Professional Documents

Culture Documents

Manual 066 Sample

Uploaded by

Vizit310 ratings0% found this document useful (0 votes)

22 views6 pagesffdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentffdf

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

22 views6 pagesManual 066 Sample

Uploaded by

Vizit31ffdf

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

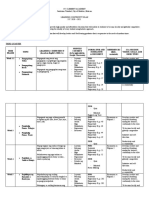

Manual 066 Requirements for Facilities For Sterile and Non-sterile Drug Manufacture

Copyrightwww.gmpsop.com. All rights reserved

Unauthorized copying, publishing, transmission and distribution of any part of the content by electronic

means are strictly prohibited. Page 2 of 13

1 Purpose

The purpose of this Guideline is to describe the requirements for meeting current

Good Manufacturing Practice (cGMP) compliance requirements for new and

upgraded facilities to be used for the manufacturing of any sterile and non sterile

product. The Guideline also aims to provide recommendations on how to achieve

compliance with the requirements.

This Guideline defines a consistent approach for establishing facilities for the

manufacture of sterile and non-sterile products using the classification set out in,

EU Good Manufacturing Practice (GMP) Annex 1, FDA 21 Code of Federal

Regulation (CFR) and International Standardization Organization (ISO) 14644-1.

Specific technical details are beyond the scope of this document; however,

individuals are referred to the International Society For Pharmaceutical

Engineering (ISPE) Pharmaceutical Engineering Guides for New and Renovated

Facilities for essential detail.

Local legislation, regulatory requirements and engineering standards with respect

to facilities will take precedence over this Guideline.

2 Scope and Applicability

This Guideline is applicable to all Operations, Marketing Companies (MCs) and

Research and Development (R&D) sites, functions and departments undertaking

work, or providing support services, required to meet cGMP or, in absence of a GMP

standard, ISO standards. Manufacturing of Active Pharmaceutical Ingredient (API) is

excluded from this Guideline.

3 Definitions

3.1 General Manufacturing Areas

Processing and packaging areas where GMP activities are taking place for non-

sterile dosage forms. Minimum requirements are discussed with the recognition

that additional engineering controls are needed as product potency, degree of

separation, degree of exposure, extent of validation, and other considerations

enter into particular site product mix and circumstances for example there are

requirements for inhalation products being manufactured in Grade D.

3.2 Air Classification

Level (or the process of specifying or determining the level) of airborne

particulate cleanliness applicable to a clean room and clean area, expressed in

terms of EU Grades, which represents maximum allowable (in particles per cubic

metre of air) for considered sizes of particles.

The comparison between EU Grades, FDA classification and ISO classes are

defined in appendix A.

Manual 066 Requirements for Facilities For Sterile and Non-sterile Drug Manufacture

Copyrightwww.gmpsop.com. All rights reserved

Unauthorized copying, publishing, transmission and distribution of any part of the content by electronic

means are strictly prohibited. Page 4 of 13

5.1.3 Access

For product safety and security reasons, doors to production and storage

areas must be secured such that access is only given to authorized personnel.

Emergency exits should be sealed for day-to-day operations but providing

immediate exit in case of emergency.

5.2 Environmental Conditions

All environmental conditions for clean areas must be classified and

maintained in accordance with requirements in EU GMP Annex 1 and FDA

21 CFR, Guidance for Industry Sterile Drug Products By Aseptic

Processing, September 2004, ISO 14644-1and IPSE Pharmaceutical

Engineering Guides for New and Renovated Facilities, Volume 2, Oral Dosage

Forms and Volume 3 Sterile Manufacturing Facilities as appropriate. Comparison

tables for particles and microbiological organisms see Appendix A - B.

Sites manufacturing for global markets should adhere to the strictest requirements

described in Appendix A B in order to meet all market requirements.

5.2.1 Environmental Conditions for Sterile Manufacturing

Sterile manufacturing must take place in clean areas. The areas should be

classified in accordance with the requirements in Appendix A - B.

All areas must be built and validated to meet these requirements.

The particulate conditions for Grade A should be maintained in the zone

immediately surrounding the product whenever the product or open container is

exposed to the environment. It is accepted that it may not always be possible to

demonstrate conformity with particulate standards at the point of fill when filling

is in progress, for example due to the generation of particles and droplets from the

product itself. There should be written justifications for any situation or process

steps where this could apply.

The particulate conditions for the at rest state should normally be achieved in the

unmanned state after a short clean up period of 15 - 20 minutes after completion

of operations. This cleanup period should be validated and periodically

monitored.

In some cases, the processing room and the adjacent clean rooms have the same

classification. Maintaining a pressure differential between the processing rooms

and the adjacent rooms can provide beneficial separation.

In order to reach Grade A, B and C the number of air changes should be related to

the activity of the room.

Re-circulation of air within clean areas should not be practiced where the

activities are creating dust. Re-circulation should preferably not be used to re-

circulate air from areas where different products are handled. In cases where re-

circulation is practiced the air should pass a filter system of an appropriate filter

Manual 066 Requirements for Facilities For Sterile and Non-sterile Drug Manufacture

Copyrightwww.gmpsop.com. All rights reserved

Unauthorized copying, publishing, transmission and distribution of any part of the content by electronic

means are strictly prohibited. Page 6 of 13

also minimized and protection is provided against contamination during filling

and closing of units.

Grade Examples of operations for blow/fill/seal technology

A Blow/fill/seal equipment used for aseptic production.

C

The background environment for blow/fill/seal equipment used

for aseptic production provided that Clean Area A/B clothing is

used.

D Blow/fill/seal equipment used for terminally sterilized production.

5.2.2 Environmental Conditions for Non-sterile Manufacturing

Non-sterile manufacturing should take place in general manufacturing areas.

There are no cGMP requirements to classify these areas with the exemption of

manufacturing of inhalation products, which must take place in Grade D.

Good engineering practice (GEP) should dictate the basic requirements for these

areas. The ISPE Pharmaceutical Engineering Guide for New and Renovated

Facilities, Volume 2, Oral Solid Dosage Forms should be consulted.

Re-circulation of air within general manufacturing areas should be justified and it

should be taken into account process activities that create dust. In cases where re-

circulation is practiced the air should pass a filter system of an appropriate filter

efficiency to avoid cross-contamination and to prevent recirculation of dust from

production. In areas where air contamination occurs during production,

consideration should be given to provide localized exhaust systems or other

means to minimize potential for cross contamination.

5.3 Production Areas

5.3.1 Layout

The layout of areas must minimize the possibility of product mix-ups.

The adequacy of the working and in-process storage space must permit the

orderly and logical positioning and separation of equipment and materials so

as to minimize the risk of confusion between different medicinal products or

their components, to avoid cross-contamination and to minimize the risk of

omission or wrong application of any of the manufacturing or control steps.

5.3.2 Air Treatment (HVAC)

5.3.2.1 General

Production areas should be effectively ventilated, by air handling units (including

filtration control and when necessary temperature and humidity control)

appropriate to the products handled, to the operating personnel, to the operations

undertaken within them and to external environment.

Temperature and humidity controls should be considered in terms of potential

adverse effect on the medicinal products during their manufacture and storage, or

the accurate functioning of equipment. Areas were aseptic processing takes

Manual 066 Requirements for Facilities For Sterile and Non-sterile Drug Manufacture

Copyrightwww.gmpsop.com. All rights reserved

Unauthorized copying, publishing, transmission and distribution of any part of the content by electronic

means are strictly prohibited. Page 8 of 13

Windows must be installed with tight connections to the wall. The number

and area of horizontal surfaces in the installation must be kept to a

minimum. Windows must be easy to clean, fixed and not capable of being

opened.

Windows should be in level with walls and ceilings.

5.3.7 Sinks and Drains

Separate process and sanitary drainage must be provided. Drains must be of

adequate size and, were connected directly to a sewer, must be provided with

an air break or other mechanical device to prevent back-siphonage. They

must be easy to clean. The floor must slope locally towards the drain.

Overflow outlets should normally not be used.

Floor drains with minimal usage should be filled with vegetable oil or contain a

trap primer in order to prevent the trap from drying out.

5.3.7.1 Special Requirements in Sterile Manufacturing

Sinks and drains should be prohibited in Grade A and B areas used for aseptic

manufacture.

5.3.8 Installations

All permanent pipe work, light fittings, ventilation ducts and other services in

classified areas should be designed and installed to avoid uncleanable recesses.

Services should run outside the processing areas and should be sealed into walls

and partitions through which they pass. The sealed pass through should be

designed to withstand vibrations.

Fixed equipment should be installed without any recesses where dirt can accumulate.

5.3.9 Airlocks

The use of airlocks should be considered as part of any manufacturing facility

design. Airlocks are one means to control containment necessary due to process

or product requirements.

Personnel airlocks may be necessary for connection of areas where dust-

generating processes are performed or certain active substances are handled. Such

airlocks should be provided with cleaning facilities as needed.

The airlocks must have a system in place to prevent the opening of entry and

exit doors at the same time. This could be achieved by means of an interlocking

system and the doors should be self-closing.

5.3.9.1 Special Requirements for Sterile Manufacturing

Personnel Airlocks

Manual 066 Requirements for Facilities For Sterile and Non-sterile Drug Manufacture

Copyrightwww.gmpsop.com. All rights reserved

Unauthorized copying, publishing, transmission and distribution of any part of the content by electronic

means are strictly prohibited. Page 10 of 13

and/or dispensing. Operator comfort should be taken into account when setting

the temperature and humidity requirements; particularly when operators are

wearing suits made of synthetic non-breathing materials.

Manual 066 Requirements for Facilities For Sterile and Non-sterile Drug Manufacture

Copyrightwww.gmpsop.com. All rights reserved

Unauthorized copying, publishing, transmission and distribution of any part of the content by electronic

means are strictly prohibited. Page 12 of 13

You might also like

- Midsem Exam 2011Document6 pagesMidsem Exam 2011Vizit31No ratings yet

- VAL-030 Equipment Specification and Qualification SampleDocument2 pagesVAL-030 Equipment Specification and Qualification SampleVizit31No ratings yet

- VAL-095 Facility and Utility Validation Guideline SampleDocument1 pageVAL-095 Facility and Utility Validation Guideline SampleVizit31No ratings yet

- VAL-090 Equipment Validation Guideline SampleDocument2 pagesVAL-090 Equipment Validation Guideline SampleVizit31No ratings yet

- VAL-085 Process Validation Guideline SampleDocument2 pagesVAL-085 Process Validation Guideline SampleVizit31No ratings yet

- Standard Operating Procedure Title:: EHS StatementDocument2 pagesStandard Operating Procedure Title:: EHS StatementVizit31No ratings yet

- MICLAB 035 SampleDocument6 pagesMICLAB 035 SampleVizit31No ratings yet

- VAL-020 Procedure For Cleaning Validation SampleDocument3 pagesVAL-020 Procedure For Cleaning Validation SampleVizit31No ratings yet

- MICLAB 060 SampleDocument7 pagesMICLAB 060 SampleVizit31No ratings yet

- MICLAB 065 SampleDocument1 pageMICLAB 065 SampleVizit31No ratings yet

- Stainless Steels and Drinking Water Around The WorldDocument12 pagesStainless Steels and Drinking Water Around The WorldVizit31No ratings yet

- Grams/Litre Ingredients Grams/Litre: Page 1 of 2Document2 pagesGrams/Litre Ingredients Grams/Litre: Page 1 of 2Vizit31No ratings yet

- MICLAB 055 Sample 2Document4 pagesMICLAB 055 Sample 2Vizit31No ratings yet

- Manual 062 SampleDocument1 pageManual 062 SampleVizit31No ratings yet

- Ucm 072171Document23 pagesUcm 072171Vizit31No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Product PolyolDocument1 pageProduct PolyolAgung SiswahyuNo ratings yet

- Air ConditionerDocument131 pagesAir ConditionerRahul AnsariNo ratings yet

- Synapse: I. Anatomical TypesDocument5 pagesSynapse: I. Anatomical TypesAswin AjayNo ratings yet

- Tomorrow Is WaitingDocument8 pagesTomorrow Is WaitingsrplsmskNo ratings yet

- Dissertation Fight ClubDocument5 pagesDissertation Fight ClubWriteMyPaperForMeCheapAlbuquerque100% (1)

- Flsmidth Private Limited: Quality Assurance Plan of Exciter CasingDocument5 pagesFlsmidth Private Limited: Quality Assurance Plan of Exciter CasingMohammad AdilNo ratings yet

- Atomic Physics Exam Qs StudentDocument7 pagesAtomic Physics Exam Qs StudentfitzttNo ratings yet

- EPR in Waste ManagementDocument11 pagesEPR in Waste Managementdorexp17No ratings yet

- Listado de Vehiculos para ChatarrizaciónDocument658 pagesListado de Vehiculos para ChatarrizacióntaycotcNo ratings yet

- WAP Push and MMS For Android Rev6Document4 pagesWAP Push and MMS For Android Rev6Shruti MahadikNo ratings yet

- Formal Declarative EndingDocument13 pagesFormal Declarative EndingMary Mariette EscalanteNo ratings yet

- Workshop On Previewing - CECARDocument12 pagesWorkshop On Previewing - CECARestefaany tejada100% (2)

- Afloat 2Document256 pagesAfloat 2Matthaios SkantrzourakisNo ratings yet

- Quiz 14Document2 pagesQuiz 14warning urgentNo ratings yet

- Cisco Catalyst 4500 Information SheetDocument3 pagesCisco Catalyst 4500 Information SheetEva CastilloNo ratings yet

- Combat Patrol - GREY KNIGHTSDocument6 pagesCombat Patrol - GREY KNIGHTSJan PolisiakNo ratings yet

- Qualities of Effective Business LettersDocument39 pagesQualities of Effective Business Letterskrystel0% (1)

- Momento de Inercia GD2 PDFDocument9 pagesMomento de Inercia GD2 PDFDavid Delgado RendónNo ratings yet

- FILIPINO 2 LEARNING PLAN 3rd QuarterDocument4 pagesFILIPINO 2 LEARNING PLAN 3rd QuarterMary Kryss DG SangleNo ratings yet

- Hydro Corr TestDocument19 pagesHydro Corr TestPramoth NarashimmanNo ratings yet

- 2021 Test3 Part5Document9 pages2021 Test3 Part5Sicut DilexiNo ratings yet

- Architecture As SpaceDocument31 pagesArchitecture As Spaceazimkhtr50% (4)

- Course Outline BRM AbasynDocument4 pagesCourse Outline BRM Abasynsadeeq sahilNo ratings yet

- F Series Flexible Elastic Resin InstructionDocument5 pagesF Series Flexible Elastic Resin InstructionChristian EnglandNo ratings yet

- 15.guitar ElectronicsDocument48 pages15.guitar Electronics王斌No ratings yet

- Lab-Journal Compiler ConstructionDocument20 pagesLab-Journal Compiler ConstructionAbdullah ArshadNo ratings yet

- Aspiration PneumoniaDocument3 pagesAspiration PneumoniaEllen Hennings100% (1)

- 10.21307 - Immunohematology 2022 048 PDFDocument6 pages10.21307 - Immunohematology 2022 048 PDFTanupreetNo ratings yet

- En Firearms Evaluation ReportDocument168 pagesEn Firearms Evaluation Reportandrew_davidson100% (2)

- MBA: International Business: SchillerDocument2 pagesMBA: International Business: SchillernancyekkaNo ratings yet