Professional Documents

Culture Documents

Steel Water Pipe Specs 06

Uploaded by

Astri Ngent0 ratings0% found this document useful (0 votes)

88 views7 pagesThis document provides specifications for steel water pipe 4 inches or larger to be used by the San Antonio Water System. It outlines requirements for the pipe materials, fittings, joints, and linings. Steel pipe must meet standards for quality assurance, pressure ratings, deflection, and joint strength. Acceptable joint types include rolled-groove rubber gasket, lap welded, and mechanical couplings. The document also specifies lining, coating, and qualification requirements to ensure durability and corrosion protection of the steel pipe.

Original Description:

analysis

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides specifications for steel water pipe 4 inches or larger to be used by the San Antonio Water System. It outlines requirements for the pipe materials, fittings, joints, and linings. Steel pipe must meet standards for quality assurance, pressure ratings, deflection, and joint strength. Acceptable joint types include rolled-groove rubber gasket, lap welded, and mechanical couplings. The document also specifies lining, coating, and qualification requirements to ensure durability and corrosion protection of the steel pipe.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

88 views7 pagesSteel Water Pipe Specs 06

Uploaded by

Astri NgentThis document provides specifications for steel water pipe 4 inches or larger to be used by the San Antonio Water System. It outlines requirements for the pipe materials, fittings, joints, and linings. Steel pipe must meet standards for quality assurance, pressure ratings, deflection, and joint strength. Acceptable joint types include rolled-groove rubber gasket, lap welded, and mechanical couplings. The document also specifies lining, coating, and qualification requirements to ensure durability and corrosion protection of the steel pipe.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 7

05-30

SAN ANTONIO WATER SYSTEM

SAN ANTONIO, TEXAS

SPECIFICATION FOR STEEL WATER PIPE

REVISED November 2006

1. SCOPE

This specification covers steel pipe 4-inches and larger in size and manufactured

for the purpose of conveying water.

2. GENERAL REQUIREMENTS

A. Quality Assurance

Commercial Standards: (All manufacturing tolerances referenced in the below

standards apply unless specifically excluded).

ANSI/AWWA C-200 Standard for Steel Water Pipe 6 Inches and Larger

ANSI/AWWA C-205 Standard for Cement-Mortar Protective Lining and

Coating for Steel Water Pipe - 4 in. and Larger-Shop

Applied

ANSI/AWWA C-206 Standard for Field Welding of Steel Water Pipe

ANSI/AWWA C-207 Standard for Steel Pipe Flanges for Water Works

Service, 4" - 144"

ANSI/AWWA C-208 Standard for Dimensions for Fabricated Steel Water

Pipe Fittings

ANSI/AWWA C-209 Standard for Cold-Applied Tape Coatings for the

Exterior of Special Sections, Connections, and Fittings

for Steel Water Pipelines

ANSI/AWWA C-210 Standard for Liquid-Epoxy Coating Systems for the

Interior and Exterior of Steel Water Pipelines

ANSI/AWWA C-214 Standard for Tape Coating Systems for the Exterior of

Steel Water Pipelines

1

Steel Water Pipe

Specification Number 05-30

ANSI/AWWA C-216 Standard for Heat-Shrinkable Cross-Linked Polyolefin

Coatings for the Exterior of Special Sections,

Connections, and Fittings for Steel Water Pipelines

ANSI/AWWA C-218 Standard for Coating the Exterior of Aboveground Steel

Water Pipelines and Fittings

ANSI/AWWA C-219 Standard for Bolted Sleeve-Type Couplings for Plain-

End Pipe

ANSI/AWWA C-222 Standard for Polyurethane Coatings for the Interior and

Exterior of Steel Water Pipelines and Fittings

AWWA M-11 Steel Pipe - A guide for Design and Installation

ASTM A 106 Standard Specification for Seamless Carbon Steel Pipe

for High-Temperature Service.

ASTM A 53 Standard Specification for Pipe, Steel, Black and Hot-

Dipped, Zinc Coated Welded and Seamless

ASTM E 165 Method for Liquid Penetrant Examination

ASTM E 709 Guide for Magnetic Particle Examination

ASME Section V Nondestructive Testing Examination

ASME Section IX Welding and Brazing Qualification.

AWS B2.1 Standard for Welding Procedure and Welding

Qualifications.

B. Qualifications

1. Manufacturers who are fully experienced, reputable, and qualified in the

manufacture of the products to be furnished shall furnish all Steel pipe

and fittings. The pipe and fittings shall be designed, constructed and

installed in accordance with the best practices and methods and shall

comply with these specifications as applicable.

2

Steel Water Pipe

Specification Number 05-30

2. Pipe shall be the product of one manufacturer that has not less than five

(5) years successful experience manufacturing pipe in the United States of

the particular type and size indicated. All pipe manufacturing including

cylinder production, lining, coating and fittings shall be produced by one

manufacture. The pipe manufacturer must have a certified quality

assurance program. This certified program shall be ISO 9001: 2000 or

other equivalent nationally recognized program.

3. MATERIALS

A. Pipe

1. Steel pipe with nominal diameters from 4-inch to 20-inch shall conform to

ASTM A 106, A 53 Grade B or A 139 Grade B standard weight class as the

minimum.

2. Steel Pipe greater than 20-inches shall conform to AWWA C200 and AWWA

M-11 except as modified herein or as required by the engineer for special

circumstances.

3. Pipe shall be designed for a minimum of 150 psi working pressure with an

additional 50% of the working pressure allowance for surge pressure unless

otherwise specified. Pipe design shall be in accordance with AWWA M-11.

4. Pipe shall be designed to cover conditions as shown on the plans. The design

for deflection shall be in accordance with AWWA M-11.

Use of an enhanced /better soil backfill to limit deflection will be allowed

with approval by the engineer. (Criteria will be based on AWWA M-11)

5. Pipe for use with sleeve-type couplings shall have plain ends at right angles to

the axis.

6 Pipe is to be furnished in joint lengths up to 50 ft. net laying lengths with

special lengths, field trim pieces and closure pieces as required by plan and

profile for location of elbows, tees, reducers and other in-line fittings. The

pipe fabricator shall prepare a pipe-laying schedule showing the location of

each piece by mark number with station and invert elevation at each bell end.

3

Steel Water Pipe

Specification Number 05-30

B. Fittings

Unless otherwise shown on the Plans, all specials and fittings shall conform to

the dimensions of AWWA Standard C208. Pipe material used in fittings shall

be of the same material and thickness as the pipe. The minimum radius of

elbows shall be 2.5 times the pipe diameter and the maximum miter angle on

each section of the elbow shall not exceed 11 1/4 degrees (One cut elbow up

to 22 1/2 deg.). If elbow radius is less than 2.5 x pipe diameter, stresses shall

be checked per AWWA M-11 and wall thickness or yield strength increased if

necessary. Fittings shall be equal in pressure design strength. Specials and

fittings, unless otherwise shown on the Plans, shall be made of segmentally

welded sections from hydrostatically tested pipe, with ends compatible with

the type of joint or coupling specified for the pipe. All welds made after

hydrostatic testing of the straight sections of pipe shall be checked per the

requirements of AWWA C-200 Section 5.2.2.1

C. Joints

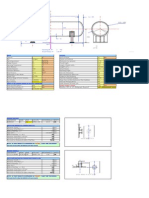

1. Rolled-Groove Rubber Gasket J oint: the standard joint shall be rolled-groove

rubber gasket joint unless otherwise noted on the plans. Rolled-grooved

rubber gasket joints shall conform to AWWA C200 Standard and as shown in

Chapter 8 of AWWA M-11.

The o-ring rubber gasket shall have sufficient volume to approximately fill the

area of the groove and shall conform to AWWA C200.

The joint shall be suitable for a safe working pressure equal to the class of

pipe furnished and shall operate satisfactorily with a deflection angle, the

tangent of which is not to exceed 1.00/D where D is the outside diameter of

the pipe in inches with a pull-out of 1 inch.

Rolled-Groove Rubber Gasket J oints may be furnished only by a

manufacturer who has furnished pipe with joints of similar design for

comparable working pressure. Pipe diameter, pipe length, and wall thickness

that has been in successful service for a period of at least 5 years.

2. Lap weld: Lap field welded joints shall be used where tied joints are indicated

on the plans. The standard bell shall provide for a 2 1/2-inch lap. The

minimum lap shall be 1 inch. The design maximum joint deflection or offset

shall be a 1" joint pull.

4

Steel Water Pipe

Specification Number 05-30

3. Mechanical Couplings: Mechanical couplings where indicated on the plans

shall be Smith Blair Style 411, Baker Style 200, Brico Depend-O-Loc or

equal. Insulating mechanical couplings where indicated on the plans shall be

double insulated Smith Blair Style 416, Baker Style 216, or equal. Mechanical

couplings shall be rated to meet or exceed the working pressures and surge

pressure of the pipe.

Couplings for buried service shall have all metal parts painted with Epoxy

paint and conform to AWWA C219.

Pipe ends for mechanical couplings shall conform to AWWA C200 and M-11.

The shop applied outside coating shall be held back as required for field

assembly of the mechanical coupling or to the harness lugs or rings. Harness

lugs or rings and pipe ends shall be painted with one shop coat of epoxy

conforming to AWWA C210. The inside lining shall be continuous to the end

of the pipe.

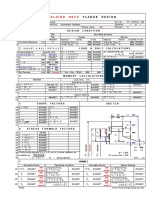

4. Flanges

a. Flanges shall be in accordance with AWWA C207 Class D for operating

pressures to 175 psi on 4 inch through 12 inch diameter, and operating

pressures to 150 psi on diameters over 12 inches; or

Flanges shall be AWWA C207 Class E for operating pressures up to 275

psi; or

Flanges shall be AWWA C207 Class F for pressures to 300 psi. (drilling

matches ANSI B 16.5 Class 250)

Shop lining and coating shall be continuous to the end of the pipe or

back of the flange. Flange faces shall be shop coated with a soluble rust

preventive compound.

b. Gaskets: Full face, 1/8-inch thick, cloth-inserted rubber, Garlock 3000,

J ohn Crane Co. Style 777 or equal.

c. Bolts and Nuts for Flanges

5

Steel Water Pipe

Specification Number 05-30

1. Bolts for flanges located indoors and in enclosed vaults and

structures shall be carbon steel, ASTM A307, Grade B for class B

and D flanges and nuts shall be ASTM A563, Grade A heavy hex.

Bolts for class E and F flanges shall be ASTM A 193 grade B7 and

nuts shall be ASTM A194, grade 2 H, heavy hex.

2. Bolts for buried and submerged flanges and flanges located

outdoors above ground or in open vaults in structures shall be

TYPE 316 stainless steel conforming to ASTM A193, Grade B8M,

Class 1 for class B and D Flanges with ASTM 194, Grade 8M

nuts. For Class E and F flanges the bolts shall be ASTM A194

grade 2H nuts with bolt and nuts to be zinc plated in accordance

with ASTM B633

D. Linings and Coatings

1. Polyethylene Tape Coating

a. Prefabricated Multi-layer Cold Applied Tape Coating - the coating

system for straight-line pipe shall be in accordance with AWWA

Standard C214. The system shall consist of three layers of

polyethylene material with a nominal thickness of 80 mills when

complete.

b. Coating Repair

Coating repair shall be made using tape and primer conforming to

AWWA Standard C209, Type II. The tape and primer shall be

compatible with the tape system used for straight-line pipe.

c. Coating of Fittings, Specials and J oints

1. General Fittings, specials and joints which cannot be machine

coated in accordance with above, shall be coated in accordance

with AWWA Standard C209. Prefabricated tape shall be Type

II and shall be compatible with the tape system used for

straight-line pipe. The system shall consist of 3 layers

consisting of the following: Alternate coating methods for

fittings specials and field joints would be Shrink sleeves per C-

216, or paint per C-210, C-218, or C-222. The field coating

shall completely encapsulate the joint bonds on o-ring joints.

6

Steel Water Pipe

Specification Number 05-30

2. Coating Repair - Coating repair for fittings and specials shall

be in accordance with the procedure described above for

straight-line pipe and as recommended by the manufacturer.

2. Other Coating Systems if specified shall be governed by the appropriate

American Water Works Association standard.

3. . Cement Mortar per AWWA C205

a. Cement Mortar Lining of Steel Pipe

1. Except as otherwise provided in AWWA Standard C205,

interior surface of all steel pipe, fittings and specials shall be

cleaned and lined in the shop with cement-mortar lining

applied centrifugally in conformity with AWWA Standard

C205.

2. The pipe ends shall be left bare where field joints occur as

shown on the Plans. Ends of the linings shall be left square and

uniform. Feathered or uneven edges will not be permitted.

3. Defective linings as identified in AWWA C-205 shall be

removed from the pipe wall and shall be replaced to the full

thickness required. Defective linings shall be cut back to a

square shoulder in order to avoid feather edged joints.

4. Cement mortar lining shall be kept moist during storage and

shipping.

b. Fittings

1. Fittings shall be lined and coated per AWWA C205.

Previous Specification Date:

Revised May 1992

7

You might also like

- Awwa C200 PDFDocument6 pagesAwwa C200 PDFangel darioNo ratings yet

- C900-22 LookInsideDocument13 pagesC900-22 LookInsideJuan GuevaraNo ratings yet

- Corrosion Control For Buried Water MainsDocument43 pagesCorrosion Control For Buried Water Mainsdelta_scopeNo ratings yet

- C219-23 LookInsideDocument13 pagesC219-23 LookInsidemrdino2012No ratings yet

- Awwa C509-23Document52 pagesAwwa C509-23Vijay KumarNo ratings yet

- Cost-Effective Air Cushion Surge Chambers for HydropowerDocument2 pagesCost-Effective Air Cushion Surge Chambers for HydropowerAli AlengineerNo ratings yet

- SHPP GL Ch2.FullDocument270 pagesSHPP GL Ch2.FullLuis Faustino Rodriguez LopezNo ratings yet

- Spiral Weld PipeDocument52 pagesSpiral Weld PipePRASHANTNo ratings yet

- Welded Steel Pipe 10.10.07Document93 pagesWelded Steel Pipe 10.10.07Jose Alberto Patterson FelixNo ratings yet

- Precoat Filter Media: Awwa StandardDocument20 pagesPrecoat Filter Media: Awwa StandardErdi ErdoganNo ratings yet

- ASWP Manual - Section 1 - IntroductionDocument17 pagesASWP Manual - Section 1 - Introductionjmvm56No ratings yet

- GRP and HDPE PipeDocument1 pageGRP and HDPE PipeRashid KayumNo ratings yet

- 0200 DSZ BrochureDocument6 pages0200 DSZ Brochurenezz_nezzNo ratings yet

- A134 PDFDocument4 pagesA134 PDFAlberto DiazNo ratings yet

- Siphon Breaker Valves (Accessories)Document2 pagesSiphon Breaker Valves (Accessories)mikeswordsNo ratings yet

- Guide to flange facing: types of damage, finishes, gaskets and machine typesDocument1 pageGuide to flange facing: types of damage, finishes, gaskets and machine typesjksankar100% (1)

- Modulus Soil Reaction E' PDFDocument2 pagesModulus Soil Reaction E' PDFSen HuNo ratings yet

- Awwa C604Document64 pagesAwwa C604Mahdi MoarrefNo ratings yet

- Liquid Sodium Silicate: Awwa StandardDocument24 pagesLiquid Sodium Silicate: Awwa Standardjuan pablo suarezNo ratings yet

- Best Practices for Conduits Through Embankment DamsDocument12 pagesBest Practices for Conduits Through Embankment Damsdjajadjaja100% (1)

- Instrumentasi Bendung LogungDocument16 pagesInstrumentasi Bendung Logunganon_507171008No ratings yet

- CAESAR II 5.00 Sneak Preview - New Interface, Technology and ReportingDocument61 pagesCAESAR II 5.00 Sneak Preview - New Interface, Technology and ReportingRokan PipelineNo ratings yet

- Self-Tapping Saddle Tees Foruse: PVC PipeDocument22 pagesSelf-Tapping Saddle Tees Foruse: PVC PipeJacques BlueqNo ratings yet

- Presentasi Design WPS - 1 Dec 10 BWDocument43 pagesPresentasi Design WPS - 1 Dec 10 BWWahyu PurbaNo ratings yet

- CVA Gate Globe Check Strainers CatalogDocument95 pagesCVA Gate Globe Check Strainers CatalogRiss0No ratings yet

- Air in Pipelines 1-19Document9 pagesAir in Pipelines 1-19BhuvanaNo ratings yet

- KS Product Specification 2015Document32 pagesKS Product Specification 2015Gilang BhismaNo ratings yet

- Water Transmission Pipelines An Updated Design GuideDocument13 pagesWater Transmission Pipelines An Updated Design GuideponjoveNo ratings yet

- JIS JFE Pipe and TubeDocument25 pagesJIS JFE Pipe and Tubedavorp1402No ratings yet

- Guide Frame Stop Log 1Document1 pageGuide Frame Stop Log 1Ilham PratamaNo ratings yet

- Aluminum Sulfate - Liquid, Ground, or Lump: AWWA StandardDocument5 pagesAluminum Sulfate - Liquid, Ground, or Lump: AWWA StandardAmri YusrulNo ratings yet

- AWWA C218-99 PaintingDocument28 pagesAWWA C218-99 PaintinglakshmananNo ratings yet

- Codes, Standards & Regulations OverviewDocument8 pagesCodes, Standards & Regulations OverviewDzaka LanaaNo ratings yet

- Comparison of SA106 Against ASTM A106 StandardsDocument15 pagesComparison of SA106 Against ASTM A106 Standardsshamoojee100% (1)

- Rock Slope Engineering PDFDocument440 pagesRock Slope Engineering PDFbufaloteNo ratings yet

- FuturePipe Installation Manual 18-7-05 PDFDocument25 pagesFuturePipe Installation Manual 18-7-05 PDFPaul WoworNo ratings yet

- ASCE Paper PDFDocument8 pagesASCE Paper PDFLeandroNo ratings yet

- Car Washer CatalogueDocument24 pagesCar Washer Cataloguesra electricalsNo ratings yet

- Ansi Awwa c225-07Document28 pagesAnsi Awwa c225-07Harli M. HavilNo ratings yet

- Pro-Piping Basic Training PresentationDocument34 pagesPro-Piping Basic Training Presentationsamprof4vw100% (1)

- Some Useful Codes and Standards OrganizationsDocument12 pagesSome Useful Codes and Standards OrganizationsBleep NewsNo ratings yet

- Tyco Vanessa DatasheetDocument16 pagesTyco Vanessa DatasheetJack ChavanNo ratings yet

- Metode Pemasangan Pipa HDPEDocument13 pagesMetode Pemasangan Pipa HDPEBudi SantonyNo ratings yet

- Pilot-Operated Control Valves: AWWA StandardDocument32 pagesPilot-Operated Control Valves: AWWA StandardAnnie De WildeNo ratings yet

- Mab Basic Hdpe Repair Options Mab4 PDFDocument10 pagesMab Basic Hdpe Repair Options Mab4 PDFJohnny Condori MarcapuraNo ratings yet

- ASWP Manual - Section 2 - Steel Pipe Design (6-2013)Document21 pagesASWP Manual - Section 2 - Steel Pipe Design (6-2013)Shahril Izzuddin Or DinoNo ratings yet

- SeismicGuidelines WaterPipelines P4Document33 pagesSeismicGuidelines WaterPipelines P4Dipankar BasakNo ratings yet

- Lifting Beams Stop LogDocument4 pagesLifting Beams Stop LogkhalidcosmosNo ratings yet

- Welding Consumables For Pipeline Construction - ENDocument64 pagesWelding Consumables For Pipeline Construction - ENmaheshNo ratings yet

- Rotodynamic Vertical Pumps: For Manuals Describing Installation, Operation, and MaintenanceDocument57 pagesRotodynamic Vertical Pumps: For Manuals Describing Installation, Operation, and MaintenanceShubhrajeet TiwariNo ratings yet

- Valve Materials AppendixDocument3 pagesValve Materials AppendixDucVikingNo ratings yet

- Cement-Mortar Lined & Coated Steel PipeDocument5 pagesCement-Mortar Lined & Coated Steel Pipenay denNo ratings yet

- STD 15080Document4 pagesSTD 15080dineshinnaci123No ratings yet

- Suggested Specification For Buried Steel Water Transmission Pipe FINALDocument10 pagesSuggested Specification For Buried Steel Water Transmission Pipe FINALA T AlhershNo ratings yet

- Cement-Mortar Lined & Coated Steel Pipe - 2Document6 pagesCement-Mortar Lined & Coated Steel Pipe - 2dwi sutiknoNo ratings yet

- Features Flanged DIP and Fittings4Document4 pagesFeatures Flanged DIP and Fittings4Sohail HanifNo ratings yet

- SEWAGE FORCE MAIN INSTALLATION REQUIREMENTSDocument9 pagesSEWAGE FORCE MAIN INSTALLATION REQUIREMENTSMarlon A. MendozaNo ratings yet

- 15510Document13 pages15510mahaboobptmNo ratings yet

- MechanicalDocument173 pagesMechanicalKerx EndranoNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- D Value CalcDocument5 pagesD Value CalcAstri NgentNo ratings yet

- Data Dial IndikatorDocument2 pagesData Dial IndikatorAstri NgentNo ratings yet

- 10 11Document9 pages10 11PrashannaNo ratings yet

- Assy Joint Pipa Line 1Document1 pageAssy Joint Pipa Line 1Astri NgentNo ratings yet

- ZX 100 K-Truss Support PadDocument4 pagesZX 100 K-Truss Support PadAstri NgentNo ratings yet

- Bekomat Produk DisplayDocument4 pagesBekomat Produk DisplayAstri NgentNo ratings yet

- Plate and Box Girder DesignDocument60 pagesPlate and Box Girder DesignKrishna ChandranNo ratings yet

- Slide Bearing PTFE Tes ReportDocument6 pagesSlide Bearing PTFE Tes ReportAstri NgentNo ratings yet

- Design of Welded ConnectionsDocument8 pagesDesign of Welded ConnectionsAstri NgentNo ratings yet

- Beam Desain1Document2 pagesBeam Desain1Astri NgentNo ratings yet

- Mud Barge Sea ChestDocument1 pageMud Barge Sea ChestAstri NgentNo ratings yet

- Gantry Crane CalculatedDocument1 pageGantry Crane CalculatedAstri NgentNo ratings yet

- Spherical Roller Thrust Bearing PDFDocument16 pagesSpherical Roller Thrust Bearing PDFAstri NgentNo ratings yet

- Flange Example CalcDocument14 pagesFlange Example CalcAstri NgentNo ratings yet

- Surge TankDocument4 pagesSurge TankAstri NgentNo ratings yet

- Hydroelectric Hydro Power 4 3 1 DesignDocument28 pagesHydroelectric Hydro Power 4 3 1 DesignLouise UmaliNo ratings yet

- 26 Pressure Vessel.Document21 pages26 Pressure Vessel.mishtinil93% (14)

- Weld Analysis-IC Method v1.1Document5 pagesWeld Analysis-IC Method v1.1jefersonpimentelNo ratings yet

- Reinforced PadDocument3 pagesReinforced PadAstri NgentNo ratings yet

- Over Head Water Tank DesignDocument5 pagesOver Head Water Tank DesignAstri Ngent100% (1)

- 6000 EN 00 04 Friction BearingDocument30 pages6000 EN 00 04 Friction BearingAstri NgentNo ratings yet

- Bearing Layout PDFDocument1 pageBearing Layout PDFAstri NgentNo ratings yet

- NTN Pillow BlockDocument54 pagesNTN Pillow BlockteguheafNo ratings yet

- ValveDocument4 pagesValveAstri NgentNo ratings yet

- Plugin Bushes PDFDocument3 pagesPlugin Bushes PDFAstri NgentNo ratings yet

- Hammer Product Data SheetDocument2 pagesHammer Product Data SheetAstri NgentNo ratings yet

- Motor Selection, Inertia PDFDocument6 pagesMotor Selection, Inertia PDFIswar Rauf Aboo 'AqilahNo ratings yet

- Gang SawDocument55 pagesGang SawAstri NgentNo ratings yet

- Calculating The Time Required To Empty A Vessel: ExamplesDocument1 pageCalculating The Time Required To Empty A Vessel: ExamplesKabir KhanNo ratings yet

- Limit State DesignDocument26 pagesLimit State DesignAstri NgentNo ratings yet

- PAS Install Lab Guide - v11.2Document145 pagesPAS Install Lab Guide - v11.2Muhammad Irfan Efendi SinulinggaNo ratings yet

- III International Congress on Teaching Cases Related to Public and Nonprofit Marketing: Nestlé's CSR in Moga District, IndiaDocument8 pagesIII International Congress on Teaching Cases Related to Public and Nonprofit Marketing: Nestlé's CSR in Moga District, IndiaIshita KotakNo ratings yet

- Politische StrategiesEnd 2012 de en FINALDocument405 pagesPolitische StrategiesEnd 2012 de en FINALFomeNo ratings yet

- Opposition To Motion For InjunctionDocument29 pagesOpposition To Motion For InjunctionBasseemNo ratings yet

- C M P (P N) : Ommunication Anagement LAN Roject AMEDocument8 pagesC M P (P N) : Ommunication Anagement LAN Roject AMEArun BungseeNo ratings yet

- Doctrine of Repugnancy ExplainedDocument13 pagesDoctrine of Repugnancy ExplainedAmita SinwarNo ratings yet

- Brother Electric Sewing xr9550prwDocument2 pagesBrother Electric Sewing xr9550prwVenkatNo ratings yet

- Win Server 2008 Manual Installation PDFDocument20 pagesWin Server 2008 Manual Installation PDFFery AlapolaNo ratings yet

- NFL 101 Breaking Down The Basics of 2-Man CoverageDocument10 pagesNFL 101 Breaking Down The Basics of 2-Man Coveragecoachmark285No ratings yet

- Stellarisware Release Notes: Sw-Rln-6852Document160 pagesStellarisware Release Notes: Sw-Rln-6852Akio TakeuchiNo ratings yet

- LGDocument5 pagesLGPreetham Kiran RodriguesNo ratings yet

- 06 Traffic Flow Fundamentals PDFDocument27 pages06 Traffic Flow Fundamentals PDFDaryl ChanNo ratings yet

- 6Tdvfutfrfr-S: of ofDocument2 pages6Tdvfutfrfr-S: of ofhim vermaNo ratings yet

- Sample & Sampling MethodDocument55 pagesSample & Sampling MethodArafat RahmanNo ratings yet

- Occurrence of Black Soldier Fly HermetiaDocument2 pagesOccurrence of Black Soldier Fly HermetiaMarcelo Geraldo TeixeiraNo ratings yet

- Score Higher On The Ukcat, 5Th Edition - 2019 UpdateDocument2 pagesScore Higher On The Ukcat, 5Th Edition - 2019 UpdateNikki Fish0% (1)

- Pizza Crust Menu in Karachi - Restaurant Online Ordering PakistanDocument2 pagesPizza Crust Menu in Karachi - Restaurant Online Ordering PakistanSyed Rafay HashmiNo ratings yet

- Political Science Class 12TH Project Work 2022-23Document2 pagesPolitical Science Class 12TH Project Work 2022-23Hariom Yadav100% (1)

- Design and Implementation of Automated Student School Fees PaymentDocument11 pagesDesign and Implementation of Automated Student School Fees PaymentTony Omorotionmwan Airhiavbere75% (4)

- Set Up A Mail Server On LinuxDocument56 pagesSet Up A Mail Server On Linuxammurasikan6477No ratings yet

- Charles L. Mader - Numerical Modeling of The Deflagration-to-Detonation TransitionDocument21 pagesCharles L. Mader - Numerical Modeling of The Deflagration-to-Detonation TransitionSteemWheelNo ratings yet

- Barangay Budget Authorization No. 11Document36 pagesBarangay Budget Authorization No. 11Clarissa PalinesNo ratings yet

- Moodlecloud 24284Document1 pageMoodlecloud 24284Giged BattungNo ratings yet

- DRS User ManualDocument52 pagesDRS User Manualwmp8611024213100% (1)

- Hand Sanitizer Solution: Sanipure: "Safe, Effective, Innovative"Document19 pagesHand Sanitizer Solution: Sanipure: "Safe, Effective, Innovative"Daniel Mariano LeãoNo ratings yet

- Assignment: Name: Armish Imtiaz Roll No: 37: TopicDocument3 pagesAssignment: Name: Armish Imtiaz Roll No: 37: TopicKhubaib ImtiazNo ratings yet

- E Studio 167Document26 pagesE Studio 167GabiNo ratings yet

- Tune boilers regularlyDocument2 pagesTune boilers regularlyEliecer Romero MunozNo ratings yet

- Tybms Sem 5 CCPRDocument45 pagesTybms Sem 5 CCPROswin DsouzaNo ratings yet