Professional Documents

Culture Documents

Overview Six Sigma Phases

Uploaded by

hans_106Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Overview Six Sigma Phases

Uploaded by

hans_106Copyright:

Available Formats

Phases, Steps and Tools for Six Sigma

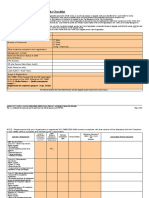

Phase Objective of the Phase Step Objective of the Step Subject or tool Customer identification Customer needs identification (customer surveys) Affinity Diagram Customer Needs Mapping Kano Quality Function Deployment Pareto CTQ-tree or CTQ flow down Correlation diagram Operationalisation SIPOC Identify which process is targeted for improvement and the scope of the project. Describe problem statement, target and benefits in a project charter. Process Map Business Case Project Charter Measurement system definition Sampling (representativeness) Sample Size (continuous data) 4) Define Measurement System Define a measurement system for the CTQ Sample Size (discrete data) and create a sufficient sample Acceptance sampling by attributes Acceptance sampling by variables Gauge R&R (crossed) Gauge R&R (nested) Attribute Gauge R&R 5) Validate measurement system Validate measurement system Type 1 Gauge Study Linearity & Bias Study Time & motion studies Kappa test (with and without known standard) Define and validate a measurement system for the CTQ. Collect CTQ data (accurate and precise). Calculate the current process capability and define statistical success. Control chart individuals (normal, box-cox); tests Run Chart Probability Plot (Normal, Weibull) Individual Distribution Identification Goodness of fit test for Poisson Chi square Goodness of fits test Capability Analysis (Normal) Capability Analysis (Weibull) Capability Analysis (other distributions) Capability Analysis Between / Within Binominal Cap An Poisson Cap An Objective of the subject / tool Start with an overview of all the customers Use different sources to identify the customers needs Affinity helps you to cluster the customer needs in logical groups Customer needs mapping creates a hierarchical structure in the customer needs Kano model classifies needs in different categories QFD links needs and process steps or departments Pareto helps you to prioritize different CTQ's and tells which CTQ you should work on A CTQ-tree shows how different CTQ's are related Use a correlation diagram to find out how strong External CTQ and Internal CTQ are correlated Make an Operational definition of the Internal CTQ SIPOC creates an overview of the process and the customers. Use SIPOC for scope definition (start and end of the process). Create a process map of the process in the way it really is. Identification of Quick Wins Calculate the benefits and costs of the project. Is the project profitable enough to work on. Write a project charter to give an overview of the project; problem, goals, benefits scope etc. Define exactly how the CTQ will be measured Create a sample that is representative for the population (strata, randomness, Calculate how many data points you need for an accurate Process Performance Analysis Calculate how many data points you need for an accurate Process Performance Analysis Create a sampling plan to make a decision whether to accept or reject an entire lot (batch) of product, based on the number of defects found in that sample Create a sampling plan to make a decision whether to accept or reject an entire lot (batch) of product, based on the number of defects found in that sample Validate measurement system for continuous data Validate measurement system for continuous data, destructive measurements Judge Bias & repeatability given a continuous measurement with a binary outcome label To estimate bias and repeatability (a sneak preview) To find out whether the measurement system measures with a small or large deviation (bias & linearity) To estimate the variance caused by the operate when replication is impossible Validate measurement system for discrete data Make a control chart to show 'the heartbeat' of the process. Distinguish between common cause and special cause variation. Is the process stable and statistically in control? Make a run chart to determine if the process show any pattern. If any, PCA is limited to short term. Use probability plots to determine whether a particular distribution fits your data. Many statistical tools use a probability distribution. These tools can only be used if the distribution is applicable Use Individual Distribution Identification to find out which probability Distribution best fits Use a Goodness of fit test for Poisson to determine if the data follow a Poisson distribution Use a Goodness of fit test for Poisson to determine if the data follow a multinomial distribution with certain proportions

Define

Define who is the customer and what their needs are Translate the customer needs to quality characteristics (CTQs). Select the project CTQ. Describe the project (IntCTQ) in measurable definitions (operationalising). Identify which process or product is targeted for improvement. Develop a high-level process map for the key process steps (Scope). Calculate the Business Case and write a project charter.

1) What does the customer want?

Define the customers and their needs

2) Establish measurement definitions

Translate the project from the customers perspective to an internal improvement project and describe the Internal CTQ in measurable definitions

3) What is the project?

Measure

6) Actual Process Performance

Calculate actual process performance related to the customers specification limits

Calculate the current process capability. Use the type that is appropriate for your data. This is the starting point for improvement

7) Define Statistical Success

Should-be performance: how much should the process improve?

Calculation of the mean and standard deviation of the improved process

Calculate the mean and standard deviation which are needed to a defect rate that meets the target.

Copyright ProjectsOne 2010. All rights reserved. No part of this training material may be reproduced in any form.

Exploratory Data Analysis (Control- and Run Charts, Probability Plots, Scatter Use graphs to find as many potential influence factors (Xs) on Y (the output of our plots, Histogram, Box plots, Dot plots, Individual Value plot, Interval plots, process) as possible Pareto charts, Etc.) Main Effects Plot Use the main effects plot for comparing magnitudes of main effects. Interactions plots are useful for judging the presence of interaction between different Interactions Plots factors. Symmetry Plot Symmetry plots help you to determine if the data comes from a symmetric distribution. Multi Vari Charts are charts that show patterns of variation from several possible causes Multivari chart on a single chart, or set of charts Time Series Analysis 8) Identify causes of defects Identify all possible causes using explorative data analyses and expert knowledge Multivariate Analysis Exploratory Data Analysis Cause & Effect Diagram (Ishikawa) Failure Mode and Effects Analysis (FMEA) Expert Knowledge (Brainstorm) 1 sample t-test 2 sample t-test Paired t-test Time series procedures can be used to analyze data collected over time, including simple forecasting and smoothing methods, correlation analysis methods, and ARIMA modelling. Multivariate Analysis can help you to 1) Analyze the data covariance structure to understand it or to reduce the data dimension, 2) Assign observations to groups and 3) Explore relationships among categorical variables. EDA methods are particularly useful for identifying extraordinary observations and noting violations of traditional assumptions, such as nonlinearity or nonconstant variance . Cause and Diagram can be used in a brainstorm with experts to collect possible influence factors (causes) Use FMEA to make an overview of potential Xs that can negatively impact process performance (Y). Always use the process knowledge of experts. Discuss the results from the explorative data analysis with an expert. Brainstorm with experts to find possible causes (X's). Use this test to assess the difference between the mean from a sample versus an historical mean from another population when s is unknown The means of two normally distributed samples are tested for differences against each other Use a paired t-test when pairs of data points are dependent or related. It tests if the differences of the pairs are significantly differ from 0. Use to perform hypothesis tests for equality, or homogeneity, of variance among two populations using an F-test and Levene's test. Many statistical procedures, including the two sample t-test procedures, assume that the two samples are from populations with equal variance. The 2 variances test procedure will test the validity of this assumption. You can use correlation to measure the degree of linear relationship (correlation coefficient) between two variables. You can calculate the covariance for all pairs of columns. Like the Pearson correlation coefficient, the covariance is a measure of the relationship between two variables. However, the covariance has not been standardized, as is done with the correlation coefficient Use variance test to perform hypothesis tests for equality or homogeneity of variance using Bartlett's and Levene's tests. An F Test replaces Bartlett's test when you have just two levels. Use regression to find out if a X variable (continuous) influences the outcome in Y. A pvalue tells you if the relationship is significant. Use binary logistic regression to perform logistic regression on a binary response variable. Anova is used to determine whether the means of samples are identical (Null-hypothesis) or differ due to a factor A two-way analysis of variance tests the equality of population means when classification of treatments is by two variables or factors . A graphical analogue to ANOVA that tests the equality of population means. The graph displays each factor level mean, the overall mean, and the decision limits. If a point falls outside the decision limits, then evidence exists that the factor level mean represented by that point is significantly different from the overall mean. A chi square (c2) statistic is used to investigate whether distributions of discrete variables differ from one another. An assumption for the one-sample Wilcoxon test and confidence interval is that the data are a random sample from a continuous , symmetric population. You can perform a 2-sample rank test (also called the Mann-Whitney test , or the twosample Wilcoxon rank sum test) of the equality of two population medians, and calculate the corresponding point estimate and confidence interval . You can perform a Kruskal-Wallis test of the equality of medians for two or more populations Mood's median test can be used to test the equality of medians from two or more populations and, like the Kruskal-Wallis Test, provides an nonparametric alternative to the one-way analysis of variance. Mood's median test is more robust for outliers. Use Runs Test to see if a data order is random. Runs Test is a nonparametric test because no assumption is made about population distribution parameters. Use this test when you want to determine if the order of responses above or below a specified value is random. A run is a set of consecutive observations that are all either less than or greater than a specified value.

2 variances Analyse

Correlation Covariance

Test for equal variances Single regression (1e 2e and 3e order) Binary Logistic regression One Way Anova (stacked & unstacked) Two way Anova

Analysis of Means

Chi Square test One sample Wilcoxon Mann-Whitney Kruskal Wallis Moods Median

Runs Test

Copyright ProjectsOne 2010. All rights reserved. No part of this training material may be reproduced in any form.

Multiple regression General Regression (Minitab 16) General Linear Model

Improve

In the Improve phase you and your project team will: Determine the optimal settings in order to reach your performance goal Specify tolerances on the critical Xs to meet our CTQ performance goal Update the initial Business Case towards a final Business Case Define implementation plan and approach Write the implementation plan

Doe Full Factorial / Plackett Burmann (Design; Analysis; Optimise)

10) Determine vital causes

Determine Transfer Function between Y & Xs and identify optimal settings for these Xs Doe Response Surface (Design; Analysis; Optimise)

Doe Taguchi (Design; Analysis; Results)

Queuing theory

Use Multiple regression to determine a transfer function for a continuous Y and one or more continuous X's (linear) Use Multiple regression to determine a transfer function for a continuous Y and one or more continuous X's (non-linear) and one ore more categorical X's General linear model is a technique that enables you to create a model out of multiple Xs for their impact on Y (our internal CTQ). These Xs are continuous or categorical by nature. The Y must be continuous. These advanced Design of Experiments (DOE) capabilities help you improve your processes. You can screen the factors to determine which are important for explaining process variation. After you screen the factors, Minitab helps you understand how factors interact and drive your process. You can then find the factor settings that produce optimal process performance Response surface methods are used to examine the relationship between one or more response variables and a set of quantitative experimental variables or factors. These methods are often employed after you have identified a "vital few" controllable factors and you want to find the factor settings that optimize the response. Designs of this type are usually chosen when you suspect curvature in the response surface. Taguchi is a robust parameter design, which is an engineering method for product or process design that focuses on minimizing variation and/or sensitivity to noise. Queuing theory is the mathematical study of waiting lines, or queues. The theory enables mathematical analysis of several related processes, including arriving at the (back of the) queue, waiting in the queue (essentially a storage process), and being served at the front of the queue. The theory permits the derivation and calculation of several performance measures including the average waiting time in the queue or the system, the expected number waiting or receiving service, and the probability of encountering the system in certain states, such as empty, full, having an available server or having to wait a certain time to be served If you need creativity to find a solution for the problem, brainstorming can help. Evaluating multiple options against each other, relative to a baseline option. Use buffering for model errors (residuals) to create a robust design Methods see step 5 Buffer for errors of the measurement systems of X's. Calculate control limits (LCL, UCL) for all X's See step 6 Capability Analysis Multiple Variables compares the capability of two datasets, for example before improvement and after improvement. See step 6

11) Define tolerance limits

12) Validate measurement system In the Control phase you and your project team will: Ensure your measurement system is adequate to measure the Vital Xs Implement all process changes and confirm that your improvement goal is achieved Implementations must be sustainable and the process will stay in control Ensure that you can detect when your process runs out of control of our Xs, so that you can undertake actions to prevent defects from occurring Calculate the final benefits after performing the PCA on the improved process

Eliminating disturbances: Expert Knowledge (analogy, anti-solution, brain Specify tolerances on the critical Xs to meet writing, etc.) our CTQ performance goal Eliminating disturbances: Selection of the best solution (pugh matrix) Robust design: tolerance design Methods see step 5 Validate measurement systems for X's Tolerance design: Buffering for variance of due to the measurement system After the implementation of all appropriate Capability analysis: see step 6 improvement actions we have to determine that we were successful. Statistically confirm Cap An Multiple Variables (normal & non-normal) that our improvement goal has been achieved! Control chart individuals (normal, box-cox); tests Control chart EWMA Control chart Cusum Control chart X Bar & R Control chart X Bar & S To control and anchor long term results. Control chart (all other charts) Finally we hand over the project with its Multivariate Control Charts results to the organisation, who owns this process Out of Control Action plan Poka Yoke Hand-over document Types of Data Mean Median Long term Standard Deviation Short term Standard Deviation Pooled Standard Deviation Other types of Standard Deviation Standard Error of the Mean Confidence intervals (mean, median) Modus Quartiles

13) Determine new process capability

Control

Use the control chart that is most appropriate for your situation

14) Implement Process Controls

Make an action plan that comes into operation when there are signals shown on the Control Chart Determine which mistakes are most likely and define suitable mistake-proofing methods Describe everything that is needed for the process owner and the employees to run the process on the higher performance level (procedures, instructions) Continuous, discrete (binary, category, count) Average Middlemost value Overall standard deviation Average moving range Meant to pool standard deviation across groups Other types of Standard Deviation Standard deviation divided by the square root of the sample size Interval within which the parameter of the population is (with a certain confidence level) Most frequent value in a set of data Q1 (First Quartile): 25% smaller, 75% larger, Q2 (Second Quartile): 50% smaller, 50% larger, Q3 (Third Quartile): 75% smaller, 25% larger Skewness is a measure for symmetry, Kurtosis is a measure of similarity to the normal distribution Probability density function (pdf), or density of a continuous random variable is a function that describes the relative likelihood for this random variable to occur at a given point --> the probability of a certain outcome The probability for the random variable to fall within a particular region is given by the integral of this variables density over the region. Probability distribution for continuous data which can be used to describe the data and calculate probabilities. For example: the probability of a defect Probability distribution for discrete data which can be used to describe the data and calculate probabilities. For example: the probability of a defect Translate the data with a certain function to make it more normal distribution-like

Basic Statistics

Basic Statistics

Basic Statistical knowledge for data-analyses

Skewness & Kurtosis Probability Density Function Cumulative Density Function Normal Probability Distribution Weibull Probability Distribution (2 and 3 parameter) Exponential distribution Binominal Probability Distribution Poisson Probability Distribution Box Cox Transformation & inverse functions Johnson Transformation & inverse functions

Copyright ProjectsOne 2010. All rights reserved. No part of this training material may be reproduced in any form.

You might also like

- Glossary of Key Terms (LSSGB)Document8 pagesGlossary of Key Terms (LSSGB)Sweety ShuklaNo ratings yet

- Project Quality Management A Complete Guide - 2019 EditionFrom EverandProject Quality Management A Complete Guide - 2019 EditionNo ratings yet

- Summary of The Project Phases PDFDocument3 pagesSummary of The Project Phases PDFLourenço PimentaNo ratings yet

- Case Study in Six Sigma Methodology ManufacturingDocument21 pagesCase Study in Six Sigma Methodology ManufacturingNemanja ĆulibrkNo ratings yet

- Manual MINITAB ReferenciasDocument168 pagesManual MINITAB ReferenciasAnonymous WRK1qDcNo ratings yet

- Boston Scientific PrimerDocument2 pagesBoston Scientific PrimerZee MaqsoodNo ratings yet

- A Comparative Review of Lean Thinking Six SigmaDocument36 pagesA Comparative Review of Lean Thinking Six SigmaAbdullah Sabry AzzamNo ratings yet

- Final DmadvDocument39 pagesFinal DmadvMehrad Sarabandi100% (1)

- Management Du Systeme D'Information: Communication Basis Meetings Management Project Reviews Reporting CapitalisationDocument19 pagesManagement Du Systeme D'Information: Communication Basis Meetings Management Project Reviews Reporting CapitalisationSơn Thủy NguyễnNo ratings yet

- Quality Metrics Presentation - June 28 2016 Meeting - FinalDocument31 pagesQuality Metrics Presentation - June 28 2016 Meeting - Finalleonardq1No ratings yet

- Comply with e-signature laws using Adobe SignDocument5 pagesComply with e-signature laws using Adobe SignClaudiaFerriNo ratings yet

- The Dmadv ModelDocument6 pagesThe Dmadv ModelAseel JameelNo ratings yet

- Project Life Cycle & Project Management Process Groups: Information Systems DepartmentDocument63 pagesProject Life Cycle & Project Management Process Groups: Information Systems DepartmentAjmal EnsanahNo ratings yet

- V&V White PaperDocument12 pagesV&V White PaperRichard CarsonNo ratings yet

- Six Sigma - Dmaic StrategyDocument12 pagesSix Sigma - Dmaic StrategyKishor kumar Bhatia100% (1)

- GMP - Design-Construction-Commission-Qualifcation - Critical Utilities - Advanstar - 2005-01 PDFDocument22 pagesGMP - Design-Construction-Commission-Qualifcation - Critical Utilities - Advanstar - 2005-01 PDFbommobNo ratings yet

- Basic Principles of GMP Basic Principles of GMPDocument33 pagesBasic Principles of GMP Basic Principles of GMPTahir KhanNo ratings yet

- Astm-E2500 PDFDocument2 pagesAstm-E2500 PDFPrashhant KavalleNo ratings yet

- Outsourcing Strategies For Capital ProductivityDocument9 pagesOutsourcing Strategies For Capital ProductivitySunnyVermaNo ratings yet

- Operations and Team Leader Empower Training v1128Document102 pagesOperations and Team Leader Empower Training v1128Joana Reyes MateoNo ratings yet

- Quality Management Lean Tools and TechniquesDocument19 pagesQuality Management Lean Tools and TechniquesAmer RahmahNo ratings yet

- Control Charts & GO NO GO GageDocument6 pagesControl Charts & GO NO GO GageRishi AndicoNo ratings yet

- Six Sigma With R: Statistical Engineering For Quality ImprovementDocument2 pagesSix Sigma With R: Statistical Engineering For Quality ImprovementsrinilsukumarkhdNo ratings yet

- Test Method Validation Case StudyDocument2 pagesTest Method Validation Case StudyXiang LiuNo ratings yet

- Six Sigma Quality Improvement at BD CompanyDocument10 pagesSix Sigma Quality Improvement at BD CompanyJLuisCarterNo ratings yet

- LESSON 5 - Quality Planning Understanding Customers and Their NeedsDocument29 pagesLESSON 5 - Quality Planning Understanding Customers and Their Needscelestetorino1No ratings yet

- Turkey Qualification ValidationDocument28 pagesTurkey Qualification ValidationBalesh NidhankarNo ratings yet

- Clinical Risk Management 1.23Document8 pagesClinical Risk Management 1.23MICHAEL BONFACE OJIAMBONo ratings yet

- NAL Manual New Automatic Spray System (12.04.2019)Document32 pagesNAL Manual New Automatic Spray System (12.04.2019)sunil0% (1)

- Product DevelopmentDocument41 pagesProduct DevelopmentSa'ed Abu YahiaNo ratings yet

- Concurrent EngineeringDocument42 pagesConcurrent EngineeringAnonymous p8bHAAxNo ratings yet

- Exploring The Barriers To Lean Health Care ImplementationDocument9 pagesExploring The Barriers To Lean Health Care ImplementationDewina Dyani Rosari IINo ratings yet

- Managerial Decision Modeling GuideDocument191 pagesManagerial Decision Modeling GuideChuvej Chansa-ngavejNo ratings yet

- Automation in Manufacturing Unit-1Document58 pagesAutomation in Manufacturing Unit-1Krishna MurthyNo ratings yet

- Programme-Managing Organisational Performance and Innovative ImprovementDocument23 pagesProgramme-Managing Organisational Performance and Innovative ImprovementTim Molefi100% (1)

- Introduction To Project Management PGPM - Excel Academy: Dr. SN NagendraDocument38 pagesIntroduction To Project Management PGPM - Excel Academy: Dr. SN Nagendraanon_821901807No ratings yet

- Engage in Quality ImprovementDocument21 pagesEngage in Quality ImprovementRegency Placer100% (1)

- Critical Book About Operations ManagementDocument40 pagesCritical Book About Operations ManagementEsra Sitanggang0% (1)

- School of Mechanical and Materials Engineering: Assignment-1Document5 pagesSchool of Mechanical and Materials Engineering: Assignment-1Ismail HussainNo ratings yet

- AQL Testing ChecklistDocument4 pagesAQL Testing ChecklistKEVSERKURTNo ratings yet

- 04 Breakout B-Control Strategy-Key MessagesDocument21 pages04 Breakout B-Control Strategy-Key MessagesOskar LazaroNo ratings yet

- 07 The Case StudyDocument67 pages07 The Case StudyJohn Jairo Trochez AmpudiaNo ratings yet

- 4 DOE Elements of SuccessDocument2 pages4 DOE Elements of SuccesscvenkatasunilNo ratings yet

- Simple Business Plan Outline-01Document33 pagesSimple Business Plan Outline-01vrgurijalaNo ratings yet

- ISO 13485: 2016 Planner and Delta Checklist: InstructionsDocument10 pagesISO 13485: 2016 Planner and Delta Checklist: InstructionsYogesh H NarkhedeNo ratings yet

- Change Control Plan TemplateDocument9 pagesChange Control Plan TemplateNagaraj MuniyandiNo ratings yet

- QC Supervisor or QC Manager or QA Supervisor or QA Manager or ReDocument2 pagesQC Supervisor or QC Manager or QA Supervisor or QA Manager or Reapi-77380607No ratings yet

- R&D EffectivenessDocument13 pagesR&D EffectivenessDhiman ChowdhuryNo ratings yet

- How To Write A Great Corporate Social Responsibility ReportDocument11 pagesHow To Write A Great Corporate Social Responsibility Reportasma246No ratings yet

- Conflict ManagementDocument7 pagesConflict ManagementMichelle Jácome FonsecaNo ratings yet

- Harvard University Syllabus Fall 2011Document3 pagesHarvard University Syllabus Fall 2011danieldarwicheNo ratings yet

- Certified Lean Six Sigma Yellow Belt TrainingDocument2 pagesCertified Lean Six Sigma Yellow Belt TrainingChuckie GarciaNo ratings yet

- Genset Load Bank Test Fuel TestDocument10 pagesGenset Load Bank Test Fuel TestGautham Raavo PainaiduNo ratings yet

- Software Development Project Manager in San Diego or Orange County California ResumeDocument2 pagesSoftware Development Project Manager in San Diego or Orange County California ResumeTerry MillerNo ratings yet

- FSC Interpretations Chain of Custody 2021.07.05Document49 pagesFSC Interpretations Chain of Custody 2021.07.05Budi Suryo UntoroNo ratings yet

- Measurement Systems Analysis: Total Quality ManagementDocument17 pagesMeasurement Systems Analysis: Total Quality ManagementmanuelNo ratings yet

- PO10 - Maintain An Organizational UnitDocument13 pagesPO10 - Maintain An Organizational Unithans_106No ratings yet

- Six Sigma Black Belt Exam ReviewDocument1 pageSix Sigma Black Belt Exam Reviewhans_106No ratings yet

- Meg de KoningDocument2 pagesMeg de Koninghans_106No ratings yet

- Assessing The Feasibility of Security MetricsDocument8 pagesAssessing The Feasibility of Security Metricshans_106No ratings yet

- SSBB AffidavitDocument2 pagesSSBB AffidavitRahul BhatnagarNo ratings yet

- Dynamics 365 For Finance and OperationsDocument14 pagesDynamics 365 For Finance and Operationshans_106No ratings yet

- BOK Six Sigma Black BeltDocument8 pagesBOK Six Sigma Black Belthans_106No ratings yet

- Request For QuotationDocument2 pagesRequest For Quotationhans_106No ratings yet

- Manual Minitab 16 Eng PDFDocument122 pagesManual Minitab 16 Eng PDFhans_106No ratings yet

- Z97 Extreme6 PDFDocument114 pagesZ97 Extreme6 PDFhans_106No ratings yet

- Server HardeningDocument1 pageServer Hardeninghans_106No ratings yet

- 1001 Audit Charter PDFDocument3 pages1001 Audit Charter PDFhans_1060% (1)

- Lect 4 - TQM Basic TenetsDocument40 pagesLect 4 - TQM Basic Tenetshans_106No ratings yet

- TQM EvolutionDocument69 pagesTQM EvolutionVijayakumarNo ratings yet

- eTOM Poster 8Document1 pageeTOM Poster 8rberganzaNo ratings yet

- Students As Customers: The Net Promoter Score As A Measure of Satisfaction and Loyalty in Higher EducationDocument10 pagesStudents As Customers: The Net Promoter Score As A Measure of Satisfaction and Loyalty in Higher Educationhans_106No ratings yet

- 01-05 eTOM and ITIL - Huang PDFDocument6 pages01-05 eTOM and ITIL - Huang PDFMayank SrivastavaNo ratings yet

- CISA Task StatementsDocument3 pagesCISA Task Statementshans_1060% (1)

- SAP BI Guide MaterialDocument32 pagesSAP BI Guide Materialgrkayyappa001No ratings yet

- BusinessObjects Enterprise InfoView User's GuideDocument240 pagesBusinessObjects Enterprise InfoView User's GuidebeyondgoodNo ratings yet

- 4 Steps To VSMDocument12 pages4 Steps To VSMJaqui MartinezNo ratings yet

- Siebel CRM 100 SuccessDocument209 pagesSiebel CRM 100 Successhans_106No ratings yet

- Understanding+the+changes+EN ISO14971 2012Document21 pagesUnderstanding+the+changes+EN ISO14971 2012hans_106No ratings yet

- Manual Minitab 16 Eng PDFDocument122 pagesManual Minitab 16 Eng PDFhans_106No ratings yet

- ISO IEC 17021 Documentation RequirementsDocument15 pagesISO IEC 17021 Documentation RequirementsSunil Arora100% (1)

- What Is 6-SgmaDocument14 pagesWhat Is 6-SgmaAhmedHafez80No ratings yet

- Start of Process: Title (Current/Future)Document2 pagesStart of Process: Title (Current/Future)hans_106No ratings yet

- VSM SheetsDocument19 pagesVSM Sheetshans_106No ratings yet

- Lean and Clean Value Stream MappingDocument11 pagesLean and Clean Value Stream MappingMansoor AliNo ratings yet

- The Stochastic Oscillator - A Harmonious System of TradingDocument9 pagesThe Stochastic Oscillator - A Harmonious System of TradingMirabo AndreeaNo ratings yet

- Journal of English For Academic Purposes: Christopher Hill, Susan Khoo, Yi-Chin HsiehDocument13 pagesJournal of English For Academic Purposes: Christopher Hill, Susan Khoo, Yi-Chin Hsiehshuyu LoNo ratings yet

- Cyient - Oil and Gas IndustryDocument8 pagesCyient - Oil and Gas Industrycyient_analyticsNo ratings yet

- 1Document584 pages1Devender Mudgal100% (1)

- Easy Guide To Learn How To Write A Thesis IntroductionDocument1 pageEasy Guide To Learn How To Write A Thesis IntroductionBernadette PagapangNo ratings yet

- Process - st-dMAIC The Complete Guide To Lean Six Sigma in 5 Key StepsDocument25 pagesProcess - st-dMAIC The Complete Guide To Lean Six Sigma in 5 Key Stepslipsy25No ratings yet

- CaSe StudyDocument5 pagesCaSe StudySachin YadavNo ratings yet

- The Emotional Intelligence-Sales Performance Relationship PDFDocument94 pagesThe Emotional Intelligence-Sales Performance Relationship PDFelisaNo ratings yet

- Kamrul Hasan PDFDocument153 pagesKamrul Hasan PDFayshabegumNo ratings yet

- Thefirstdayofschoolharrywong PDFDocument339 pagesThefirstdayofschoolharrywong PDFsauldez100% (1)

- Group 9 - ANALYTICAL RESEARCHDocument36 pagesGroup 9 - ANALYTICAL RESEARCHGenuslee MapedzeNo ratings yet

- Calculating Variance and Standard Deviation of Discrete Random VariablesDocument3 pagesCalculating Variance and Standard Deviation of Discrete Random VariablesGeosippi San Antonio LaymanNo ratings yet

- Research Final ProjectDocument17 pagesResearch Final ProjectbagusNo ratings yet

- Group A - Consolidated Article Critique - Managing Family Business TensionsDocument4 pagesGroup A - Consolidated Article Critique - Managing Family Business TensionsRonelyCalairoNo ratings yet

- An Assessment of The Critical Success Factor For The Reduction of Cost of Poor Quality in Construction Projects in Swaziland.Document7 pagesAn Assessment of The Critical Success Factor For The Reduction of Cost of Poor Quality in Construction Projects in Swaziland.Juan AlayoNo ratings yet

- Rinkal Solanki PDFDocument61 pagesRinkal Solanki PDFSinuminu0% (1)

- Reading and Summarizing A Research Article (QALMRI)Document2 pagesReading and Summarizing A Research Article (QALMRI)vanjunior2014No ratings yet

- DemintroDocument31 pagesDemintroiketNo ratings yet

- Module Handbook For Negotiated Learning (Work Based Learning) Academic Year 2021/22Document9 pagesModule Handbook For Negotiated Learning (Work Based Learning) Academic Year 2021/22Calum SyersNo ratings yet

- Sports Betting Literature ReviewDocument29 pagesSports Betting Literature ReviewSeven StreamsNo ratings yet

- Job Stress and Its Impact On Employees' Performance A Study With Reference To Employees Working in Bpos M.Kotteeswari Dr.S.Tameem ShariefDocument8 pagesJob Stress and Its Impact On Employees' Performance A Study With Reference To Employees Working in Bpos M.Kotteeswari Dr.S.Tameem ShariefAnonymous 18INMzLJNo ratings yet

- Knowledge-Based Dynamic Capabilities - A Scientometric Analysis of Marriage Between Knowledge Management and Dynamic CapabilitiesDocument35 pagesKnowledge-Based Dynamic Capabilities - A Scientometric Analysis of Marriage Between Knowledge Management and Dynamic CapabilitiesGil Santos DosNo ratings yet

- Comparative Study of Infrastructure, Teaching and Results in Girls and Boys Secondary SchoolsDocument48 pagesComparative Study of Infrastructure, Teaching and Results in Girls and Boys Secondary SchoolsimranNo ratings yet

- Quantitative-Methods Summary-Qm-NotesDocument35 pagesQuantitative-Methods Summary-Qm-NotesShannan RichardsNo ratings yet

- Impact of Music Therapy On DementiaDocument6 pagesImpact of Music Therapy On DementiaSaul MorenoNo ratings yet

- W8 Pembolehubah Dan Skala PengukuranDocument38 pagesW8 Pembolehubah Dan Skala PengukuranIlley IbrahimNo ratings yet

- How To Write An Introduction For A Research Paper PowerpointDocument6 pagesHow To Write An Introduction For A Research Paper Powerpointefhs1rd0No ratings yet

- Chem 162 Formal Lab ReportDocument5 pagesChem 162 Formal Lab ReportLiem LimantoNo ratings yet

- SW 3050 Miley Text Discussion Questions (For Reading Responses)Document6 pagesSW 3050 Miley Text Discussion Questions (For Reading Responses)Ronie Enoc SugarolNo ratings yet

- EDUU 512 RTI Case Assignment DescriptionDocument2 pagesEDUU 512 RTI Case Assignment DescriptionS. Kimberly LaskoNo ratings yet