Professional Documents

Culture Documents

MICLAB 060 Sample

Uploaded by

Vizit310 ratings0% found this document useful (0 votes)

172 views7 pagesfsdg

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentfsdg

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

172 views7 pagesMICLAB 060 Sample

Uploaded by

Vizit31fsdg

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 7

Standard Operating Procedure

Title: Micro Laboratory Procedure for Sterility Testing

______________________________________________________________________________________

Copyrightwww.gmpsop.com. All rights reserved

Unauthorized copying, publishing, transmission and distribution of any part of the content by electronic

means are strictly prohibited. Page 2 of 19

6. Repeat Testing of Sterile Products..................................................................................................... 7

7. Media Check after Sterility Testing (Stasis Test)................................................................................ 8

8. Validation and Revalidation of Sterility Test Methods......................................................................... 8

9. Appendix 1 - Flowchart of Sterility Test results - Interpretation and Retests.......................................11

10. Summary of Changes.......................................................................................................................12

Procedure

1. Obtaining of Samples

1.1. Sampling

Production personnel conduct all sampling in the following areas. Details of these sampling

procedures are outlined in MICLAB 095.

Terminally Sterilised Products

Samples are to be selected randomly from throughout the autoclave load.

Aseptically Filled Products

Samples are to be selected from the beginning, middle and end of each batch, plus the first

units filled after any prolonged downtime (greater than one hour). Samples are to be of

saleable standard, not rejects.

1.2. Sample Size required for Initial Sterility Testing

Determine the sample size of the product type and batch size.

2. Setting up a Testing Session

2.1. Checking the testing requirements for each product code

Every product sampled must be documented properly in details when setting up a test

session.

This will indicate what tests are required for each product code. Always cross-check the

BPN on the sample container against the sample ID sheet.

2.1.1. Parametric Release

Not all terminally sterilised products require sterility testing. Check for Parametric

Release status of any product code.

2.1.2. Sterility Test

These products require sterility testing. A standard sterility testing session is

comprised of 4 products and a sterile control to be membrane filtered and any

number of direct inoculations along with a suitable sterile control.

2.1.3. Bacterial Endotoxin

Check if a product requires Bacterial Endotoxin testing and also by which test

method, either gel clot or KCA. If the product requires Bacterial Endotoxin testing,

separate these samples from the sterility samples. Ensure that these samples are

labelled with the Product Name & strength, batch, code and place these in the

receptacle for the type of Endotoxin test required.

2.1.4. Biological Assay

If a biological assay is required separate the samples from the Sterility samples.

Ensure these samples are labelled with the Product Name, batch and code and are

given or communicated to the technician responsible for Assay testing.

2.2. Known Sterile Controls

Standard Operating Procedure

Title: Micro Laboratory Procedure for Sterility Testing

______________________________________________________________________________________

Copyrightwww.gmpsop.com. All rights reserved

Unauthorized copying, publishing, transmission and distribution of any part of the content by electronic

means are strictly prohibited. Page 5 of 19

Incubate the TSB and FTM bottles as described below in point 3.6 Incubation.

Secondary Transfer Process

After not less than 14 days of incubation and working within the sterility test LAF,

aseptically transfer the following:

- 1 mL of the initial FTM media into a new bottle of 100mL FTM, and,

- 1 mL of the initial TSB media into a new bottle of 100 mL TSB.

Continue the incubation of the initial media and transfer media bottles as follows:

FTM Not less than 4 days @ 322C.

TSB Not less than 4 days @ 222C.

Examine the media for growth at intervals during the incubation period. If no

evidence of growth is found the batch meets the requirements for the Test of

Sterility.

3.2. Agar Plates

One irradiated Letheen Agar plate and one irradiated Nutrient Agar plate are to be taken into

the Sterility Test room for every sterility test session.

The Nutrient Agar plate is to be left exposed on the Laminar Flow bench (sterile

Environmental) throughout the entire time of the sterility test session.

The Letheen Agar plate is to be used to record the Operator's finger print impressions during

the test session or at its conclusion. If a needle stick injury occurs, before leaving the sterility

test room to change gloves, conduct a finger print impression. Use an additional Letheen

Agar plate to monitor the finger impressions at the conclusion of the session.

Four (4) contact plates are used for personnel monitoring of the hood, sleeve, chest and leg

after all testing has been completed, on exiting the change room.

NOTE: If a double consecutive session is being tested, perform personnel monitoring after

the second session only.

Record the Name, Date and Session details on the plates. Incubate all plates according to

MICLAB 045. Record results in the Monitoring Results for Sterility Test Sessions Finger,

Fallout, Environmental and Personnel Results File.

NOTE: After recording the finger print impression, the Operator must don a new pair of

sterile gloves in the change room and disinfect their hands with 70% IPA prior to resumption

of testing. See MICLAB 045 for limits.

3.3. Environmental Monitoring

Environmental monitoring must be performed with each Sterility Testing Session and in each

room and transfer hatch in use, on a daily basis. See the Table below for details:

Area Environmental Monitoring Required Frequency

Laminar Flow Cabinet 1000L Air Sample

1 x Contact Plate

Each Session

Each Session

Change Room 200L Air Sample

1 x Contact Plate (Floor)

Daily, when in use

Daily, when in use

Transfer Hatch 200L Air Sample

1 x Contact Plate

Daily, when in use

Daily, when in use

Sterility test Room 200L Air Sample

1 x Contact Plate (Floor)

1x Contact Plate (Trolley)

Daily, when in use

Daily, when in use

Daily, when in use

The environmental Agar plates and contact plates are to be labelled with all details and

incubated according to MICLAB 045. Results from the Laminar Flow monitoring are to be

entered in the Monitoring Results for Sterility Test Sessions Finger, Fallout, Environmental

and Personnel Results File. Results from ALL environmental samples are to be entered in

the Environmental Results Air / Surfaces Non-Sterile File . After the total count is recorded,

Standard Operating Procedure

Title: Micro Laboratory Procedure for Sterility Testing

______________________________________________________________________________________

Copyrightwww.gmpsop.com. All rights reserved

Unauthorized copying, publishing, transmission and distribution of any part of the content by electronic

means are strictly prohibited. Page 8 of 19

The product is to be regarded as a separate session with a known sterile control. No other

product is to be tested during this procedure.

a) Non-injectable, Non-filterable products

For non-injectable, non-filterable products follow the same procedure as for the

initial test. The known Sterile Control is Paraffin Oil in this test session.

b) Aqueous Solutions

1. For aqueous solutions the same quantity of product is filtered.

2. Include a known sterile control of X units of Water for Injection that has been

autoclaved at least twice in the test session.

3. Wash the canister filters with 3 x 100 mL of Sterile Peptone Water. These 3

washes should be individual. Fill the canisters with the appropriate medium,

seal and incubate as for an initial sterility test.

6.4. Recording of the session and results

Details of the test sessions and the results are to be recorded in the log book.

6.5. Interpretation of sterility repeat test results

6.5.1. If no evidence of microbial growth is found in the repeat test, the product examined

complies with the test for sterility. If microbial growth is found in the repeat test, the

product examined does not comply with the test for sterility.

7. Media Check after Sterility Testing (Stasis Test)

7.1. Membrane Filtration and Direct Inoculation

Once every 12 months media containers from a product tested by Membrane Filtration and

also if possible those from a product tested by Direct Inoculation must be subjected to a

challenge by a low number of microorganisms after the sterility test has been completed.

This is to ensure that any inhibitory effects present in the products have been successfully

inactivated by the dilution effect of the testing procedure, or the washing procedure as

appropriate to the Test Method, and hence any microorganisms that may have been present

in the product would have been able to grow in the media when the product was tested. It is

important that on an annual basis, the range of sterile products are to be subjected to a

Stasis Test.

A Stasis Check on Sterility Tests Form must be filled out on an annual basis detailing the

product type and date the Stasis test was conducted. NOTE: The product types listed are

not exhaustive; they represent the range of products manufactured by the company and list

only the specific products most likely to be inhibitory to the Sterility test.

7.2. See MICLAB 090 for the procedure of Stasis tests and to determine the method of

preparation of Stock Suspensions of micro organisms used for Stasis work and media

checks.

8. Validation and Revalidation of Sterility Test Methods

8.1. General Requirements

8.1.1 All products, which require sterility testing, must have a corresponding validated

method.

8.1.2 Validation is required for each new product formulation, changes in product

formulation, changes in containers / closure types and any other changes that

impact the status of a validated system, process or equipment.

8.1.3 Re-validations of existing methods are to be performed once every 5 years.

8.1.4 A revalidation of the sterility test system, using at least one product is to be

conducted on an annual basis.

Standard Operating Procedure

Title: Micro Laboratory Procedure for Sterility Testing

______________________________________________________________________________________

Copyrightwww.gmpsop.com. All rights reserved

Unauthorized copying, publishing, transmission and distribution of any part of the content by electronic

means are strictly prohibited. Page 11 of 19

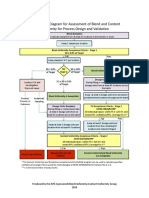

9. Appendix 1 - Flowchart of Sterility Test results - Interpretation and Retests

Initial Test

Test

Result =

no growth

Test

Result =

Growth

Control

Result =

growth

Control

Result =

no growth

PASS

FAIL

Repeat test

Test result =

no growth

Test Result =

Growth

Problem with

session?

YES

NO

Does the

organism

match the

environment?

YES

NO

Form 680

Issue date:

Sterility Test Failure Investigation

(Ref. MICLAB 060)

Copyrightwww.gmpsop.com. All rights reserved

Unauthorized copying, publishing, transmission and distribution of any part of the content by electronic

means are strictly prohibited. Page 13 of 19

Table Contents DR____________

1. Purpose of report

2. Batch Details

3. Batch Manufacturing review and Sterility testing

4. Summary of Conclusions found

5. Possible causes

6. Corrective action

7. Preventative action

8. Disposition of filling room

9. Documentation Approval of Investigation

1 Purpose of report

The purpose of this document is to provide a summary report of the incident investigation conducted into:

2 Batch Details

Product Name Batch #

Date of Manufacturing Filling Room #

Product Code Filling Machine

Container and size

Terminally sterilized Y/N Autoclave Cycle

Sterility Test Details

Date Technician

Test room

Number of products

tested

Time of test session

Session number that

day

Validated test method Tested to

Specification

Date of results Test session results

Contaminant/s type

Negative control

result

3 Batch review from manufacturing and testing.

Product Manufacturing Review

REVIEW AREA DETAILS & Results REVIEWED BY

Dispensing results:

Review of raw materials

used for the manufacture

Batch #

Materials code

Validated test method

Results of tests

Sign:

Date:

Review Attached: Yes/No

Dispensing of the raw

materials

Sign:

Date:

Review Attached: Yes/No

Sterilization cycles for

components

Autoclave

Cycle#

Date

Result

Sign:

Date:

Review Attached: Yes/No

Form 680

Issue date:

Sterility Test Failure Investigation

(Ref. MICLAB 060)

Copyrightwww.gmpsop.com. All rights reserved

Unauthorized copying, publishing, transmission and distribution of any part of the content by electronic

means are strictly prohibited. Page 16 of 19

Interview of Operator for

any excursion of

procedures:

Name:

Date

Sign:

Date:

Review Attached: Yes/No

Training records

Gowning validations

Name

Training Record

Sign:

Date:

Review Attached: Yes/No

Operators Finger Dabs

Name

Results

Sign:

Date:

Review Attached: Yes/No

Operators Uniform

Name

Results

Sign:

Date:

Review Attached: Yes/No

Packing Line:

Autoclave cycle finished

product

Autoclave #

Cycle #

Result

Sign:

Date:

Review Attached: Yes/No

Issues on Inspection /

Finishing line

Sign:

Date:

Review Attached: Yes/No

QA Review Manufacturing:

Product Review of past

12 months of results

Sign:

Date:

Review Attached: Yes/No

Deviation Reports

Review

Sign:

Date:

Review Attached: Yes/No

Similar incidents

Sign:

Date:

Review Attached: Yes/No

Change control history

review

Sign:

Date:

Review Attached: Yes/No

Audit of security card

swipe

Sign:

Date:

Review Attached: Yes/No

Review of Media run

reports past 12 months

Sign:

Date:

Review Attached: Yes/No

Summary

Micro. Lab. to place a HOLD on adjacent & subsequent batches until establishing a cause which will

eliminate their risk of contamination and also;

Batches on HOLD (Q)

Batch # Code Product & % Container Size

Sterility Testing Review

REVIEW AREA DETAILS REVIEWED BY

Results of known sterile

controls

Sign:

Date:

Review Attached: Yes/No

Level of false positives in

routine testing (previous

12 months)

Sign:

Date:

Review Attached: Yes/No

Level false positives in

known sterile controls

previous 12 months)

Sign:

Date:

Review Attached: Yes/No

Review of sampling

procedures

Sign:

Date:

Review Attached: Yes/No

Date done: Notify QA Manager

Form 680

Issue date:

Sterility Test Failure Investigation

(Ref. MICLAB 060)

Copyrightwww.gmpsop.com. All rights reserved

Unauthorized copying, publishing, transmission and distribution of any part of the content by electronic

means are strictly prohibited. Page 18 of 19

Interview of Technician

Sign:

Date:

Review Attached: Yes/No

Sterility Log Book

Sign:

Date:

Review Attached: Yes/No

Comparison of Isolates

Date of Streaking all Isolates:_________________

Technician:________________________________

Source of Isolate

No. of

Colonies

Colony Morphology

Microscopic

Appearance

Product

N/A

Finger Dab Plate

Uniform Plate

Laminar Flow Contact plate

Laminar Flow Air Sample

Fallout Plate

IPA Exp. Date:

Bucket 1

N/A

Bucket 2

N/A

4. Summary of Conclusions found

5. Possible cause/ Root Cause

You might also like

- MICLAB 055 Sample 2Document4 pagesMICLAB 055 Sample 2Vizit31No ratings yet

- Bioburden TestDocument4 pagesBioburden TestMujeeb Ullah KhanNo ratings yet

- СОП - media - fill Micro LaboratoryDocument7 pagesСОП - media - fill Micro LaboratoryMykolaNo ratings yet

- Validation Protocol For Disinfectant Efficacy ValidationDocument12 pagesValidation Protocol For Disinfectant Efficacy ValidationMubarak PatelNo ratings yet

- Biocontamination Control for Pharmaceuticals and HealthcareFrom EverandBiocontamination Control for Pharmaceuticals and HealthcareRating: 5 out of 5 stars5/5 (1)

- Sterlity Validation (Membrane Filtration Method) in Pharmaceuticals - Pharmaceutical GuidelinesDocument4 pagesSterlity Validation (Membrane Filtration Method) in Pharmaceuticals - Pharmaceutical GuidelinesDucNo ratings yet

- Bioburden ALERT Levels PDFDocument17 pagesBioburden ALERT Levels PDFRudhy21No ratings yet

- VAL-095 Facility and Utility Validation Guideline SampleDocument1 pageVAL-095 Facility and Utility Validation Guideline SampleVizit31No ratings yet

- Cleaning Validation White PaperDocument7 pagesCleaning Validation White PaperAngga PratamaNo ratings yet

- The Environmental Monitoring Program in A GMP Environment: Microbiology TopicsDocument9 pagesThe Environmental Monitoring Program in A GMP Environment: Microbiology Topicsdavincicode888No ratings yet

- MICLAB 110 Microbiology Laboratory Investigation and Retest Procedure For Atypical Results PDFDocument4 pagesMICLAB 110 Microbiology Laboratory Investigation and Retest Procedure For Atypical Results PDFalnzeer omerNo ratings yet

- Cleaning Validation 02Document25 pagesCleaning Validation 02sreedharguptaNo ratings yet

- Quality AssuranceDocument3 pagesQuality AssuranceDevanshi JadaunNo ratings yet

- ValidationDocument56 pagesValidationAmit Singh100% (1)

- Sop Fumigation Vapour Hydrogen Peroxide-H2o2 VHPDocument6 pagesSop Fumigation Vapour Hydrogen Peroxide-H2o2 VHPMohamed FetouhNo ratings yet

- VAL-090 Equipment Validation Guideline SampleDocument2 pagesVAL-090 Equipment Validation Guideline SampleVizit31No ratings yet

- SOP Aseptic Filling PDFDocument6 pagesSOP Aseptic Filling PDFSandraNo ratings yet

- EO Annual Requalification ReviewDocument30 pagesEO Annual Requalification ReviewVenkatesh VenkateshNo ratings yet

- Cleaning Validation To Be Developed From This Article On Metformin TabletsDocument9 pagesCleaning Validation To Be Developed From This Article On Metformin TabletsPramba Kumar AhujaNo ratings yet

- General Test ProcedureDocument5 pagesGeneral Test ProcedureRahul PatilNo ratings yet

- Cleaning Validation Guideline SampleDocument3 pagesCleaning Validation Guideline SampleSagi NguyenNo ratings yet

- Cleaning Validation Report Dec2018 PDFDocument21 pagesCleaning Validation Report Dec2018 PDFPrashansa ShresthaNo ratings yet

- Ethylene+oxide+Gas+Sterilization 한신메디칼+ (호환+모드)Document30 pagesEthylene+oxide+Gas+Sterilization 한신메디칼+ (호환+모드)SACHIN KUMARNo ratings yet

- Validation of IncubatorsDocument4 pagesValidation of Incubatorsltrevino100No ratings yet

- Yang 2013Document9 pagesYang 2013Tanneru Hemanth KumarNo ratings yet

- Food Microbiology Quality Control Nov 14Document36 pagesFood Microbiology Quality Control Nov 14Harith AtrisNo ratings yet

- Selection Off Conttaiinmentt For Fill-Finish OperationsDocument59 pagesSelection Off Conttaiinmentt For Fill-Finish OperationsindexmxNo ratings yet

- Sterility Test Validation ProtocolDocument6 pagesSterility Test Validation ProtocolԼուսինե Հովսեփյան100% (1)

- GUI 0028 Cleaning Validation - Ltr&doc EngDocument11 pagesGUI 0028 Cleaning Validation - Ltr&doc EngKaran SharmaNo ratings yet

- STP of Purified Talc BPDocument9 pagesSTP of Purified Talc BPMd. Moniruzzaman0% (1)

- Dirty-Hold Time Effect On The CleaningDocument6 pagesDirty-Hold Time Effect On The CleaningOmar FaruqNo ratings yet

- Validation of Analytical Method: Ashok Suthar Regulatory Associate Regulatory Affairs Amneal PharmaceuticalsDocument40 pagesValidation of Analytical Method: Ashok Suthar Regulatory Associate Regulatory Affairs Amneal Pharmaceuticalsshashank786No ratings yet

- Nvironmental Onitoring: Omprehensive AndbookDocument7 pagesNvironmental Onitoring: Omprehensive Andbookdavincicode888No ratings yet

- Sanitation of Pharmaceutical FacilitiesDocument5 pagesSanitation of Pharmaceutical FacilitiesDoan Chi ThienNo ratings yet

- Blend Content Uniformity Process Flow Diagram Design ValidationDocument1 pageBlend Content Uniformity Process Flow Diagram Design Validationhicham1963No ratings yet

- 03 VDmax Method1 FAQDocument4 pages03 VDmax Method1 FAQFrengki Hadi Eko SantosoNo ratings yet

- ECA Task Force CCS GuidelineDocument48 pagesECA Task Force CCS Guidelinemercedes100% (1)

- MICRO 4 SOP For Microbial Monitoring in Drain Point of Pharmaceutical Manufacturing SitesDocument2 pagesMICRO 4 SOP For Microbial Monitoring in Drain Point of Pharmaceutical Manufacturing SitesAjesh Tk100% (1)

- Compressed AirDocument7 pagesCompressed Airpradeep281001No ratings yet

- Cleaning Validation Problems - Global PerspectiveDocument66 pagesCleaning Validation Problems - Global PerspectiveGaoussou TimitéNo ratings yet

- Cleaning Validation RequirementDocument7 pagesCleaning Validation RequirementPrince MoniNo ratings yet

- Particulate Matter and Visual Inspection Industry Trends 2015Document48 pagesParticulate Matter and Visual Inspection Industry Trends 2015Blank BacktobasicNo ratings yet

- SOP On Procedure For Microbiological Monitoring of Purified Water in Pharmaceutical CompanyDocument3 pagesSOP On Procedure For Microbiological Monitoring of Purified Water in Pharmaceutical CompanyReza JafariNo ratings yet

- Validation of Sterilization ProcessesDocument3 pagesValidation of Sterilization ProcessesNovitra DewiNo ratings yet

- Microbiology Audit Guidance EbookDocument23 pagesMicrobiology Audit Guidance EbookArmando Saldaña100% (1)

- Hygicult Guide To Monitoring CleanlinessDocument36 pagesHygicult Guide To Monitoring Cleanlinessroem1104100% (1)

- Sop For Good Documentation PracticesDocument2 pagesSop For Good Documentation Practicesgreen solutionNo ratings yet

- Cleaning Validation: Acme PharmaceuticalsDocument43 pagesCleaning Validation: Acme PharmaceuticalsDebashisNo ratings yet

- Microbiological Enviromental MonitoringDocument34 pagesMicrobiological Enviromental MonitoringAna Dulce100% (1)

- Zone 1 Sampling For Spp. in Fresh Produce Operations:: ListeriaDocument10 pagesZone 1 Sampling For Spp. in Fresh Produce Operations:: Listeriaamir ShehzadNo ratings yet

- Rideal Walker CoefficientDocument3 pagesRideal Walker CoefficientManjusha KondepudiNo ratings yet

- 3 2 - MicrobiologicalQualityControl 1Document37 pages3 2 - MicrobiologicalQualityControl 1Tong ChanNo ratings yet

- Content: Standard Operating Procedure (SOP) Use and Maintenance of A PH MeterDocument6 pagesContent: Standard Operating Procedure (SOP) Use and Maintenance of A PH MeterChristian JosephNo ratings yet

- Disinfectant ValidationDocument7 pagesDisinfectant Validationrose itaNo ratings yet

- Annex - 4 (CAPA Report)Document3 pagesAnnex - 4 (CAPA Report)ajmalnasirNo ratings yet

- Cleaning and Cleaning Validation PDFDocument6 pagesCleaning and Cleaning Validation PDFedgar palominoNo ratings yet

- Production of Plasma Proteins for Therapeutic UseFrom EverandProduction of Plasma Proteins for Therapeutic UseRating: 3 out of 5 stars3/5 (5)

- Midsem Exam 2011Document6 pagesMidsem Exam 2011Vizit31No ratings yet

- VAL-085 Process Validation Guideline SampleDocument2 pagesVAL-085 Process Validation Guideline SampleVizit31No ratings yet

- VAL-095 Facility and Utility Validation Guideline SampleDocument1 pageVAL-095 Facility and Utility Validation Guideline SampleVizit31No ratings yet

- VAL-090 Equipment Validation Guideline SampleDocument2 pagesVAL-090 Equipment Validation Guideline SampleVizit31No ratings yet

- VAL-030 Equipment Specification and Qualification SampleDocument2 pagesVAL-030 Equipment Specification and Qualification SampleVizit31No ratings yet

- MICLAB 035 SampleDocument6 pagesMICLAB 035 SampleVizit31No ratings yet

- VAL-020 Procedure For Cleaning Validation SampleDocument3 pagesVAL-020 Procedure For Cleaning Validation SampleVizit31No ratings yet

- Grams/Litre Ingredients Grams/Litre: Page 1 of 2Document2 pagesGrams/Litre Ingredients Grams/Litre: Page 1 of 2Vizit31No ratings yet

- Standard Operating Procedure Title:: EHS StatementDocument2 pagesStandard Operating Procedure Title:: EHS StatementVizit31No ratings yet

- MICLAB 065 SampleDocument1 pageMICLAB 065 SampleVizit31No ratings yet

- Manual 062 SampleDocument1 pageManual 062 SampleVizit31No ratings yet

- Ucm 072171Document23 pagesUcm 072171Vizit31No ratings yet

- Stainless Steels and Drinking Water Around The WorldDocument12 pagesStainless Steels and Drinking Water Around The WorldVizit31No ratings yet

- PROBLEM 17.129: SolutionDocument14 pagesPROBLEM 17.129: SolutiontaNo ratings yet

- Shear Wall Modelling Techniques: A ReviewDocument9 pagesShear Wall Modelling Techniques: A ReviewAmanulla MullaNo ratings yet

- The Strange Case of Mole Airlines Flight 1023: Preib/Ap Chemistry - Unit 5 Chemical QuantitiesDocument7 pagesThe Strange Case of Mole Airlines Flight 1023: Preib/Ap Chemistry - Unit 5 Chemical QuantitiesGiordi Emmanuel SalinasNo ratings yet

- Coatings Word August 2010Document52 pagesCoatings Word August 2010sami_sakrNo ratings yet

- ACCDocument18 pagesACCSanchit AgarwalNo ratings yet

- Safety Data Sheet: 3M Brand Fire Barrier CP-25WB+Document12 pagesSafety Data Sheet: 3M Brand Fire Barrier CP-25WB+ErickoNo ratings yet

- A Reviewof Studies On Central Receiver Solar Thermal Power PlantsDocument28 pagesA Reviewof Studies On Central Receiver Solar Thermal Power PlantsValeria Rueda100% (1)

- Petroleum Systems of Indonesia PDFDocument28 pagesPetroleum Systems of Indonesia PDFWahyu Probo Ananto HadiNo ratings yet

- L&T Document Number:: 0 1 ARN DDU ARN DDUDocument56 pagesL&T Document Number:: 0 1 ARN DDU ARN DDUFayaz AhammedNo ratings yet

- Bonding Theories of Coordination CompoundsDocument6 pagesBonding Theories of Coordination Compoundsmark carlo SanorjoNo ratings yet

- THE TITLE OF EXPERIMENT Ion ExchangeDocument18 pagesTHE TITLE OF EXPERIMENT Ion Exchangeputri wildanaNo ratings yet

- ReportDocument20 pagesReportAidaFarzanaNanaNo ratings yet

- Seismic Principles: - Chapter 1Document13 pagesSeismic Principles: - Chapter 1Mahardika Aji KurniawanNo ratings yet

- 2.Pv Semisolid FDADocument37 pages2.Pv Semisolid FDARahayu Maulida RNo ratings yet

- Removal of Gaseous Chlorine From Cylinders and Ton ContainersDocument4 pagesRemoval of Gaseous Chlorine From Cylinders and Ton Containersmailmaverick8167No ratings yet

- Geography Sheet Work About HydrographsDocument1 pageGeography Sheet Work About HydrographsIsaac CharlesonNo ratings yet

- Laboratory ManualDocument13 pagesLaboratory ManualPaul UyNo ratings yet

- Ec 1Document443 pagesEc 1Chaitanya KumarNo ratings yet

- Els&CommunicationDocument145 pagesEls&Communicationapi-3827000100% (1)

- Weo Water Treatment and ReuseDocument4 pagesWeo Water Treatment and ReuseWendyNo ratings yet

- Analytical Concepts of Errors, Accuracy and Precision: Group: 2 Eman Fatima Fajar Eman Khadija LubainaDocument12 pagesAnalytical Concepts of Errors, Accuracy and Precision: Group: 2 Eman Fatima Fajar Eman Khadija LubainaAzhan HassanNo ratings yet

- Module - 1 Lecture Notes - 5: Remote Sensing: Introduction and Basic Concepts Spectral Reflectance CurvesDocument13 pagesModule - 1 Lecture Notes - 5: Remote Sensing: Introduction and Basic Concepts Spectral Reflectance CurvesYogesh SharmaNo ratings yet

- XXI Paper 044Document9 pagesXXI Paper 044RICARDO3454No ratings yet

- Bc20122lnh-1 Assay Sheet (For Bc-30 Vet Research Use Only)Document1 pageBc20122lnh-1 Assay Sheet (For Bc-30 Vet Research Use Only)Subodh SahuNo ratings yet

- IBR Amendment 2004,3Document10 pagesIBR Amendment 2004,3BIRANCHINo ratings yet

- A101 Design Calculation For Foundation of New VCM Storage TankDocument25 pagesA101 Design Calculation For Foundation of New VCM Storage TankzatenneNo ratings yet

- Bfs4063 & Bfs 40603 Concrete EngineeringDocument4 pagesBfs4063 & Bfs 40603 Concrete EngineeringUtaya Kumar VeelmuruganNo ratings yet

- Instruction Manual: 2700 Series Benchtop MetersDocument60 pagesInstruction Manual: 2700 Series Benchtop Meterssebastian florez sernaNo ratings yet

- Chapter 2 Pharmaceutical Aids and NecessitiesDocument11 pagesChapter 2 Pharmaceutical Aids and NecessitiesZarah Pauline Jimenez100% (2)

- Ass 1 SDFGHJK DFGHJK DFGHJK Ertyuiop SDFGHJKLDocument10 pagesAss 1 SDFGHJK DFGHJK DFGHJK Ertyuiop SDFGHJKLriniz92No ratings yet