.09

3.43

3.43

3.43

3.43

0.07

0.07

0.07

0.07

.3

.3

0

0

0.07

0.07

0.1379

0

0

.3

.3

6

9

6

9

3

9

9

3

6

9

9

3

9

3

9

10

10

10

10

161

177

161

177

147

177

177

147

161

177

177

147

177

147

177

98

98

98

98

8222G68

8222G70

8222G64

8222G74

8220G1

8220G19

8222G1

8222G93

8222G66

8222G76

8222G47

8222G94

8222G2

8220G3

8220G21

4

4

4

4

5

5

6

7

4

4

9

7

6

5

5

SERIES

Hot Water/

Steam

Specifications (Metric units continued)

Operating Pressure Differential (bar)

Pipe

Size

(ins.)

Orifice

Size

(mm)

Kv Flow

Factor

(m3/h)

Max.

Min.

Steam

Hot Water

Max. Fluid

Temp. C

Steam

Hot Water

PILOT OPERATED - NORMALLY CLOSED (Closed when de-energized)

3/4

16

3.86

0

3

147

3/4

16

3.86

0

9

177

3/4

19

4.29

0

3

147

.3

3/4

19

4.29

3

10

147

98

.3

3/4

19

4.29

9

10

177

98

3/4

19

4.29

0

9

177

3/4

13

3.94

0.14

9

177

3/4

13

3.94

0.3

14

196

1

25

9.60

0.3

9

177

.3

1

25

11.57

3

10

147

98

.3

1

25

11.57

9

10

177

98

1

25

11.57

0.3

9

177

1

25

11.14

0

14

196

.3

1 1/4

29

12.86

3

10

147

98

.3

1 1/4

29

12.86

9

10

177

98

.3

1 1/2

32

19.29

3

10

147

98

.3

1 1/2

32

19.29

9

10

177

98

.3

2

44

36.86

3

10

147

98

.3

2

44

36.86

9

10

177

98

.3

2 1/2

44

38.57

3

10

147

98

.3

2 1/2

44

38.57

9

10

177

98

DIRECT ACTING, STRAIGHT-THROUGH DESIGN - NORMALLY CLOSED (Closed when de-energized)

3/8

6

1.29

0

5

158

3/8

10

4.37

0

2

136

1/2

6

1.20

0

5

158

1/2

10

3.86

0

1

120

3/4

10

4.63

0

2

136

3/4

13

8.31

0

1

120

-

Brass Body

Stainless Steel Body

Constr.

Ref. No.

Catalog Number

AC Watt

Rating/

Class of Coil

Insulation

Catalog Number

Constr.

Ref. No.

8222G95

8220G5

8220G23

8222G3

8222G49

8222G5

8220G7

8220G25

8222G4

822299

8220G9

8220G27

8220G11

8220G29

8220G13

8220G31

8220G15

8220G33

10

8

8

11

9

12

14

14

13

13

15

15

16

16

17

17

18

18

8222G62

8222G88

8222G89

-

28

29

30

-

10.1/F

17.1/H

10.1/F

10.1/F

10.1/H

17.1/H

10.1/H

10.1/H

10.1/F

10.1/F

10.1/H

10.1/H

28.2/H

10.1/F

10.1/H

10.1/F

10.1/H

10.1/F

10.1/H

10.1/F

10.1/H

8267G1

8267G3

8267G5

8267G7

8267G17

8267G19

19

19

19

19

20

20

16.1/H

16.1/H

16.1/H

16.1/H

16.1/H

16.1/H

DIRECT ACTING, STRAIGHT-THROUGH DESIGN - NORMALLY OPEN (Open when de-energized)

3/8

6

1.29

0

5

158

8267G9

19

16.1/H

3/8

10

4.37

0

2

136

8267G11

19

16.1/H

1/2

6

1.20

0

5

158

8267G13

19

16.1/H

1/2

10

3.86

0

1

120

8267G15

19

16.1/H

3/4

10

4.63

0

2

129

8267G21

20

16.1/H

3/4

13

8.31

0

1

120

8267G23

20

16.1/H

PILOT OPERATED - NORMALLY OPEN (Open when de-energized)

3/8

14

2.57

0.3

3

10

147

98

8220G71

21

16.1/F

3/8

14

2.57

0.3

9

10

177

98

8220G91

21

16.1/F

1/2

14

3.43

0.3

3

10

147

98

8220G73

21

16.1/F

1/2

14

3.43

0.3

9

10

177

98

8220G93

21

16.1/F

3/4

19

4.29

0.3

3

10

147

98

8220G75

22

16.1/F

3/4

19

4.29

0.3

9

10

177

98

8220G95

22

16.1/F

1

25

11.57

0.3

3

10

147

98

8220G77

23

16.1/F

1

25

11.57

0.3

9

10

177

98

8220G97

23

16.1/H

1 1/4

29

12.86

0.3

3

10

147

98

8220G79

24

16.1/F

1 1/4

29

12.86

0.3

9

10

177

98

8220G99

24

16.1/H

1 1/2

32

19.29

0.3

3

10

147

98

8220G81

25

16.1/F

1 1/2

32

19.29

0.3

9

10

177

98

8220G101

25

16.1/H

2

44

36.86

0.3

3

10

147

98

8220G83

26

16.1/F

2

44

36.86

0.3

9

10

177

98

8220G103

26

16.1/H

2 1/2

44

38.57

0.3

3

10

147

98

8220G85

27

16.1/F

2 1/2

44

38.57

0.3

9

10

177

98

8220G105

27

16.1/F

Notes: Once opened at higher pressure, valve will remain open to 0 bar at inlet.

Once opened at higher pressure, valve will remain open to 0.2 bar at inlet.

0 psi on AC construction, 0.02 bar on DC construction.

Series 8220 Normally Closed valves through 3/4" will remain open to 0 bar while energized. Once opened at 0.3 bar, larger sizes will remain open to 0.2 bar, as will all Series 8220

Normally Open valves.

EPDM disc.

7.41 R3

SERIES

Hot Water/

Steam

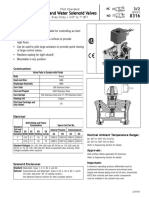

Dimensions: inches (mm)

Const.

Ref. No.

1

ins.

mm

2

ins.

mm

3

ins.

mm

4

ins.

mm

5

ins.

mm

7

ins.

mm

8

ins.

mm

9

ins.

mm

10

ins.

mm

12

ins.

mm

32

ins.

mm

33

ins.

mm

34

ins.

mm

35

ins.

mm

2.52

64

3.01

76

3.25

83

4.17

106

4.05

103

3.84

98

4.34

110

4.81

122

4.14

105

4.81

122

3.84

98

3.36

85

4.13

105

3.66

93

1.30

33

1.73

44

1.70

43

3.25

83

2.52

64

2.31

59

2.68

68

3.62

92

2.47

63

3.63

92

2.31

59

1.94

49

2.47

63

2.10

53

1.19

30

1.25

32

1.88

48

2.28

58

2.75

70

2.75

70

2.81

71

2.75

70

2.81

71

2.75

70

2.75

70

2.75

70

2.81

71

2.81

71

2.16

55

2.59

66

2.67

68

3.63

92

3.48

88

3.28

83

3.65

93

4.01

102

3.44

87

4.01

102

3.28

83

2.80

71

3.44

87

2.96

75

1.69

43

1.69

43

1.95

50

1.69

43

2.28

58

2.29

58

2.28

58

1.95

50

2.29

58

1.95

50

2.29

58

2.28

58

2.29

58

2.28

58

Constr. Ref. 4, 9, 12

7.42 R3

Constr. Ref. 1, 2

Constr. Ref. 3

Constr. Ref. 5, 7, 8, 10, 32-35

SERIES

Hot Water/

Steam

Dimensions: inches (mm)

Const.

Ref. No.

6

ins. 4.68 3.15 2.75 4.12 2.28

mm 119 80

70 105

58

11

ins. 4.97 3.45 2.81 4.28 2.28

mm 126 88

71 109

58

13

ins. 5.82 3.22 3.75 4.19 3.31

mm 148 82

95 106

84

14

ins. 5.81 3.22 3.75 4.19 3.14

mm 148 82

95 106

80

15

ins. 5.81 3.22 3.66 4.19 3.56

mm 148 82

93 106

90

16

ins. 6.29 3.37 4.38 4.34 4.10

mm 160 86 111 110 104

17

ins. 7.51 3.78 5.06 4.75 4.71

mm 191 96 129 121 120

18

ins. 7.51 3.78 5.50 4.75 5.18

mm 191 96 140 121 132

23

ins. 6.46 3.36 3.75 4.86 3.14

mm 164 85

95 123

80

24

ins. 6.39 3.36 3.66 4.86 3.56

mm 162 85

93 123

90

25

ins. 6.97 3.51 4.38 5.01 4.10

mm 177 89 111 127 104

26

ins. 8.18 3.92 5.06 5.42 4.71

mm 208 100 129 138 120

27

ins. 8.18 3.92 5.50 5.42 5.18

mm 208 100 140 138 132

29

ins. 5.04 3.34 2.81 4.31 2.28

mm 128 85

71 109

58

38

ins. 5.64 3.15 3.75 4.01 3.14

mm 143 80

95 102

80

39

ins. 5.64 3.15 3.66 4.01 3.56

mm 143 80

93 102

90

40

ins. 6.11 3.30 4.38 4.16 4.10

mm 155 84 111 106 104

41

ins. 7.35 3.63 5.06 4.58 4.71

mm 187 92 129 116 120

42

ins. 7.35 3.63 5.50 4.58 5.18

mm 187 92 140 116 132

45

ins. 6.53 3.36 3.75 4.91 3.14

mm 166 85

95 125

80

46

ins. 6.46 3.36 3.66 4.91 3.56

mm 164 85

93

25

90

47

ins. 7.03 3.51 4.38 5.06 4.10

mm 179 89 111 129 104

48

ins. 8.22 3.97 5.06 5.47 4.71

mm 209 101 129 139 120

49

ins. 8.22 3.97 5.50 5.47 5.18

mm 209 101 140 139 132

* Valves must be mounted with solenoid vertical

and upright.

Constr. Ref. 6, 11, 13, 29

Constr. Ref. 19 *

Constr. Ref. 20 *

Constr. Ref. 14 - 16, 23 - 25, 45 - 49

7.43 R3

SERIES

Hot Water/

Steam

Dimensions: inches (mm)

Const.

Ref. No.

21

43

87

58

95 106 113

51

68

50

69

90

88

ins. 5.12 3.14 2.71 4.35 3.65

mm 130 80

44

71

ins. 4.32 2.69 2.71 3.56 3.45

mm 110 68

43

71 115 91

ins. 3.25 1.70 2.00 2.67 1.95

mm 83

36

69 111 91

ins. 5.82 3.22 3.75 4.19 4.44

mm 148 82

31

Constr. Ref. 17, 18, 26, 27, 38 - 42

ins. 4.17 2.47 2.81 3.44 2.28

mm 106 63

30

ins. 5.30 3.29 2.78 4.51 3.58

mm 135 84

28

ins. 5.11 3.13 2.71 4.35 3.58

mm 130 80

22

69 111 93

ins. 5.30 3.30 2.78 4.51 3.65

mm 135 84

71 115 93

Constr. Ref. 28

Constr. Ref. 31

Constr. Ref. 30

Constr. Ref. 21, 22, 36, 43, 44

P

K

7.44 R3

You might also like

- ButterflyDocument6 pagesButterflysachin2010No ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Autocad Structural Detailing ManualDocument222 pagesAutocad Structural Detailing ManualLuqmanuel Hugoz Savalovic65% (17)

- 2007 Nissan Quest Power Steering Repair ManualDocument26 pages2007 Nissan Quest Power Steering Repair ManualService Manual50% (2)

- Cpi Gtr50 Service ManualDocument43 pagesCpi Gtr50 Service ManualKlara PataiNo ratings yet

- 3006-500A-DM281001 - Rev.1 - Standard Support DWG PDFDocument199 pages3006-500A-DM281001 - Rev.1 - Standard Support DWG PDFJoselyn LiraNo ratings yet

- Catalogo de Peças QSK 50 G4Document58 pagesCatalogo de Peças QSK 50 G4Evander SarraffNo ratings yet

- B62 0030 (Rev. E 2008.03) EN - THERMOPLASTIC, THERMOSETTING MATERIALS, THERMOPLASTIC ELASTOMERS AND RUBBERS - SPECIFICATIONSDocument15 pagesB62 0030 (Rev. E 2008.03) EN - THERMOPLASTIC, THERMOSETTING MATERIALS, THERMOPLASTIC ELASTOMERS AND RUBBERS - SPECIFICATIONSDiego CamargoNo ratings yet

- ASCO Miniature Valve Products (AV017R5)Document96 pagesASCO Miniature Valve Products (AV017R5)vasudeva yasasNo ratings yet

- Corrosion AllowanceDocument3 pagesCorrosion AllowanceSarbendu PaulNo ratings yet

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsFrom EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsRating: 4 out of 5 stars4/5 (6)

- Solenoid Valve Data SheetDocument14 pagesSolenoid Valve Data SheetGuido Moreno PeredoNo ratings yet

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Cilindros Hidráulicos Parker - 2H - 1110-UkDocument42 pagesCilindros Hidráulicos Parker - 2H - 1110-UkPeterson MagroNo ratings yet

- 8222G66Document8 pages8222G66Van LudwingNo ratings yet

- ASCO Solenoid ValvesDocument8 pagesASCO Solenoid ValvesclonakiltyNo ratings yet

- Valvulas ASCO PDFDocument4 pagesValvulas ASCO PDFelkin880604No ratings yet

- Dust CollectDocument4 pagesDust CollectGustavo GuerraNo ratings yet

- Valvula SolenoideDocument6 pagesValvula SolenoideArnezNo ratings yet

- Asco Series 210 General Service CatalogDocument6 pagesAsco Series 210 General Service CatalogEric ToroNo ratings yet

- ASCO SolenoidDocument10 pagesASCO Solenoidsharib26No ratings yet

- Asco Valve 8327Document2 pagesAsco Valve 8327Yorkist100% (1)

- XFP 80C 201G TDS 60Hz USDocument4 pagesXFP 80C 201G TDS 60Hz USMeu nomeNo ratings yet

- Válvulas Solenoides ASCO ECIDocument35 pagesVálvulas Solenoides ASCO ECIFernando MendezNo ratings yet

- General Service Solenoid Valves: NC NO UDocument4 pagesGeneral Service Solenoid Valves: NC NO UDevinNo ratings yet

- SELENOIDE-Valv Solen 8210Document6 pagesSELENOIDE-Valv Solen 8210MARACO46No ratings yet

- General Service Solenoid Valves: NC NODocument6 pagesGeneral Service Solenoid Valves: NC NOAngel Azathoth GoetzNo ratings yet

- Section E: EnclosuresindexDocument32 pagesSection E: EnclosuresindexNMETETRNo ratings yet

- Válvula DurcoDocument12 pagesVálvula DurcoJames Henrry López EspejoNo ratings yet

- Asco Long Life Valves CatalogDocument4 pagesAsco Long Life Valves Catalog胡伟No ratings yet

- Asco Series 043 Gas Shutoff CatalogDocument4 pagesAsco Series 043 Gas Shutoff CatalogHomer SilvaNo ratings yet

- F LP - Gas - ValvesDocument2 pagesF LP - Gas - ValvesZMCONTROLNo ratings yet

- ASCO 35-1 General Service 3-Way Valves PDFDocument36 pagesASCO 35-1 General Service 3-Way Valves PDFprsiva2420034066No ratings yet

- 8214 200aDocument8 pages8214 200aisaac-espinosa-430No ratings yet

- Asco Series 316 Air Water CatalogDocument4 pagesAsco Series 316 Air Water CatalogekoNo ratings yet

- Valvula ASCO Falcon SB2500Document2 pagesValvula ASCO Falcon SB2500Elmer HuashuayoNo ratings yet

- Air and Water Solenoid Valves: NC NODocument4 pagesAir and Water Solenoid Valves: NC NODevinNo ratings yet

- Ti 2 516 UsDocument2 pagesTi 2 516 Uswill_streetNo ratings yet

- XFP 80C 201G TDSDocument4 pagesXFP 80C 201G TDSkeifferNo ratings yet

- SST Series Engineering Manual 413a-Sem 0Document52 pagesSST Series Engineering Manual 413a-Sem 0Gerber GarciaNo ratings yet

- Series VL Air Cylinders For Valve Actuation: Catalog HY08-0947-1/NA April, 2004Document12 pagesSeries VL Air Cylinders For Valve Actuation: Catalog HY08-0947-1/NA April, 2004Anthony Saavedra AbarulloNo ratings yet

- Dorot 68-De - El - MRDocument6 pagesDorot 68-De - El - MRJosé Daniel ArenasNo ratings yet

- General Service Solenoid Valves: NC NO UDocument4 pagesGeneral Service Solenoid Valves: NC NO UgiopetrizzoNo ratings yet

- Valvulas Solenoide para DieselDocument4 pagesValvulas Solenoide para DieselCarlos Ramos MorenoNo ratings yet

- TEADIT CamprofileDocument4 pagesTEADIT CamprofileMichael SandersNo ratings yet

- Tee Type StrainersDocument3 pagesTee Type StrainersSrinu AmulojuNo ratings yet

- Valvula Solenoide 8040 - 8215R2Document4 pagesValvula Solenoide 8040 - 8215R2Billy Isea DenaroNo ratings yet

- MS 01 177Document8 pagesMS 01 177Fabian Antonio RoldanNo ratings yet

- Flanged Immersion Heaters Design GuideDocument7 pagesFlanged Immersion Heaters Design GuidecamspsNo ratings yet

- Series TY-B - 2.8, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Standard Response, Standard CoverageDocument8 pagesSeries TY-B - 2.8, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Standard Response, Standard CoverageFlorin IordacheNo ratings yet

- ASCO Info Filter Canada PDFDocument8 pagesASCO Info Filter Canada PDFdicicaNo ratings yet

- Interruptor de Presion - AscoDocument9 pagesInterruptor de Presion - AscoJosephGutierrezNo ratings yet

- Asco8210 PDFDocument6 pagesAsco8210 PDFoscar_rent_torresNo ratings yet

- General Service Solenoid Valves: NC NO UDocument4 pagesGeneral Service Solenoid Valves: NC NO UGoyito Chavez MixNo ratings yet

- Caleffi: Safety Relief Valves For Thermal, Hydraulic and Domestic Water SystemsDocument6 pagesCaleffi: Safety Relief Valves For Thermal, Hydraulic and Domestic Water SystemsjeffjozoNo ratings yet

- Dust Collector Main Pulse Valves: FeaturesDocument4 pagesDust Collector Main Pulse Valves: FeaturesQuân TrịnhNo ratings yet

- 43-7500401 (Versa) PDFDocument20 pages43-7500401 (Versa) PDFAnthony WilliamsNo ratings yet

- SV97Document2 pagesSV97nclogesh_1981No ratings yet

- Asco 8325Document4 pagesAsco 8325Aletz AlegríaNo ratings yet

- Dimensiones Válvulas de Diluvio (Por Seguridad)Document6 pagesDimensiones Válvulas de Diluvio (Por Seguridad)Luis Fernando Manjarrez AriasNo ratings yet

- 3 Piece Tube Bore Ball Valves, / "-4": High Purity ApplicationsDocument4 pages3 Piece Tube Bore Ball Valves, / "-4": High Purity ApplicationsrodrurenNo ratings yet

- 7721 Tee Mecanica Rosc Marca Americana Shurjoint TycoDocument3 pages7721 Tee Mecanica Rosc Marca Americana Shurjoint TycoDavid EnríquezNo ratings yet

- Gates CatalogDocument72 pagesGates CatalogAldo B Aldo BNo ratings yet

- Codigo de Colores para Termopar PDFDocument1 pageCodigo de Colores para Termopar PDFJosé ManuelNo ratings yet

- SELENOIDE-Valv Solen 8210Document6 pagesSELENOIDE-Valv Solen 8210MARACO46No ratings yet

- SELENOIDE-Valv Solen 8290Document4 pagesSELENOIDE-Valv Solen 8290MARACO46No ratings yet

- Valv Bola JomarT100Document2 pagesValv Bola JomarT100MARACO46No ratings yet

- Valv Bola JomarT100plusDocument1 pageValv Bola JomarT100plusMARACO46No ratings yet

- 2Pc Threaded Ball Valve: Material ListDocument1 page2Pc Threaded Ball Valve: Material ListMARACO46No ratings yet

- Reduccion 150Document2 pagesReduccion 150MARACO46No ratings yet

- Inner Box Master CTN NO - of Weight Size Dimensions "A"Document1 pageInner Box Master CTN NO - of Weight Size Dimensions "A"MARACO46No ratings yet

- Inner Box Master CTN NO - of Weight Size Dimensions "A"Document1 pageInner Box Master CTN NO - of Weight Size Dimensions "A"MARACO46No ratings yet

- Bushing 150Document2 pagesBushing 150MARACO46No ratings yet

- DKOM Lab ManualDocument24 pagesDKOM Lab Manualaakash chakrabortyNo ratings yet

- K GBDocument18 pagesK GBLuis Fernando Juchani MoralesNo ratings yet

- Presentation 1Document44 pagesPresentation 1Adugna GosaNo ratings yet

- AC/DC Contour Probe: Product Data SheetDocument2 pagesAC/DC Contour Probe: Product Data SheetDarwin Zuni RosadoNo ratings yet

- EG1109 Lectures 10-12Document61 pagesEG1109 Lectures 10-12Steven KuaNo ratings yet

- WE104 Handout PDFDocument38 pagesWE104 Handout PDFalainraadNo ratings yet

- Updated Mark PMDocument10 pagesUpdated Mark PMRoy MokNo ratings yet

- Theoretical Plates Calculation by McCabe-Thiele Method PDFDocument4 pagesTheoretical Plates Calculation by McCabe-Thiele Method PDFGODWIN ANYIMAHNo ratings yet

- Soot BlowingDocument11 pagesSoot BlowingHoncho Abhi SinhaNo ratings yet

- Astm D2882Document8 pagesAstm D2882Lucobit LuNo ratings yet

- User Manual: BA and BA-C SeriesDocument138 pagesUser Manual: BA and BA-C SeriesNAHASALI11No ratings yet

- High Torque Drive Rod (SLHT) Rod Introduction-HUAMINGDocument18 pagesHigh Torque Drive Rod (SLHT) Rod Introduction-HUAMINGKevin XuNo ratings yet

- Shop Assembly Tank JDocument5 pagesShop Assembly Tank JSyed JafarNo ratings yet

- Shell Helix Ultra Professional AF 5W-20: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Helix Ultra Professional AF 5W-20: Performance, Features & Benefits Main ApplicationsCristiBvNo ratings yet

- FichaTécnicaMotor200KW PDFDocument1 pageFichaTécnicaMotor200KW PDFEdward Jr ChapetonNo ratings yet

- Lecture 39 PDFDocument23 pagesLecture 39 PDFmyusuf_engineerNo ratings yet

- WindSeminar SlidessummaryDocument36 pagesWindSeminar SlidessummaryM Refaat FathNo ratings yet

- Comparative Cost Analysis - MechanicalDocument1 pageComparative Cost Analysis - MechanicalRayley Daven SusiNo ratings yet

- 1 BDocument9 pages1 BJON LOPEZNo ratings yet

- Attachment - 2 - GA For Shop Fabricated Tanks PDFDocument3 pagesAttachment - 2 - GA For Shop Fabricated Tanks PDFShah Newaz KabirNo ratings yet

- Screw Type - Elite Air CompressorDocument1 pageScrew Type - Elite Air Compressorimron rosyadiNo ratings yet

- Südmo DSV Complete Mix Proof: Valve Id KeyDocument2 pagesSüdmo DSV Complete Mix Proof: Valve Id KeyMike MurdaughNo ratings yet

- Cataloque Torc-Tensionador-TentecDocument11 pagesCataloque Torc-Tensionador-TentecDeividas BNo ratings yet

- CWCH4IN Instal Manual WebDocument39 pagesCWCH4IN Instal Manual WebEnrique ScibiliaNo ratings yet