Professional Documents

Culture Documents

Axle Shafts

Uploaded by

ankitsarvaiya0 ratings0% found this document useful (0 votes)

63 views13 pages1) Rear axles can be either dead axles which only support weight, or live axles which also transmit driving torque to the wheels. 2) Axle shafts (half shafts) transmit drive from the differential to the wheel hub and must resist various stresses. 3) Axle shafts are classified as semi-floating, three-quarter floating, or fully floating depending on how stresses are distributed between the shaft and axle casing.

Original Description:

fgasgtsdg

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1) Rear axles can be either dead axles which only support weight, or live axles which also transmit driving torque to the wheels. 2) Axle shafts (half shafts) transmit drive from the differential to the wheel hub and must resist various stresses. 3) Axle shafts are classified as semi-floating, three-quarter floating, or fully floating depending on how stresses are distributed between the shaft and axle casing.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

63 views13 pagesAxle Shafts

Uploaded by

ankitsarvaiya1) Rear axles can be either dead axles which only support weight, or live axles which also transmit driving torque to the wheels. 2) Axle shafts (half shafts) transmit drive from the differential to the wheel hub and must resist various stresses. 3) Axle shafts are classified as semi-floating, three-quarter floating, or fully floating depending on how stresses are distributed between the shaft and axle casing.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 13

Axle Shafts Design

Rear axle construction

In cases where the rear suspension is non-independent, the type of axle used is either a

dead axle or a live axle. The former only has to support the weight of the vehicle, where

the latter has to fulfill this task and, in addition, contain a gear and shaft mechanism to

drive the road wheels.

Axle shafts

The axle shaft (half shaft) transmits the drive from the differential sun wheel to the rear

hub. The arrangement of a simple rear axle can be seen in the figure, the road wheel

attached to the end of the half shaft, which in turn is supported by bearing located in the

axle casing. The diagram illustrates the forces acting on the rear axle assembly under a

under different operating conditions.

Operating conditions

The total weight of the rear of the vehicle may exert a bending action on the half shaft.

Furthermore, there is a tendency for the overhanging section of the shaft to be subject to a

shearing force.

During cornering a side force acts upon the road wheel which imposes a bending load and

Axle shafts http://www.thecartech.com/subjects/design/axle_shafts_design.htm

1 of 13 3/8/2014 9:55 AM

an end thrust becomes a pull. A side force also tends to bend the overhanging section of

the half shaft. Finally, under driving conditions the half shaft has to transmit the driving

torque which subjects the shaft to torsional stress.

Stresses

The various types may be compared by considering the stresses the shaft has to resist Fig.

1a shows a line sketch of a simple haft which is subjected to:

1- torsional stress due to driving and braking torque.

2- Shear stress due to the weight of the vehicle (Fig. 1b).

3- Bending stress due to the weight of the vehicle (Fig. 1c).

4- Tensile and compressive stress due to cornering forces.

Types of axles

Axle shafts are divided into three main groups

depending on the stresses to which the shaft is

subjected:

Semi-floating

Three-quarter floating

Fully floating.

Semi-floating

Fig. 2a shows a typical mounting of an axle shaft suitable for light cars. A single bearing

at the hub end is fitted between the shaft and the casing, so the shaft will have to resist all

the stresses previously mentioned. To reduce the risk of fracture at the hub end (this

would allow the wheel to fall off), the shaft diameter is increased. Any increase must be

gradual, since a sudden change in cross-sectional area would produce a stress-raiser and

increase the risk of failure due to fatigue. (Fatigue may be defined as breakage due to

continual alteration of the stress in the material).

Although the final-drive oil level is considerably lower than the axle shaft, the large

Axle shafts http://www.thecartech.com/subjects/design/axle_shafts_design.htm

2 of 13 3/8/2014 9:55 AM

amount of splash would cause the lubricant to work along the shaft and enter the brake

drum. Sealing arrangements normally consists of an oil retainer fitted at the hub end (the

lip of the seal is positioned towards the final drive). The half shaft in this assembly

required to be able to withstand the torsion load involved in driving the road wheel, and

bending loads in both the horizontal and vertical planes plus the percentage of car

weight on the wheel.

Three-quarter floating

Having defined the semi-and the fully floating shaft, any alternative between the two may

be regarded as a three-quarter floating shaft. Fig. 2b shows a construction which has a

single bearing mounted between the hub and the casing. The main shear stress on the

shaft is relieved but all other stresses still have to be resisted. The half shaft must

withstand bending loads due to side thrust when cornering and, of course, at the same

time transmit driving torque.

Fully floating

This is generally fitted on commercial vehicles where torque and axle loads are greater.

The construction shown in Fig. 2c consists of and independently mounted hub which

rotates on two bearings widely spaced on the axle casing. This arrangement relieves the

shaft of all stresses except torsional, so the construction is very strong. Studs connecting

the shaft to the hub transmit the drive and when the nuts on theses studs are removed, the

Axle shafts http://www.thecartech.com/subjects/design/axle_shafts_design.htm

3 of 13 3/8/2014 9:55 AM

shaft may be withdrawn without jacking up the vehicle. The shaft is to transmit only the

driving torque to the rear wheel.

Axel shaft material

A tough, hard material must be used to withstand the various stresses, resist spline wear

and provide good resistance to fatigue. A medium carbon alloy steel containing such

elements as nickel, chromium and molybdenum is the usual choice.

Axle shafts http://www.thecartech.com/subjects/design/axle_shafts_design.htm

4 of 13 3/8/2014 9:55 AM

Calculation of axle shafts

The following forces act on a moving wheel:

The torque due to the traction or braking force (T

w

and T

b

)

The traction or braking force (F

w

and F

b

)

The lateral force F

y

when the vehicle makes a turn or skid

The normal reaction R

w

Simultaneous appearance of maximum longitudinal and transverse forces at the wheel

road contact is not possible, for joint action is restricted by the adhesion force

The loading conditions of axle shafts and beams reduce to the following three cases:

Axle shafts http://www.thecartech.com/subjects/design/axle_shafts_design.htm

5 of 13 3/8/2014 9:55 AM

1- Rectilinear motion

The longitudinal force (F

w

or F

b

) attain its maximum value equal to R

w

, Maximum

torque is

where:

T

w

= wheel torque

T

e max

= maximum engine torque

i

g

= gearbox ratio (1

st

gear)

i

f

= final drive ratio

k

d

= dynamic factor

k

l

= the coefficient of differential locking

m

a

= automobile mass accounted for the driving axle

g = 9.81 m/s

2

wt = transferred weight

where

= coefficient of adhesion (0.8)

* In this case, F

y

= 0

2- Skidding of automobile

In this case a lateral force and normal reaction are acting on the wheel. Assume that the

longitudinal force F

w

= 0. The largest lateral force- centrifugal force- whose value is

limited by the wheel-road grip equals

The vertical reactions and lateral forces of the inner and outer wheels are

where

v = vehicle speed (km/h)

R = radius of turn of the road

t = wheel track width

= coefficient of road adhesion during sidewise skidding =1.0

Axle shafts http://www.thecartech.com/subjects/design/axle_shafts_design.htm

6 of 13 3/8/2014 9:55 AM

+ = plus sign is used for the axle shaft of the wheel which is inner relative to the

skidding direction, and the negative sign, the outer wheel.

3-Driving wheels overcome irregularities

Here, only the vertical force is accounted for

where

k

dr

= is the dynamic factor of road;

for cars, k

dr

= 1.75; for trucks, k

dr

= 2.50

-The axle shaft dimensions are determined for the most dangerous case of loading. For s

semi-floating axle the dangerous cress section lies in the bearing installation zone. For

the first condition, the equivalent stress due to bending and torsion is

where

d = the axle shaft diameter

b = the overhanging length

During skidding the following bending moments and stresses act on the axle shaft

M

i

= R

w i

b F

y i

r

w

;

M

o

= R

w

o

b + F

y o

r

w

where

r

w

= wheel radius

(the upper sings are used for the inner axle shaft, and the lower sign, for the outer axle

shaft relative to the skidding direction).

-When the driving wheels overcome an irregularity, the bending stress is

- The floating axle is calculated only for torsion at the maximum traction force

The axle shaft is calculated also for the maximum twist angle

where

L = the length of the axle shaft

Axle shafts http://www.thecartech.com/subjects/design/axle_shafts_design.htm

7 of 13 3/8/2014 9:55 AM

G = the shear modulus

J = the moment of inertia of the cross section of axle shaft

s

b

= 55 MPa for shafts without keyway

40 MPa for shafts with keyway

* The permissible twist angle is ! = 8

o

for 1 m length of the shaft.

# Number of splines of the axle shaft is form 10 (for cars) to 18 (for trucks)

# the shaft factor of safety = 2.0- 2.5

Critical Speeds of Shaft

All rotating shafts, even in the absence of external load, deflect during rotation; the

magnitude of the deflection depends upon the stiffness of the shaft and its supports, the

total mass of the shaft and attachment parts, the imbalance mass with respect to the axis

of rotation, and the amount of damping in the system.

Shafts of constant cross section:

Example:

Axle shafts http://www.thecartech.com/subjects/design/axle_shafts_design.htm

8 of 13 3/8/2014 9:55 AM

Find the half axle critical speed, the half axle has the following dimensions the length

between bearings is 0.6 m and its diameter is 25 mm. The unit weight of shaft materials is

76.0 kN/m

3

, E = 200 GPa.

Calculation of wheel-hub bearings

For the bearings of the driving axle with semi-floating axle shafts (as seen in the figure),

the loads on wheel bearing are calculated using the following formulas:

Straight-line motion

F

r

= R

z

l / a; F

a

= 0

Curvilinear motion

F

r o

= R

z o

l / a + R

y o

r

w

/ a; F

a o

= R

y

o

F

r i

= R

z o

l / a R

y i

r

w

/ a; F

a

i

= R

y i

Necessary service life of bearings (in millions of revolutions) is ascertained based on the

specified life of the automobile with due consideration of overhaul periods.

Axle shafts http://www.thecartech.com/subjects/design/axle_shafts_design.htm

9 of 13 3/8/2014 9:55 AM

Bearing Classifications

Rolling Bearings versus Journal Bearings:

Features Ball Bearings Journal Bearings

Starting torque High (advantage) Low

Quit operation Noisy at high speed Quit operation

Space Limitation Preferable when the axial

dimension are limited

Preferable when the radial

dimension are limited

Electrical insulation - Oil film provides insulation

Failure warning Becoming noisy when failure is

imminent

Failure is sudden

Thrust load Can carry combination of radial

and thrust loads

-

Clearance Much less the journal bearing,

more accurate position (gears)

-

Axle shafts http://www.thecartech.com/subjects/design/axle_shafts_design.htm

10 of 13 3/8/2014 9:55 AM

Lubrication problem Not sensitive Very sensitive

Overload Can take high overloads for

short time

-

Bearing Selection:

The selection of an appropriate bearing for a

given task, whoever, in an involved activity,

which needs to take into account, amongst

other factors:

- load

- speed

- location

- size

- cost

- starting torque

- noise

- lubrication supply

Definitions:

The basic static load rating, C

o

,

is the load the bearing can withstand without any permanent deformation of any

component.

The basic dynamic load rating, C,

is the constant radial load which a bearing can endure for 1x10

6

revolutions without

evidence of the development of fatigue in any of the bearing components.

The life of a ball bearing, L,

is the number of revolutions (or hours at some constant speed), which the bearing runs

before the development of fatigue in any of the bearing components.

The equivalent load, P,

is defined as the constant radial load which if applied to a bearing would give the same

life as that which the bearing would attain under the actual conditions of load and

rotation.

P = VXR + YT

Where:

P = equivalent load (N);

V = 1.2 if mounting rotates is recommended

= 1.0 if shaft rotates;

X = radial factor (given in bearing catalogues), see table 2 for example data;

Y = thrust factor (given in bearing catalogues), see table 2 for example data;

T = applied thrust load (N)

Axle shafts http://www.thecartech.com/subjects/design/axle_shafts_design.htm

11 of 13 3/8/2014 9:55 AM

Axle shafts http://www.thecartech.com/subjects/design/axle_shafts_design.htm

12 of 13 3/8/2014 9:55 AM

Axle shafts http://www.thecartech.com/subjects/design/axle_shafts_design.htm

13 of 13 3/8/2014 9:55 AM

You might also like

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- Axle ShaftsDocument14 pagesAxle ShaftsAnonymous QiMB2lBCJLNo ratings yet

- Rear Axle ConstructionDocument19 pagesRear Axle ConstructionMohseen KarcheNo ratings yet

- Digital Assignment - 1: Name: Shaik Naveed REG NO:20BMA0032 Subject: Automotive ChassisDocument8 pagesDigital Assignment - 1: Name: Shaik Naveed REG NO:20BMA0032 Subject: Automotive ChassisNaveed kingNo ratings yet

- Theory Da1Document13 pagesTheory Da1sanchit sawantNo ratings yet

- Rear Axle Shaft DesignDocument11 pagesRear Axle Shaft DesignSandeep Chauhan100% (3)

- Handling CharacteristicsDocument15 pagesHandling CharacteristicsSaket NihalNo ratings yet

- Automotive Laboratory Manual: MAK 411E Experimental Methods in Mechanical EngineeringDocument22 pagesAutomotive Laboratory Manual: MAK 411E Experimental Methods in Mechanical EngineeringSenthil Muthu Kumar TNo ratings yet

- Nikhil PawarDocument16 pagesNikhil PawarNikhil PawarNo ratings yet

- Nav 009Document10 pagesNav 009Vishnu Vardhan Reddy YerasiNo ratings yet

- 00-Temari 01 - 18 PDFDocument232 pages00-Temari 01 - 18 PDFJordi_fgNo ratings yet

- Sr. No Topic Page Number: MAE 577 CAD Applications Adwait Joshi (2954-1696)Document38 pagesSr. No Topic Page Number: MAE 577 CAD Applications Adwait Joshi (2954-1696)Narendra Kumar DhayalNo ratings yet

- Unit 2-At6402 Automotive ChassisDocument20 pagesUnit 2-At6402 Automotive ChassisSathis KumarNo ratings yet

- Final Suspension DesignDocument60 pagesFinal Suspension DesignSNEHASIS MOHANTY100% (1)

- 08 Chapter 3Document23 pages08 Chapter 3Sahaya GrinspanNo ratings yet

- Understanding The Influence of Pressure and Radial Loads On Stress and Displacement Response of A Rotating Body: The Automobile WheelDocument9 pagesUnderstanding The Influence of Pressure and Radial Loads On Stress and Displacement Response of A Rotating Body: The Automobile WheelxxxtoyaxxxNo ratings yet

- 10 Mechanical Design HL ExtensionDocument38 pages10 Mechanical Design HL ExtensionSyeda Fariya Nisar AliNo ratings yet

- The Gearbox (Transmission) : B A A B A B B A A BDocument12 pagesThe Gearbox (Transmission) : B A A B A B B A A BVijay PanchalNo ratings yet

- Semi Float Vs Full FloatDocument16 pagesSemi Float Vs Full FloatadamtuongNo ratings yet

- PRESENTION 2 MPPDocument28 pagesPRESENTION 2 MPPKhairul SyahreelNo ratings yet

- Road Performance Curves: Acceleration, Gradability and Drawbar PullDocument83 pagesRoad Performance Curves: Acceleration, Gradability and Drawbar Pullpbd123autoNo ratings yet

- Vehicle Dynamics For Racing GamesDocument18 pagesVehicle Dynamics For Racing GamescsorionutNo ratings yet

- Vehicle Dynamics For Racing GamesDocument18 pagesVehicle Dynamics For Racing GameskrishnasrikanthNo ratings yet

- Brake and DynamometerDocument51 pagesBrake and DynamometerArvin Arvini100% (1)

- Chapter 5 - Friction Devices - Theory of Machines - Part 1Document17 pagesChapter 5 - Friction Devices - Theory of Machines - Part 1Sandip GhoshNo ratings yet

- Truck Chassis - MethodologyDocument8 pagesTruck Chassis - MethodologyJawahar Raj100% (1)

- METU ME 465 (Automotive) - ch5Document73 pagesMETU ME 465 (Automotive) - ch5Tt OwnsqqNo ratings yet

- Design Consideration of Ladder Chassis Frame For Hyundai TruckDocument12 pagesDesign Consideration of Ladder Chassis Frame For Hyundai TruckWatt Pauk LayNo ratings yet

- Automobile Transmission SystemDocument26 pagesAutomobile Transmission SystemSupravat KarmakarNo ratings yet

- Chassis Da2Document13 pagesChassis Da2sanchit sawantNo ratings yet

- ATV Roll CageDocument23 pagesATV Roll CageAkrit Kumar ChaturvediNo ratings yet

- Bicycle Wheel Spoke Lacing PDFDocument10 pagesBicycle Wheel Spoke Lacing PDFherrnikolicNo ratings yet

- AT6602 - Chassis Component DesignDocument14 pagesAT6602 - Chassis Component Designpavanrane100% (3)

- Gear Box ReportDocument39 pagesGear Box ReportNisar HussainNo ratings yet

- ACS Notes 1Document63 pagesACS Notes 1roy rockNo ratings yet

- CE-461 Coning of Wheels Train Resistances Hauling CapacityDocument43 pagesCE-461 Coning of Wheels Train Resistances Hauling CapacityManjul PratapNo ratings yet

- Design and Assembly AnalysisDocument96 pagesDesign and Assembly AnalysisVinayak RaoNo ratings yet

- Trends Regarding Needle Roller Bearings For Automatic Transmission Planetary GearsDocument0 pagesTrends Regarding Needle Roller Bearings For Automatic Transmission Planetary GearsankitsarvaiyaNo ratings yet

- Vehicle DynamicsDocument7 pagesVehicle DynamicsDeepakNo ratings yet

- Assignment 3 AutomobileDocument11 pagesAssignment 3 Automobilepawan sharmaNo ratings yet

- A Skid Steering Model With Track Pad Flexibility 2007 Journal of TerramechanicsDocument16 pagesA Skid Steering Model With Track Pad Flexibility 2007 Journal of TerramechanicsSetiyawan TrioNo ratings yet

- TUe 4AUB20 Exercise3Document4 pagesTUe 4AUB20 Exercise3Saad ullah ZiaNo ratings yet

- Automobile Suspension Detailed Analysis PDFDocument19 pagesAutomobile Suspension Detailed Analysis PDFalpNo ratings yet

- Crane GirderDocument45 pagesCrane GirderbolarinwadeNo ratings yet

- Flywheel Types and DesignDocument23 pagesFlywheel Types and DesignALL IN ONE0% (1)

- Mass College ProjectDocument68 pagesMass College ProjectGLOBAL INFO-TECH KUMBAKONAMNo ratings yet

- Wheel and AxleDocument6 pagesWheel and AxleJon PotterNo ratings yet

- Vehicle Dynamics NotesDocument116 pagesVehicle Dynamics NotesJagadesh AbbuNo ratings yet

- Spring Rates Roll Centers and HandlingDocument9 pagesSpring Rates Roll Centers and HandlingfizznitNo ratings yet

- 2008-36-0219 - Balancer Shaft Development For A In-Line 4 Cylinder High Speed Diesel EngineDocument8 pages2008-36-0219 - Balancer Shaft Development For A In-Line 4 Cylinder High Speed Diesel Engineangelus256No ratings yet

- Man GN PDF 6Document36 pagesMan GN PDF 6Adrian A UPD78% (9)

- Lec 9Document7 pagesLec 9poulomi gangulyNo ratings yet

- 7 - Motion in A Circle-1Document9 pages7 - Motion in A Circle-1Beavon MorigoriNo ratings yet

- List of Material For SpringDocument8 pagesList of Material For SpringPatranNo ratings yet

- Transportation Engineering-II (254412) : 1) A) Functions of SleepersDocument10 pagesTransportation Engineering-II (254412) : 1) A) Functions of SleepersCivil EngineeringNo ratings yet

- Mathcad - GeneralDocument17 pagesMathcad - Generalapi-232034744No ratings yet

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsFrom EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsNo ratings yet

- Gmail - Booking Confirmation On IRCTC, Train - 12932, 09-Mar-2024, CC, ADI - VAPIDocument1 pageGmail - Booking Confirmation On IRCTC, Train - 12932, 09-Mar-2024, CC, ADI - VAPIankitsarvaiyaNo ratings yet

- NABH Accredited HospitalsDocument12 pagesNABH Accredited HospitalsJai GoyalNo ratings yet

- NABH Accredited HospitalsDocument12 pagesNABH Accredited HospitalsJai GoyalNo ratings yet

- Ahmedabad PPN List of HospitalsDocument14 pagesAhmedabad PPN List of HospitalsankitsarvaiyaNo ratings yet

- A Textbook of Engineering Mechanics by R.K. BansalDocument130 pagesA Textbook of Engineering Mechanics by R.K. BansalClydelle Rondaris77% (94)

- Project Team Member Team Id: 130007633: Enrollment Number Student Name College Name Branch NameDocument1 pageProject Team Member Team Id: 130007633: Enrollment Number Student Name College Name Branch NameankitsarvaiyaNo ratings yet

- April 2012 Gal DoytsherDocument18 pagesApril 2012 Gal DoytsherankitsarvaiyaNo ratings yet

- High-Speed Operation: Ball and Roller Dynamic Loads and Bearing Internal Load DistributionDocument32 pagesHigh-Speed Operation: Ball and Roller Dynamic Loads and Bearing Internal Load DistributionankitsarvaiyaNo ratings yet

- 7182 C007 PDFDocument18 pages7182 C007 PDFankitsarvaiyaNo ratings yet

- Cut of Marks EngineeringDocument11 pagesCut of Marks EngineeringHarikrishna ShenoyNo ratings yet

- JB Cable Schedule: Multicore Cable No.: XXX: 3 X 32P 0.5 mm2 Shielded CableDocument17 pagesJB Cable Schedule: Multicore Cable No.: XXX: 3 X 32P 0.5 mm2 Shielded CableankitsarvaiyaNo ratings yet

- A1 PDFDocument12 pagesA1 PDFankitsarvaiyaNo ratings yet

- 1480249339054vbdmBIyYoXzlbjT4 PDFDocument1 page1480249339054vbdmBIyYoXzlbjT4 PDFankitsarvaiyaNo ratings yet

- Vibration Analysis of Lubricated Angular Contact Ball Bearing of Rigid Rotor Considering Waviness of Ball and RacesDocument6 pagesVibration Analysis of Lubricated Angular Contact Ball Bearing of Rigid Rotor Considering Waviness of Ball and RacesankitsarvaiyaNo ratings yet

- "Joining Time": A. Cases in Which Joining Time Is AdmissibleDocument24 pages"Joining Time": A. Cases in Which Joining Time Is Admissiblevijaygarge59100% (1)

- Infosheet MXPLC - TERRAVISIONDocument1 pageInfosheet MXPLC - TERRAVISIONAntonia AdsuarNo ratings yet

- SUMUDocument12 pagesSUMUJean Anderson WilliamsNo ratings yet

- Questions 1 - 4: The Physics of Traffic BehaviorDocument3 pagesQuestions 1 - 4: The Physics of Traffic BehaviorSonika VermaNo ratings yet

- Nissan PATROL 2023 - Price List QatarDocument8 pagesNissan PATROL 2023 - Price List QatarghNo ratings yet

- AED Design Requirements:: Sanitary Sewer & Septic SystemDocument16 pagesAED Design Requirements:: Sanitary Sewer & Septic SystemIsuruSameeraNo ratings yet

- TFL Bus SafetyDocument1,737 pagesTFL Bus SafetyLiran GordonNo ratings yet

- GRT880 Om CTRL643-01Document202 pagesGRT880 Om CTRL643-01Le DuNo ratings yet

- Benjamin C. Santos & Ofelia Calcetas-Santos Law OfficesDocument8 pagesBenjamin C. Santos & Ofelia Calcetas-Santos Law OfficesAnonymousNo ratings yet

- Case Study of MS Sea PrincessDocument3 pagesCase Study of MS Sea PrincessAndrewChi100% (1)

- Assessing The 'Poverty of Cruise Theory' HypothesisDocument22 pagesAssessing The 'Poverty of Cruise Theory' Hypothesisnaeemp25No ratings yet

- Redbus JavedDocument14 pagesRedbus Javedakhtarjaved12No ratings yet

- Body Control Module X1Document3 pagesBody Control Module X1Men PanhaNo ratings yet

- Zlj5480jqzv3 Spare Parts CatalogDocument244 pagesZlj5480jqzv3 Spare Parts Catalogmliugong100% (1)

- Air Compressors Export 750 1050cfm T2T1Document2 pagesAir Compressors Export 750 1050cfm T2T1curlyjockey100% (1)

- Fish Farming Technology Supplement 1404Document14 pagesFish Farming Technology Supplement 1404International Aquafeed magazine100% (1)

- Besing, Jessa Mae - ESSAYDocument5 pagesBesing, Jessa Mae - ESSAYJessa Mae Saguran BesingNo ratings yet

- Installing An Outboard To The Boat TransomDocument13 pagesInstalling An Outboard To The Boat TransomДмитрий КирзуновNo ratings yet

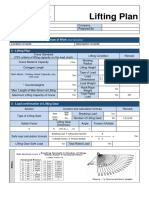

- Lifting PlanDocument2 pagesLifting PlanDoo PLTGU86% (37)

- Supply Chain Management Practices in Printing Industry: University of Hyderabad, Hyderabad 500046, IndiaDocument7 pagesSupply Chain Management Practices in Printing Industry: University of Hyderabad, Hyderabad 500046, IndiasaifrahmanNo ratings yet

- Gahp Standard Malaysia Final DraftedDocument25 pagesGahp Standard Malaysia Final DraftedFcpo Bursa Malaysia100% (1)

- Human Settlement and Planning 1 To 5 Units With Question PaperDocument137 pagesHuman Settlement and Planning 1 To 5 Units With Question PaperAnas Mohamed100% (2)

- Final Draft of The Elder Care BusinessDocument15 pagesFinal Draft of The Elder Care Businesslakmal_795738846No ratings yet

- Hausted Horizon Stretcher - Models 462 Series M2102EN 0411Document4 pagesHausted Horizon Stretcher - Models 462 Series M2102EN 0411Belal AhmedNo ratings yet

- Schematic For LED Driver IC BP2851Document1 pageSchematic For LED Driver IC BP2851ztxNo ratings yet

- 4th Smart Cities India 2018 Expo Post Show Report PDFDocument28 pages4th Smart Cities India 2018 Expo Post Show Report PDFbalajicaptainNo ratings yet

- Concrete Polishing & Laser Screed FlooringDocument7 pagesConcrete Polishing & Laser Screed FlooringLamba Techno Flooring SolutionsNo ratings yet

- Air ConditionerDocument12 pagesAir Conditionerchris5gNo ratings yet

- Bridgestone-Manual 2018 PDFDocument119 pagesBridgestone-Manual 2018 PDFEmily Simpson100% (1)

- 35 Dunwich DynamoDocument4 pages35 Dunwich DynamoAaron AppletonNo ratings yet