Professional Documents

Culture Documents

Chadwick 2007 S

Uploaded by

Miguel MuchoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chadwick 2007 S

Uploaded by

Miguel MuchoCopyright:

Available Formats

L

ooking at the global mining software business,

merger and acquisition activity is driving

consolidation, and costs are skyrocketing,

according to Dan Miklovic, Vice President, Gartner

(an IT research and advisory consultancy). As such,

many resource-centric companies are looking to IT

to improve mining operations from ore extraction

through processing and enable a more flexible

business operating model.

HighGrade recently reported on a Gartner

report produced in the latter part of last year

saying that the market for mining execution

systems (MES) as opposed to the more

traditional manufacturing execution systems

was coming to life, attracting the interest of

ERP and enterprise asset management (EAM)

vendors such as SAP, Oracle and Mincom, who

were beginning to position themselves as

capable of aiding in mining operations. Indeed

at the AIMEX exhibition there was an exhibit

featuring Microsoft and various partners

working on a comprehensive software package.

Gartner believes it is unlikely ERP/EAM

vendors would come up with a single-source,

comprehensive mining execution and operations

management solution before 2010. Moreover, it

was in the ERP vendors best interests to keep

the market for mining execution fragmented.

MES solutions evolved from supervisory

control or data historian type software (such

as SCADA) or from mining technical systems

(mining software developers) presented mine

operators with pros and cons, with the former

offering challenges of a more technical nature,

according to Gartner. Whereas limitations of

MES products from the mining software sector

included vendor viability issues and Microsoft

platform dependency (now changing).

Consolidation in the mining industry is being

mirrored in the mining software area, with

Gemcom more than doubling in size since

acquiring Australias Surpac, and companies

such as Micromine and Maptek growing

strongly. Others such as Mincom and Runge are

acquiring software businesses, such that the

sector landscape is increasingly being

dominated by fewer, bigger vendors that are

more financially stable.

GijimaAst may be a new name to some, but

it is also big, though it has worked quietly

developing its mining customer base at the user

level rather than splashing its brand everywhere.

The biggest?

Gemcom Software International claims to be

the largest global supplier of specialised

mining productivity solutions. It has been a

busy year for the company, having released

GEMS 6.1 underground software; Minex 5.2

geology and mine planning software;

MineSched 5.1 target-based scheduling

software; and Gemcom Insite 2.1 mine

performance management software.'

The year 2007 has also been busy for

Mincom, which has strengthened its mining

position. First it acquired the metallurgical

accounting solution, JKMetAccount, from

JKTech, a leading Australian technology

provider and transfer company of the world

renowned Julius Kruttschnitt Mineral Research

Centre. As part of the agreement, Mincom and

JKTech agreed that Mincom will have first right

of refusal over third parties to acquire JKTech's

other software solutions.

Richard Mathews, Mincom CEO: The

acquisition of JKTechs software solutions

increases Mincoms technical mining platform

by providing advanced solutions. JKTech has a

strong track record for developing systems that

enable mining and mineral processing

organisations to enhance their product

recovery. Dave Stevenson, Mincom Vice

President Mining: Production accounting is a

vital tool for the minerals industry similar to

financial accounting, except rather than

tracking the movement of finance; it focuses

on the movement of metal and mineral

products through mining, enrichment, refining

and distribution. The addition of a metallurgical

accounting solution will assist mining and metal

processing facilities to align themselves with

key accounting codes of practice.

This acquisition was quickly followed by the

purchase of Karjeni, a software development

company based in Perth, Western Australia.

This increases Mincom's technical mining

platform by providing complementary software

solutions for end-to-end production

accounting. Stevenson: End-to-end production

accounting functionality is not only a strategic

MINING SOFTWARE

Software and mine planning

John Chadwick reports on consolidation among the providers and increasing

customer interest for integration of mining technical and financial systems.

Scheduling and compliance are also priority software areas

NOVEMBER 2007 International Mining 19

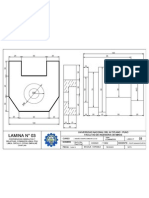

GijmaASTs EPS Visualiser

SOFTWARE 24/10/07 11:27 am Page 3

part of mining but has emerged as a key

requirement in the industry. The addition of

Karjeni's software solutions adds a number of

modules to our metallurgical accounting

solution recently acquired from JKTech. Karjeni's

flagship solution, dPipe, delivers high levels of

technical data management automation

through sophisticated data transformation

workflow management and smart data error

handling. This enables our technical mining

solutions to access, validate and transform data

from the production control systems as well as

other disparate data sources.

Software in

Siberia

In September, Mincom

announced signing a new

large, long-term contract

with the worlds largest

nickel producer, MMC

Norilsk Nickel in Russia. Under this agreement,

Mincom Ellipse is assigned as the standard

solution for Polar Divisions mining and

metallurgical sites, located in Norilsk. The

Mincom Enterprise Mining Solution (MEMS) is a

modular, fully integrated solution, providing

extensive functionality in the area of asset

management, materials/supply chain and

maintenance management, in combination

with management of financial flows and

personnel. Mincom Ellipse will be implemented

to manage operational activities in

underground mining and above-ground

management areas and workshops, and will

provide real-time visibility of operational and

financial metrics across the organisation.

Accordingly this solution will support Norilsk in

making optimal management decisions.

Yuri Filippov, Director of Production, said,

Our key objective is to increase shareholder

value and one of the ways to achieve this, is to

introduce cutting edge technologies facilitating

higher efficiency of business operations and

executive decision-making.

Norilsk became Mincoms customer in

December 2003 and since then it has

progressively implemented the Mincom Ellipse

system. During the past three and a half years

of co-operation a number of large projects

were successfully carried out. These included

implementation of a maintenance management

system for mobile mining equipment in all the

mines of Norilsks Polar Division, as well as an

asset management module at the Taymyrsky

and Oktjabrsky mines. The solution developed

during these projects and the standards and

experience will help Norilsk to carry out a full

implementation of the system over the next

three years.

Moreover Norilsk represents the largest user

of Mincom MineScape in Russia. MineScape is

an integrated solution for geological modelling

and mine planning that Oktjabrsky, Europes

MINING SOFTWARE

20 International Mining NOVEMBER 2007

Geosoft's Oasis montaj is

powerful processing and

mapping software for

mineral exploration and

earth science investigations

including environmental

projects

SOFTWARE 24/10/07 11:27 am Page 4

biggest polymetallic mine, has been using since

2005. Implementation of this solution is

planned for all Polar Division mines.

Enhancements to the system have been made

jointly in order to satisfy the requirements of

Russian legislation and this system has

successfully received certification from

RosTechNadzor for use in Norilsks mines.

Surveying at the face

GijimaAsts products division has two new

software applications, mineMarkup and EPS

Viz, launched during AIMEX. MineMarkup is a

suite of underground survey solutions that

captures survey and geological information and

records it directly into 3D mine plans. A

ruggedised pen computer is used to

communicate with an automated total station.

The head of GijimaAsts product development

team, Wayne Romer, says that mineMarkup

will revolutionise the speed of capture and

communication of survey data to all the users

on a mine site.

EPS Viz is a complementary module for the

existing EPS product that provides a dynamic

3D visualisation of EPS Gantt Chart mining

schedules. 3D animation displays the impacts of

schedule changes instantly, and activities can be

selected in the Gantt chart and automatically

highlighted in the graphic environment.

Many of GijimaAsts

packaged products are

developed, published

and/or distributed in

conjunction with its global

partner Datamine. Flagship

products include Mine2-4D,

EPS, mineCAD, CADSmine, mineServ and G-

Risk.

On the solution side of GijimaAsts business,

there is continuing strong demand for

customised solutions emerging from the

industry. Examples of these are the custom

developed ventilation and rock mechanics

management systems in place at one of

Australias largest underground mines, and the

recent outsourcing by DeBeers of around 50

customised applications for ongoing

maintenance, support and development.

Complementing its involvement with SAP as

an Alliance Partner, Channel Partner and

Customer Competence Centre, GijimaAst has

now joined the SAP Mining Industry Value

Network (IVN). There is increasing customer

interest for integration of mining technical and

financial systems, and the initial focus of

GijimaAsts involvement in the IVN is to convert

the existing platform for transferring EPS data

to SAP to the emerging standard xMII platform.

Datamine is continuing to develop software

that reinforces the delivery of its Operational

Improvement programs, particularly in the area

of enabling mines to routinely make better use

of geotechnical data to make engineering

decisions. The companys integrated Sirovision

11/07

NOVEMBER 2007 International Mining 21

Mapteks Studio 3.1 extends I-

Site's language capabilities

further to include American

English, modern Chinese,

Spanish, German and

Japanese

SOFTWARE 20/10/07 12:11 pm Page 5

system is nearing completion with initial

projects being undertaken with AngloGold

Ashanti in Australia and Xstrata in Canada.

Sirovision is a technology that combines the

power of digital photography with advanced

mathematics to rapidly produce accurate 3D

structural models of mine features using non

specialised digital cameras. Sirovision has been

specifically designed to support rapid mapping

of mine features with a minimum of expertise

in photogrammetry. Using Sirovision, it is

possible to build accurate three-dimensional

models from sections as small as 2 m

2

up to

40,000 m

2

in minutes. The core Sirovision

technology has been developed by the CSIRO

and the integrated system is being developed

by Datamine in conjunction with Century

Systems.

Datamines GeoTech Modeller complements

the integrated Sirovison system by enabling

geotechnical data collected from Sirovision 3D

images and other sources to be systematically

used for tasks such as adjusting blast patterns

to obtain better fragmentation, refining slope

designs and in underground mines helping to

determine support requirements.

Another forthcoming product from Datamine

is MineTrust. MineTrust provides a new and

flexible approach to giving global mining

organisations access to and visibility of the

status and progress of data being created and

used by technical staff at mining locations for

reserve and resource estimation, mine design

and scheduling. MineTrust runs as a stand

alone system meaning it can be used with all

general mining packages but it will also run

embedded in Datamine Studio.

Datamine has also released NPV Scheduler

Version 4, including geological risk assessment

as well as improved display and animations of

schedules.

Mine planning

Mintecs MineSight

mine planning tools

provide an integrated solution for planning

open pit and underground operations, from the

conceptual strategic planning stage to the daily

production stage. There are now four

integrated mine planning software tools

encompassing all levels of mine planning, from

scoping studies through feasibility; long,

medium, and short-range planning; to daily

mine operations planning.

MineSight Economic Planner (MSEP) is the

combination of two programs: MSOPIT

performs open pit/phase optimisation tasks and

MSVALP carries out simplified strategic long-

range open pit production scheduling with

cutoff grade and material process optimisation.

Block models and surface files are read

directly from MineSight 3D aiding the

development of an optimal mine plan.

Economic values can then be calculated based

on multiple material destinations and multiple

metal or product types. NPV calculations can be

incorporated into the mine design or applied to

the schedule.

MineSight Strategic Planner (MSSP) is

designed for long-range open pit mine

scheduling, providing the guidelines for

MineSight SP in terms of estimated optimum

cutoff grades and estimated best mining

sequence for the life span of a mining project.

MSSP then generates the detailed long-range

production scheduling following the guidelines

provided by MSEP.

MSSP takes in pushback reserves data and

examines all combinations of mining patterns

for feasible mining layouts which meet current

period targets and satisfy current period

operating constraints. When a feasible layout is

found, the use of material destination

locations/capacities and the use of trucks and

shovels are simulated. If the removal of the

mined materials is successful, the mining

layout becomes a feasible solution and the

costs and revenues associated with this feasible

solution are computed and recorded.

At the end of a period, an examination of all

feasible solutions is made. An optimum

solution is chosen based on the period

objective with mining then carried out based

22 International Mining NOVEMBER 2007

MINING SOFTWARE

SOFTWARE 24/10/07 11:05 am Page 6

on the optimum solution. Reserves

status, material destinations

capacities, and available trucks and

shovels hours are updated. This

process is repeated period-by-

period until all resources are

scheduled.

MineSight Interactive Planner

(MSIP) is an interactive tool used to

calculate short and medium-range

mine plans for open pit and

underground mines. Since many

projects are highly variable and

complex, this repetitive and

interactive task requires a flexible

and highly interactive tool.

MSIP imports model and surface information

from existing MineSight block or gridded seam

models or initialises a third party block model

and loads it with ASCII values graphically

displaying all required information in 3D. As

planned mining progresses, feedback is

provided in terms of data critical to the

planning process including block model grade

and rock type information, constraining limits

such as design pits, geological boundaries, and

characteristics of material moved during the

planning session.

Information generated during a planning

session is stored in a third party, ODBC

compliant database. For the cuts created during

the planning session, the cut geometry,

attributes, and reserves can be stored in the

attributed geometry database. Cut geometry

can be a 2D or 3D representation of a bench

shovel cut or stope blast ring. Attributes are

any user-defined properties of the material

within the cut, and the reserves consist of

tonnes, grade, and materials above a set of

user defined cutoffs.

Reserves summaries, on-screen reports, and

plots are easily generated. The flexibility of the

scripting interface allows total customisation of

reports, as well as on-screen progress controls.

MineSight

Activity Planner (MSAP) is

Mintecs latest mine scheduling tool flexible

enough to be used in any planning scenario,

but with an emphasis on short-range mine

production planning, creating executable plans.

MSAP is designed to bridge the interface

between the short-range mine planning from

MSIP and mine operations providing

opportunity for plan creation at any required

level of detail.

The scheduling system works for both

underground and open pit planning. However,

MSAP makes the biggest impact to

underground mines where production plans are

often complex and susceptible to unforeseen

circumstances.

The goal is to optimise the allocation of

manpower and equipment resources to achieve

a target production or development. By

planning the available resources instead of

general tasks, there is a much higher likelihood

that the plan is viable. The Planning Board, a

graphical representation of resource use as a

function of time for resource-based scheduling

is a key feature. It assigns activities to

resources, which can be moved around the

Planning Board, changing duration or

reassigning them to

other resources. MSAP

also includes the ability

to manage disturbances

such as unavailable

equipment or road

restrictions allowing the

engineer to effectively

manage resource and

activity constraints,

implement work

calendars, plan for

disturbances, and chart

resource attributes such

as tonnage and grade.

MSAP automatically

alerts users to potential

scheduling errors by

enforcing user-defined

rules. It prevents

dragging or modifying an

activity if it violates the

rules.

From the resource

Planning Board, Gantt

Charts can be built

showing all activities in

graphical form and

visually defining

constraints between activities for

building complex activities and

managing activity sequencing.

Summary reports for resources and

activities are built using Seagate

Crystal Reports and may be

printed or exported to a variety of

formats such as Microsoft Word

and Adobe Acrobat.

Industry value

network

In September, Runge announced

its xSTMS (Short Term Mining

Scheduling) 1.0 packaged

composite application based on its

Mining Dynamics solution has achieved SAPr

xApps Certified Powered by SAP NetWeaver

status. Runge says xSTMS integrated with SAP

solutions will provide a complete, standard and

fully integrated solution for mine scheduling,

supply chain logistics and end-customer

delivery. This certification follows Runge joining

SAPs Mining IVN, in May this year, which was

established by SAP to address priority mining

industry needs and business challenges.

The certification marks the successful

integration of an end-to-end business process

covering Runges expert mining scheduling

solution and the SAP ERP application-based

production process. The new xSTMS composite

Mintec now offers four integrated mine planning

software tools for open pit and underground

operations

11/07

NOVEMBER 2007 International Mining 23

SOFTWARE 24/10/07 11:38 am Page 7

application uses SAPs strategic shop-floor

integration platform, the SAP xApp

Manufacturing Integration and Intelligence

(SAP xMII) composite application, based on

a service-oriented architecture (SOA).

Tony Kinnane, CEO of Runge: The

members of the IVN for mining identified

scheduling and compliance as priority areas

that needed to be addressed to provide

business value for global mining

organisations. We now have a solution

that enables adaptive mining scheduling

processes.

The IVN for mining includes

representatives of the Industry Advisory

Council for Mining, comprised of leading

global companies. The members intend to

evaluate new composite solutions and

integration scenarios in the areas of mining

operations management, enterprise asset

management and operational compliance.

Runges Mining Dynamics delivers a

visual system to support data management

and discovery across the entire production

chain; from geology, modelling and design,

through scheduling and reconciliation. The

solution provides information control, access,

legislative compliance and enterprise systems

integration. Operations, technical, and

corporate employees have instant access to

information about mine site operations. The

system is vendor independent and works with

mining companies existing systems avoiding

the need for costly replacement software.

Other news from Runge is that it has entered

into strategic business partnership with ESRI,

the US software firm which designs and

develops the worlds leading geographic

information system (GIS) technology. Runge

and ESRI will collaborate to bring solutions to

mining customers in the area of advanced

2D/3D integration and visualisation.

The first Runge product to emerge from the

new partnership was the Mining Dynamics

Platform. Kinnane: This is an important

partnership because in collaboration with ESRI,

Runge can provide rapid solution development

coupled with other technology vendors

expertise, thus delivering superior integrated

solutions to the global mining industry.

The company says the 2D/3D integration

and visualisation project will permit any mining

user, at any time, in any location to access and

view their mining data in a full 3D world. It will

simplify the end use by removing the need for

complex and expensive technical software.

The latest releases of Mapteks three key

products have focused on integration, usability

and performance. Maptek Vulcan version 7

was rolled out in February 2007, with 7.5

interim release now ready for delivery.

Performance and usability improvements in

Vulcan 7.5 include enhanced capacity to store

metadata, such as survey, drill hole and grade

attributes, with design objects. Targeting

specific commodities in the global market

resulted in a new oil sands module in Version

7.5, developed in conjunction with Maptek

customers in Canada. The module includes

tools for greater control over block models, and

the ability to quickly determine the average

value of multiple variables of specified blocks.

Vulcan creates a triangulated mining floor for

reference in the mine planning stage.

A dedicated development team in

eastern Australia is using feedback from

local coal operations to improve

geological modelling to handle even

more complex structures. A total

overhaul of the Vulcan architecture to

support extremely large datasets and

faster graphics will result in a 64-bit

release, as Version 8 next year. As well as

multiple language offerings, this version

will begin to introduce the concept of

third party database support for Vulcan

data structures, along with data security,

data auditability and revision control.

Maptek says that what this comes

down to is development in line with

customer needs. Clients who have

studied the payback over a 10-year

period have seen that although Vulcan

was a larger investment, lower annual

payments have made it better value for

money.

A year down the track from release,

Maptek I-Site Studio 64-bit version has

proved itself on large project datasets. The next

major release, 3.1, focuses on graphics and

modelling. New tools for open pit update allow

users to scan sections of a pit and integrate the

new data into their current pit model. For the first

time, Studio users can incorporate photography

from multiple scans as part of the modelling

process, streamlining geological interpretation on

highwalls. Studios rendering and animation

options deliver professional quality, high fidelity

digital video output for corporate presentations.

In North America US, Studio software is

being picked up by companies who need the

extra power to process airborne lidar data. The

oil sands market is a case in point where

traditional methods were not delivering the

results needed.

I-Sites mobile mapping solution has

incidentally addressed minings labour crisis,

allowing operations to be more productive with

their existing workforce. A survey group can

cover more territory, with improved safety and

speed. Studio 3.1 extends I-Sites language

capabilities further to include American English,

modern Chinese, Spanish, German and

Japanese. The language interface is chosen

MINING SOFTWARE

24 International Mining NOVEMBER 2007

Runges XPAC Autoscheduler

SOFTWARE 24/10/07 11:07 am Page 8

automatically based on the users PC settings.

Maptek MineSuite is a mine production

monitoring system and the 4.7 release features

a new mapping interface, improved

performance and extended integration

capabilities. The mapping display work area has

been maximised, running in headerless full

screen mode, rather like a gaming interface.

Any information captured in real-time can be

replayed live, so event data like tonnage, gear

selected and fuel usage can be seen along with

the location of the vehicle or equipment.

Maptek is developing MineSuite to perform

more data mining, a term given to the science

of extracting useful information from large

datasets or databases. OLAP online analytical

data processing allows miners to maximise

transfer of useful data from collected

information. Planned upgrades to MineSuite

include implementing Java 6 programming to

improve performance and integration with the

Windows desktop. Integrating MineSuite with

third party reporting tools and real-time

dashboards is also on the development horizon,

to further promote seamless workflow with

existing mine operation systems.

Version 11 of MICROMINE was due for

release at the end of October 2007 and is, the

company says, an exciting release which

continues the evolution of Micromine from

exploration software to mining and exploration

software. Our company is also evolving and has

grown from being a developer of software to

being a provider of integrated IT solutions to

the mineral resource sector. This paradigm shift

means that the latest version of Micromine has

not only been developed with a greater

emphasis on mining, but with a greater

emphasis on flexibility and ease-of-use.

Micromine software solutions have been

used in the mineral resource industry in

Australia for more than 20 years and recently

the company has experienced significant

growth in countries like China, Russia (see

Aricom article this issue) , Mongolia, South

Africa and the USA. Micromine continues to

raise the benchmark for innovation with its

MICROMINE, PITRAM, DOME, GBIS, and FIELD

MARSHAL suite of products. Exploration and

mining companies across the globe use these

products to assist them in the design,

planning and management of their

operations.

The current trend is to use integrated

systems, ranging from exploration to mineral

processing. A significant part of this is the use

of real-time mine control software to control

production and increase efficiency and

productivity of mining operations. Large new

mines, such as Fortescue Metals Groups

Western Australia Iron Operations are using

Micromine as their preferred supplier.

Micromine products are being used to manage

data and run the mine using GPS equipment

tracking and telemetry to send mine events to

the production database. The use of this system

allows mine management to continually

improve the production of the mine and

control mine costs.

3-D modelling

Coffey Mining has just reported that it has

become the only mining consultancy to gain

access to Beck Arndt Engineerings world-

class 3D non-linear rock mass modelling

technology and expertise with the recent

signing of an agreement. Coffey says: Access

to this best-practice mine modelling will allow

[it] to improve extraction sequencing and mine

design throughout the mining process for

underground and open pit mines. Better

managed mine stability improves safety and

boosts productivity and production rates to

optimise a mines life cycle.

CEO of Coffey Mining Dan OToole: We

were looking to link up with a specialist applied

mechanics company and provider in the field of

simulation of the 3D rock mass response to

mining. Beck Arndt emerged as an exciting

option. Beck Arndt specialises in engineering

for large and complex mining operations,

building, calibrating and running large,

geometrically accurate mine-scale 3D non-linear

models. It is the largest provider of non-linear

modelling services to the Australian mining

industry and an emerging preferred provider to

a number of the largest mine operators,

including BHP Billiton in Australia and North

America, Codelco Norte in Chile and Rio Tinto

in Australia.

Coffey Mining will formulate and plan the

modelling with clients, working closely with the

Berlin and Perth-based Beck Arndt simulation

and engineering teams. Beck Arndt will

conduct the simulations and, where required,

will be available to assist Coffey Mining with

interpretation and engineering using the model

results. Peter Fuller, Chief Mine Geotechnical

Engineer at Coffey Mining said: Calibrated

with our observations, we will use this

information to develop reliable predictions of

ground behaviour and design optimum mining

approaches for our clients. It will enable us to

highlight areas that will be damaged by mining

so remedial processes such as reinforcing rock

or changing the extraction sequence can be

formulated ahead of time. The information

from this modelling will provide early

intelligence on which parts of the mine are

likely to be damaged and predictions on how

11/07

NOVEMBER 2007 International Mining 25

Put ToughMet

in your corner.

The 900-lb gorilla of bearing materials.

ToughMet is the hardest working

bearing material in the industry,

giving you unparalleled strength

and lubricity in one superior material.

Proven successful in the toughest

applications, ToughMet requires

less maintenance and lubrication

while virtually eliminating

unplanned downtime.

So, don't monkey around with

conventional bronze or steel

bearing materials. Put the 900 lb.

gorilla to work for you, and you'll

be eating your competition's lunch.

Visit us at Toughmet.com/gorilla-im

or call us toll-free at

800-375-4205.

BEARI NG

DESI GN GUI DE

Optimize the fit and performance

of your ToughMet alloy

replacement bushings online

at www.toughmet.com/

bearingdesign

NEW

SOFTWARE 20/10/07 12:23 pm Page 9

key points of the mine will behave the

mine progresses, including pillars and

shafts, infrastructure and access points.

Beck Arndt has been developing the

application of the widely used ABAQUS

modelling package to mining problems

for many years. ABAQUS is a 3D, non-

linear computer modelling package that

is widely used throughout the world in a

range of engineering applications

including aerospace, automotive, civil

and nuclear engineering. Beck Arndt

identified the opportunity to apply the

advanced modelling technology to rock mass

simulation, and with some in-house

development the result has been a step change

in simulation capabilities for mining.

Very detailed 3D mine simulation on a

massive scale is now possible for pits and

underground mines. The simulation is

efficient and detailed enough to allow true

simulation-aided mining engineering and

planning, where engineers and modellers

work closely to optimise and continuously

improve design before mining, or using field

measurements and data during operations,

David Beck said.

Vehicle tracking

acQuire Technology Solutions (formerly

Metech) focuses on solving one of the most

difficult problems in the industry the

capture, management and delivery of quality

geoscientific observations and

measurements - on which resource models

depend. The philosophy is that data integrity

starts in the field and acQuire continually

provides innovation in data capture tools to

encourage validation at the field data

capture stage.

The technology is used in more than 300

sites around the world and in over 35

countries. Its success is based on the

architecture of the technology as well as the

companys commitment and ability in

delivering a complete solution. The

company understands that customers are

seeking the effective integration of acQuire

technology with their processes and people.

The acQuire solution optimises the

workflow, capturing, managing and

delivering high integrity data equally well in

the exploration setting as it does in resource

development and production.

acQuire has devoted the last eight years to

developing and implementing the acQuire

database technology which is now recognised

as a premier standard in this domain. IM

26 International Mining NOVEMBER 2007

REVIEW

New

Optimization

Module

Net Present Value Optimization

Minimum and Maximum

Constraints on Tonnes, Grade

and Development Metres

Blending Functionality

Suite 1, 45 Ord St, West Perth 6005 Western Australia

Tel: +618 9226 3288 Fax: +618 9226 3299 Web: www.minemax.com

Earlier this year, Atlas Copco launched three

new upgraded packages of the software

Tunnel Manager. Thanks to usage of latest

computer technology the new programs are

easier to use compared to the previous

versions. The most advanced package, Tunnel

Manager MWD, offers a completely new

functionality built on several years of research

at Lule University of Technology in Sweden

SOFTWARE 20/10/07 12:23 pm Page 10

You might also like

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- The Loss of Space Shuttle Columbia PDFDocument11 pagesThe Loss of Space Shuttle Columbia PDFMiguel MuchoNo ratings yet

- Terminal Velocity Gpo 4Document4 pagesTerminal Velocity Gpo 4Miguel MuchoNo ratings yet

- Terminal Velocity Gpo 4Document4 pagesTerminal Velocity Gpo 4Miguel MuchoNo ratings yet

- Blasting and Mining PDFDocument40 pagesBlasting and Mining PDFF Aguirre100% (2)

- DocumentDocument38 pagesDocumentMiguel MuchoNo ratings yet

- Let ReroDocument1 pageLet ReroMiguel MuchoNo ratings yet

- Leyenda: Carretera RIO Camino Afloramiento Rumbo Vivienda Puente BuzamientoDocument1 pageLeyenda: Carretera RIO Camino Afloramiento Rumbo Vivienda Puente BuzamientoMiguel MuchoNo ratings yet

- SDC - Rules & Forms 2015-2016Document16 pagesSDC - Rules & Forms 2015-2016Miguel MuchoNo ratings yet

- Pre Venta Perumin - Libros SmeDocument1 pagePre Venta Perumin - Libros SmeMiguel MuchoNo ratings yet

- SME S Student Chapter BylawsDocument4 pagesSME S Student Chapter BylawsMiguel MuchoNo ratings yet

- Balance Antamina M1-2Document20 pagesBalance Antamina M1-2Fernando Gonzales HernandezNo ratings yet

- Blast Design and Assessment For Surface Mines and Quarries Part 1: IntroductionDocument5 pagesBlast Design and Assessment For Surface Mines and Quarries Part 1: IntroductionMiguel MuchoNo ratings yet

- Lamina 01 OkDocument1 pageLamina 01 OkMiguel MuchoNo ratings yet

- Drawing3 ModelDocument1 pageDrawing3 ModelMiguel MuchoNo ratings yet

- Lamina 03 OkDocument1 pageLamina 03 OkMiguel MuchoNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Template RFP Draft (050516)Document13 pagesTemplate RFP Draft (050516)UGHANo ratings yet

- Evs 3643 Summary ProductDocument43 pagesEvs 3643 Summary ProductishaqnfNo ratings yet

- Function CatalogueDocument591 pagesFunction CatalogueAshish PatwardhanNo ratings yet

- An Elementary Textbook of Physics Sound - R. W. StewartDocument161 pagesAn Elementary Textbook of Physics Sound - R. W. StewartJonak SandilyaNo ratings yet

- Actron Digital Multimeter cp7676 Manual de UsuarioDocument72 pagesActron Digital Multimeter cp7676 Manual de UsuarioManuel OrtizNo ratings yet

- Management Information Systems PDFDocument96 pagesManagement Information Systems PDFPuneet GajendragadNo ratings yet

- Shneiderman's 8 Golden Rules of Interface Design: The Principles Questions To Consider Mark CompleteDocument1 pageShneiderman's 8 Golden Rules of Interface Design: The Principles Questions To Consider Mark CompletellNo ratings yet

- 8 Active-JourneysDocument5 pages8 Active-JourneysZhennan ZhangNo ratings yet

- Subcontracting For MRO Processes Sap PMDocument22 pagesSubcontracting For MRO Processes Sap PMratnesh_xp100% (2)

- CFS VehicleHistoryReportDocument8 pagesCFS VehicleHistoryReportJAVINo ratings yet

- Module 7 - Bootable MediaDocument17 pagesModule 7 - Bootable Mediajerome24diassanNo ratings yet

- JSA Lifting With Equipment+Load ChartDocument13 pagesJSA Lifting With Equipment+Load ChartBoas BoetarzNo ratings yet

- What Editions Are Available in Windows Server 2016?Document2 pagesWhat Editions Are Available in Windows Server 2016?John MikeNo ratings yet

- 1.introduction To Bigdata Chap1Document35 pages1.introduction To Bigdata Chap1Snoussi OussamaNo ratings yet

- AMP Check ListDocument8 pagesAMP Check ListCAM TAVNo ratings yet

- GujaratiDocument7 pagesGujaratiVijay KumarNo ratings yet

- Osisense XC Xckp2118g11Document2 pagesOsisense XC Xckp2118g11Luis Enrique PariapazaNo ratings yet

- PTW ManualDocument13 pagesPTW Manualkhiladikumar24No ratings yet

- Keyboard ManualDocument11 pagesKeyboard Manualafnan a.muhammadNo ratings yet

- Hitz Work and PayDocument2 pagesHitz Work and Paynajergodfred12No ratings yet

- How To Recognize The SMD Components On The Motherboard of The LaptopDocument6 pagesHow To Recognize The SMD Components On The Motherboard of The LaptopBartek Ar100% (2)

- PWM Generation Using 8051 MicrocontrollerDocument3 pagesPWM Generation Using 8051 Microcontrollerveeramaniks40867% (6)

- 1PH EswfDocument9 pages1PH EswfSomaraju PitchikaNo ratings yet

- ACS723 Datasheet PDFDocument23 pagesACS723 Datasheet PDFNguyên NghĩaNo ratings yet

- Proxy Exams Being Cert-1Document4 pagesProxy Exams Being Cert-1Bryan GoetzNo ratings yet

- Python Date TimeDocument5 pagesPython Date Timemlungisigcabashe44No ratings yet

- Complete PowerlineDocument164 pagesComplete PowerlineHarshal AmbatkarNo ratings yet

- Global CommunityDocument14 pagesGlobal CommunityRyan BuerNo ratings yet

- Power Electronic TransformerDocument7 pagesPower Electronic TransformerNarendra TrivediNo ratings yet

- Manish AssignmentDocument7 pagesManish AssignmentAnkitNo ratings yet