Professional Documents

Culture Documents

Process Improvement Model

Uploaded by

Fouzan SoniwalaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Improvement Model

Uploaded by

Fouzan SoniwalaCopyright:

Available Formats

FICCI

CE

Process Improvement model

FICCI

CE

Process Improvement model

2. Application of Process improvement Principles

1.

F E E D B A C K L O O P

Operational Analysis of process Who, what, how & where

3. Benchmarking

4. PDCA

FICCI

CE

Process improvement principles

1. Waste Reduction

Process Improvement Principles

2. Process Simplification 3. Cycle-time reduction 4. Process measures 5. Mistake - proofing

FICCI

CE

1. Waste reduction

The first step in improving a processes is to eliminate waste with the following techniques :I. Value-added assessment II. Eliminating non-value adding activities III. Minimize checks and inspections IV. Minimize administrative tasks V. Minimize storage and transportation activities

FICCI

CE

I. Value added assessment

Value to customer : First, the customers view point should be considered. The customers are only interested in receiving the product or service that satisfies their requirements. All activities that must be performed to cater to the customers requirements are value -added activities.

FICCI

CE

Does the activity add value to the customer ?

Would any customer care if the activity was not performed ? Would any customer object if the activity was not performed ? Do the customers appreciate the results of the activity?

FICCI

CE

II. Eliminate non-value adding activities

Value to business : There are many activities that may not add value from the customers point of view. Attending meetings, developing plans, compliance with regulatory guidelines, writing procedures etc are examples of activities that may not add value to the customers, but they do add value to the organization. Each of these activities must be carefully examined.

FICCI

CE

III. Minimize checks & inspections

Checks and inspections may be necessary in a process, however they do not add value to the process. Each inspection point should be identified and challenged. The next slide lists some questions to use in this challenge.

FICCI

CE

What if the inspection was eliminated?

What if the inspection was eliminated? Would the inspection be missed? What is the potential impact in eliminating the inspection? What potential consequences exist if the inspection is eliminated? What is the likelihood that the inspection would have revealed a problem?

FICCI

CE

IV. Minimize administrative tasks

Administrative tasks often result in delays in process time due to excessive paper work, levels of reviews and multiple signatures (mostly by people who, it seems, are never available when needed). Reviews, approvals, signatures, preparing written documentation, making and distributing copies etc needs to be thoroughly reviewed..

FICCI

CE

V. Minimize storage and transportation activities

Sometimes storage and transportation are necessary evils but because they are both non-value adding they should be minimized. The purpose of just-in-time inventory systems to minimize the amount of inventory stored.

FICCI

CE

Minimize storage and transportation activities

Transportation activities are also non-value adding. Often the relocation of single activity can significantly reduce the transportation requirements.

FICCI

CE

2. Process simplification

Simplification means reducing the complexities of process. Simplification can lead to lessor activities and lessor things to go wrong. Process simplification can be done by combining similar activities and by analyzing decision points. Efforts should focus on reducing layers of management and structures that cause delays. Outdated systems and procedures need to be evaluated.

FICCI

CE

Old Process

Visit Bank

Example of waste elimination: Cash withdrawal

New Process

Present Cheque Visit ATM Quality checks built-in

WASTE

Balance verification Withdraw cash

Collect cash

FICCI

CE

3. Cycle-time reduction

Cycle-time is the time required to deliver a product or service to a customer. Long cycle-times not only prevent prompt delivery of product/ service to your customers, but also increase costs. One of the best ways to cut down on your cycle-time is to conduct activities in parallel and eliminate unnecessary waste times as demonstrated on the next slide.

FICCI

CE

1. Activities Performed in serial

2. Activities performed in parallel

FICCI

CE

4. Create and implement performance based measures

If the performance of any system or process is not measured, it can not be meaningfully improved. Quantitative and qualitative measures that address both objective and subjective elements should be implemented. The measures recommended are Revenue per employee, percent defectives, cost of quality, profitability ratios, customer satisfaction index etc.

FICCI

CE

Incorrect performance measures create barriers

Profit

Strategies Sales Customer satisfaction

Build inventory

Many unfocused projects

Select low price supplier Performance measures

Efficiency variance

Many improved teams

Purchase price

FICCI

CE

Correct performance measures

Profit

Sales Customer satisfaction Strategies Performance measures

Cycle-time

Cost of poor quality

Supplier quality

FICCI

CE

5. Mistake proofing

Mistake proofing is a scientific technique for improvement of operating systems including materials, machines and methods with an aim of preventing problems due to human error. The term error means a sporadic deviation from standard procedures resulting from loss of memory, perception or motion.

For more details see Mistake proofing under M

You might also like

- Function keys in ExcelDocument27 pagesFunction keys in Excel1012804201No ratings yet

- Auto Tax CalculatorDocument7 pagesAuto Tax CalculatorFouzan SoniwalaNo ratings yet

- Perfect Written EnglishDocument174 pagesPerfect Written EnglishArzuPal100% (23)

- Communication Skills PDFDocument145 pagesCommunication Skills PDFaumakua100% (1)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Business Excellence AssessmentDocument30 pagesBusiness Excellence AssessmentFouzan SoniwalaNo ratings yet

- Susan Morem-101 Tips For Graduates - A Code of Conduct For Success and Happiness in Your Professional Life-Ferguson - Facts On File (2005)Document225 pagesSusan Morem-101 Tips For Graduates - A Code of Conduct For Success and Happiness in Your Professional Life-Ferguson - Facts On File (2005)Domingos TolentinoNo ratings yet

- Karate DanDocument8 pagesKarate DanFouzan SoniwalaNo ratings yet

- Health TipsDocument36 pagesHealth TipsAmit PandeyNo ratings yet

- Working With LanguageDocument240 pagesWorking With LanguageFouzan Soniwala100% (1)

- EffeEffective Speakingctive SpeakingDocument288 pagesEffeEffective Speakingctive SpeakingArief RahmanNo ratings yet

- English To Hindi Dictionary Roman LipiDocument717 pagesEnglish To Hindi Dictionary Roman Lipisonuakhil60% (5)

- Brain Storming - ToolDocument5 pagesBrain Storming - ToolFouzan SoniwalaNo ratings yet

- Business Process Reengg - TechniqueDocument8 pagesBusiness Process Reengg - TechniqueFouzan SoniwalaNo ratings yet

- Employee AttitudeDocument9 pagesEmployee AttitudeshalinivalechhaNo ratings yet

- Employee RecognitionDocument8 pagesEmployee RecognitionFouzan SoniwalaNo ratings yet

- Emotional IntelligenceDocument6 pagesEmotional IntelligenceFouzan SoniwalaNo ratings yet

- Employee RetentionDocument4 pagesEmployee RetentionFouzan SoniwalaNo ratings yet

- Eliminating Non Value Adding ActivitiesDocument8 pagesEliminating Non Value Adding ActivitiesFouzan SoniwalaNo ratings yet

- Earnings Strength Comparison Jun 2007Document15 pagesEarnings Strength Comparison Jun 2007Fouzan SoniwalaNo ratings yet

- PDCA CycleDocument10 pagesPDCA CycleFouzan SoniwalaNo ratings yet

- DMAICDocument8 pagesDMAICranydiNo ratings yet

- Customers - Best PracticesDocument7 pagesCustomers - Best PracticesFouzan SoniwalaNo ratings yet

- Design of Experiments - ToolDocument17 pagesDesign of Experiments - ToolFouzan SoniwalaNo ratings yet

- Deming - Quality GuruDocument4 pagesDeming - Quality GuruFouzan SoniwalaNo ratings yet

- Customer Practices of Global LeadersDocument17 pagesCustomer Practices of Global LeadersFouzan SoniwalaNo ratings yet

- Deming Prize AwardDocument2 pagesDeming Prize AwardFouzan SoniwalaNo ratings yet

- Cycle TimeDocument2 pagesCycle TimeFouzan SoniwalaNo ratings yet

- Customer Supplier - ModelDocument5 pagesCustomer Supplier - ModelmuneerppNo ratings yet

- Customer Satisfaction ManagementDocument12 pagesCustomer Satisfaction ManagementFouzan SoniwalaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Sun Tzu and Information Warfare PDFDocument178 pagesSun Tzu and Information Warfare PDFtazman10102458100% (4)

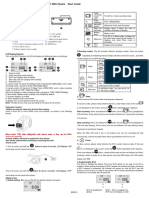

- Denver Ac-5000w Mk2 - EnglishDocument2 pagesDenver Ac-5000w Mk2 - EnglishPrva CetaNo ratings yet

- Samsung CS29A5HT8XBWT PDFDocument53 pagesSamsung CS29A5HT8XBWT PDFHootOwl IDNo ratings yet

- Literature Review For Petrol Station Management SystemDocument7 pagesLiterature Review For Petrol Station Management Systemc5qp53eeNo ratings yet

- 3HAC049194 AM Lincoln ArcLink Interface and Weld Editor-EnDocument48 pages3HAC049194 AM Lincoln ArcLink Interface and Weld Editor-EnRosmery MilagrosNo ratings yet

- Limits of Variations of Inlet Steam ConditionsDocument1 pageLimits of Variations of Inlet Steam ConditionsShashi NaganurNo ratings yet

- Syllabus - Ec E16 - Satellite Communication SystemsDocument2 pagesSyllabus - Ec E16 - Satellite Communication SystemsPRADEEP JNo ratings yet

- Process DocumentationDocument26 pagesProcess DocumentationKhaleel NazeerNo ratings yet

- Ti Sns50-Hba0-S01 1034097Document8 pagesTi Sns50-Hba0-S01 1034097zaleksNo ratings yet

- MySQL Triggers GuideDocument21 pagesMySQL Triggers Guidesatya prakash singhNo ratings yet

- DAQO CatalogueDocument24 pagesDAQO CatalogueZigor Larrabe UribeNo ratings yet

- Uci 401 AssignmentDocument15 pagesUci 401 Assignmentevans kiplimoNo ratings yet

- Manual Tecnico InglesDocument6 pagesManual Tecnico InglesyuleysNo ratings yet

- It SecurityDocument285 pagesIt SecuritySUSOVAN GARAINo ratings yet

- KD-208 User ManualDocument17 pagesKD-208 User ManualmazacotesNo ratings yet

- Unit 2 - Practice 1Document11 pagesUnit 2 - Practice 1Mauricio MartinezNo ratings yet

- IT Disaster Recovery Planning ChecklistDocument2 pagesIT Disaster Recovery Planning ChecklistYawe Kizito Brian PaulNo ratings yet

- TD100 VDM Installation ManualDocument25 pagesTD100 VDM Installation ManualSumit KumarNo ratings yet

- Google Analytics Individual Qualification Certification AnswersDocument15 pagesGoogle Analytics Individual Qualification Certification AnswersE KaynaklarNo ratings yet

- 2021 UNI-T InstrumentsDocument70 pages2021 UNI-T InstrumentsOdyem SadamNo ratings yet

- Silibus Dum 20022Document266 pagesSilibus Dum 20022lyssa daudNo ratings yet

- New Office ShredderDocument2 pagesNew Office ShredderR Lilianitha SiboNo ratings yet

- Maintenance of Electrical Equipment For FM Personnel: E-LearningDocument1 pageMaintenance of Electrical Equipment For FM Personnel: E-LearningNigel AngNo ratings yet

- Design of Engine Cylinder Block : M NareshDocument4 pagesDesign of Engine Cylinder Block : M NareshMudavath NareshNo ratings yet

- CO & A All Modules Notes 21CS34 PDFDocument190 pagesCO & A All Modules Notes 21CS34 PDFMalini R100% (1)

- Thesis Power System SecurityDocument8 pagesThesis Power System Securitytsfublhld100% (2)

- Sunrise Systems: Presentation Pipenet SoftwareDocument35 pagesSunrise Systems: Presentation Pipenet SoftwareKathirNo ratings yet

- Professional Resume Form For Key Project Personnel: Job HistoryDocument4 pagesProfessional Resume Form For Key Project Personnel: Job HistoryUbaid ZiaNo ratings yet

- EE021 - Sub-Station Earth Grid DesignDocument4 pagesEE021 - Sub-Station Earth Grid DesignbhavikNo ratings yet

- Hirakud-Odisha: S.No Equipment Specification Qty (Nos) SpecificationDocument2 pagesHirakud-Odisha: S.No Equipment Specification Qty (Nos) SpecificationHytech Pvt. Ltd.No ratings yet