Professional Documents

Culture Documents

104 118

Uploaded by

vprochockyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

104 118

Uploaded by

vprochockyCopyright:

Available Formats

Relay

Switching

Techniques

VOLTECHNOTES

VPN 104-118/3

Figure 2

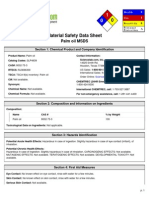

The picture on the right is a screen shot from

the AT Editor software. It is a graphical repre-

sentation of the actual 20-node relay matrix

on the AT tester itself. Each numbered node

(1-20) represents the four-relay schematic

shown in Figure 1 above. There are four

relays per node and 20 nodes, totalling 80

relays.

2001 Voltech Instruments. All rights reserved.

RELAY SWITCHING TECHNIQUES

VOLTECHNOTES

The 20-Node Relay Matrix

The Voltech AT3600 uses a 20-node relay matrix, terminating in pairs of spring probes,

to allow standard fixtures to be connected to the unit. Each pair of spring probes (a node)

connects to four high-voltage relays, configured for full Kelvin (4-wire) measurement.

Two of these relays, Source Hi and Source Lo (the power pair), are energized to

supply the voltage/current source to the component under test. The remaining two

relays, Measure Hi and Measure Lo (the sense pair), are energized to route the

voltage/current source to the measure circuit. This configuration is shown below, in

Figure 1, for one of the nodes connected to one end of a transformer winding under test.

This type of Kelvin relay arrangement for each of the 20 nodes is fully controlled by the

AT3600 and is programmable through the supplied AT Editor software. There are no limi-

tations as to which node is used for which transformer winding.

2

MEASURE HI

MEASURE LO

SOURCE HI

SOURCE LO

VOLTAGE/

CURRENT

SOURCE

MEASURE

CIRCUIT

~~

S P

S = Sense Node

P = Power Node

NODE 1 NODE 20

V

Figure 1

Optimizing Relay Reliability

Relays are often assumed to be an inferior alternative to solid-state switches as a switching

device. However, relays offer the means to hold off thousands of volts when they are open, and

they still provide a few tens of milliohms of contact resistance when they are closedcharacter-

istics that cannot be provided by any solid-state device either now or in the foreseeable future.

The main reason relays are seen as inferior components is that they are assumed to be unreli-

able. However, the mechanical life of a relay is in excess of 100,000,000 operationsenough to

last more than ten years in a heavy-use transformer tester application, provided the proper tech-

nique is used for switching the relay. Voltech has developed such a technique.

In order to maximize the life of the relays, the AT3600s voltage and current sources are switched

off prior to any opening and closing of the 80 high-voltage relays. At the start of any test, the relays

are closed before any voltage is ramped up. At the end of a test, the AT3600 checks the current

through the relays and, if there is still current flowing, the AT3600 will wait until this has decayed

to zero before opening the relays. This technique is known as cold switching and minimizes any

arcing across the relay contacts, ensuring that the contacts undergo the minimum of degradation

and thus maximizing the service life of the relays and the AT3600 itself.

The importance of measuring the current for cold switching is illustrated in Figure 3 below.

The opening and closing action of the relays is extremely fast (approximately 3 millisec-

onds closing time and 1 millisecond release time). In order to maintain the operating accu-

racy of the AT3600, a very comprehensive self-test routine has been incorporated into the

AT3600's firmware. The self-test sequence is user-initiated after the power-up sequence

has completed. Self-test has been designed to fully test the product's range of operation,

including a contact resistance test of its 40-source relays and 40-measure relays. Each

contact resistance test is operated in pairs and the relay contact resistance must be

<200m for both relays. Where >200m is detected on a relay contact a unique electronic

cleaning process is automatically deployed and the relay contact re-measured to a

maximum of three cleaning processes. This action maximizes the life cycle of the relays

currently in excess of 10,000,000 operations.

VOLTECHNOTES RELAY SWITCHING TECHNIQUES

3

2001 Voltech Instruments. All rights reserved.

Applied Voltage

from Power Source

Inductor

Current

30ms

60ms

Decay for low inductance

or high winding resistance

Decay for high inductance

or low winding resistance

Power

Source

Figure 3

VOLTECHNOTES

4

If relays are opened a fixed time after turning off the supply, then this would have to be a long

time to cope with the worst-case component, unnecessarily wasting test time for the majority

of components. On the other hand, if the time chosen is too short, relays will be subject to

breaking current, causing arcing and degrading their lifetime.

Most transformer tester solutions using an external matrix simply use a fixed time to deter-

mine when to open relays, with the consequent risk of relay arcing and degradation. On its

AT series of products, Voltech maximizes both speed and reliability by using an integrated

matrix with source and measure, an active discharge method to force the current to decay as

quickly as possible, and measuring when the current falls to zero before opening. The

opening and closing action of the relays is extremely fast (approximately three milliseconds

closing time and one millisecond release time).

In order to maintain the operating accuracy of the AT3600, a very comprehensive self-test

routine has been incorporated into the AT3600. The self-test sequence is user-initiated after

the power-up sequence has completed. Self test has been designed to fully test the product's

range of operation, including the contact resistance of its 40 source and 40 measure relays.

Contact resistance may increase over many months usage due to molecule-thick impurities

migrating to the contact surface. If a contact resistance greater than a pre-determined value

is detected on a relay contact, a unique electronic cleaning process is automatically deployed

until the relay contact achieves its original low value. This action further maximizes the life

cycle of the relays.

RELAY SWITCHING TECHNIQUES

2001 Voltech Instruments. All rights reserved.

VOLTECHNOTES

5

Conclusions

Each of the AT3600s 80 relays has an average, field-proven mean time between failures

(MTBF) in excess of 100,000,000 operations, a high-voltage stand-off rating of 10kV DC or

peak AC, and a switching current of up to 3A DC or peak AC. Coupling this with the built-in

self-test sequence, the relay switching speeds, Kelvin measurement system, actual switch-

ing methods, and the AT3600's unique electronic relay cleaning process makes it one of the

most accurate and reliable methods of transformer fixturing and testing available in one

instrument.

Notice

The arrangement of multiple relays, signal sources and measuring circuits used

in Voltech AT series testers is protected by the following patents:

U.S.A.: US5500598; U.K.: 2261957B; Europe: 0621953B.

The AT3600 Automatic Transformer Tester

RELAY SWITCHING TECHNIQUES

2001 Voltech Instruments. All rights reserved.

VPN 104-118/3

VOLTECHNOTES

Voltech Instruments Ltd.

148 Sixth Street

Harwell International Business Centre

Harwell, Didcot, Oxon OX11 0RA

United Kingdom

Telephone: +44 (0)1235 834555

Facsimile: +44 (0)1235 835016

E-mail: sales@voltech.co.uk

Voltech Instruments Inc.

11637 Kelly Road, Suite 306

Fort Myers, FL 33908

U.S.A.

Telephone: +1 239 437 0494

Facsimile: +1 239 437 3841

E-mail: sales@voltech.com

www.voltech.com

Note: While every care has been taken in compiling the information for this publication, Voltech Instruments cannot accept legal liabil-

ity for any inaccuracies. Voltech Instruments reserves the right to alter product specifications without notice and whenever necessary

to ensure optimum performance from its product range.

You might also like

- Transformer Design and Design Parameters PDFDocument56 pagesTransformer Design and Design Parameters PDFHemendra Jani60% (5)

- Django Reinhardt - Selmer GuitarsDocument3 pagesDjango Reinhardt - Selmer GuitarsvprochockyNo ratings yet

- A Guide To Noise Measurement TerminologyDocument24 pagesA Guide To Noise Measurement TerminologyvprochockyNo ratings yet

- Franklin Tester FT 510Document2 pagesFranklin Tester FT 510vprochockyNo ratings yet

- Partial Discharge TheoryDocument62 pagesPartial Discharge TheoryVijay Kumar100% (6)

- Why Use Copper Rather Than Aluminium in Power TransformersDocument2 pagesWhy Use Copper Rather Than Aluminium in Power TransformersvprochockyNo ratings yet

- MES AstraZenecaDocument51 pagesMES AstraZenecavprochockyNo ratings yet

- Low Resistance Measurement Guide PDFDocument34 pagesLow Resistance Measurement Guide PDFbill1022No ratings yet

- Wayne Kerr 3245 OperatingDocument90 pagesWayne Kerr 3245 OperatingvprochockyNo ratings yet

- Twain Running GovernorDocument5 pagesTwain Running GovernorvprochockyNo ratings yet

- d1.2 The Endless Runway Background v3Document161 pagesd1.2 The Endless Runway Background v3vprochockyNo ratings yet

- Electrical Steel Tester C 510Document2 pagesElectrical Steel Tester C 510vprochockyNo ratings yet

- Flamenco Rhythms by Oscar HerreroDocument12 pagesFlamenco Rhythms by Oscar HerreroGiovanni Miatto100% (1)

- Bulería Falseta - Flamenco Guitar TranscriptionsDocument2 pagesBulería Falseta - Flamenco Guitar Transcriptionsvprochocky0% (1)

- Takadimi Short GuideDocument4 pagesTakadimi Short Guidelu1think100% (20)

- Ten Brazilian Folk TunesDocument10 pagesTen Brazilian Folk TunesAthos Barbosa Lima100% (1)

- Fundamentals of PhotogrammetryDocument25 pagesFundamentals of PhotogrammetryvprochockyNo ratings yet

- ElectricDocument42 pagesElectricAbd ZouhierNo ratings yet

- Encoders and Resolvers How To Choose The Right Feedback OptionsDocument5 pagesEncoders and Resolvers How To Choose The Right Feedback OptionsvprochockyNo ratings yet

- The Calibration of Flow Meters PDFDocument35 pagesThe Calibration of Flow Meters PDFRené Mora-CasalNo ratings yet

- Takadimi Short GuideDocument4 pagesTakadimi Short Guidelu1think100% (20)

- Guitar Methods General InstructionDocument72 pagesGuitar Methods General Instructionvprochocky0% (2)

- Quality Tools - YanezDocument49 pagesQuality Tools - YanezvprochockyNo ratings yet

- Electric Circuits Ch13 05.19更新Document21 pagesElectric Circuits Ch13 05.19更新vprochockyNo ratings yet

- Latin Paleography PDFDocument82 pagesLatin Paleography PDFmedijumNo ratings yet

- Engineering Fundamentals ThreadFasteners RalphShoberg SR1Document39 pagesEngineering Fundamentals ThreadFasteners RalphShoberg SR1Juan RiveraNo ratings yet

- ESA Best Available Techniques Issue 1Document4 pagesESA Best Available Techniques Issue 1vprochockyNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Study of Advanced Structural Concepts For FuselageDocument200 pagesStudy of Advanced Structural Concepts For FuselageaerostressNo ratings yet

- 20MCC New Brochure Compressed-CompressedDocument22 pages20MCC New Brochure Compressed-Compressedfranchise.adajanNo ratings yet

- Covalent Bonding in ElementsDocument31 pagesCovalent Bonding in ElementsOsmany Madrigal100% (1)

- Manufacturing Engineer or CNC Programmer or CNC Set Up or CNC OpDocument2 pagesManufacturing Engineer or CNC Programmer or CNC Set Up or CNC Opapi-77548017No ratings yet

- The Rheology Degradation Processing and Characterization of ReDocument261 pagesThe Rheology Degradation Processing and Characterization of ReDeidra CadeNo ratings yet

- How Enzymes Dissolve EggsDocument3 pagesHow Enzymes Dissolve Eggsbhanuday100% (1)

- Palm Oil MSDSDocument5 pagesPalm Oil MSDSCaliche Omn100% (1)

- Technical & Service Manual: Sap-Krv93Eh + Sap-Crv93Eh SAP-KRV123EH + SAP-CRV123EHDocument77 pagesTechnical & Service Manual: Sap-Krv93Eh + Sap-Crv93Eh SAP-KRV123EH + SAP-CRV123EHpht12345No ratings yet

- RCC Water Tank Construction TenderDocument12 pagesRCC Water Tank Construction Tendersurya0588No ratings yet

- Simrit Cassette SealsDocument6 pagesSimrit Cassette SealsfahazumeeNo ratings yet

- Conversion of Lignocellulosic Biomass To Nanocellulose - Structure and Chemical ProcessDocument21 pagesConversion of Lignocellulosic Biomass To Nanocellulose - Structure and Chemical ProcessJaqueline SilvaNo ratings yet

- Raven 2350 Ultra Carbon Black Technical Data SheetDocument2 pagesRaven 2350 Ultra Carbon Black Technical Data SheetCoopertiva PlastcooperNo ratings yet

- Definition of Tunnel BoringDocument13 pagesDefinition of Tunnel BoringUji FauziahNo ratings yet

- NGK Spark Plug SchemeDocument1 pageNGK Spark Plug Schemeiskra vasileva100% (1)

- 3 PoleDocument3 pages3 PoleSejahtra AbadiNo ratings yet

- Loan Application FormDocument3 pagesLoan Application FormRijal Abd ShukorNo ratings yet

- DIY Knifemaker's Info Center - Heat Treatment Oven ProjectDocument34 pagesDIY Knifemaker's Info Center - Heat Treatment Oven ProjectRicardo VelozNo ratings yet

- Chapter 2 (Lecture 3)Document25 pagesChapter 2 (Lecture 3)SchaieraNo ratings yet

- A Review On Rubber Compound Mixing in Banbury Mixer at Tire Industries-864 PDFDocument4 pagesA Review On Rubber Compound Mixing in Banbury Mixer at Tire Industries-864 PDFJin HernNo ratings yet

- 5E Series Tractors from John Deere: 55-75hp Reliable Performance for Small Farms and Specialty TasksDocument4 pages5E Series Tractors from John Deere: 55-75hp Reliable Performance for Small Farms and Specialty Tasksbrujula24100% (1)

- Civil Engineering Materials UOL Lahore: ConcreteDocument119 pagesCivil Engineering Materials UOL Lahore: ConcreteNawab Zada ManekaNo ratings yet

- Ingersoll Rand Dryer O&M Manual 80442833-EnDocument48 pagesIngersoll Rand Dryer O&M Manual 80442833-EnBill BrighamNo ratings yet

- Flow Diagram SymbolsDocument5 pagesFlow Diagram SymbolshussainNo ratings yet

- PEB Specification and Standards With DetailsDocument15 pagesPEB Specification and Standards With DetailsMujjo SahbNo ratings yet

- Kajian Penerapan Soil NailingDocument5 pagesKajian Penerapan Soil Nailinghandry solimudinNo ratings yet

- ATA24 Bombardier q400 Electrical PowerDocument85 pagesATA24 Bombardier q400 Electrical PowerAbiyot AderieNo ratings yet

- Test Report: H.D.G. Bolts, Nuts & Plain WasherDocument1 pageTest Report: H.D.G. Bolts, Nuts & Plain WasherSumanta AdhikariNo ratings yet

- Adokapı Technical PresentationDocument32 pagesAdokapı Technical PresentationHussain BagasrawalaNo ratings yet

- Almex Light Weight BrochureDocument16 pagesAlmex Light Weight BrochureGijoNo ratings yet

- Rapport Stoppons Le Torrent de Plastique WWF-minDocument46 pagesRapport Stoppons Le Torrent de Plastique WWF-minshamimshawonNo ratings yet