Professional Documents

Culture Documents

Classification of Garment Pressing Equipment: Need For Ironing/Pressing

Uploaded by

agga1111Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Classification of Garment Pressing Equipment: Need For Ironing/Pressing

Uploaded by

agga1111Copyright:

Available Formats

INTRODUCTION In the garment industry, equipment for handling fabrics with damp heat to iron surfaces, fold edges,

iron out seams, shape flat parts, and raise the pile during the manufacture of clothing. Ironing and pressing equipment shapes the semi finished garment by bringing the fabric fibers into a highly elastic state and then deforming and setting them.

Need for Ironing/Pressing

To smooth away unwanted creases and crush marks:- these are normally caused by bad operator handling. To make creases where the designs of the garment requires them:- for eg creases in trousers and skirts. To mould the garment to the contour of the body:

Ironing: It is the process of using an iron to remove wrinkles from damp, washable clothing. Heat and pressure are used to flatten the fabric. Ironing is done with a gliding or sliding motion. It is done to entire garments after laundering.

Elements of Pressing Heat Steam (Moisture) Pressure Vacuum

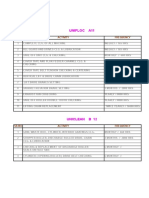

Classification Of Garment Pressing Equipment

There are various types of garment pressing equipment used in the garment industry for different types of garments. Most garment pressing equipment machines range from miniature ironing boards to specialized steam machinery for different types of garments. Pressing equipment is also used in industries such as Laundromats and small fabric shops.

Pre-Design Garment Pressing Equipment

Pre-design garment pressing equipment prepares un-pressed fabric through ironing before it is designed or cut. These machines are manually operated by pressing down on the fabric with a push bar that lowers the presser onto the fabric. Pre-garment pressers also are used to define stitching lines in a garment before it is cut or designed.

Collar and Lapel Garment Pressing equipment

Garment collar and lapel pressing equipment is ergonomically designed to press shirt collars, blouses, coats and jackets. The pressing board is curved so the collar or lapel of a garment fits snugly on the layout board of the garment pressing equipment. Many collar and lapel presses are hand operated.

Jacket Garment Pressing Equipment

Jacket garment pressing equipment is engineered to the shape of the jacket, and is manually operated by a pressing bar. It is designed to press the inside and outside of the jacket, which includes the base fabric or lining inside of the jacket. Jacket garment pressing equipment can range from 51 inches on a flat surface to 72 inches for large coats and jackets.

Sleeve and Arm Garment Pressing Equipment

Sleeve and arm garment pressing equipment is used to iron the sleeves of jackets and coats after the garment is manufactured or designed. Sleeve and arm pressers are engineered vertically or as flat-surface machines with the pressing boards shaped in the form of an arm. Depending on the type of fabric the jacket or coat is made of, there are different settings for each type of fabric. These settings range from low, medium or high settings, which can be adjusted by a dial or switch.

Miniature Garment Pressing Equipment

Miniature garment pressing equipment is used to iron smaller fabrics after the manufacturing or design phase. These finishing garment pressing machines consist of hand-ironing devices attached to the pressing board for manual ironing. The ironing boards are flat surfaces shaped in a square or rectangle for easy ironing

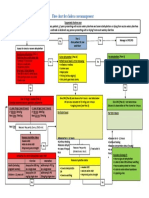

Iron Table

The decisive factor for an ironing station is the air flow through the garment to cool the fabric and set the ironing result.Ironing tables are used with an iron. The textiles are ironed between the heat and steam of the iron and the padded board. Jacket Seam Ironing Station

This special-purpose ironing station has been designed for opening seams along the backs, sides and shoulders of any type of jacket. With its special triple buck complemented by the shoulder seam attachment five seams are ironed at one time with less folding effort. The timer automatically repeats the required ironing program and guarantees a constant high-quality ironing result with short ironing times.

For processing of jackets and mens blazers and under pressing.

Trouser Seam Ironing Station Standard The special ironing buck, which is mounted on the standard base module, guarantees easy opening of the crotch and the side seams and optimum hip ironing. The hip area can be ironed without problems due to the special shape of the buck. The standard trouser seam ironing station standard is available with a ladies trouser seam buck shape or a mens trouser seam buck shape it is also available with a Timer unit as an option.

for trousers and under pressing

Trouser Seam Ironing Station with chain The trouser seam ironing buck is completed with a chain tensioning system. The trouser seam is positioned correctly and there is no overstretching by the chain thus avoiding wrinkles. The ironing result is therefore better compared to the trouser seam buck standard. The trouser is held in place by the tensioning system th erefore the operators hands are free for ironing. The crotch seam and side seams of single legs as well as complete trousers can be opened in a minimum amount of time. The trouser seam ironing station with chain is available with a ladies trouser seam opening buck shape or a mens trouser seam opening buck shape.

for trousers and under pressing

Sleeve Seam Ironing Station The sleeve seam buck guarantees an easy and perfect opening of sleeve seams of jackets, mens blazers and coats. The sleeve seam buck includes an iron rest as a standard feature.

Dress Board Ironing Tables These are available, as required, pointing left or right. They can be equipped with various shapes and sizes of ironing surfaces and are ideal for the ironing of skirts, dresses, jackets, blouses. A swivelarm assembly designed for a large variety of ironing bucks as well as a support gantry and a lighting system make this station a perfect ironing unit for processing of ladies wear. All dress board ironing stations can also be assembled pointing right.

All purpose table: An all-purpose ironing station offering a wide range of bucks. With its custom designed ironing surface, trousers, dresses, skirts, coats, blouses, jackets and other garments can be processed most efficiently. This ironing station is a perfect solution for those who need as much flexibility as possible such as studios, tailors, and returns departments, refinishers and textile care companies.

Flat Top Ironing Tables Fitted with a suction and blowing unit, this unit can be used to finish trousers. This allpurpose ironing station can be fitted with smaller or larger ironing surfaces. A great advantage of this ironing table is its universal use.

Blouse and Shirt Ironing Station On this special rectangular ironing buck featuring rounded edges, blouses and shirts can be perfectly positioned for excellent finishing results with minimal lay-out and handling times. Depending upon the particular application, round or pointed surfaces are available for this blouse ironing station. The ironing surface has been developed to fit the form of a shirt or blouse so that a complete front part can be ironed with only one working step. This saves time and minimizes the lay-out and handling times compared to the dress board ironing table.

You might also like

- Jewelry Mixed Media PDFDocument15 pagesJewelry Mixed Media PDFQishar100% (3)

- Cercei SoutacheDocument5 pagesCercei SoutacheGabriela Pisica100% (2)

- J 20 Air-Jet Spinning Machine Brochure 2386-V1 en 34515Document16 pagesJ 20 Air-Jet Spinning Machine Brochure 2386-V1 en 34515Ishwar DudagiNo ratings yet

- Garment Production Starts With The Cutting ProcessDocument3 pagesGarment Production Starts With The Cutting ProcessrajasekaranvgNo ratings yet

- Spme Assignment: Sewing Products Machinery and EquipmentDocument29 pagesSpme Assignment: Sewing Products Machinery and EquipmentVishnu P RNo ratings yet

- Comparison - Jewellery CompaniesDocument40 pagesComparison - Jewellery CompaniesKushagra VermaNo ratings yet

- Pharaonic Egyptian ClothingDocument259 pagesPharaonic Egyptian Clothingrichardmck100% (9)

- Six Elements of A Successful Maintenance Management SystemDocument2 pagesSix Elements of A Successful Maintenance Management Systemsunny_2502No ratings yet

- Tanishq Jewellers FinalDocument73 pagesTanishq Jewellers FinalGaurav Ramesh Kapoor67% (3)

- Jewelry Manufacturing ProcessDocument8 pagesJewelry Manufacturing Processagga1111No ratings yet

- Jewelry Manufacturing ProcessDocument8 pagesJewelry Manufacturing Processagga1111No ratings yet

- Carr and Latham's Technology of Clothing ManufactureFrom EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerRating: 4 out of 5 stars4/5 (1)

- National Institute of Fashion Technology: Report On Supply Chain Practices OFDocument19 pagesNational Institute of Fashion Technology: Report On Supply Chain Practices OFagga1111No ratings yet

- Pre Wetting in SizingDocument3 pagesPre Wetting in SizingKhubab Shaker100% (2)

- Wicked Affairs 3 Eliza Lloyd Wicked LordDocument197 pagesWicked Affairs 3 Eliza Lloyd Wicked LordJanie8288% (8)

- Seam TypeDocument6 pagesSeam TypeAmrita Singh60% (5)

- Deluxe - How Luxury Lost Its Luster - Thomas, DanaDocument968 pagesDeluxe - How Luxury Lost Its Luster - Thomas, DanaAdina Aribasoiu4% (27)

- H&M FMDocument67 pagesH&M FMagga1111100% (1)

- End BreakageDocument2 pagesEnd BreakageMitu Chowdhury100% (1)

- Latest trends in pneumatic tools for garment industryDocument42 pagesLatest trends in pneumatic tools for garment industryAnand DubeyNo ratings yet

- 04 ITMA ChemDocument87 pages04 ITMA ChemDEVANG MISTRINo ratings yet

- Cutting Room ManagmentDocument11 pagesCutting Room ManagmentkattaaaaNo ratings yet

- Everything You Need to Know About Home Tech ProductsDocument35 pagesEverything You Need to Know About Home Tech ProductsMd. Wahidur Rahman LimonNo ratings yet

- Denim FinishingDocument4 pagesDenim FinishingH. R. PatelNo ratings yet

- Multi Layer FabricDocument17 pagesMulti Layer FabricSaad AlamNo ratings yet

- Ch3 Flow of SocksDocument12 pagesCh3 Flow of SocksAhmad NawazNo ratings yet

- Apron Slippage in Ring Frame Part 2Document7 pagesApron Slippage in Ring Frame Part 2Selvakumar ThirumaniNo ratings yet

- Marker Making Guide: Layout, Efficiency, Methods & DuplicationDocument10 pagesMarker Making Guide: Layout, Efficiency, Methods & DuplicationM.José Copons GalloNo ratings yet

- Productivity Improvement in Apparel Industry .PPT PesentationDocument14 pagesProductivity Improvement in Apparel Industry .PPT Pesentationsudincr100% (3)

- Color Reduction and CleaningDocument170 pagesColor Reduction and CleaningDora BANo ratings yet

- Automation in Spreading and Cutting - Mansi, Akriti, Khushi, Nisha PDFDocument30 pagesAutomation in Spreading and Cutting - Mansi, Akriti, Khushi, Nisha PDFMansi ChandNo ratings yet

- Chapter 3 - Secondary Motions of Weaving PDFDocument26 pagesChapter 3 - Secondary Motions of Weaving PDFHugo Eduardo Ipiales MesaNo ratings yet

- Serviceability, Wear, and Abrasion ResistanceDocument6 pagesServiceability, Wear, and Abrasion ResistanceNiaz IslamNo ratings yet

- Set up production with BOM and routingDocument4 pagesSet up production with BOM and routingBalanathan VirupasanNo ratings yet

- ZNZ R&S Uttara UniversityDocument62 pagesZNZ R&S Uttara UniversityFahad chowdhuryNo ratings yet

- P04734 PDFDocument120 pagesP04734 PDFOdd BoyNo ratings yet

- Automation in WeavingDocument7 pagesAutomation in Weavingsalsabila fuNo ratings yet

- Knitting BookDocument8 pagesKnitting BookMd. Abrar Ahmed ApuNo ratings yet

- Warping 140522102148 Phpapp02Document65 pagesWarping 140522102148 Phpapp02Anonymous Pt7NHkat9No ratings yet

- Amt 191003082 Lab-1Document9 pagesAmt 191003082 Lab-1Nafis HossainNo ratings yet

- Modern Developments in WeavingDocument13 pagesModern Developments in WeavingRakeahkumarDabkeyaNo ratings yet

- Open-End Spinning - Wikipedia PDFDocument16 pagesOpen-End Spinning - Wikipedia PDFK.s. PandianNo ratings yet

- Textile Industry Internship ReportDocument6 pagesTextile Industry Internship ReportPiyush PatelNo ratings yet

- List of All Machinery Used in Garment IndustryDocument7 pagesList of All Machinery Used in Garment IndustryR RNo ratings yet

- Unit 1 Functional GarmentsDocument60 pagesUnit 1 Functional GarmentsSivakumar KNo ratings yet

- Requirements For Fabric CuttingDocument4 pagesRequirements For Fabric CuttingSîronamHin MonirNo ratings yet

- Industrial Attachment of Alltex Industries LimitedDocument79 pagesIndustrial Attachment of Alltex Industries LimitedNur E Alam Nuru100% (1)

- Denim Washing Note 9th BatchDocument43 pagesDenim Washing Note 9th BatchWrestling HighlightNo ratings yet

- Denimfabricstextile Cottontrbrush: APPAREL PRODUCTION SYSTEMS (Wholesale Denim Fabrics in CHINA)Document6 pagesDenimfabricstextile Cottontrbrush: APPAREL PRODUCTION SYSTEMS (Wholesale Denim Fabrics in CHINA)Thamara Dananjaya GunarathnaNo ratings yet

- 2 Maintenance Schdule Blow Room, Carding DecDocument15 pages2 Maintenance Schdule Blow Room, Carding DecBHASKAR MITRANo ratings yet

- ITMA 2019 Highlights New Textile Machinery InnovationsDocument8 pagesITMA 2019 Highlights New Textile Machinery InnovationsPadmanaban PasuvalingamNo ratings yet

- Appendix 11. Flow Chart For Cholera Case ManagementDocument1 pageAppendix 11. Flow Chart For Cholera Case ManagementGerard Pio Wee100% (1)

- Machine Layout For Apparel Industry?: Sewing Sequences of T-Shirt Applied in Garments IndustryDocument1 pageMachine Layout For Apparel Industry?: Sewing Sequences of T-Shirt Applied in Garments IndustryMohammed Ĺukman100% (2)

- Fibrograph Method PDFDocument4 pagesFibrograph Method PDFMd Amir HossainNo ratings yet

- Final Mill Tariniggng ReportDocument53 pagesFinal Mill Tariniggng ReportPriyanka VishnoiNo ratings yet

- Fabric Dyeing, Printing, and Finishes: Apparel and Textile Production IiDocument33 pagesFabric Dyeing, Printing, and Finishes: Apparel and Textile Production IiSachin RoyNo ratings yet

- Straight Knife Cutting MachineDocument5 pagesStraight Knife Cutting MachineTESayed100% (2)

- Warping - Objects of Warping - Importance of Warping in Weaving - Textile LearneDocument4 pagesWarping - Objects of Warping - Importance of Warping in Weaving - Textile LearneGOWTHAM CHANDRUNo ratings yet

- Tajima Rel NotesDocument44 pagesTajima Rel NotesdetonatNo ratings yet

- SCAP Session 10 Fabric LossesDocument21 pagesSCAP Session 10 Fabric LossesReena VermaNo ratings yet

- Company Profile: Crystal Textile Mill PVT LTDDocument8 pagesCompany Profile: Crystal Textile Mill PVT LTDclearheart123No ratings yet

- 3D Woven FabricDocument9 pages3D Woven FabricCrystal NewmanNo ratings yet

- Spreading and Cutting MachinaryDocument21 pagesSpreading and Cutting Machinarypsyish100% (1)

- Knitting Technology II: Lecture Note 12, 13 &14 Etsehiwot Yisma 2019Document16 pagesKnitting Technology II: Lecture Note 12, 13 &14 Etsehiwot Yisma 2019fekadeNo ratings yet

- Modern Developments in Spinning and Weaving MachineryDocument20 pagesModern Developments in Spinning and Weaving MachinerysuganNo ratings yet

- Auto Cutter AnalysisDocument11 pagesAuto Cutter AnalysisRadwan Rahat100% (1)

- 1.bale Management SystemDocument8 pages1.bale Management SystemMd NurunnabiNo ratings yet

- Yarn Preparation For Weaving IDocument18 pagesYarn Preparation For Weaving IKathirrveluSubramainan0% (1)

- Textile Dyeing and Printing: AssignmentDocument8 pagesTextile Dyeing and Printing: AssignmentshailajaNo ratings yet

- Study On Lock Stitch Sewing MachineDocument5 pagesStudy On Lock Stitch Sewing MachineNaimul HasanNo ratings yet

- Polo Shirt-Layout PlanDocument1 pagePolo Shirt-Layout PlanHemelNo ratings yet

- Automation in Apparel Industry: By: Jaideep Singh & Yogesh PrasadDocument16 pagesAutomation in Apparel Industry: By: Jaideep Singh & Yogesh PrasadpriyalNo ratings yet

- Marketing Strategies for Neeta Lulla to Become a Luxury BrandDocument12 pagesMarketing Strategies for Neeta Lulla to Become a Luxury Brandagga1111No ratings yet

- LEARNING POINT 4: Protecting Your Website: 1. What Elements of Your Website Can Be ProtectedDocument1 pageLEARNING POINT 4: Protecting Your Website: 1. What Elements of Your Website Can Be Protectedagga1111No ratings yet

- Despite ConfusionsDocument5 pagesDespite Confusionsagga1111No ratings yet

- The Company Has Roped in LondonDocument5 pagesThe Company Has Roped in Londonagga1111No ratings yet

- PepsiCo Wins Aquafina Trademark CaseDocument7 pagesPepsiCo Wins Aquafina Trademark Caseagga1111No ratings yet

- LM CaseDocument3 pagesLM Caseagga1111No ratings yet

- Brand PrismDocument4 pagesBrand PrismKaran K AroraNo ratings yet

- Brand Management in Luxury Markets ReimsDocument6 pagesBrand Management in Luxury Markets Reimsagga1111No ratings yet

- GucciLouisVuitton Vertu CaseStudyDocument9 pagesGucciLouisVuitton Vertu CaseStudyzana_georgiana747No ratings yet

- Ratio Analysis of WalmartDocument31 pagesRatio Analysis of Walmartagga1111100% (1)

- Ent Case1Document9 pagesEnt Case1agga1111No ratings yet

- Chapter 2Document30 pagesChapter 2agga1111No ratings yet

- The Jewellery Industry As A Career Option, Its Jobs and PossibilitiesDocument1 pageThe Jewellery Industry As A Career Option, Its Jobs and Possibilitiesagga1111No ratings yet

- Fexm Group 3Document20 pagesFexm Group 3agga1111No ratings yet

- Tanishq The Indian Wedding JewellerDocument3 pagesTanishq The Indian Wedding Jewelleragga1111No ratings yet

- To Whom It May Concern-2Document1 pageTo Whom It May Concern-2agga1111No ratings yet

- Fashion Show IdayDocument30 pagesFashion Show Idayagga1111No ratings yet

- Garment Finishing Process and Equipments: Presented By: Akansha Gupta Devika Rastogi Isha Milap Sanskriti VarmaDocument33 pagesGarment Finishing Process and Equipments: Presented By: Akansha Gupta Devika Rastogi Isha Milap Sanskriti Varmaagga1111No ratings yet

- SEVEN DOMAINS FRAMEWORK FOR ASSESSING BUSINESS IDEASDocument2 pagesSEVEN DOMAINS FRAMEWORK FOR ASSESSING BUSINESS IDEASagga1111No ratings yet

- Excel Basic-Akansha GuptaDocument29 pagesExcel Basic-Akansha Guptaagga1111No ratings yet

- Ms Access - Akansha GuptaDocument26 pagesMs Access - Akansha Guptaagga1111No ratings yet

- FindingsDocument1 pageFindingsagga1111No ratings yet

- KinaDocument5 pagesKinaagga1111No ratings yet

- Itm Presentation ON Ibm Spss (Question 4) : Presented By: Akansha GuptaDocument23 pagesItm Presentation ON Ibm Spss (Question 4) : Presented By: Akansha Guptaagga1111No ratings yet

- Pochampally Ikat Saree ArtDocument23 pagesPochampally Ikat Saree Artagga11110% (1)

- Akansha FFPDDocument16 pagesAkansha FFPDagga1111No ratings yet

- T-Shirt As MessageDocument1 pageT-Shirt As MessageJessica MichaultNo ratings yet

- Ad Data D110 Skincare PullsDocument63 pagesAd Data D110 Skincare Pullsday emailNo ratings yet

- "Fashionable Dentistry": Let's Make Dentistry A Fashion Trend - IDA Student DigestDocument1 page"Fashionable Dentistry": Let's Make Dentistry A Fashion Trend - IDA Student DigestHindol DasNo ratings yet

- FAD VS TREND VS CLASSIC: WHAT'S THE DIFFERENCEDocument2 pagesFAD VS TREND VS CLASSIC: WHAT'S THE DIFFERENCEPedimor Dolor CabansagNo ratings yet

- Mens WearDocument30 pagesMens WearAnuradha MasurkarNo ratings yet

- Male Grooming and Standards Guidelines For Cabin Crew Qatar Airways New JoinerDocument2 pagesMale Grooming and Standards Guidelines For Cabin Crew Qatar Airways New Joinerhksbqnvrmw100% (1)

- YSL Vs CL Trademark LawsuitDocument31 pagesYSL Vs CL Trademark LawsuitShrutiNo ratings yet

- UAPA Adult English Advanced II Salvador Dali Biography Art AnalysisDocument10 pagesUAPA Adult English Advanced II Salvador Dali Biography Art AnalysisErmil Manuel Adames GómezNo ratings yet

- ProphecyDocument2 pagesProphecyIra MejiaNo ratings yet

- Malaysian StudiesDocument7 pagesMalaysian StudiesSanjeev ManutdNo ratings yet

- How to leverage luxury brands in 2019-2025Document14 pagesHow to leverage luxury brands in 2019-2025shanyu zhangNo ratings yet

- Anime Best Girl - Búsqueda de GoogleDocument1 pageAnime Best Girl - Búsqueda de GooglejuanNo ratings yet

- Vogue American Pop CultureDocument4 pagesVogue American Pop Culturekitten katsuNo ratings yet

- Boast Magazine - Issue 13 - 2023-08-AugDocument86 pagesBoast Magazine - Issue 13 - 2023-08-AugDiogoNo ratings yet

- We Love - Casa Cook, RhodesDocument1 pageWe Love - Casa Cook, RhodesJuliet BenningNo ratings yet

- Rank/Name Unit Detailed To Authority EffectivityDocument18 pagesRank/Name Unit Detailed To Authority EffectivitySouthern PoliceNo ratings yet

- APPLYING PUNCHDRUNK'S METHODOLOGIES TO ANTIGONEDocument3 pagesAPPLYING PUNCHDRUNK'S METHODOLOGIES TO ANTIGONESofia NietoNo ratings yet

- Brand Audit - CottononDocument17 pagesBrand Audit - Cottononapi-337554075100% (1)

- Uniforms 1Document6 pagesUniforms 1api-473019343No ratings yet

- Global Market Assessment For HandicraftsDocument78 pagesGlobal Market Assessment For HandicraftsMuadong NuocngaNo ratings yet

- Proposal Letter: "Metrowear Filipiniana 2019" On September 21, 2019Document16 pagesProposal Letter: "Metrowear Filipiniana 2019" On September 21, 2019Rona Uy EstevesNo ratings yet

- Plaza Indonesia AR 2011 FINALDocument172 pagesPlaza Indonesia AR 2011 FINALHiroshi Gozali MasehiNo ratings yet