Professional Documents

Culture Documents

WSM 0000003 01

Uploaded by

Anderson BombistaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WSM 0000003 01

Uploaded by

Anderson BombistaCopyright:

Available Formats

Scania CV AB 2003, Sweden

1 587 796

07:02-01

Issue 2 en

Driving front axle AMD900

Work Description

1

0

3

0

5

6

2

Scania CV AB 2003, Sweden 07:02-01

Contents

General Important .................................................................. 3

Exploded view drawing, hub reduction gear ............ 4

Exploded view drawing, axle beam.......................... 6

Exploded view drawing, hub with ABS................... 8

Work Description Renewing axle ........................................................ 10

Hub dismantling ..................................................... 17

Hub reduction gear ................................................. 24

Shaft journal dismantling ....................................... 27

Half shaft dismantling ............................................ 31

Axle beam dismantling........................................... 32

Central gear, removing and fitting.......................... 34

Axle beam, assembling........................................... 35

Half shaft, assembling ............................................ 38

Shaft journal, assembling ....................................... 40

Hub, assembling ..................................................... 44

Specifications ......................................................... 52

07:02-01

Scania CV AB 2003, Sweden 3

General

Important

A clean working environment is a condition for

correct function and long lifetime for axle gears

and wheel hubs.

Always clean the outside and surrounding parts

to prevent contaminants entering the axle gear

or the hub when the components are removed

from the axle beam.

Clean all parts, new as well as old, before

reassembling the gear.

All moving parts should be lubricated before

being fitted.

Always use lubricants as specified in group 0 in

the workshop manual.

General

4

Scania CV AB 2003, Sweden 07:02-01

Exploded view drawing,

hub reduction gear

Exploded view drawing, hub reduction gear

07:02-01

Scania CV AB 2003, Sweden 5

1 Half shaft

2 Needle bearing

3 Retaining ring

4 Bearing inner race

5 Nut

6 Seal

7 Seal

8 Seal

9 Seal seat

10 O-ring

11 Sleeve

12 Seal seat

13 Bearing

14 Snap ring

15 Planet wheel carrier

16 Cover

17 Ring gear

18 Ring gear retainer

19 Sun wheel

20 Planet gear

21 Bearing journal

22 Snap ring

23 Thrust washer

24 Thrust washer

25 Needle bearing

26 Thrust washer

27 Wire ring

28 Snap ring

29 O-ring

30 Gasket

31 Snap ring

32 Hexagon bolt

33 Cup spring

34 Stud

35 Cone

36 Nut

37 Plug

38 Magnetic plug

39 O-ring

Exploded view drawing, hub reduction gear

6

Scania CV AB 2003, Sweden 07:02-01

Exploded view drawing,

axle beam

Exploded view drawing, axle beam

07:02-01

Scania CV AB 2003, Sweden 7

1 Axle beam

2 Plug

3 Sealing washer

4 Magnetic plug

5 Bolt

6 Hexagon nut

7 Shaft journal

8 Link

9 Clamp

10 Bolt

11 Nut

12 Adjusting sleeve

13 Ball joint

14 Nut

15 Split pin

16 Swivel pin

17 Bearing

18 Seal

19 Spring

20 Shim

21 Bracket

22 O-ring

23 Cover

24 Hexagon bolt

25 Grease nipple

26 Plug

27 Sleeve

28 Stud

29 Nut

30 Axle gear

Exploded view drawing, axle beam

8

Scania CV AB 2003, Sweden 07:02-01

Exploded view drawing,

hub with ABS

Exploded view drawing, hub with ABS

07:02-01

Scania CV AB 2003, Sweden 9

1 Wheel hub

2 Roller bearing

3 O-ring

4 Spacing sleeve

5 Shim

6 Protective plate

7 Seal

8 Pulse wheel

9 Magnetic plug

10 O-ring

11 Wheel stud

12 Wheel nut

13 Nut cap

14 Cover

15 Sleeve

16 Sensor

Exploded view drawing, hub with ABS

10

Scania CV AB 2003, Sweden 07:02-01

Work Description

Renewing axle

Tools

Number Designation Illustration Tool board

99 345 Puller AM3

588 608 Hydraulic ball joint puller

Work Description

07:02-01

Scania CV AB 2003, Sweden 11

Removal

!

WARNING!

Never work under a vehicle with air

suspension, which is not fully secured

against falling, in case there is a change

of pressure in the air bellows. There is a

risk of getting trapped and injured.

Both the chassis and moving axle

suspension components must be

secured against falling with stands to

ensure absolute safety when working

under a raised vehicle.

1 Lift up the vehicle and place it on stands as

shown in the picture.

2 Remove the wheels.

3 Detach brake hoses and any connections for

the ABS.

4 Detach electric and compressed air lines for

the differential lock.

5 Remove the propeller shaft.

6 Disconnect the anti-roll bar from the front

bracket.

Renewing axle

12

Scania CV AB 2003, Sweden 07:02-01

7 Remove the draglink using tool as shown in

picture.

Tighten the puller.

Lightly tap the draglink arm and the

puller as shown in the picture.

Repeat these steps until the drag link

comes off.

!

WARNING!

Keep in mind the risk of tipping when the

axle is lowered and drawn out from the

vehicle.

8 Remove the U-bolts and lower the axle onto

two axle stands.

Renewing axle

07:02-01

Scania CV AB 2003, Sweden 13

9 Draw out the axle using two pallet jacks.

Renewing axle

14

Scania CV AB 2003, Sweden 07:02-01

Fitting

1 Run the axle in under the vehicle.

!

WARNING!

Keep in mind the risk of tipping when the

axle is run in under the vehicle and when

it is lifted up against the springs.

2 Clean and oil the U-bolt threads.

Renewing axle

07:02-01

Scania CV AB 2003, Sweden 15

IMPORTANT! Tighten the U-bolts as specified

in the tightening diagram described in service

literature 12:01-01.

3 Fit new nuts and tighten the U-bolts as

shown in the diagram.

4 Fit the anti-roll bar and tighten the nuts to

180 Nm.

5 Fit the draglink and tighten the ball joint nut

to 250 Nm and then further to the nearest

hole.

Renewing axle

16

Scania CV AB 2003, Sweden 07:02-01

6 Lock the nut with a split pin.

7 Fit the propeller shaft and tighten the bolts

as described in the workshop manual

06:01-01.

8 Fit the brake hoses and any connections for

ABS.

9 Fit the electrical wiring and compressed air

lines for the differential lock.

10 Adjust the brakes as described in the

workshop manual 10:02-06.

11 Fill with oil (see Hub, assembly and

Specifications).

12 Fit the wheels and lower the vehicle.

13 Retighten the U-bolt nuts when the axle is

loaded.

Note: The U-bolt nuts should be retightened

after the vehicle has been in use equivalent to

R-inspection. Refer to Workshop Manual

group 0.

Renewing axle

07:02-01

Scania CV AB 2003, Sweden 17

Hub

Dismantling

Tools

Number Designation Illustration Tool board

87 368 Puller bolts AD/AS1, B1

87 596 Slide hammer D2

98 401 V block F1

98 402 Holder for fixture shafts F1

98 404 End yoke bracket F1

98 405 Bracket and fixture beam A

98 590 Puller ADAS1

00

1805

87 368

87 596

0

0

1

6

1

0

0

0

1

8

9

9

98 401

98 404

1

1

4

9

6

5

00_1808

98 590

Hub, dismantling

18

Scania CV AB 2003, Sweden 07:02-01

98 616 Adjustable drift AD2, R2

98 691 Support drift AD/AS1

98 700 Short fixture shaft F2

99 345 Adapter B2

99 351 Sleeve for wheel bearing

setting

AM3

99 353 Special sleeve AM3

99 363 Stand tool C1

587 313 Jack A

Number Designation Illustration Tool board

98 616

110 806

98 700

1

1

5

8

0

2

103 516

99 345

99353

1

0

3

0

5

1

1

0

7

3

4

1

102 902

Hub, dismantling

07:02-01

Scania CV AB 2003, Sweden 19

!

WARNING!

Never work under a vehicle with air

suspension, which is not fully secured

against falling, in case there is a change

of pressure in the air bellows. There is a

risk of getting trapped and injured.

Both the chassis and moving axle

suspension components must be

secured against falling with stands to

ensure absolute safety when working

under a raised vehicle.

1 Lift and support the front axle. Remove the

wheel(s) and brake components as specified

in Workshop Manual 10:02-06.

587 428 Bearing puller XA1

587 432 Puller plate XA1

Number Designation Illustration Tool board

1

1

4

0

5

6

1

1

4

6

9

3

Hub, dismantling

20

Scania CV AB 2003, Sweden 07:02-01

2 Drain the oil.

1

0

4

0

3

4

3 Remove the cover and outer thrust washer.

1

0

4

0

3

5

4 Loosen the nuts which hold the planetary

unit in place, but leave them threaded a few

turns.

!

WARNING!

If the lock nuts are not left in place, there

is a great risk of the cones flying off at

high speed when they release.

5 Tap on the sides of the planetary unit to

loosen the cones.

6 Remove the plastic plugs for the puller hole.

7 Clean the puller hole with a pilot tap and

remove the planetary unit using the puller

bolts.

1

0

4

0

3

6

87 368

Hub, dismantling

07:02-01

Scania CV AB 2003, Sweden 21

8 Remove snap ring 31, thrust washer 26, sun

wheel 19, thrust washer 24 and wire ring 27.

9 Remove the hub nut using splined socket

99 353.

1

0

4

0

3

7

99 353

10 Set up gearbox jack 587 313 as shown in the

picture.

Hub, dismantling

22

Scania CV AB 2003, Sweden 07:02-01

11 Set the gearbox jack up against the hub as

shown in the picture.

12 Screw 99 351 (without thrust bearings and

threaded dowel) on the shaft journal, screw

pull rods 98 690 on two opposite wheel

studs, fit puller 98 590, hold 98 691 against

99 351 and screw in the puller bolt.

13 Draw out the hub with internal ring gear and

ring gear retainer.

14 Remove internal ring gear and ring gear

retainer from the hub.

15 Remove the internal ring gear from the ring

gear retainer.

16 Remove the outer wheel bearing from the

ring gear retainer as shown in the picture,

using three fully threaded bolts M10x80.

17 Remove the hub seal using a slide hammer.

1

0

4

0

3

9

87 596

Hub, dismantling

07:02-01

Scania CV AB 2003, Sweden 23

18 Remove four wheel studs (see picture) to

facilitate supporting under the hub.

19 Remove the bearing outer races using

98 616.

20 Remove the spacing sleeve, O-ring and

shims.

21 Remove the brake camshaft and brake

shield as described in the workshop manual

10:02-06.

22 Remove the inner wheel bearing using

puller 587 428 and puller plate 587 432

(tighten the puller plate bolts hard so it grips

well), spacer 99 691 and sleeve 99 351

(without thrust bearing and threaded dowel).

Remove the protective plate on the inside of

the bearing.

Hub, dismantling

24

Scania CV AB 2003, Sweden 07:02-01

Hub reduction gear

Renewing planet wheel bearings

Tools

1 Check that the four planet wheels rotate

easily and without noise. Where there is a

suspicion that one of the bearings are

defective, all four bearings should be

renewed at the same time.

2 Place the planet wheel carrier in a press as

shown in the picture and press out the

bearing journals.

Number Designation Illustration Tool board

98 450 Shank AM1, AD/AS2,

R2

98 450

0

0

1

6

3

3

Hub reduction gear

07:02-01

Scania CV AB 2003, Sweden 25

3 The needle bearings for each planet wheel

consist of two rows of needles. The bearings

are supplied in an outer and an inner

cardboard tube, which can be used as a

fitting tool. The inner cardboard tube is

provided with plastic plugs on both sides of

each bearing set.

4 Oil the race in the planet wheel and then

press in a set of needle bearings using, for

example, shank 98 450.

Hub reduction gear

26

Scania CV AB 2003, Sweden 07:02-01

5 Carefully remove the plastic cover from the

inner pipe.

6 Fit the two thrust washers, one on each side

of the planet wheel. The washers should be

oiled. Press down the inner pipe a little so

that it centres the lower thrust washer.

7 Slip in the planet wheel with the two thrust

washers in the planet wheel carrier.

8 Position the planet wheel carefully in the

middle of the hole in the planet wheel

carrier. Press down the inner pipe by hand

so that it enters the hole for the bearing

journal (a few mm).

9 Oil the bearing journal and turn it so the

raised part is pointed towards the middle of

the planet wheel carrier.

Note: The bearing journal's raised part must be

directed in towards the middle of the planet

wheel carrier as shown in the picture. The cover

cannot otherwise be fitted.

10 Tap in the bearing journal using a plastic

mallet, which forces out the cardboard pipe.

Hub reduction gear

07:02-01

Scania CV AB 2003, Sweden 27

Shaft journal

Dismantling

Tools

1 Remove the brake slack adjuster and the

brake chamber (hang it up so that the brake

hose is not strained). For working with

brake components, see workshop manual

10:02-06.

2 Remove the brake chamber bracket.

Number Designation Illustration Tool board

87 596 Slide hammer D2

98 224 Pressplate

98 450 Shank AM1, AD/AS2,

R2

99 345 Puller AM3

588 608 Hydraulic ball joint puller

87 596

00

1610

98 224

1

1

0

0

6

5

98 450

0

0

1

6

3

3

Shaft journal, dismantling

28

Scania CV AB 2003, Sweden 07:02-01

3 Remove the draglink using puller 99 435.

Tighten the puller.

Tap lightly on the draglink arm and the

puller as shown in the picture.

Repeat these steps until the drag link

comes off.

4 Remove the cover for the lower swivel pin.

The outer bearing race can loosen and fall

down.

5 Remove the lower swivel pin including

bearing, spring and sealing.

Note: The thread is locked with locking

compound. Careful heating may be needed to

release the locking compound.

Shaft journal, dismantling

07:02-01

Scania CV AB 2003, Sweden 29

6 Remove the upper swivel pin including

bearing, spring, sealing and shims. Save the

shims and use them when assembling.

Note: The thread is locked with locking

compound. Careful heating may be needed to

release the locking compound.

7 Lower the shaft journal.

8 Remove the sealing ring retainer and the

sealing rings using slide hammer 87 596.

1

0

4

0

4

7

87 596

9 Remove the snap ring.

1

0

4

0

5

0

Shaft journal, dismantling

30

Scania CV AB 2003, Sweden 07:02-01

10 Tap loose the half shaft bearing using a

drift.

1

0

4

0

5

1

11 Remove the swivel pin bearing inner races

in a press using pressplate 98 224, shank

98 450.

Shaft journal, dismantling

07:02-01

Scania CV AB 2003, Sweden 31

Half shaft

Dismantling

1 Draw out the half shaft. To remove the half

shaft, the differential lock must be engaged

using compressed air.

!

WARNING!

Wear protective goggles!

2 Remove the bearing inner races by grinding

a groove and cracking them with a chisel.

Protect the half shaft joint from grinding

dust.

1

0

4

0

5

4

Half shaft, dismantling

32

Scania CV AB 2003, Sweden 07:02-01

Axle beam

Dismantling

Tools

1 Draw out the sealing ring retainer.

Number Designation Illustration Tool board

587 311 Retaining ring pliers G1

587 316 Puller XA2

587 317 Expanding sleeve XA2

587 311

1

1

1

4

4

4

1

1

4

0

5

8

1

1

4

0

5

9

1

0

4

0

5

5

587 317

587 316

Axle beam, dismantling

07:02-01

Scania CV AB 2003, Sweden 33

2 Remove the snap ring using 587 311.

1

0

4

5

9

8

3 Draw out the half shaft bearing using puller

587 316 and 587 317.

Note: Carefully centre the puller.

4 Remove the sleeve.

1

0

4

0

5

6

587 317

587 316

Axle beam, dismantling

34

Scania CV AB 2003, Sweden 07:02-01

Central gear

Removing and fitting

Before the axle gear can be removed the shaft

journals on both sides must be removed and the

half shafts drawn out of the axle gear.

For removing and fitting the central gear,

see the workshop manual 08:05-01.

For work on the central gear, see the

workshop manual 08:05-01.

Central gear

07:02-01

Scania CV AB 2003, Sweden 35

Axle beam

Assembling

Tools

Number Designation Illustration Tool board

87 441 Drift AM1

98 450 Shank AM1, AD/AS2,

R2

99 191 Drift G4

99 005-1 Pusher adapter H1

98 450

0

0

1

6

3

3

1

0

9

7

8

5

99 191

99 0051

1

1

1

4

2

3

Axle beam, assembly

36

Scania CV AB 2003, Sweden 07:02-01

1 Fit the sleeve and tap the bearing into the

axle beam using 87 441 and 98 450 and fit

the snap ring.

2 Lubricate the holder for the sealing ring.

Press the inner sealing ring carefully into

the sealing ring retainer and then the outer

sealing ring using the tool as shown in the

picture.

Note: Ensure that the sealings are correctly

turned (see picture).

3 Fit a well oiled O-ring on the sealing ring

retainer and tap it into the axle beam using

drift 87 441 and shank 98 450.

4 Fill with axle gear oil up to the hole in the

sleeve.

5 Smear a bearing with grease and make sure

that it is evenly distributed around the

sealings.

Axle beam, assembly

07:02-01

Scania CV AB 2003, Sweden 37

Axle beam, assembly

38

Scania CV AB 2003, Sweden 07:02-01

Half shaft

Assembling

General

Tools

Adhesive 816 064

Number Designation Illustration Tool board

99 352 Assembly sleeve AM3

1

0

3

0

5

0

99352

Half shaft, assembly

07:02-01

Scania CV AB 2003, Sweden 39

1 Fit the dust cover to the half shaft joint, on

the inner part of the half shaft. Glue the

sealing with adhesive 816 064.

2 Fit the bearing races on the half shaft using

99 352.

3 Fill the space between the dust cover and

the sealing ring retainer with grease, see

picture.

Note: Feel with a finger whether the bearing

rollers sit correctly in the bearing in the axle

beam.

4 Apply the differential lock using

compressed air and push the half shaft into

the axle beam.

Half shaft, assembly

40

Scania CV AB 2003, Sweden 07:02-01

Shaft journal

Assembling

Specifications

Tools

General Part No.

Locking compound 561 200

Number Designation Illustration Tool board

87 348 Drift AM1

87 579 Drift R1

98 574 Drift R1

99 477 Drift AM3

587 588 Spring balance A

1

0

4

8

6

2

87 348

109 783

98 574

Shaft journal, assembly

07:02-01

Scania CV AB 2003, Sweden 41

1 Press the half shaft bearing outer race onto

the shaft journal using drift 99 477.

2 Fit the snap ring.

3 Press carefully on the first sealing using

drift 99 477.

4 Lubricate the sealing ring retainer and press

in the sealing ring by hand.

Note: Make sure that the sealings are correctly

turned.

5 Press the sealing ring retainer into the shaft

journal using 99 477.

6 Smear a bearing with grease and make sure

that it is evenly distributed around the

sealings.

7 Press the sealing rings for the swivel pins

onto the shaft journal by hand.

Shaft journal, assembly

42

Scania CV AB 2003, Sweden 07:02-01

8 Press the bearing inner races onto the swivel

pins using drift 98 574.

9 Lift the stub axle and feed the half shaft into

the stub axle.

Note: Take care not to damage the sealings.

10 Push the shaft journal carefully into place.

11 Apply locking compound 561 200 to the

thread.

12 First fit the upper and then the lower swivel

pin.

Note: Take care not to damage the threads.

13 Tighten the swivel pins to 1,400 Nm.

1

0

4

0

6

2

14 Fit the springs and the swivel pin bearing

outer races using drift 87 579.

15 Fit the old shims on the upper bearing outer

race. Fit the oiled O-rings and tighten the

brake chamber bracket and the lower cover

to 135 Nm.

1

0

4

0

6

1

Shaft journal, assembly

07:02-01

Scania CV AB 2003, Sweden 43

16 Fit a spring balance to the track rod bracket.

Check that resistance to rotation is around

130 N. Adjust where necessary by adding or

removing shims from the upper swivel pin.

Shims are available in thicknesses: 0.10,

0.178, 0.25, 0.50 and 1.0 mm.

17 Fit the track rod and the drag link. Tighten

the ball joint nuts to 250 Nm and further to

the next hole. Lock using a split pin.

18 Fit brake shield, brake camshaft and brake

chamber.

130 N

1

0

4

0

5

2

Shaft journal, assembly

44

Scania CV AB 2003, Sweden 07:02-01

Hub

Assembling

Tools

Number Designation Illustration Tool board

87 550 Drift AD2

98 075 Dial gauge D2

98 364 Assembly drift R1

98 450 Shank AM1, AD/AS2,

R2

98 590 Puller AD1

99 120 Pressplate AM1

10

20

30

40

50

60

70

80

90

0

10

20

30

40

50

60

70

80

90

15

10

5

00_1637

98 075

98 450

0

0

1

6

3

3

00_1808

98 590

Hub, assembly

07:02-01

Scania CV AB 2003, Sweden 45

99 142 Support ring PT1

99 147 Drift

99 350 Adapter for wheel bearing

setting

AM3

99 351 Sleeve for wheel bearing

setting

AM3

99 353 Special sleeve AM3

99 476 Drift AD/AS4

587 250 Indicator stand A

Number Designation Illustration Tool board

99 142

0

0

1

6

2

4

1

0

3

0

4

8

99353

1

0

3

0

5

1

102350

Hub, assembly

46

Scania CV AB 2003, Sweden 07:02-01

1 Fit the protective plate on the inside of the

inner bearing inner race. Turn it in the

correct orientation as shown.

2 Check the venting.

3 Fit the inner wheel bearing on the shaft

journal using drift 87 550.

1

0

4

8

5

3

4 Press the outer races into the wheel hub

using the tool as shown in the pictures.

Hub, assembly

07:02-01

Scania CV AB 2003, Sweden 47

5 Press on the ABS gear wheel using drift

99 142 and 99 283, if it was removed.

6 Fit 4 x 1.3 mm shims to the shaft journal.

The shims' total thickness should be at least

5.2 mm to always provide a measurable

bearing play. Fit the spacing sleeve and an

O-ring to hold the sleeve in place.

7 Fit the inner race to the adapter 99 350.

8 Fit the wheel hub using the tool as shown in

the picture.

9 Fit the bearing and the adapter instead of the

ring gear retainer.

10 Oil the shaft journal thread and thread on

the hub nut. Tighten the nut to 400 Nm

using splined socket 99 353. Rotate the hub

at least 5 rotations and continue to tighten,

with the hub rotating, to 900 Nm.

1

0

4

5

9

9

99 353

400 Nm

5r

900 Nm

Hub, assembly

48

Scania CV AB 2003, Sweden 07:02-01

11 Fit the indicator stand to the hub as shown in

the picture, with the dial gauge against the

end plate on 99 351.

12 Set up tool 98 590 as shown in the picture.

13 Tighten the puller bolt clockwise to 20 Nm.

Rotate the hub 5 rotations. Zero the dial

gauge. Mark the measurement point on

99 351.

14 Tighten the puller bolt anticlockwise to

20 Nm. Rotate the hub 5 rotations. Turn the

hub so that dial gauge tip is in the same

position as when it was zeroed. Read the

dial gauge.

15 Remove the tool, the adapter and the hub.

Reduce the thickness of the washer

assembly by the value read on the dial

gauge, the bearing play. Reduce a further

0 - 0.10 mm to obtain the correct bearing

preload. Try to get as close to 0.10 mm

bearing preload as possible.

Shims are available in thicknesses: 1.00,

1.05, 1.20 and 1.30 mm.

Hub, assembly

07:02-01

Scania CV AB 2003, Sweden 49

16 Press the bearing onto the ring gear retainer

using tool as shown in the picture. Centre

the tool precisely.

17 Assemble the internal ring gear and the ring

gear retainer.

18 Turn the sealing ring with the text 'oil side

in' and press the sealing ring into the hub

using the tool and as shown in the picture.

19 Fit the four wheel studs which were

removed when dismantling.

20 Lubricate the sealing ring inside diameter

with oil.

Hub, assembly

50

Scania CV AB 2003, Sweden 07:02-01

21 Set up the hub using the gearbox jack, as

shown in the picture. Fit it in onto the shaft

journal.

Note: Take great care so that the sealing ring is

not damaged. The gearbox jack is used to reduce

the risk of damaging the sealing.

22 Oil the shaft journal splines and threads. Fit

the ring gear retainer with internal ring gear

and thread the hub nut on by hand, as far as

it will go.

23 Remove the gearbox jack.

24 Tighten the hub nut to 400 Nm using

splined socket 99 353. Rotate the hub at

least 5 rotations and tighten, with the hub

rotating, to 900 Nm.

25 Lock the hub nut by upsetting it on three

points in the hole on the ring gear retainer.

1

0

4

5

9

9

99 353

400 Nm

5r

900 Nm

26 Fit wire ring 27, thrust washer 24, sun wheel

19, thrust washer 26 and snap ring 31.

Hub, assembly

07:02-01

Scania CV AB 2003, Sweden 51

27 Fit an oiled O-ring to the planetary unit.

28 Fit the planetary unit (note the hole for oil

filling and level) with cones and nuts.

Tighten the nuts crosswise to 87 Nm.

29 Fit an oiled gasket to the cover.

30 Fit the thrust washer and cover and tighten

the bolts crosswise to 39 Nm.

31 Turn the hub until the cover marking line 1

is in a horizontal position.

32 Fill with oil in oil filler hole 2 to the lowest

level hole 3.

33 Fill the puller hole threads halfway with

grease and press in the protective plugs.

34 Fit the remaining brake components and

adjust as described in the workshop manual

10:02-06.

35 Fit the wheel and tighten the wheel bolts as

described in the workshop manual 09:00-01.

Lower the axle.

1

2

3

1

0

4

8

5

8

Hub, assembly

52

Scania CV AB 2003, Sweden 07:02-01

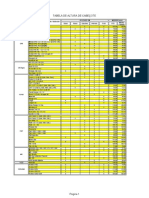

Specifications

General

Settings and test values

Tightening torques

Oil volume RP731 13.5 litres

Oil volume, hub reduction gear 0.8 litres

Oil type Refer to Group 0.

Sealing compound for axle beam 816 064

Adhesive for dust cover 816 064

Locking compound 561 200

Torque, shaft journal 130 N

Preload, wheel bearing 0.00 - 0.10

Hub nut 400 Nm and up to 900 Nm

Nuts for central gear 300 Nm

Studs in axle beam 80 Nm

Swivel pins 1400 Nm

Bracket, brake chamber 135 Nm

Lower swivel pin cover 135 Nm

Ball joints, shaft journal 250 Nm and then on to the closest

hole

Planetary unit nuts 87 Nm

Hub cover 39 Nm

Bolts for anti-roll bar bracket on axle 350 Nm

Nuts for front bracket for anti-roll bar 180 Nm

U-bolt nuts See tightening diagram in service

literature 12:01-01

Specifications

You might also like

- enDocument55 pagesenRegistr Registr100% (4)

- Scania P, G, R, T Series Workshop Manual - Removing The Reductant Main UnitDocument1 pageScania P, G, R, T Series Workshop Manual - Removing The Reductant Main Unitmusharrf100% (1)

- enDocument30 pagesenRegistr RegistrNo ratings yet

- Scania Inter AxleDocument14 pagesScania Inter AxleKharis Mahfudz100% (2)

- Clucth ScaniaDocument2 pagesClucth ScaniaNoeRtjahya Ahmad100% (1)

- enDocument44 pagesenRegistr Registr90% (10)

- Scania Engine Data 1588878Document20 pagesScania Engine Data 1588878Anderson Aguiar69% (16)

- enDocument83 pagesenRegistr Registr100% (12)

- enDocument72 pagesenRegistr Registr100% (4)

- Wabco ABS/TC "D" 4 and 6 Channel System: Issue 3Document34 pagesWabco ABS/TC "D" 4 and 6 Channel System: Issue 3user100% (10)

- WSM - 01!03!01 - En.11,12 and 16 Litre EngineDocument36 pagesWSM - 01!03!01 - En.11,12 and 16 Litre EngineSubkhi Fauzan94% (16)

- enDocument31 pagesenRegistr Registr100% (4)

- CALIBRACIONDocument65 pagesCALIBRACIONNuñez JesusNo ratings yet

- enDocument64 pagesenRegistr Registr100% (6)

- Sistema de Combustible Con Inyector Bomba PDE y EDC S6. Descripción de FuncionamientoDocument48 pagesSistema de Combustible Con Inyector Bomba PDE y EDC S6. Descripción de FuncionamientoFelipe Sierra97% (35)

- Scania Workshop Manual - Removing InjectorsDocument4 pagesScania Workshop Manual - Removing InjectorsocnogueiraNo ratings yet

- Scania P, G, R and S Series Workshop Manual - Dismantling Information PDFDocument106 pagesScania P, G, R and S Series Workshop Manual - Dismantling Information PDFLuciana Silveira100% (3)

- enDocument84 pagesenRegistr Registr100% (11)

- Scania Dismantling ManualDocument48 pagesScania Dismantling ManualTaqi Syed93% (15)

- Ko OrdinatorDocument31 pagesKo Ordinatoruser100% (6)

- Scania D9 Engine Manual RomanianDocument67 pagesScania D9 Engine Manual RomanianRomica Ciornei100% (1)

- Chequeo Frenos ScaniaDocument68 pagesChequeo Frenos ScaniaOmar Zerna100% (3)

- en PDFDocument44 pagesen PDFAlex Renne Chambi100% (1)

- enDocument17 pagesenRegistr Registr60% (5)

- GRS 890 900 GR 801 900Document28 pagesGRS 890 900 GR 801 900Osmar Franco Pires100% (23)

- Scania ServiceDocument48 pagesScania Servicecoco05fubu100% (2)

- enDocument40 pagesenRegistr Registr91% (11)

- Catalogo Scania CromadosDocument96 pagesCatalogo Scania CromadosDusanMasle100% (1)

- Scania P, G, R, T Series Workshop Manual - Removing A Manual GearboxDocument11 pagesScania P, G, R, T Series Workshop Manual - Removing A Manual GearboxFachrie50% (2)

- Maintenace Program ScaniaDocument14 pagesMaintenace Program ScaniaAmir Bambang Yudhoyono100% (1)

- WSM 0003232 01Document38 pagesWSM 0003232 01David Murray100% (5)

- Tacometro y Velocimetro ScaniaDocument48 pagesTacometro y Velocimetro ScaniaChristian Ramos Campos60% (5)

- Trouble Shoot ScaniaDocument77 pagesTrouble Shoot ScaniaTjoa Gin Hao75% (4)

- Scania Helper PDFDocument79 pagesScania Helper PDFCris_eu09100% (4)

- DC16 Engine 478kWDocument4 pagesDC16 Engine 478kWmuniNo ratings yet

- ScaniaDocument111 pagesScaniasimi012392% (12)

- SCANIA Work Description Engine - 12 Industrial and Marine EngineDocument76 pagesSCANIA Work Description Engine - 12 Industrial and Marine Enginemliugong82% (22)

- Scania HelperDocument79 pagesScania HelperHenrique Gonçalves Abreu100% (19)

- Scania Skrzynia BiegówDocument67 pagesScania Skrzynia Biegówandrzej100% (1)

- Scania P, G, R, T Series Workshop Manual - Removing The EngineDocument16 pagesScania P, G, R, T Series Workshop Manual - Removing The EngineVictor SampaNo ratings yet

- 120302en PDFDocument35 pages120302en PDFduongpn100% (2)

- Scania+Opticruise+transmission+troubleshooting PDFDocument84 pagesScania+Opticruise+transmission+troubleshooting PDFMikwile Julias KephaNo ratings yet

- WSM - Maintenance Instruction Part - 1 Truk - en PDFDocument120 pagesWSM - Maintenance Instruction Part - 1 Truk - en PDFDul AdulNo ratings yet

- Communication ErrorDocument24 pagesCommunication Errorali wardanaNo ratings yet

- Scania 12L - EMS - Operator - Manual - enDocument60 pagesScania 12L - EMS - Operator - Manual - enАнатолий ЩербаковNo ratings yet

- SM PC300-8 SN01983-01Document44 pagesSM PC300-8 SN01983-01aldy yasi77% (13)

- R6016-6018-6020#6030-6031-6031 Manual TallerDocument232 pagesR6016-6018-6020#6030-6031-6031 Manual TallerPedro Carvalho0% (1)

- باص وتو كارDocument12 pagesباص وتو كارRamiNo ratings yet

- Ont & Rear AxleDocument22 pagesOnt & Rear Axleghar_dash100% (1)

- Volvo d12 Workshop Manual Less Specifications AbbyDocument709 pagesVolvo d12 Workshop Manual Less Specifications Abbykoaa8597% (60)

- Pto Volvo A35Document8 pagesPto Volvo A35FilipposNo ratings yet

- DIFERENCIAL SCÂNIA (2)Document60 pagesDIFERENCIAL SCÂNIA (2)telmorogeriocariolattozinelliNo ratings yet

- Engine DismantlingDocument9 pagesEngine DismantlingRezha100% (1)

- 2008 7 8Document8 pages2008 7 8Peps Ren100% (2)

- Camshaft removal and installationDocument9 pagesCamshaft removal and installationpizandolaNo ratings yet

- SS Sports Chassis Saab 9-3Document21 pagesSS Sports Chassis Saab 9-3splod100% (2)

- Axial Detuner MaintenanceDocument5 pagesAxial Detuner MaintenanceKarthik ReddiarNo ratings yet

- Dismantling, Assembling and Adjusting: 9223-1/A1 Crank Angle Sensor UnitDocument18 pagesDismantling, Assembling and Adjusting: 9223-1/A1 Crank Angle Sensor UnitGaby CrisNo ratings yet

- Tabela de Altura de CabeçoteDocument2 pagesTabela de Altura de Cabeçotejuliotolentino75% (81)

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©Anderson BombistaNo ratings yet

- Manual Oficina c4.2 c6.4 CaterpillaDocument177 pagesManual Oficina c4.2 c6.4 CaterpillaIvo Silva88% (52)

- Manual Oficina c4.2 c6.4 CaterpillaDocument177 pagesManual Oficina c4.2 c6.4 CaterpillaIvo Silva88% (52)

- Diesel Engine 2.0L TDI Common RailDocument90 pagesDiesel Engine 2.0L TDI Common Railsmcsosvas100% (9)

- Stanadyne Sistema DB4 PDFDocument52 pagesStanadyne Sistema DB4 PDFAnderson Bombista100% (1)

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©Anderson BombistaNo ratings yet

- Tabela de Altura de CabeçoteDocument2 pagesTabela de Altura de Cabeçotejuliotolentino75% (81)

- Stanadyne Service Tool ManualDocument19 pagesStanadyne Service Tool ManualAnderson BombistaNo ratings yet

- Stanadyne Service Tool ManualDocument19 pagesStanadyne Service Tool ManualAnderson BombistaNo ratings yet

- Stanadyne Sistema DB4 PDFDocument52 pagesStanadyne Sistema DB4 PDFAnderson Bombista100% (1)

- TD 420 VeDocument92 pagesTD 420 VepurushmicroNo ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©Anderson BombistaNo ratings yet

- TD 420 VeDocument92 pagesTD 420 VepurushmicroNo ratings yet

- 320D EngineDocument109 pages320D Engineanton94% (35)

- Diesel Engine 2.0L TDI Common RailDocument90 pagesDiesel Engine 2.0L TDI Common Railsmcsosvas100% (9)

- Amaroks ServiceDocument419 pagesAmaroks ServicebvhdareldalmassoNo ratings yet

- TD 420 VeDocument92 pagesTD 420 VepurushmicroNo ratings yet

- Idioma PDFDocument1 pageIdioma PDFAnderson BombistaNo ratings yet

- Diesel Engine 2.0L TDI Common RailDocument90 pagesDiesel Engine 2.0L TDI Common Railsmcsosvas100% (9)

- 320D EngineDocument109 pages320D Engineanton94% (35)

- Diesel Engine 2.0L TDI Common RailDocument90 pagesDiesel Engine 2.0L TDI Common Railsmcsosvas100% (9)

- Diesel Engine 2.0L TDI Common RailDocument90 pagesDiesel Engine 2.0L TDI Common Railsmcsosvas100% (9)

- Scanner Diesel Cargo SDC 701 Scanner Diesel Cargo SDC 701Document1 pageScanner Diesel Cargo SDC 701 Scanner Diesel Cargo SDC 701Anderson BombistaNo ratings yet

- Diesel Engine 2.0L TDI Common RailDocument90 pagesDiesel Engine 2.0L TDI Common Railsmcsosvas100% (9)

- D 4 CBDocument429 pagesD 4 CBAnderson Bombista100% (36)

- Amaroks ServiceDocument419 pagesAmaroks ServicebvhdareldalmassoNo ratings yet

- Scan File 4Document1 pageScan File 4Anderson BombistaNo ratings yet

- Diesel Engine 2.0L TDI Common RailDocument90 pagesDiesel Engine 2.0L TDI Common Railsmcsosvas100% (9)

- Amaroks ServiceDocument419 pagesAmaroks ServicebvhdareldalmassoNo ratings yet

- Decision Maths 1 AlgorithmsDocument7 pagesDecision Maths 1 AlgorithmsNurul HafiqahNo ratings yet

- DC Motor Dynamics Data Acquisition, Parameters Estimation and Implementation of Cascade ControlDocument5 pagesDC Motor Dynamics Data Acquisition, Parameters Estimation and Implementation of Cascade ControlAlisson Magalhães Silva MagalhãesNo ratings yet

- Thin Film Deposition TechniquesDocument20 pagesThin Film Deposition TechniquesShayan Ahmad Khattak, BS Physics Student, UoPNo ratings yet

- Guidelines On Occupational Safety and Health in Construction, Operation and Maintenance of Biogas Plant 2016Document76 pagesGuidelines On Occupational Safety and Health in Construction, Operation and Maintenance of Biogas Plant 2016kofafa100% (1)

- Sri S T Kalairaj, Chairman: Income Tax TaxesDocument3 pagesSri S T Kalairaj, Chairman: Income Tax TaxesvikramkkNo ratings yet

- Exercises 6 Workshops 9001 - WBP1Document1 pageExercises 6 Workshops 9001 - WBP1rameshqcNo ratings yet

- Rishte ki baat SMS messages collectionDocument108 pagesRishte ki baat SMS messages collectionTushar AggarwalNo ratings yet

- Riddles For KidsDocument15 pagesRiddles For KidsAmin Reza100% (8)

- Inorganica Chimica Acta: Research PaperDocument14 pagesInorganica Chimica Acta: Research PaperRuan ReisNo ratings yet

- Clark DietrichDocument110 pagesClark Dietrichikirby77No ratings yet

- S5-42 DatasheetDocument2 pagesS5-42 Datasheetchillin_in_bots100% (1)

- Rounded Scoodie Bobwilson123 PDFDocument3 pagesRounded Scoodie Bobwilson123 PDFStefania MoldoveanuNo ratings yet

- The European Journal of Applied Economics - Vol. 16 #2Document180 pagesThe European Journal of Applied Economics - Vol. 16 #2Aleksandar MihajlovićNo ratings yet

- Propiedades Grado 50 A572Document2 pagesPropiedades Grado 50 A572daniel moreno jassoNo ratings yet

- PRODUCTDocument82 pagesPRODUCTSrishti AggarwalNo ratings yet

- всё необходимое для изучения английского языкаDocument9 pagesвсё необходимое для изучения английского языкаNikita Chernyak100% (1)

- Free Radical TheoryDocument2 pagesFree Radical TheoryMIA ALVAREZNo ratings yet

- 8dd8 P2 Program Food MFG Final PublicDocument19 pages8dd8 P2 Program Food MFG Final PublicNemanja RadonjicNo ratings yet

- QuickTransit SSLI Release Notes 1.1Document12 pagesQuickTransit SSLI Release Notes 1.1subhrajitm47No ratings yet

- If V2 would/wouldn't V1Document2 pagesIf V2 would/wouldn't V1Honey ThinNo ratings yet

- John Hay People's Alternative Coalition Vs Lim - 119775 - October 24, 2003 - JDocument12 pagesJohn Hay People's Alternative Coalition Vs Lim - 119775 - October 24, 2003 - JFrances Ann TevesNo ratings yet

- Attributes and DialogsDocument29 pagesAttributes and DialogsErdenegombo MunkhbaatarNo ratings yet

- Prenatal and Post Natal Growth of MandibleDocument5 pagesPrenatal and Post Natal Growth of MandiblehabeebNo ratings yet

- Contact and Profile of Anam ShahidDocument1 pageContact and Profile of Anam ShahidSchengen Travel & TourismNo ratings yet

- Origins and Rise of the Elite Janissary CorpsDocument11 pagesOrigins and Rise of the Elite Janissary CorpsScottie GreenNo ratings yet

- Audit Acq Pay Cycle & InventoryDocument39 pagesAudit Acq Pay Cycle & InventoryVianney Claire RabeNo ratings yet

- Pom Final On Rice MillDocument21 pagesPom Final On Rice MillKashif AliNo ratings yet

- PLC Networking with Profibus and TCP/IP for Industrial ControlDocument12 pagesPLC Networking with Profibus and TCP/IP for Industrial Controltolasa lamessaNo ratings yet

- JurnalDocument9 pagesJurnalClarisa Noveria Erika PutriNo ratings yet

- BIBLIO Eric SwyngedowDocument34 pagesBIBLIO Eric Swyngedowadriank1975291No ratings yet