Professional Documents

Culture Documents

Reciprocating Engine Dynamic Forces

Uploaded by

Gthulasi78Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reciprocating Engine Dynamic Forces

Uploaded by

Gthulasi78Copyright:

Available Formats

Reciprocating engine dynamic properties

1. Combustion engines main principles and definitions 2. Reciprocating combustion engines architecture 3. Reciprocating engines dynamic properties 4. Engine components and systems 5. The engine management system for gasoline and Diesel engines 6. The emission Requirements & Technology 7. Engine vehicle integration

7.1 Engine layout and mounting 7.2 Engine-vehicle cooling system 7.3 Intake system 7.4 Exhaust system

Scuola di Dottorato di Ricerca 2010 - Road vehicle and engine engineering science

Reciprocating engine dynamic properties

Reciprocating engines dynamic properties 1. Engine operation forces 2. Engine Excitation Mechanisms (Single Cylinder Engine) 3. Key issue on masses balancing

In line 4 cylinder engine balance Flat 4 cylinder engine balance In line 5 cylinder engine balance In line 6 cylinder engine balance V60 6 cylinder engine balance V90- 30crank offset 6 cylinder engine balance V90 8 cylinder engine balance V90 - flat crankshaft 8 cylinder engine balance

John Heywood, Internal Combustion Engine Fundamentals / McGraw-Hill Charles F. Taylor, The internal Combustion Engine in Theory and Practice /The M.I.T. Press Automotive Handbook R. Bosch/SAE Advanced engine technology (Heinz Heisler) Butterworth/Heinemann Light and Heavy Vehicle Technology (M.J. Nunney) - CGIA, MSAE, MIMI Scuola di Dottorato di Ricerca 2010 - Road vehicle and engine engineering science

Reciprocating engine dynamic properties Engine operation forces

The purpose of the piston-connecting rod-crankshaft assembly in the reciprocating piston-engines is to transform the gas forces generated during combustion within the working cylinder into a piston stroke, which the crankshafts converts into useful torque available at the flywheel. The cyclic operation leads to unequal gas forces, and the acceleration and deceleration of the reciprocating power-transfer components generate inertia forces.

The mass inertia properties of the piston-connecting rod-crankshaft assembly are a composite of the rotating mass of the crankshaft about their axis and the reciprocating masses in the cylinder direction.

The inertial properties of a single cylinder engine are determined by the piston mass, exclusively oscillating mass, the crankshaft mass, exclusively rotating mass, and the corresponding connecting-rod mass components, usually assumed to amount to 1/3 for rotating and to 2/3 for oscillating mass.

The inertia force components are identified as inertial forces of the 1st, 2nd, 4th order, depending upon their rotational frequencies, relative to engine speed: in general only the 1st and 2ndorder components are significant.

In the case of multi-cylinder engines, free moments of inertia are present when all the complete crankshaft assemblys inertial forces combine to generate a force couple at the crankshaft.

Scuola di Dottorato di Ricerca 2010 - Road vehicle and engine engineering science

Reciprocating engine dynamic properties Inertia or mass forces

Eccitanti alterne di inerzia in un motore alternativo monocilindro Eccitanti alterne di inerzia in un motore alternativo monocilindro

Massa alterna ma

acc = r * * [cos + cos( 2)] = d / dt Force = m a * acc = FI + FII

Il Motore come sorgente di con vibrazioni e rumore The alternate motion of the rod - crank system Fig. 1. 1

Scuola di Dottorato di Ricerca 2010 - Road vehicle and engine engineering science

Reciprocating engine dynamic properties Considerations on gas forces

The gas forces are generated by the fuel combustion acting on the piston to be transferred to the crankshaft by connecting- rod through the expansion stroke: therefore during the complete cycle they depend on the crankshaft position. When multiplied by the crank radius, the gas forces produce a periodically variable torque value.

Leffetto dellecom bu stioniiin un m o tore alternativo m onocilindrico Leffetto delleco m bustion in un m oto re alternativo m o nocilindrico

F gas = P* A F tot = F gas +F rec

The diagram shows the curve of the engine torque as a function of crankshaft position: this is one of the most important characteristics in assessing the dynamic engine behavior.

G as pressure Inertial effect R esulting pressure

F n =F tot * sin Te =Fn* x

C oppia m edia erogata

Il M otore com esorgente di vibrazionie rum ore

Fig. 1.3

Scuola di Dottorato di Ricerca 2010 - Road vehicle and engine engineering science

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

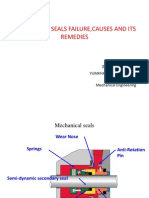

- MECHANICAL SEALS FAILURE CAUSESDocument26 pagesMECHANICAL SEALS FAILURE CAUSESFaruque Khan Yumkhaibam100% (6)

- Manual RT760EDocument159 pagesManual RT760EJonathan Velasco Arce100% (2)

- Steel and Cast Iron Bar Compression ProblemDocument26 pagesSteel and Cast Iron Bar Compression ProblemLarete PaoloNo ratings yet

- Cryogenic Vacuum Insulated Piping System DesignDocument55 pagesCryogenic Vacuum Insulated Piping System DesignRajesh ReghuNo ratings yet

- Service & Maintenance Manual for 260MRT Aerial LiftDocument110 pagesService & Maintenance Manual for 260MRT Aerial LiftКосNo ratings yet

- Overview of Drilling OperationDocument106 pagesOverview of Drilling OperationTemitope BelloNo ratings yet

- Flare SystemDocument29 pagesFlare Systemvikkoo7100% (4)

- Design of PenstocksDocument28 pagesDesign of Penstockschithirai10No ratings yet

- Engine Dynamic Properties-2Document5 pagesEngine Dynamic Properties-2Gthulasi78No ratings yet

- Synchronous PM Motors: Stator Field Needs To Be Close To Orthogonal (90°) To Rotor Field To GetDocument4 pagesSynchronous PM Motors: Stator Field Needs To Be Close To Orthogonal (90°) To Rotor Field To GetGthulasi78No ratings yet

- Manual Transmission - 2Document6 pagesManual Transmission - 2Gthulasi78No ratings yet

- Manual Transmission - 1Document6 pagesManual Transmission - 1Gthulasi78No ratings yet

- SensorlessBLDCControl 2Document7 pagesSensorlessBLDCControl 2Gthulasi78No ratings yet

- BLDC 4Document5 pagesBLDC 4Gthulasi78No ratings yet

- Weibull Tutorial 1Document5 pagesWeibull Tutorial 1Gthulasi78No ratings yet

- Engine Dynamic Properties-1Document5 pagesEngine Dynamic Properties-1Gthulasi78No ratings yet

- Weibull Tutorial 2Document6 pagesWeibull Tutorial 2Gthulasi78No ratings yet

- BLDC 3Document4 pagesBLDC 3Gthulasi78No ratings yet

- BLDC 5Document7 pagesBLDC 5Gthulasi78No ratings yet

- SensorlessBLDCControl 2Document7 pagesSensorlessBLDCControl 2Gthulasi78No ratings yet

- The Steady State Magnetic FieldDocument28 pagesThe Steady State Magnetic FieldRashmi HarishNo ratings yet

- BLDC 3Document4 pagesBLDC 3Gthulasi78No ratings yet

- BLDC 2Document4 pagesBLDC 2Gthulasi78No ratings yet

- Brushless DC Motors Are A Type of Synchronous MotorDocument5 pagesBrushless DC Motors Are A Type of Synchronous MotorGthulasi78No ratings yet

- Brushless DC Motors Are A Type of Synchronous MotorDocument5 pagesBrushless DC Motors Are A Type of Synchronous MotorGthulasi78No ratings yet

- Sensorless BLDC Motor Control With BEMF Zero-Crossing DetectionDocument6 pagesSensorless BLDC Motor Control With BEMF Zero-Crossing DetectionGthulasi78No ratings yet

- Brushless DC Motors Are A Type of Synchronous MotorDocument5 pagesBrushless DC Motors Are A Type of Synchronous MotorGthulasi78No ratings yet

- Rotor Sectional View and Commutation SequenceDocument5 pagesRotor Sectional View and Commutation SequenceGthulasi78No ratings yet

- BLDC 3Document4 pagesBLDC 3Gthulasi78No ratings yet

- 3-Phase Sensorless BLDC Motor Control Using MC9S08MP16: PresentationDocument7 pages3-Phase Sensorless BLDC Motor Control Using MC9S08MP16: PresentationGthulasi78No ratings yet

- BLDC 2Document4 pagesBLDC 2Gthulasi78No ratings yet

- ECE 753 Fault Tolerant Computing Reliability ModelingDocument6 pagesECE 753 Fault Tolerant Computing Reliability ModelingGthulasi78No ratings yet

- Engine Dynamic Properties - 6Document5 pagesEngine Dynamic Properties - 6Gthulasi78No ratings yet

- V6 Engine Dynamic PropertiesDocument3 pagesV6 Engine Dynamic PropertiesGthulasi78No ratings yet

- Engine Dynamic Properties - 5Document5 pagesEngine Dynamic Properties - 5Gthulasi78No ratings yet

- Engine Dynamic Properties - 3Document5 pagesEngine Dynamic Properties - 3Gthulasi78No ratings yet

- Engine Dynamic Properties - 4Document5 pagesEngine Dynamic Properties - 4Gthulasi78No ratings yet

- Engine Dynamic Properties - 2Document5 pagesEngine Dynamic Properties - 2Gthulasi78No ratings yet

- Operating Manual - Dehumidifier TTK 31 EDocument17 pagesOperating Manual - Dehumidifier TTK 31 EEşanu ViorelNo ratings yet

- Helical gear units specs and dimensionsDocument75 pagesHelical gear units specs and dimensionsamir_tstfrm1No ratings yet

- High-Strength Epoxy Grouting SystemDocument6 pagesHigh-Strength Epoxy Grouting SystemGihasAbdNo ratings yet

- Productdata 1LDocument23 pagesProductdata 1Lsharif_alNo ratings yet

- Pressure Relief Valve Fig.1319Document2 pagesPressure Relief Valve Fig.1319fernandoNo ratings yet

- Gyro CompassDocument4 pagesGyro CompassABDU RAHEEM A. SNo ratings yet

- Postgrad Courses PDFDocument36 pagesPostgrad Courses PDFShah Wali UllahNo ratings yet

- To Study The Construction and Working of 4 - Stroke Petrol / Diesel EngineDocument7 pagesTo Study The Construction and Working of 4 - Stroke Petrol / Diesel EngineBanwari Lal PrajapatNo ratings yet

- FEA Answers by Professor GuruprasadDocument146 pagesFEA Answers by Professor GuruprasadManendra SaiNo ratings yet

- Eu 3800Document2 pagesEu 3800Fernando MilmanNo ratings yet

- Characteristics Series CE, CP, C: 2 Way Slip-In Cartridge ValvesDocument17 pagesCharacteristics Series CE, CP, C: 2 Way Slip-In Cartridge Valvess_waqarNo ratings yet

- Escort Limited Champion F 11 Brand Name - FarmtracDocument12 pagesEscort Limited Champion F 11 Brand Name - Farmtrachugo fernandezNo ratings yet

- Redox Breaker + Hour MeterDocument6 pagesRedox Breaker + Hour Meterhenry vegaNo ratings yet

- Leser US Order Price Information 2012Document204 pagesLeser US Order Price Information 2012Matheus de AlmeidaNo ratings yet

- CylindersDocument17 pagesCylindersEng-Mohammed SalemNo ratings yet

- Altronics DC-CPU IOM 06-1988 PDFDocument22 pagesAltronics DC-CPU IOM 06-1988 PDFSMcNo ratings yet

- 2022.08.08 Fabrication and Installation Steel StructureDocument21 pages2022.08.08 Fabrication and Installation Steel StructureArifian NugrohoNo ratings yet

- WAHLER Imagebroschuere SERIE enDocument16 pagesWAHLER Imagebroschuere SERIE ensagarpatel337No ratings yet

- An Insight of Compacted Graphite Iron (Cgi) Characteristics and Its Production A ReviewDocument18 pagesAn Insight of Compacted Graphite Iron (Cgi) Characteristics and Its Production A ReviewMiguel BrionesNo ratings yet

- Is-1566-1982 (2000)Document15 pagesIs-1566-1982 (2000)hhr2412100% (1)

- HP237Document20 pagesHP237Asif HameedNo ratings yet

- A Mechanical Engineer S Handbook by ONGC PDFDocument303 pagesA Mechanical Engineer S Handbook by ONGC PDFshujad77No ratings yet