Professional Documents

Culture Documents

Re26892 2003-02

Uploaded by

DANIZACHOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Re26892 2003-02

Uploaded by

DANIZACHCopyright:

Available Formats

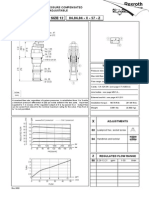

DR 1/10 RE 26 892/05.

02

2003

by Bosch Rexroth AG, Industrial Hydraulics, D-97813 Lohr am Main

All rights reserved. No part of this document may be reproduced or stored, processed, duplicated or circulated using

electronic systems, in any form or by any means, without the prior written authorisation of Bosch Rexroth AG.

In the event of contravention of the above provisions, the contravening party is obliged to pay compensation.

Overview of contents

Contents Page

Features 1

Ordering details 2

Preferred types 2

Function, section 3

Symbols 3

Technical data 4

Characteristic curves 5, 6

Performance limits 5

Unit dimensions 7 to 9

RE 26 892/02.03

Replaces: 05.02

Pressure reducing valve, pilot operated

Type DR

Nominal sizes 10 to 32

Series 5X

Maximum operating pressure 350 bar

Maximum flow 400 L/min

Type DR 20-5-5X/315Y...

K

4

6

6

0

-

9

Features

For subplate mounting, porting pattern to DIN 24 340 form D,

ISO 5781 and CETOPRP 121 H, subplates to catalogue sheet

RE 45 062 (separate order)

For threaded connections

For manifold mounting

4 adjustment elements:

Rotary knob

Sleeve with hexagon and protective cap

Lockable rotary knob with scale

Rotary knob with scale

5 pressure stages

Check valve, optional (only for subplate mounting valves).

RE 26 892/05.02 2/10 DR

DR 5X Y

*

Ordering details

Pilot operated

valve = No code

Pilot operated valve = C

without main spool insert

(do not enter nom. size)

Pilot operated valve = C

with main spool insert

(enter valve size 30)

Nom. Valve for

size Subplate mounting Threaded connections

G

Ordering details

10 = 10 = 10 (G 1/2)

16 = 15 (G 3/4)

25 = 20 = 20 (G 1)

25 = 25 (G 1 1/4)

32 = 30 = 30 (G 1 1/2)

For subplate mounting =

For threaded connections = G

Adjustment element

Rotary knob = 4

Sleeve with hexagon and protective cap = 5

Lockable rotary knob with scale = 6

1)

Rotary knob with scale = 7

Further details

in clear text

No code = NBR seals

V = FKM seals

(other seals on request)

Attention! The compatibility of the seals

and pressure fluid has to be taken into account!

No code

3)

= With check valve

M = Without check valve

Pilot oil supply

Y = Internal pilot oil supply,

external pilot oil drain

50 = Settable pressure up to 50 bar

100 = Settable pressure up to 100 bar

200 = Settable pressure up to 200 bar

315 = Settable pressure up to 315 bar

350

2)

= Settable pressure up to 350 bar

5X = Series 50 to 59

(50 to 59: unchanged installation and connection dimensions)

1)

H-key to Material No. R900008158 is included within the

scope of supply

2)

Only possible for version without check valve

3)

Only available as pilot operated valve for subplate mounting

Preferred types (readily available)

Preferred types and standard components are

highlighted in the RPS (standard price list).

RE 26 892/02.03

Type Material number

DR 10 -5-5X/100Y R900596766

DR 10 -5-5X/200Y R900503741

DR 10 -5-5X/315Y R900596883

DR 20 -5-5X/100Y R900597198

DR 20 -5-5X/200Y R900597892

DR 20 -5-5X/315Y R900597048

DR 30 -5-5X/100Y R900596339

DR 30 -5-5X/200Y R900596500

DR 30 -5-5X/315Y R900596928

DR 3/10 RE 26 892/05.02

A

B

16

B

A Y

B

A

Y

a a

A B Y

5

1

4

3

8

7

17

2

9 10 6 11 14

12

13

15

Function, section

Symbols

Type DR pressure valves are pilot operated pressure reducing valves,

which are controlled from the secondary circuit.

They basically consist of main valve (1) with main spool insert (3)

and pilot control valve (2) with pressure adjustment element.

At rest, the valves are open, this means that fluid can freely pass

from port B, to port A via the main spool insert (3).

Pressure present in port A acts on the under side of the main spool.

At the same time there is pressure acting on the ball (6) in the pilot

control valve (2) via the orifice (4) on the spring-loaded side of the

main spool (3) and via port (5). This pressure also acts on the ball (6),

via the orifice (7), control line (8), check valve (9) and orifice (10).

Depending on the setting of spring (11), pressure builds up in front

of the ball (6), in port (5) and in spring chamber (12), which holds

the control spool (13) in the open position. Pressure fluid can freely

flow from port B to port A via mian spool insert (3) until the pressure

in port A exceeds the value set at spring (11) and opens the ball (6).

The control spool (13) moves to the closed position.

The desired reduced pressure is achieved, when a balance between

the pressure in port A and the pressure set at spring (11) is reached.

Pilot oil drain from spring chamber (14) to tank always takes place

externally via control line (15).

Free return flow from port A to port B can be achieved by installing

an optional check valve (16).

A pressure gauge connection (17) allows the reduced pressure in

port A to be monitored.

Type DR..-.-5X/...YM.. Type DR..-.-5X/...Y..

(only for subplate mounting)

Type DR..-4-5X/...Y...

Without

check valve

With

check valve

RE 26 892/05.02 4/10 DR

Technical data (for applications outside these parameters, please consult us!)

General

Installation Optional

Ambient temperature range C 30 to + 50 for NBR seals

C 20 to + 50 for FKM seals

Weight DR 10 DR 16 DR 20 DR 25 DR 32

Subplate mounting DR kg 3.4 5.3 8.0

DRC kg 1.2

DRC 30 kg 1.5

Threaded connections DR..G kg 5.3 5.2 5.1 5.0 4.8

1)

350 bar only possible for version without check valve

2)

Suitable for NBR and FKM seals

3)

Only suitable for FKM seals

4)

The cleanliness class stated for the components must be

adhered too in hydraulic systems. Effective filtration prevents

faults from occurring and at the same time increases the

component service life.

For the selection of filters see catalogue sheets RE 50 070,

RE 50 076 and RE 50 081.

Hydraulic

Nominal pressure bar 350

1)

Maximum operating pressure at port B bar 350

1)

Operating pressure range at port A bar 10 to 350

1)

Maximum back pressure at port Y bar 350

1)

Settable pressure Minimum bar Flow related (see characteristic curves on page 5)

Maximum bar 50; 100; 200; 315; 350

1)

Maximum flow DR 10 DR 16 DR 20 DR 25 DR 32

Subplate mounting L/min 150 300 400

Threaded connections L/min 150 300 300 400 400

Pressure fluid Mineral oil (HL, HLP) to DIN 51 524

2)

;

Fast bio-degradable pressure fluids is to

VDMA 24 568 (also see RE 90 221); HETG (rape seed oil)

2)

;

HEPG (polyglycols)

3)

; HEES (synthetic ester)

3)

;

Other pressure fluids on request

Pressure fluid temperature range C 30 to + 80 for NBR seals

C 20 to + 80 for FKM seals

Viscosity range mm

2

/s 10 to 800

Cleanliness class to ISO code Maximum permissible degree of contamination of the pressure

fluid is to ISO 4406 (C) class 20/18/15

4)

RE 26 892/02.03

DR 5/10 RE 26 892/05.02

0 50 100 150 250 400

2

4

8

10

14

6

300

16

200 350

12

1 2

3

p

A min

0 50 100 150 250 400

50

100

200

250

300

150

300

350

200 350

315

0 50 100 150 250 400

2

4

8

10

14

6

300 200 350

12

Characteristic curves (measured with HLP46, !

oil

= 40 C 5 C)

Outlet pressure p

A

in relation to the flow q

V

(B to A)

Flow in L/min "

O

u

t

l

e

t

p

r

e

s

s

u

r

e

i

n

b

a

r

"

Flow in L/min "

R

e

d

u

c

e

d

p

r

e

s

s

u

r

e

i

n

b

a

r

"

Flow in L/min "

P

r

e

s

s

u

r

e

d

i

f

f

e

r

e

n

t

i

a

l

i

n

b

a

r

"

#p-q

V

-characteristic curves (B to A; lowest settable pressure differential)

Minimum settable pressure at p

A min

in relation to the flow q

V

(B to A)

Performance limit

(dependent on system)

1 = NS 10

2 = NS 25

3 = NS 30

RE 26 892/06.91

NS 25 NS 10 NS 32

NS 25 NS 32 NS 10

NS 10 NS 25 NS 32

RE 26 892/05.02 6/10 DR

0 50 100 150 250 400

0,5

1,0

300 200 350

1,5

#p = 50 bar

#p = 200 bar

0 50 100 150 250 400

10

20

300 200 350

30

15

25

5

NS 10

Characteristic curves (measured with HLP46, !

oil

= 40 C 5 C)

Control flow in relation to the flow (B to A) and to the pressure differential

#p-q

V

-characteristic curves via the check valve (A to B)

Flow in L/min "

C

o

n

t

r

o

l

f

l

o

w

i

n

L

/

m

i

n

"

Flow in L/min "

P

r

e

s

s

u

r

e

d

i

f

f

e

r

e

n

t

i

a

l

i

n

b

a

r

"

Flow resistance via check valve, the main stage closed

Flow resistance via check valve with the main stage fully open

RE 26 892/draft

NS 25 NS 32

NS 10 NS 25

NS 32

DR 7/10 RE 26 892/05.02

0,01/100mm

R

max

4

3

2

49

3

5

3

8

2

9

0

1

110

118

145

169 18

5

H

1

2

0

2

B

1

B

3

A

Y

Y

H

2

H

3

5

6

L6

L5

L4

L3

L2

5 L1

B

2

B

4

B

5

2

9

L8

L7

L9

L10

X

A

B

Y

11

1

6

5

G 1/4; 12

3

9

,

5

5 8 4 6; 7 9

2.2

11

2.1

11

10

3 1

12

13

Unit dimensions: subplate mounting (Dimensions in mm)

1 Name plate

2.1 Port Y for external pilot oil drain

2.2 Port Y optional

for external pilot oil drain (G 1/2; 12)

3 Port X without function

(blind bore)

4 Adjustment element 4

5 Adjustment element 5

6 Adjustment element 6

7 Adjustment element 7

8 Hexagon 10A/F

9 Space required to remove key

10 Locating pin

11 4 valve fixing holes for DR 10 and 20

6 valve fixing holes for DR 30

12 Pressure gauge connection

13 Same seal rings for ports A and B,

same seal rings for ports X and Y

Subplates to catalogue sheet RE 45 062 and

valve fixing screws must be ordered separately.

Subplates for:

DR 10 G 460/01 (G 3/8)

G 461/01 (G 1/2)

DR 20 G 412/01 (G 3/4)

G 413/01 (G 1)

DR 30 G 414/01 (G 1 1/4)

G 415/01 (G 1 1/2)

Valve fixing screws for:

DR 10 4 off M10 x 50 DIN 912-10.9; M

A

= 75 Nm

DR 20 4 off M10 x 60 DIN 912-10.9; M

A

= 75 Nm

DR 30 6 off M10 x 70 DIN 912-10.9; M

A

= 75 Nm

Required surface finish of

mating piece

RE 26 892/06.91

Type L1 L2 L3 L4 L5 L6 L7 L8 L9 L10 B1 B2 B3 B4 B5 H1 H2 H3

DR 10 96 35.5 33 42.9 21.5 7.2 21.5 31.8 35.8 85 50 66.7 58.8 7.9 112 92 28

DR 20 116 37.5 35.4 60.3 39.7 11.1 20.6 44.5 49.2 102 59.5 79.4 73 6.4 122 102 38

DR 30 145 33 29.8 84.2 59.5 42.1 16.7 24.6 62.7 67.5 120 76 96.8 92.8 3.8 130 110 46

RE 26 892/05.02 8/10 DR

90

3

2

49

3

5

3

8

9

0

1

110

118

145

169 18

5

4

4

1

3

4

2

0

1

1

4

D

1

Y

2

T

1

1

4

7

5

6

72

T1 1

D1

5 17

8

0

7

2

B

A

11

G 1/4; 12

25

G 1/4; 12

5,5

D2

D

2

3

9

,

5

2

5 8 4 6; 7 9

2.1

12

11

1

Unit dimensions: threaded connections (dimensions in mm)

1 Name plate

2.1 Port Y for external pilot oil drain

4 Adjustment element 4

5 Adjustment element 5

6 Adjustment element 6

7 Adjustment element 7

8 Hexagon 10A/F

9 Space required to remove key

11 Valve fixing hole

12 Pressure gauge connection

Type D1 D2 T1

DR 10 G G 1/2 34 14

DR 15 G G 3/4 42 16

DR 20 G G 1 47 18

DR 25 G G 1 1/4 58 20

DR 30 G G 1 1/2 65 22

RE 26 892/06.91

DR 9/10 RE 26 892/05.02

3

2

49

3

5

3

8

2

9

0

1

110

118

145

169

18

5

2

0

Y

2

4

0

2

9

61

28

3

2

37,5

6

51

11,5

35

4

4

2

9

3

1

4

G 1/4; 12

X

Y

8,4

3

9

,

5

5 8 4 6; 7 9

20

21

18

19

14

15

22

2.2

11

2.1 1

45

29

0,2

2

x

3

0

2

5

,

5

1

7

3

4

3

2

4

0

+

0

,

1

0,02 A

24,8

+0,2

32

6

M4; 6

2

x

4

5

2

x

4

5

max. R 0,3

Z

X

0

,

0

1

/

1

0

0

m

m A

X

Y

A

B

Y

26

0,2

32

H7

28,5

+0,1

0,008

Y

0,05 B

Z

B

Z

4

4

18

5

5

5

1

,

5

0

,

1

4

2

+

0

,

1

+

0

,

0

5

Z

23 17 16

4

4

3

2

51

16

X Y

4 x M8; 12

61

=

Y

=

Z

R

z

16

R

z

8

=

X

R

max

4

Unit dimensions: pilot valve with (DRC 30) or without (DRC) main spool insert (Dimensions in mm)

1 Name plate

2.1 Port Y for external pilot oil

drain

2.2 Port Y optional for

external pilot oil drain

4 Adjustment element 4

5 Adjustment element 5

6 Adjustment element 6

7 Adjustment element 7

8 Hexagon 10A/F

9 Space required to

remove key

11 Valve fixing holes

14 Seal rings

15 Main spool insert

16 Hole 32 can meet hole

45 at any point. Care

however has to be taken

that the connection hole X

and the fixing holes are not

damaged

17 Back-up ring and seal rings

are to be inserted into this

cavity before fitting the

main spool

18 Seal ring

19 Seal ring

20 Seal ring

21 Back-up ring

22 Back-up ring

23 Orifice must be ordered

separately

4 off valve fixing screws M8 x 40

DIN 912-10.9, M

A

= 37 Nm, must be

ordered separately

View Z

RE 26 892/04.92

RE 26 892/05.02 10/10 DR

Bosch Rexroth AG

Industrial Hydraulics

D-97813 Lohr am Main

Zum Eisengieer 1 D-97816 Lohr am Main

Telefon 0 93 52 / 18-0

Telefax 0 93 52 / 18-23 58 Telex 6 89 418-0

eMail documentation@boschrexroth.de

Internet www.boschrexroth.de

The data specified above only serves to describe

the product. No statements concerning a certain

condition or suitability for a certain application

can be derived from our information.

The details stated do not release you from the

responsibility for carrying out your own

assessment and verification. It must be

remembered that our products are subject to a

natural process of wear and ageing.

Bosch Rexroth Limited

Cromwell Road, St Neots,

Cambs, PE19 2ES

Tel: 0 14 80/22 32 56

Fax: 0 14 80/21 90 52

E-mail: info@boschrexroth.co.uk

Notes

You might also like

- Re21468 2005-07Document8 pagesRe21468 2005-07LuHa1No ratings yet

- Re 25402Document16 pagesRe 25402ShortcutterNo ratings yet

- Re 25402Document8 pagesRe 25402Arturo MendozaNo ratings yet

- RE 22 371/03.98 - 4/3 and 4/2 directional control valves with hand lever Type WMMDocument8 pagesRE 22 371/03.98 - 4/3 and 4/2 directional control valves with hand lever Type WMMAhmed Abd ElhakeemNo ratings yet

- Check d180 - HR KRDocument4 pagesCheck d180 - HR KRDANIZACHNo ratings yet

- Re92060 2014-04Document28 pagesRe92060 2014-04Ibrahim GökmenNo ratings yet

- Directional Control Valves GuideDocument193 pagesDirectional Control Valves GuidephaindikaNo ratings yet

- Ac PDFDocument95 pagesAc PDFCarlos TorresNo ratings yet

- Check Valve Type Z2SRK 10 Technical SpecificationsDocument4 pagesCheck Valve Type Z2SRK 10 Technical SpecificationsAhmed Abd ElhakeemNo ratings yet

- Re 22049Document16 pagesRe 22049ShortcutterNo ratings yet

- Hydraulic TechnologyDocument76 pagesHydraulic TechnologyOgulcan CafNo ratings yet

- Bomba Hidrailica A10VSODocument44 pagesBomba Hidrailica A10VSOkiarabenitezparejaNo ratings yet

- Yukenmodularvalves Yuken CatDocument140 pagesYukenmodularvalves Yuken Catchidambaram kasi100% (1)

- Rexroth 4we10 Data SheetDocument10 pagesRexroth 4we10 Data SheetOrlando Arias100% (1)

- Re92105 2003-11Document32 pagesRe92105 2003-11Madhu RajagopalanNo ratings yet

- Select the Right Gas and Air Filter for Your ApplicationDocument8 pagesSelect the Right Gas and Air Filter for Your ApplicationJulio OrtegaNo ratings yet

- Re 15224Document12 pagesRe 15224Ahmed Abd ElhakeemNo ratings yet

- A11vo - Re 92 500 - PDFDocument60 pagesA11vo - Re 92 500 - PDFSyed Azhar Hussain50% (2)

- CMB Iso 6020-2Document63 pagesCMB Iso 6020-2David AlbellaNo ratings yet

- Rexroth PumpsDocument24 pagesRexroth PumpsAmanda SmithNo ratings yet

- About Axial Displacement Pump A4VSoDocument68 pagesAbout Axial Displacement Pump A4VSomrkadu_61No ratings yet

- Rexroth 4WE6D6X-G24 Directional ValveDocument12 pagesRexroth 4WE6D6X-G24 Directional ValveCosma Petru-RaulNo ratings yet

- Rexroth Re29564 XN 102 b2 - 2010 05Document12 pagesRexroth Re29564 XN 102 b2 - 2010 05boilerqwerty81No ratings yet

- Hydraulic Check ValveDocument8 pagesHydraulic Check ValveswainpiyushNo ratings yet

- SDM 141 eDocument28 pagesSDM 141 eseaqu3stNo ratings yet

- Valvulas XT PDFDocument4 pagesValvulas XT PDFIsidro Gomez GarciaNo ratings yet

- Pressure Reducing Valves ExplainedDocument7 pagesPressure Reducing Valves ExplainedSharon LambertNo ratings yet

- Variable displacement pump technical data sheetDocument19 pagesVariable displacement pump technical data sheetJose Maria CuencaNo ratings yet

- HYD. PumpDocument40 pagesHYD. Pumprohitbhat2345No ratings yet

- Bomba Hidraulica A7VODocument52 pagesBomba Hidraulica A7VOanon_491700336100% (2)

- SMC Neumatic CatalogDocument98 pagesSMC Neumatic CataloganderssonpcNo ratings yet

- Check Valve Data SheetDocument5 pagesCheck Valve Data SheetshahganNo ratings yet

- Adjustable spring-loaded pressure regulator for gas applicationsDocument6 pagesAdjustable spring-loaded pressure regulator for gas applicationsFlorin GoiaNo ratings yet

- Re 10039Document10 pagesRe 10039Ahmed Abd ElhakeemNo ratings yet

- Re 22058Document16 pagesRe 22058ShortcutterNo ratings yet

- Catalogo ASCODocument4 pagesCatalogo ASCOIkaro MatosNo ratings yet

- Inline Filter RFLD Inline Filter RFLD Inline Filter RFLD Inline Filter RFLD Inline Filter RFLDDocument11 pagesInline Filter RFLD Inline Filter RFLD Inline Filter RFLD Inline Filter RFLD Inline Filter RFLDAllan ArraisNo ratings yet

- Proportional Throttle Valves Technical SpecificationsDocument15 pagesProportional Throttle Valves Technical Specificationsabuzer1981No ratings yet

- Re 10223Document26 pagesRe 10223medi38No ratings yet

- Rexroth电磁阀手册Document12 pagesRexroth电磁阀手册davidwang85120% (1)

- Rexroth Bomba HidraulicaDocument52 pagesRexroth Bomba HidraulicaHernan LopezNo ratings yet

- Pump A4vgDocument68 pagesPump A4vgbiabamanbemanNo ratings yet

- 7-En 5150-B - CarDocument15 pages7-En 5150-B - Carabuzer1981No ratings yet

- Re 10460Document20 pagesRe 10460Ahmed Abd ElhakeemNo ratings yet

- Filtro RexrothDocument12 pagesFiltro RexrothduhgrandoNo ratings yet

- Pressure Control Valves SpecificationsDocument79 pagesPressure Control Valves SpecificationsAnonymous DjTnqWXUNo ratings yet

- SD 16 eDocument20 pagesSD 16 eseaqu3stNo ratings yet

- Axial Piston Compact Unit A10CODocument8 pagesAxial Piston Compact Unit A10COJohn SimmondsNo ratings yet

- SD 25 eDocument20 pagesSD 25 eseaqu3stNo ratings yet

- 2-Way Flow Control Bosch-RexrothDocument12 pages2-Way Flow Control Bosch-RexrothKemal GokovicNo ratings yet

- A10VSO18 Bomba HidraulicaDocument16 pagesA10VSO18 Bomba HidraulicaGuilherme RodriguesNo ratings yet

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Fluid Power Valves & Hose Fittings World Summary: Market Values & Financials by CountryFrom EverandFluid Power Valves & Hose Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- 305 TransmissionDocument2 pages305 TransmissionDANIZACHNo ratings yet

- Valvula de Acc Manual - E150Document4 pagesValvula de Acc Manual - E150DANIZACHNo ratings yet

- Baldor MotorsDocument124 pagesBaldor Motorsangel_basualdoNo ratings yet

- Alivio - d120 - HM - KMDocument4 pagesAlivio - d120 - HM - KMDANIZACHNo ratings yet

- Nema Chart 04Document1 pageNema Chart 04zguy360No ratings yet

- Valvula Tn10 - Dke E025Document4 pagesValvula Tn10 - Dke E025DANIZACHNo ratings yet

- Check en Linea - c406Document2 pagesCheck en Linea - c406DANIZACHNo ratings yet

- Single and double acting hydraulic cylinders specificationsDocument1 pageSingle and double acting hydraulic cylinders specificationsDANIZACHNo ratings yet

- En - b1 - 070 PATINES LINEALESDocument2 pagesEn - b1 - 070 PATINES LINEALESDANIZACHNo ratings yet

- Valve configuration and solenoid directional valvesDocument8 pagesValve configuration and solenoid directional valvesFabinhoTowerNo ratings yet

- Aloy High Pressure Filters 20 BarDocument2 pagesAloy High Pressure Filters 20 BarDANIZACHNo ratings yet

- Sun - Hydraulics CatalogDocument44 pagesSun - Hydraulics CatalogAndreea75% (4)

- Hsr-300e - CC PATINES LINEALES THKDocument26 pagesHsr-300e - CC PATINES LINEALES THKDANIZACHNo ratings yet

- Allround Line Floor 100 250kNDocument4 pagesAllround Line Floor 100 250kNDANIZACHNo ratings yet

- Gear flow dividers technical specifications and application guideDocument20 pagesGear flow dividers technical specifications and application guideDANIZACHNo ratings yet

- Series 34Document10 pagesSeries 34DANIZACHNo ratings yet

- Catalogo Componentes 2007Document39 pagesCatalogo Componentes 2007DANIZACHNo ratings yet

- 742Document52 pages742DANIZACHNo ratings yet

- Pump Polaris SeriesDocument47 pagesPump Polaris SeriesDANIZACHNo ratings yet

- Pump Magnun SeriesDocument63 pagesPump Magnun SeriesDANIZACHNo ratings yet

- 040404X57ZDocument1 page040404X57ZDANIZACHNo ratings yet

- Basic Training: Motors, Gears & DrivesDocument80 pagesBasic Training: Motors, Gears & DrivesDANIZACH50% (2)

- Pump KappaDocument112 pagesPump KappaDANIZACHNo ratings yet

- 4 - Way Directional Control Valve "HPV4": FeaturesDocument2 pages4 - Way Directional Control Valve "HPV4": FeaturesDANIZACHNo ratings yet

- Baldor MotorsDocument124 pagesBaldor Motorsangel_basualdoNo ratings yet

- 742Document52 pages742DANIZACHNo ratings yet

- MPHDocument16 pagesMPHDANIZACHNo ratings yet

- Absorb Shock and Reduce Vibration with Flexible Grid CouplingsDocument18 pagesAbsorb Shock and Reduce Vibration with Flexible Grid CouplingsRafo Vega GuerovichNo ratings yet

- C-Robot Simulator: Program StructureDocument17 pagesC-Robot Simulator: Program StructureAyessa Karyl GanirNo ratings yet

- Traffic Violations: of The 3th and 4th DegreeDocument14 pagesTraffic Violations: of The 3th and 4th DegreeGovind VenugopalanNo ratings yet

- Ionizing Radiation Effects in SONOS-Based Neuromorphic Inference AcceleratorsDocument8 pagesIonizing Radiation Effects in SONOS-Based Neuromorphic Inference AcceleratorsUpaangana DasNo ratings yet

- Chapter 1 Lewis Sorel MethodDocument8 pagesChapter 1 Lewis Sorel MethodMUHAMMAD LUQMAN HAKIMI MOHD ZAMRINo ratings yet

- The Magician EmpowermentDocument8 pagesThe Magician EmpowermentAndy TrandafNo ratings yet

- International Finance CorporationDocument12 pagesInternational Finance CorporationJane Cresthyl LesacaNo ratings yet

- Cavity Wall Insulation Inspection ReportDocument100 pagesCavity Wall Insulation Inspection ReportAbbas LadonniNo ratings yet

- Pecha Kucha Group PresentationDocument22 pagesPecha Kucha Group PresentationBor ShonNo ratings yet

- Hotel BaliDocument2 pagesHotel BaliFong Cai YingNo ratings yet

- Kelley Bollen All About DogsDocument141 pagesKelley Bollen All About DogsRoxanaAndreeaNo ratings yet

- Multi VibratorsDocument11 pagesMulti VibratorsPallavi Kr K RNo ratings yet

- 10x Security Bitcoin Guide: How To Store Bitcoin Without Any Single Point of FailureDocument80 pages10x Security Bitcoin Guide: How To Store Bitcoin Without Any Single Point of Failureanton vier100% (1)

- Syllabus: Ilocos Sur Polytechnic State CollegeDocument12 pagesSyllabus: Ilocos Sur Polytechnic State Collegely kaNo ratings yet

- Homework 1 Section 1-Open-Ended Questions: (2 Marks)Document6 pagesHomework 1 Section 1-Open-Ended Questions: (2 Marks)jabirNo ratings yet

- The Wayland News July 2105Document12 pagesThe Wayland News July 2105Julian HornNo ratings yet

- List of Foods That Are Genetically ModifiedDocument3 pagesList of Foods That Are Genetically ModifiedMelmel TheKnightNo ratings yet

- Quickstart Guide Guía de Inicio Rápido Guide D'Utilisation Rapide Guida Rapida KurzanleitungDocument40 pagesQuickstart Guide Guía de Inicio Rápido Guide D'Utilisation Rapide Guida Rapida KurzanleitungMario LoayzaNo ratings yet

- TOBUL OandMsheet052909v2Document5 pagesTOBUL OandMsheet052909v2Walter JosephNo ratings yet

- Daily Practice Problems: C-B (Level-B)Document3 pagesDaily Practice Problems: C-B (Level-B)Ved NarsekarNo ratings yet

- Alarm Codes: Alarm Code Alarm Text SeverityDocument2 pagesAlarm Codes: Alarm Code Alarm Text SeverityЕТМNo ratings yet

- The Denotation of Generic Terms in Ancient Indian Philosophy Grammar, Nyāya, andDocument334 pagesThe Denotation of Generic Terms in Ancient Indian Philosophy Grammar, Nyāya, andLangravio Faustomaria Panattoni100% (1)

- SDV7 PDFDocument16 pagesSDV7 PDFFranco David Chiarella TapiaNo ratings yet

- LAZZATI BrochureDocument140 pagesLAZZATI BrochureLazzati - High Performance Boring MillsNo ratings yet

- Bachelor of Science in Applied Physics With Electronics and InstrumentationDocument16 pagesBachelor of Science in Applied Physics With Electronics and InstrumentationwvairaNo ratings yet

- 1.8t Oil Pressure Survival Guide and Troubleshooting DIYDocument89 pages1.8t Oil Pressure Survival Guide and Troubleshooting DIYPatrascu GabrielNo ratings yet

- What Is Plant MaintenanceDocument5 pagesWhat Is Plant Maintenancesamplc2011No ratings yet

- Uy,' Sino Siya?: Ms. Johanna Rania U. SalicDocument39 pagesUy,' Sino Siya?: Ms. Johanna Rania U. SalicAnia AbdulbayanNo ratings yet

- Sigmund FreudDocument4 pagesSigmund FreudP NjroNo ratings yet

- Configurations & Parts Identification: Trailer Suspension SeriesDocument26 pagesConfigurations & Parts Identification: Trailer Suspension SeriesleosignareNo ratings yet

- List of Items - SiemensDocument4 pagesList of Items - Siemensriyadh al kamalNo ratings yet