Professional Documents

Culture Documents

Diffractive Optics From Holo /or: Services & Capabilities

Uploaded by

asdfasdfsharklasersOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Diffractive Optics From Holo /or: Services & Capabilities

Uploaded by

asdfasdfsharklasersCopyright:

Available Formats

Diffractive Optics from Holo /Or

In the past 15 years we developed, designed and manufactured a variety of diffractive optical

elements that accomplish difficult tasks, conventional optics fails to address effectively. Proven

solutions developed for high power lasers include:

Uniform Splitting of beams Beam Sampling

Tailored Shaping of spots Chromatic and Spherical

Aberation Correction

1D, 2D and 3D spot array

generation

Intensity profile management

Diffusers and Homogenizers Enlongating Depth of Focus

Top-Hat Beam Shaping Frame focusser

Lenslet Arrays, symetric and

asymetric

Tailored spot SHAPES and sizes

The company employs highly skilled technical personal, and occupies a prodcution facility at the Kiryat

Weizmann High-Tech Industrial Park, Rehovot, Israel. Holo-Or has a full capability of developing and

manufacturing diffractive optical elements in clean room facilities. The company holds the key patents on its

method of manufacturing multi-level elements. Holo-Or is cooperating with Laser Components, GmbH.

SERVICES & CAPABILITIES

x Diffractive optical elements: Custom & Stock

x Diffractive design and performance analyses

x Optical design incorporating diffractive optics

x Reactive ion and wet etching and

photolithography for visible and IR materials

x Mask fabrication

IN-HOUSE ELABORATED SOFTWARE

DOECAD software for design, mask files generation and computer simulation of diffractive optical elements

Germany and other countries: LASER COMPONENTS GmbH, Phone: +49 8142 2864 0, Fax: +49 8142 2864 11, info@lasercomponents.com

USA: LASER COMPONENTS IG, Inc., Phone: +1 603 821 7040, Fax: +1 603 821 7041, info@laser-components.com

Great Britain: LASER COMPONENTS (UK) Ltd., Phone: +44 1245 491 499, Fax: +44 1245 491 801, info@lasercomponents.co.uk

France: LASER COMPONENTS S.A.S., Phone: +33 1 3959 5225, Fax: +33 1 3959 5350, info@lasercomponents.fr

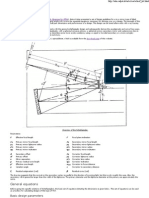

DIFFRACTIVE-CORRECTED FOCUSING LENS

Our single diffractive-corrected focusing lens demonstrates sharp focusing with diffraction-limited spot-size.

The lens is fabricated by etching an aberrations-correction diffractive microrelief pattern on the plane side of a

bulky spherical plano-convex lens.

Part number Wavelength Efl Diam.

SE-1511 10.6 m 1.5 s 1.1s

SE-2511 10.6 m 2.5 s 1.1s

SE-2515 10.6 m 2.5 s 1.5s

SE-3711 10.6 m 3.75 s 1.1s

SE-5015 10.6 m 5.0 s 1.5s

LONG-FOCAL -DEPTH DIFFRACTIVE FOCUSING LENS

The "Easy-F" lens design yields a longer focal depth while still maintaining near to diffraction limited spot size,

sharp and cleaner edges of the focal spot. "Easy-F" lenses achieve high cutting and drilling speeds, together

with smoother and cleaner edges and the ease of focusing of longer-focal-length lenses

TOP-HAT BEAM SHAPING

The diffractive top-hat beam shapers are diffractive phase

optical elements used to transform a near-gaussian incident

laser beam into a uniform-intensity spot of either round or

rectangular shape with sharp edges. Applications include laser

heat treatment, annealing of surfaces in machinery and

microelectronics, optical heads of laser writers and optical

information processing.

Part No. Function Dia. Wavelength Diameter Working dist Spot size(1/e2) Spot Shape

TH-001 Top-Hat 1.5 10600 25 mm 250 mm 3 mm Round

TH-002 Top-Hat 1.1 10600 12 mm 250 mm 6 mm Square

TH-003 Top-Hat-1D 0.5 10600 3.7 mm 42.5 mm 0.3X0.1mm Line

TH-004 Top-Hat 1.1" 10600 12 mm 63.5 mm 0.39 mm Round

TH-005 Top-Hat 1.1" 92500 12 mm 63.5 mm 0.35 mm Round

TH-014 Top-Hat-

Sharp edge

20 mm 1064 7.0 mm 42.52 mm 0.190 mm Round

TH-015 Top-Hat-1D 1" 1064 5.1 mm infinity 0.83 deg x nat.

divergence

Line

TH-016 Top-Hat 1" 980 7.0 mm infinity 0.94x0.94 deg Square

TH-031 Top-Hat 1 532 5 mm 52.4 mm 0.1 mm Round

TH-032 Top-Hat 1 532 10.9 mm 200 mm 2 mm (FWHM) Round

TH-041 Top-Hat 1 355 2 mm 100 mm 0.1 mm Square

TH-042 Top-Hat 1 355 2.5 mm 50 mm 0.05mm Round

TH-044 Top-Hat 20 mm 337 8.0 mm 49.395 mm 0.020 mm Round

TH-051 Top-Hat 1 266 5 mm 42 mm 0.015mm Round

Conventional plano-convex lens

Diffractively-corrected lens

Easy-F diffractively-corrected lens

Plane side

Plane with diffractive

Germany and other countries: LASER COMPONENTS GmbH, Phone: +49 8142 2864 0, Fax: +49 8142 2864 11, info@lasercomponents.com

USA: LASER COMPONENTS IG, Inc., Phone: +1 603 821 7040, Fax: +1 603 821 7041, info@laser-components.com

Great Britain: LASER COMPONENTS (UK) Ltd., Phone: +44 1245 491 499, Fax: +44 1245 491 801, info@lasercomponents.co.uk

France: LASER COMPONENTS S.A.S., Phone: +33 1 3959 5225, Fax: +33 1 3959 5350, info@lasercomponents.fr

ABERRATION-CORRECTION PLATES FOR MULTILENS OBJECTIVES

We design diffractive microrelief pattern on a

surface of refractive lens or window in order to

correct for chromatic, spherical and other

aberrations of broad-band objectives. Diffractive

pattern results in reduced of number of components

Applications include thermal imaging and FLIR

systems covering wavelength range the 8-12Pm or

3-5Pm.

PHASE DIFFRACTION GRATINGS

We produce transmissive phase diffraction gratings etched in materials like Fused Silica and ZnSe. Gratings can

be binary rectangular-groove shaped or blazed multilevel. Grooved might be straight of curvilinear,

BEAM MULTIPLICATION AND MULTIPLE-SPOT LENSES

Diffractive beam-multiplication elements split a laser beam into several beams, each with the characteristics

of the original beam except for power and angle of propagation. Focusing multi-spot elements provide a line

or an array of identical focal spots located in the focal plane, with spacing between neighboring spots

BEAM SAMPLER

Diffractive beam samplers are used to monitor high-

power lasers by extraction of exact sampled copies

of the beam with only a small fraction of the total

power. The passing beam corresponds to the zero

diffraction order, while two sampled beams

propagate at the symmetrical angles of the first

diffraction orders. We offer our high quality beam

samplers for various angles and power fractions of

sampled beam.

High power

laser beam

Diffractive

sampler

Sampled fraction of

the beam , (+1) order

Main beam , zero

diffraction order

Sampled fraction of

the beam , (-1) order

Part No. Function Dim. Wave-length Nomin. angle sep. Ratio/ Angle

SA-010 Sampler 12x12mm 1.06 Pm 15.2 deg 0.40%

SA-015 Sampler 1.0 0.355 Pm 5.1 deg 3.87%

SA-020 Sampler 1.1 10.6 Pm 12.8 deg 0.40%

LENSLET ARRAYS

A set of small spherical, aspherical or cylindrical

lenses on s a single substrate is called a lenslet array.

It is used for focusing and sampling as well as for

diffusing of light. The Diffractive lenslet arrays we

offer have the advantage of a fill factor of 100%,

and a diffraction limited focal spot size. We also

have the flexibility to design each of the lens-

elements independenly from its neighbor.

Part No. Function Dia.

Wave-

length

Collimation

Angle

separation

DS-001 Double-spot 1.1 10.6 Pm Collimated 1.35 deg

DS-002 Double-spot 1.1 10.6 Pm Collimated 2.70 deg

TS-004 Triple-spot 1.1 10.6 Pm Collimated 1.35 deg

DS-006 Double-spot 1.0 1.06 Pm Collimated 2.53 deg

TS-008 Triple-spot 1.0 1.06 Pm Collimated 1.27 deg

DS-015 Double-spot 1.0 0.532 Pm Collimated 1.27 deg

DS-016 Double-spot 1.0 0.355 Pm Collimated 0.85 deg

DS-017 Double-spot 1.0 0.266 Pm Collimated 0.64 deg

LENS

Multiple foci

DOE

Incident laser beam

Germany and other countries: LASER COMPONENTS GmbH, Phone: +49 8142 2864 0, Fax: +49 8142 2864 11, info@lasercomponents.com

USA: LASER COMPONENTS IG, Inc., Phone: +1 603 821 7040, Fax: +1 603 821 7041, info@laser-components.com

Great Britain: LASER COMPONENTS (UK) Ltd., Phone: +44 1245 491 499, Fax: +44 1245 491 801, info@lasercomponents.co.uk

France: LASER COMPONENTS S.A.S., Phone: +33 1 3959 5225, Fax: +33 1 3959 5350, info@lasercomponents.fr

DUAL WAVELENGTH LENS

The dual wavelength beam combiners are diffractive optical elements used to bring two incident beams with

different wavelengths into the same focal point.

Performance of regular ZnSe lens in dual-

wavelength beam of CO

2

and HeNe lasers

Performance of diffractive-refractive ZnSe lens in

dual-wavelength beam of CO

2

and HeNe lasers

HOMOGENIZERS

Unlike competing designs, Holo-Ors Diffractive Homogenizers consist of pure fused silica with

an optional high power AR V-Coating on both surfaces. This can reduce the back reflection to

0.2% (0.1% per surface) depending on the coating grade ordered. Back reflection usually hinders

the stable operation of the laser and should therefore be reduced to a minimum, as in this design.

Part

number

Full

Diffusing angle

Wavelength Part

number

Full

Diffusing angle

Wavelength

DF-106 0.5

0

1064nm DF-035 0.17

0

355nm

DF-075 0.35

0

755nm DF-026 0.125

0

266nm

DF-069 0.33

0

694nm DF-024 0.12

0

248nm

DF-053 0.25

0

532nm DF-019 0.09

0

193nm

General specifications for All Diffractive Optical Elements

Mounting: unmounted

Wavelengths: UV, visible, near IR, far IR

Materials: ZnSe, Ge, Si, fused silica, PMMA

Power handling: up to 3 kW

Coating: AR/AR

Substrate: window or lens

Number of output beams: up to 100

Efficiency: up to 98%

Special effects in lenses

Off-axis sharp focusing

Introduction of a custom spherical aberration

Chromatic correction

Control of the shape of focal spot

Longer depth of focus ( Easy-F)

Double(multiple) - spot focus

We can customize, material, wavelength, diameter, beam size, working distance, central thickness, and

other special effects

Ask for our

o Standard Element leaflet that lists more designs and more details on them.

o Tailored Optics datasheet to get a better feeling of how close we can approach your ideal

optical function within one optical surface.

He-Ne

CO

2

He-Ne, CO

2

Micro relief

www.lasercomponents.com 11/04 / V5 / HW / holoor/ diff_opt.pdf

Germany and other countries: LASER COMPONENTS GmbH, Phone: +49 8142 2864 0, Fax: +49 8142 2864 11, info@lasercomponents.com

USA: LASER COMPONENTS IG, Inc., Phone: +1 603 821 7040, Fax: +1 603 821 7041, info@laser-components.com

Great Britain: LASER COMPONENTS (UK) Ltd., Phone: +44 1245 491 499, Fax: +44 1245 491 801, info@lasercomponents.co.uk

France: LASER COMPONENTS S.A.S., Phone: +33 1 3959 5225, Fax: +33 1 3959 5350, info@lasercomponents.fr

You might also like

- Prolok NEWESTDocument8 pagesProlok NEWESTMarvin BlackwellNo ratings yet

- Lens &prismDocument16 pagesLens &prismJulian Massey100% (1)

- The Csec HelperDocument71 pagesThe Csec Helperapi-291242485100% (1)

- AN/PVS-14 Night Vision Device ManualDocument143 pagesAN/PVS-14 Night Vision Device Manualtyra24100% (1)

- Aspheric lenses: Thinner and lighter by designDocument9 pagesAspheric lenses: Thinner and lighter by designTuan Do100% (1)

- OptiFDTD 32-Bit Technical Background PDFDocument45 pagesOptiFDTD 32-Bit Technical Background PDFDimple Bansal100% (1)

- PhysicsDocument15 pagesPhysicsKim Al-Gin Rayos ManongsongNo ratings yet

- Aspheric Lens Design PDFDocument1 pageAspheric Lens Design PDFAnonymous HGOomkn69No ratings yet

- Physics Grade 12 Concepts and Connections PDFDocument720 pagesPhysics Grade 12 Concepts and Connections PDFgiyono100% (2)

- 2nd QUARTER EXAM SCIENCE 10Document13 pages2nd QUARTER EXAM SCIENCE 10Manuela Kassandra Soriao Tribiana0% (1)

- 08 Subjective Refraction AstigmatismDocument51 pages08 Subjective Refraction Astigmatismgenalinang100% (1)

- Thick LensDocument51 pagesThick LensRiska Lidia100% (1)

- Nikkor LensesDocument16 pagesNikkor LensesOzan Ozan0% (1)

- IRIS Valves for Pharma ApplicationsDocument2 pagesIRIS Valves for Pharma ApplicationsmehtahemalNo ratings yet

- IAT14 - Imaging and Aberration Theory Lecture 1 Paraxial OpticsDocument40 pagesIAT14 - Imaging and Aberration Theory Lecture 1 Paraxial OpticsShiva MohammadzadehNo ratings yet

- Characterization of Optical MaterialsDocument36 pagesCharacterization of Optical MaterialsMomentum PressNo ratings yet

- Century of OpticsDocument365 pagesCentury of OpticsDanny100% (2)

- Retrofocus lenses – and why they were inventedDocument15 pagesRetrofocus lenses – and why they were inventedseifadiazNo ratings yet

- Getting Started Using ZEMAXDocument74 pagesGetting Started Using ZEMAXstreetcribdealerNo ratings yet

- Zemax in GeneralDocument31 pagesZemax in GeneralgordansimNo ratings yet

- Tolerance On Material Inhomogenity and Surface Irregularity - Wen RuiDocument14 pagesTolerance On Material Inhomogenity and Surface Irregularity - Wen RuiKrishna ReddyNo ratings yet

- Fabrication of Freeform OpticsDocument3 pagesFabrication of Freeform Opticskndprasad01100% (1)

- Lens CoatingDocument43 pagesLens CoatingjorgeNo ratings yet

- Ray Optics by SenjicsDocument49 pagesRay Optics by SenjicssenjicsNo ratings yet

- CODE V Optical Design Software: Design, Optimize and Fabricate Reliable Imaging OpticsDocument8 pagesCODE V Optical Design Software: Design, Optimize and Fabricate Reliable Imaging OpticsDeaw EggTofuNo ratings yet

- AberrationDocument16 pagesAberrationPaul G Paul100% (1)

- 2009 Class Summary Essay - Vineeth AbrahamDocument40 pages2009 Class Summary Essay - Vineeth AbrahamRachel OnealNo ratings yet

- The Importance of Induced Aberrations in The Correction of Secondary ColorDocument11 pagesThe Importance of Induced Aberrations in The Correction of Secondary ColorDannyNo ratings yet

- DLP System OpticsDocument26 pagesDLP System OpticsAnonymous kg7YBMFHNo ratings yet

- Anamorficos PanavisionDocument7 pagesAnamorficos PanavisionBlas De LezoNo ratings yet

- The Iris DiaphragmDocument8 pagesThe Iris DiaphragmRandy WigginsNo ratings yet

- Simulation of Wave Front Propagation With ZEMAX: Sara Casalbuoni and Rasmus Ischebeck DesyDocument48 pagesSimulation of Wave Front Propagation With ZEMAX: Sara Casalbuoni and Rasmus Ischebeck DesyZeynep Nilüfer Güven ÖztürkNo ratings yet

- Study of Lenses Focal Length 25.5cmDocument4 pagesStudy of Lenses Focal Length 25.5cmKristella DraheimNo ratings yet

- Sampled Imaging Systems: Analysis and Evaluation ofDocument20 pagesSampled Imaging Systems: Analysis and Evaluation ofSurajit AcharyaNo ratings yet

- How To Integrate A Diffractive Axicon Lens Into An Optical System in ZEMAXDocument4 pagesHow To Integrate A Diffractive Axicon Lens Into An Optical System in ZEMAXDu Roy100% (1)

- Analytical Study and Optical Design of Offner Based Hyperspectral Imager in Vnir RegionDocument69 pagesAnalytical Study and Optical Design of Offner Based Hyperspectral Imager in Vnir RegionTanushrii RameshNo ratings yet

- Build Your Own Beam ExpanderDocument12 pagesBuild Your Own Beam ExpanderRio Ananda PutraNo ratings yet

- Optics of LithographyDocument143 pagesOptics of LithographyChang MingNo ratings yet

- Design of A 10x, 0.25 N.A., Microscope ObjectiveDocument20 pagesDesign of A 10x, 0.25 N.A., Microscope ObjectiveaqsaehsanNo ratings yet

- F Number PDFDocument6 pagesF Number PDFnandan akNo ratings yet

- Aspheric Lens Design PDFDocument1 pageAspheric Lens Design PDFJhon Cena100% (1)

- 521.tutorial - Zemax Tolerancing - HaynesDocument10 pages521.tutorial - Zemax Tolerancing - Haynesodane3113No ratings yet

- Defence Space Optics BrochureDocument4 pagesDefence Space Optics BrochureRavishankarNo ratings yet

- Designing A Double-Gauss Lens, The Hard Way: David Shafer David Shafer Optical Design Fairfield, CT, 06824 #203-259-1431Document22 pagesDesigning A Double-Gauss Lens, The Hard Way: David Shafer David Shafer Optical Design Fairfield, CT, 06824 #203-259-1431resuscitatNo ratings yet

- Beam ExpandersDocument4 pagesBeam ExpandersVaBi LeftNo ratings yet

- Optical validation of Schwarzschild Couder telescope ASTRI SST-2MDocument6 pagesOptical validation of Schwarzschild Couder telescope ASTRI SST-2MegiroNo ratings yet

- Laser Beam Expanders Basics and Applications: Vision System Vision SystemDocument6 pagesLaser Beam Expanders Basics and Applications: Vision System Vision SystemAtul SharmaNo ratings yet

- OptiFDTD TutorialsDocument36 pagesOptiFDTD TutorialsDr-Mandeep SinghNo ratings yet

- CollimatorDocument5 pagesCollimatorskc3128No ratings yet

- Zernike polynomials describe eye aberrationsDocument26 pagesZernike polynomials describe eye aberrationsgastromonoNo ratings yet

- 2013 Benz ManualDocument22 pages2013 Benz ManualArif MohammadNo ratings yet

- An Introduction to Electrooptic Devices: Selected Reprints and Introductory Text ByFrom EverandAn Introduction to Electrooptic Devices: Selected Reprints and Introductory Text ByNo ratings yet

- Optical Digital Signal ProcessingDocument21 pagesOptical Digital Signal ProcessingAbhijith SugathanNo ratings yet

- Optical Coherence TomographyDocument20 pagesOptical Coherence TomographyDr. Nikhil saranNo ratings yet

- Collimation Instructions APMAPOBino Version 1 3Document7 pagesCollimation Instructions APMAPOBino Version 1 3aandrassyNo ratings yet

- Eye ModelsDocument16 pagesEye ModelsgenalinangNo ratings yet

- Multifocal Tutorial ZemaxDocument8 pagesMultifocal Tutorial ZemaxDu RoyNo ratings yet

- Design of Basic Double Gauss LensesDocument11 pagesDesign of Basic Double Gauss LensesHarry H LeeNo ratings yet

- Optical Aberrations in Head-Up Displays - DiazDocument98 pagesOptical Aberrations in Head-Up Displays - DiazElke AnderssonNo ratings yet

- MATLAB Integration with ZemaxDocument30 pagesMATLAB Integration with ZemaxCristina Martinez GonzalezNo ratings yet

- Polarization LectureDocument46 pagesPolarization LectureSyed IrfanNo ratings yet

- Light Pipes For MatlabDocument113 pagesLight Pipes For MatlabHaripriya MuralikrishnanNo ratings yet

- VR Headset QR Codes – Hypergrid BusinessDocument58 pagesVR Headset QR Codes – Hypergrid BusinessMelvin FarfanNo ratings yet

- Satellite Communication Slides of Chap 5 (Polarization) of Dennis RoddyDocument28 pagesSatellite Communication Slides of Chap 5 (Polarization) of Dennis RoddyMir Sohail67% (3)

- Schiefspiegler ToolkitDocument5 pagesSchiefspiegler ToolkiteolocosNo ratings yet

- Lecture3 OptimisationDocument23 pagesLecture3 OptimisationlowteckweeNo ratings yet

- Collimator Alignment Procedure - 2Document7 pagesCollimator Alignment Procedure - 2alpharepairNo ratings yet

- SSC Je Survey One Liner NotesDocument64 pagesSSC Je Survey One Liner NotesRananjay Singh100% (1)

- (K14) - Contact LensesDocument33 pages(K14) - Contact LensesSyarifah FauziahNo ratings yet

- Minerals Under The Microscope - Earth Sciences - University of BristolDocument10 pagesMinerals Under The Microscope - Earth Sciences - University of Bristolpravat sahNo ratings yet

- TAPhS 100, 3, Secc. 1, A. Mark Smith - Alhacen On Refraction Volume 1, Introduction and Latin Text PDFDocument341 pagesTAPhS 100, 3, Secc. 1, A. Mark Smith - Alhacen On Refraction Volume 1, Introduction and Latin Text PDFManticora PretiosaNo ratings yet

- Cucs 016 13 PDFDocument16 pagesCucs 016 13 PDFAnonymous SlyvspdBNo ratings yet

- XC 003Document6 pagesXC 003mihailNo ratings yet

- Phy13 EXIT Key PDFDocument4 pagesPhy13 EXIT Key PDFChelsea MartinezNo ratings yet

- B76-90 (2013) Standard Test Method For Accelerated Life of Nickel-Chromium and Nickel-Chromium-Iron Alloys For Electrical HeatingDocument6 pagesB76-90 (2013) Standard Test Method For Accelerated Life of Nickel-Chromium and Nickel-Chromium-Iron Alloys For Electrical HeatingEhab HarbNo ratings yet

- The Optical Quality of The CorneaDocument32 pagesThe Optical Quality of The CorneaacalossiNo ratings yet

- Optical Aberrations ExplainedDocument25 pagesOptical Aberrations Explainedadam1234we0% (1)

- Form 4 Physics Lesson Plan on Forces and MotionDocument18 pagesForm 4 Physics Lesson Plan on Forces and MotionWong Teck KimNo ratings yet

- Lubitel 2Document7 pagesLubitel 2Mihai AndreiNo ratings yet

- Thesis On Microscope Optical DesignDocument76 pagesThesis On Microscope Optical Designnantha3256No ratings yet

- Unit 7 Guided NotesDocument10 pagesUnit 7 Guided NotesflyingmsNo ratings yet

- Refractive Errors: Raisa Janet Ariestha (I 111 09 041)Document26 pagesRefractive Errors: Raisa Janet Ariestha (I 111 09 041)Nauli PanjaitanNo ratings yet

- Masina de Masurat 3D PDFDocument40 pagesMasina de Masurat 3D PDFIoana TriscaNo ratings yet

- Online Test Series Syllabus Class 10 2019Document6 pagesOnline Test Series Syllabus Class 10 2019ABHISHEK SURYANo ratings yet

- Fotoceldas Laser LG10Document12 pagesFotoceldas Laser LG10Armando SotoNo ratings yet

- Module09 NewDocument71 pagesModule09 NewMiltiadis ZabelasNo ratings yet