Professional Documents

Culture Documents

Viscosity - Ratio of Slurries

Uploaded by

nazmul hasanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Viscosity - Ratio of Slurries

Uploaded by

nazmul hasanCopyright:

Available Formats

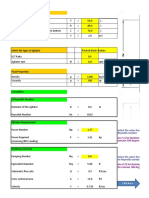

Viscosity of slurries [1] Thomas (1965) formula

Data Ratio of viscosities

t = 32 C

p

/

f

= (1+2.5*Cv + 10.05*Cv^2+0.00273*Exp(16.6*Cv) )

C

w

= 35.0 % C

v

= 0.17 /1

S

= 2.7

T/m

3

p

/

f

= 1.73

L

= 1.0

T/m

3

Pulp dynamic viscosity

Volume concentration

p

= (

p

/

w

) * w

C

v

= 1/ (1 +((100-C

w

)/C

w

)*

s

/

L

)

p

/

f

= 1.73

C

w

= 35.0 %

w

= 0.0008 Pa s

s

= 2.7

t/m

3

p

= 0.0013 Pa s

L

= 1.0

t/m

3

C

v

= 0.17 /1 Pulp density

P

=

L

*S

S

/ ( C

w

+ (1-Cw) * S

S

)

L

= 1.0

t/m

3

Water dynamic viscosity C

w

= 0.35 -

t = 32 C S

s

= 2.71 -

w

=SaturatedWaterAbsoluteViscosity_t

P

= 1.283 t/m

w

= 0.00077 Pa s

Rev. cjc 29.04.2013

Pulp kinematic viscosity

(1+2.5*Cv + 10.05*Cv^2+0.00273*Exp(16.6*Cv) ) v

p

=

p

/

P

p

= 0.0013 Pa s

P

= 1283 kg/m

v

p

= 1.036E-06 m/s

L

*S

S

/ ( C

w

+ (1-Cw) * S

S

)

Viscosity [2] Rev. cjc 29.04.2013

1-5 DYNAMIC VISCOSITY OF A NEWTONIAN SLURRY MIXTURE

Although density is essentially a static property, absolute (or dynamic) viscosity

is a dynamic property and tends to reduce in magnitude as the shear rate in a

pipeline increases. Thus, engineers have had to define different forms of viscosity

over the years, everything from dynamic viscosity, to kinematic viscosity, to

effective pipeline viscosity.

The effective pipeline viscosity will be discussed in detail in Chapters 3, 4,

and 5. In this chapter, the reader is introduced to basic concepts of the mixture of

slurry in a stationary state. This is effectively what the pump, or a mixer, might

see at the start-up of a plant. As is often the case, when the driver cannot deliver

enough torque to overcome the absolute (or dynamic) viscosity, the operator is

forced to dilute the slurry mixture.

Plasticity as defined in Section 1-1-4 is an important parameter in determining

overall absolute (or dynamic) viscosity of a mixture of clay and water. There are,

however, numerous soils in nature, such as sand and water or gravel and water, in

which the solids contribute little to the overall absolute (or dynamic) viscosity,

except in terms of their concentration by volume.

1-5-1 Absolute (or Dynamic) Viscosity of Mixtures with Volume

Concentration Smaller Than 1%

For such solidliquid mixtures in diluted form, Einstein developed the following

formula for a linear relationship between absolute (or dynamic) viscosity and

volume concentration:

where

m

= absolute (or dynamic) viscosity of the slurry mixture

L

= absolute (or dynamic) viscosity of the carrying liquid

This is a very simple equation that is based on the following assumptions:

- Particles are fairly rigid

- The mixture is fairly dilute and there is no interaction between the particles

Such a flow is not encountered, except in laminar regimes of very dilute

concentrations (below a volume concentration of 1%).

1-5-2 Absolute (or Dynamic) Viscosity of Mixtures with Solids

with Volume Concentration Smaller than 20%

Thomas (1965) took the equation of Einstein further by calculating for higher

volumetric concentrations of Newtonian mixtures:

where K1, K2, K3, and K4 are constants

K1 is the Einstein constant of 2.5 (from Equation 1-7), and K2 has been found to

be in the range of 10.0514.1 according to Guth and Simha (1936). It is difficult to Frmula de Thomas

extrapolate the higher terms K3 and K4 in Equation 1-8. They are ignored with

volumetric concentrations smaller than 20%.

p

=

p

:

1-5-3 Absolute (or Dynamic) Viscosity of Mixtures with High

f

:

C

v

:

Volume Concentration of Solids

For higher concentrations, Thomas (1965) proposed the following equation with an Water properties (fluid f)

exponential function: t =

f

=

Volumetric concentration

C

v

=

Ratio of viscosities

p

/

f

=

C

v

=

p

/

f

=

where

K2 = 10.05 Absolute viscosity of pulp

A = 0.00273

p

=

B = 16.6

f

=

Figure 1-9 is based on Equation 1-9 and is widely accepted in the slurry industry C

v

=

for heterogeneous mixtures of a Newtonian rheology.

p

=

1-1-4 Plasticity of Soils

For clays and silts, an additional test for the liquid limit (LL) and the plastic limit

(PL) are recommended.

The liquid limit is defined as the moisture content in soil above which it starts to

act as a liquid and below which it acts as a plastic. To conduct a test, a sample of

clay is thoroughly mixed with water in a brass cup. The number of bumps required

| | ) 6 . 16 ( 00273 . 0 05 . 10 5 . 2 1

2

v v v f p

C Exp C C + + + =

to close a groove cut in the pot of clay in the cup is then measured. This test is

called the Atterberg test.

The plastic limit is defined as the limit below which the clay will stop behaving as

a plastic and will start to crumble. To measure such a limit, a sample of the soil is

formed into a tubular shape with a diameter of 3.2 mm (0.125 in) and the water

content is measured when the cylinder ceases to roll and becomes friable.

m

/

L

= 1 + 2.5 * (C

v

/100) SSHB (1-7) Einstein formula

C

v

= 1 %

m

/

L

= 1.025 Valid for C

v

< 1 %

This is a very simple equation that is based on the following assumptions:

- Particles are fairly rigid

- The mixture is fairly dilute and there is no interaction between the particles

Such a flow is not encountered, except in laminar regimes of very dilute concentrations

(below a volume concentration of 1%).

m

/

L

= 1 + 2.5 * (C

v

/100) + K

2

* (C

v

/100)^2 SSHB (1-8) Thomas (1965) formula

C

v

= 16.58 %

K

2

= 10.5 Valid for C

v

< 20 %

m

/

L

= 1.70 K

3

and K

4

are zero for Cv < 20 %

K

2

is in the range 10.05 to 14.1

m

/

L

= 1 + 2.5 * (C

v

/100) + K

2

* (C

v

/100)^2

C

v

= 19 %

K

2

= 14.1

m

/

L

=

1.98

m

/

L

= 1 + K

1

* (C

v

/100) + K

2

* (C

v

/100)^2 +A * Exp(B*(C

v

/100) )

C

v

= 19 % SSHB (1-9) Thomas (1965) formula

K

1

= 2.5

K

2

= 10.5 Equation 1-9 is widely accepted in

A = 0.00273 the slurry industry for heterogeneous

B = 16.6 mixtures of a Newtonian rheology.

m

/

L

=

1.92

C

v

= 19 %

SVR = SlurryAbsViscosityRatio_SVR_Cv(I48)

SVR = 1.92

This equation is widely accepted in the slurry industry for heterogeneous mixtures of a Newtonian rheology.

Cv SVR

5 1.16

10 1.37

15 1.64

20 2.00

25 2.45

30 3.09

35 4.07

40 5.77

45 9.04

50 15.86

55 30.74

30.00

40.00

50.00

60.00

70.00

S

V

R

[

-

]

.

Slurry abs. viscosity ratio

60 64.05

Frmula de Thomas Frmula de Wellman

f

* (1+2.5*Cv + 10.05*Cv^2+0.00273*Exp(16.6*Cv) )

Absolute viscosity of fluid (water)

Concentration by volume /1

p

=

Water properties (fluid f) Water properties (fluid f)

32 C t =

0.00077 Pa s

f

=

Volumetric concentration Volumetric concentration

0.0017 /1 C

v

=

Ratio of viscosities Ratio of viscosities

(1+2.5*Cv + 10.05*Cv^2+0.00273*Exp(16.6*Cv) )

p

/

f

=

0.0017 /1 C

v

=

1.01

p

/

f

=

Absolute viscosity of pulp Absolute viscosity of pulp

f

* (1+2.5*Cv + 10.05*Cv^2+0.00273*Exp(16.6*Cv) )

p

=

0.00077 Pa s

f

=

0.0017 /1 C

v

=

7.72E-04 Pa s

p

=

0.00

10.00

20.00

0 10 20 30 40 50

S

V

R

[

Volume concentration Cv [%]

| | ) 6 . 16 ( 00273 . 0 05 . 10 5 . 2 1

2

v v v f p

C Exp C C + + + =

8

62 . 0

1

) 4 . 10 (

|

.

|

\

|

=

v

v

f p

C

C Exp

This equation is widely accepted in the slurry industry for heterogeneous mixtures of a Newtonian rheology.

Series1

Frmula de Wellman

m

/

L

= 1 + 2.5 * (C

v

/100)

JRI (2.2.3.a) C

v

= 1

Wellman(1977) formula

m

/

L

= 1.025

This is a very simple equation that is based on the following assumptions:

- Particles are fairly rigid

f

* Exp(-10.4*Cv) / (1-Cv/0.62 )^8

- The mixture is fairly dilute and there is no interaction between the particles

Such a flow is not encountered, except in laminar regimes of very dilute

Water properties (fluid f) concentrations (below a volume concentration of 1%).

32 C

0.00077 Pa s

m

/

L

= 1 + 2.5 * (C

v

/100) + K

2

* (C

v

/100)^2

Volumetric concentration C

v

= 0.17

0.0017 /1 K

2

= 10.5

m

/

L

= 1.00

Ratio of viscosities

Exp(-10.4*Cv) / (1-Cv/0.62 )^8

m

/

L

= 1 + 2.5 * (C

v

/100) + K

2

* (C

v

/100)^2

0.0017 C

v

= 19

1.00 K

2

= 14.1

m

/

L

=

1.98

Absolute viscosity of pulp

f

* Exp(-10.4*Cv) / (1-Cv/0.62 )^8

m

/

L

= 1 + K

1

* (C

v

/100) + K

2

* (C

v

/100)^2 +A * Exp(B*(C

v

/100) )

0.00077 Pa s C

v

= 0.17

0.0017 /1 K

1

= 2.5

7.70E-04 Pa s

K

2

=

10.05

A = 0.00273

B = 16.6

m

/

L

=

1.01

60 70

8

62 . 0

1

) 4 . 10 (

|

.

|

\

|

=

v

v

f p

C

C Exp

1 + 2.5 * (C

v

/100) SSHB (1-7) Einstein formula

%

Valid for C

v

< 1 %

This is a very simple equation that is based on the following assumptions:

- The mixture is fairly dilute and there is no interaction between the particles

Such a flow is not encountered, except in laminar regimes of very dilute

concentrations (below a volume concentration of 1%).

1 + 2.5 * (C

v

/100) + K

2

* (C

v

/100)^2 SSHB (1-8) Thomas (1965) formula

%

Valid for C

v

< 20 %

K

3

and K

4

are zero for Cv < 20 %

K

2

is in the range 10.05 to 14.1

1 + 2.5 * (C

v

/100) + K

2

* (C

v

/100)^2

%

1 + K

1

* (C

v

/100) + K

2

* (C

v

/100)^2 +A * Exp(B*(C

v

/100) )

% SSHB (1-9) Thomas (1965) formula

JRI (2.2.3.a)

Equation 1-9 is widely accepted in

the slurry industry for heterogeneous

mixtures of a Newtonian rheology.

[1] Curso de transporte hidraulico de solidos

Tecnex (JR)

[2] Slurry systems handbook

You might also like

- Understanding Infrared Thermography Reading 6 (PDFDrive) PDFDocument510 pagesUnderstanding Infrared Thermography Reading 6 (PDFDrive) PDFINDRAJIT SAONo ratings yet

- Valve Basics and Valve SizingDocument32 pagesValve Basics and Valve SizingDouglas Booyens100% (2)

- Slurry-Flow Pressure Drop in Pipes With Modified Wasp Method (Ej) (MALI KHUDABADI Et Al) (SME Annual Meeting 2014-02) (13s)Document13 pagesSlurry-Flow Pressure Drop in Pipes With Modified Wasp Method (Ej) (MALI KHUDABADI Et Al) (SME Annual Meeting 2014-02) (13s)R_M_M_100% (4)

- Phase Equilibria: Basic Principles, Applications, Experimental TechniquesFrom EverandPhase Equilibria: Basic Principles, Applications, Experimental TechniquesNo ratings yet

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsFrom EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNo ratings yet

- Pressureloss in Slurry PipesDocument10 pagesPressureloss in Slurry PipesKarthick Velayutham100% (1)

- Slurry Pump Sizing1Document4 pagesSlurry Pump Sizing1chennaimechNo ratings yet

- Control Valve CharacteristicsDocument65 pagesControl Valve CharacteristicsAzar DeenNo ratings yet

- Slurry Pump Calculations Com MacroDocument50 pagesSlurry Pump Calculations Com Macrolavascudo100% (1)

- Design of AgitatorDocument12 pagesDesign of AgitatorPatil HemantNo ratings yet

- A-1 Head: Section A - Centrifugal Pump FundamentalsDocument18 pagesA-1 Head: Section A - Centrifugal Pump FundamentalsReNyy ChowNo ratings yet

- Restriction Orifice Calculation SheetDocument2 pagesRestriction Orifice Calculation Sheetparykoochak50% (2)

- Agitator Power Requirement and Mixing Intensity CalculationDocument26 pagesAgitator Power Requirement and Mixing Intensity CalculationWael Abdel-Mageed100% (1)

- Disclaimer: This Calculation Provides An Estimate For Specifying Pumps. We Cannot Be Held Responsible For Its Use. AsDocument7 pagesDisclaimer: This Calculation Provides An Estimate For Specifying Pumps. We Cannot Be Held Responsible For Its Use. AsbratkpNo ratings yet

- Centrifugal PumpDocument23 pagesCentrifugal Pumpheri monawir zebuaNo ratings yet

- MIP Thickener DesignDocument3 pagesMIP Thickener DesignHatem SalahNo ratings yet

- Design Mix Calculation Grade 30NDocument6 pagesDesign Mix Calculation Grade 30NikhwanNo ratings yet

- AgitatorDocument10 pagesAgitatoragrocel_bhv5591No ratings yet

- Normalizing NPSHDocument5 pagesNormalizing NPSHorchids28No ratings yet

- Engineering Design Guidelines - Compressors Rev02 KLM Technology GroupDocument32 pagesEngineering Design Guidelines - Compressors Rev02 KLM Technology GroupAhmed Fgt Kaasehg0% (1)

- SDM Cyclone SizingDocument7 pagesSDM Cyclone Sizingmohamed_sahnoun_enisNo ratings yet

- Agitator Power Calculation FormatDocument2 pagesAgitator Power Calculation FormatSandeep GosaviNo ratings yet

- Finned Tube Heat ExchangerDocument3 pagesFinned Tube Heat ExchangerShreya Sahajpal KaushalNo ratings yet

- Mixing in TankDocument5 pagesMixing in TankWan Ling LeeNo ratings yet

- Impeller Design For Mixing of SuspensionsDocument16 pagesImpeller Design For Mixing of SuspensionsFaycel OuerdienNo ratings yet

- Comparison of Different Calculation Methods For Structural Stresses at Welded JointsDocument11 pagesComparison of Different Calculation Methods For Structural Stresses at Welded JointsBob LoblawNo ratings yet

- Vent Sizing - SpreadsheetDocument2 pagesVent Sizing - SpreadsheetPradip ShindeNo ratings yet

- Pump. Froth Selection WarmanDocument40 pagesPump. Froth Selection WarmanJuan Pablo Apaza100% (3)

- Slurry Pump CalculationsDocument41 pagesSlurry Pump Calculationsyuli_o2100% (7)

- Dynamic Behavior of Materials - I - Meyers PDFDocument684 pagesDynamic Behavior of Materials - I - Meyers PDFAamir RazaNo ratings yet

- Water Pump Impeller TheoryDocument9 pagesWater Pump Impeller TheoryspdhimanNo ratings yet

- Pipe Dimensions and Friction FactorDocument24 pagesPipe Dimensions and Friction FactorJuan Pablo ApazaNo ratings yet

- Process Control Fundamentals 2Document73 pagesProcess Control Fundamentals 2Otuekong Ukpong100% (2)

- Agitator Power Requirementand Mixing Intensity CalculationDocument26 pagesAgitator Power Requirementand Mixing Intensity Calculationkkaranag100% (1)

- Pump DesignDocument10 pagesPump DesignashokrangasamyNo ratings yet

- Power Requirement (Agitator and High-Torque Stirrer)Document8 pagesPower Requirement (Agitator and High-Torque Stirrer)DozdiNo ratings yet

- Agitator - Ag-C8-102Document4 pagesAgitator - Ag-C8-102uttam prabhuNo ratings yet

- Orifice Plate Showing VenaDocument6 pagesOrifice Plate Showing VenahugepotatoNo ratings yet

- MIP Thickener Design-02Document3 pagesMIP Thickener Design-02Bellary SreedharNo ratings yet

- Agitator Design PrinciplesDocument130 pagesAgitator Design PrinciplesHamlet GhookasianNo ratings yet

- CycloSim SingleDocument12 pagesCycloSim Singlejvchique100% (1)

- Fluid Flow Basiics of Throttliing ValvesDocument56 pagesFluid Flow Basiics of Throttliing Valvesdanne_eNo ratings yet

- How To Check Variability of Mass Flow in A Pneumatic Conveying System PDFDocument4 pagesHow To Check Variability of Mass Flow in A Pneumatic Conveying System PDFnazmul hasanNo ratings yet

- Hydrodynamic Simulation of Horizontal Slurry Pipeline Flow Using ANSYS-CFXDocument39 pagesHydrodynamic Simulation of Horizontal Slurry Pipeline Flow Using ANSYS-CFXAvinash VasudeoNo ratings yet

- Thicken Er Design and ControlDocument20 pagesThicken Er Design and ControlHarshalNo ratings yet

- Design of AgitatorDocument3 pagesDesign of Agitatorkaps12No ratings yet

- Slurry PumpingDocument12 pagesSlurry Pumpingmanoj983@gmail.comNo ratings yet

- Science 7 Third Quarter ExamDocument7 pagesScience 7 Third Quarter ExamKenny Ann Grace Batiancila100% (1)

- Unity Pro XL ManualDocument722 pagesUnity Pro XL ManualCarlos Gallegos100% (3)

- Pump Calculation - SlurryDocument1 pagePump Calculation - SlurryBilly Brikz YanisNo ratings yet

- Theory and Design of Dilute Phase Pneumatic Conveying Systems-TN Agarwal 2005Document6 pagesTheory and Design of Dilute Phase Pneumatic Conveying Systems-TN Agarwal 2005cordobaluisf100% (2)

- Efficient Pneumatic ConveyingDocument14 pagesEfficient Pneumatic Conveying설동하100% (2)

- Liquid Orifice SizingDocument4 pagesLiquid Orifice SizingrmaganNo ratings yet

- Info RASCHIG Column Internals-1101Document100 pagesInfo RASCHIG Column Internals-1101Frits32100% (3)

- Slurry. Pumps. Power Law, Bingham. Heterogeneous FlowDocument113 pagesSlurry. Pumps. Power Law, Bingham. Heterogeneous FlowAnonymous K3FaYFlNo ratings yet

- Materials Transfer: Types of Pneumatic Conveying & Design ConsiderationsDocument5 pagesMaterials Transfer: Types of Pneumatic Conveying & Design ConsiderationsRosa María Córdova100% (1)

- Viscosity Ratio of SlurriesDocument17 pagesViscosity Ratio of SlurriesradanpetricaNo ratings yet

- Mathcad - 2Document4 pagesMathcad - 2Desejo SozinandoNo ratings yet

- Sludge Thickener Pump Head CalculationDocument4 pagesSludge Thickener Pump Head CalculationgawtomNo ratings yet

- Science Raking in Gravity Thickeners PDFDocument17 pagesScience Raking in Gravity Thickeners PDFJuan Alberto Giglio FernándezNo ratings yet

- Agitator Power Requirement and Mixing Intensity CalculationDocument28 pagesAgitator Power Requirement and Mixing Intensity CalculationVasu DevanNo ratings yet

- Orifice SizingDocument2 pagesOrifice SizingXheikhKaleemNo ratings yet

- CHAPTER 8 Sizing and CostingDocument20 pagesCHAPTER 8 Sizing and CostingNurul Amelia Mustaffa0% (1)

- Gas - Liquid Mixing Impeller of New GenerationDocument8 pagesGas - Liquid Mixing Impeller of New GenerationscranderiNo ratings yet

- Flow in Pipe ManifoldsDocument4 pagesFlow in Pipe Manifoldskasandra01100% (1)

- 5.4.3. Power Requirements For Pumping Liquids: 5.4. Pumps and CompressorsDocument3 pages5.4.3. Power Requirements For Pumping Liquids: 5.4. Pumps and Compressorsamir885No ratings yet

- Pbe - 200810-Conveying Line Elbows Provide Maintenance-Free OperationDocument4 pagesPbe - 200810-Conveying Line Elbows Provide Maintenance-Free Operation설동하No ratings yet

- Question 1 (8 Marks) : ENCH 629 - Fall 2006. Final Examination - Closed Book Closed Notes Maximum Marks 40Document9 pagesQuestion 1 (8 Marks) : ENCH 629 - Fall 2006. Final Examination - Closed Book Closed Notes Maximum Marks 40erev_20No ratings yet

- Computation of Coefficient of Permeability FunctionDocument4 pagesComputation of Coefficient of Permeability FunctionIndranil BanerjeeNo ratings yet

- Fluid Mechanics: University of LeedsDocument16 pagesFluid Mechanics: University of LeedsHasitha MadusankaNo ratings yet

- Addis Ababa Science and Technology UniversityDocument9 pagesAddis Ababa Science and Technology UniversityLamiNo ratings yet

- ForScribd Difussion ProbsetDocument25 pagesForScribd Difussion Probsetmendoza21203831mNo ratings yet

- Certificate With Cut-Out Report PDFDocument1 pageCertificate With Cut-Out Report PDFnazmul hasanNo ratings yet

- Change Readiness - EN - Final Questionnaire PDFDocument3 pagesChange Readiness - EN - Final Questionnaire PDFnazmul hasanNo ratings yet

- BenchtopPIDController WhPaperDocument26 pagesBenchtopPIDController WhPaperfirosekhanNo ratings yet

- Aspen DMC3 Builder Jump Start Guide JSGDocument33 pagesAspen DMC3 Builder Jump Start Guide JSGnazmul hasanNo ratings yet

- 3dlevelscanner: Non-Contact, Multiple-Point MeasurementDocument4 pages3dlevelscanner: Non-Contact, Multiple-Point Measurementnazmul hasanNo ratings yet

- WBCSD CO2 Protocol en PDFDocument80 pagesWBCSD CO2 Protocol en PDFnazmul hasanNo ratings yet

- 20409: Optimal Design of Cooling Towers Eusiel Rubio-Castro1, Medardo Serna-González1, José M. Ponce-Ortega1 and Arturo Jiménez-Gutiérrez2 1Universidad Michoacana de San Nicolás de Hidalgo, Morelia, Michoacán, 2Instituto Tecnológico de Celaya, Celaya, Guanajuato, MéxicoDocument27 pages20409: Optimal Design of Cooling Towers Eusiel Rubio-Castro1, Medardo Serna-González1, José M. Ponce-Ortega1 and Arturo Jiménez-Gutiérrez2 1Universidad Michoacana de San Nicolás de Hidalgo, Morelia, Michoacán, 2Instituto Tecnológico de Celaya, Celaya, Guanajuato, MéxicoRajat Yadav YaduvanshiNo ratings yet

- Ideal Otto CycleDocument15 pagesIdeal Otto Cyclenazmul hasanNo ratings yet

- Energy Efficiency CHP SystemDocument2 pagesEnergy Efficiency CHP Systemnazmul hasanNo ratings yet

- Procedure and Scope: Good Luck, Ravi SankarDocument27 pagesProcedure and Scope: Good Luck, Ravi SankarRazook MohammedNo ratings yet

- Control Vavle and Its Effect On Process Loop PDFDocument8 pagesControl Vavle and Its Effect On Process Loop PDFArun BabuNo ratings yet

- Air Brayton CycleDocument46 pagesAir Brayton Cyclenazmul hasanNo ratings yet

- Ainilinemanual PDFDocument168 pagesAinilinemanual PDFnazmul hasanNo ratings yet

- On The Rheological ParametersDocument7 pagesOn The Rheological Parametersnazmul hasanNo ratings yet

- Cost EstimationDocument4 pagesCost Estimationnazmul hasanNo ratings yet

- Absorber Design ParametersDocument13 pagesAbsorber Design Parametersnazmul hasanNo ratings yet

- Duct Traverse Point DeterminationDocument2 pagesDuct Traverse Point Determinationnazmul hasanNo ratings yet

- Tire CreepDocument3 pagesTire Creepnazmul hasan0% (1)

- Lower and Higher Heating Values of Gas Liquid and Solid FuelsDocument1 pageLower and Higher Heating Values of Gas Liquid and Solid FuelsNikunj PipariyaNo ratings yet

- Experimental Study On Effect Factors of NH3 Slip in SNCR ProcessDocument6 pagesExperimental Study On Effect Factors of NH3 Slip in SNCR Processnazmul hasanNo ratings yet

- Plastic Analysis AssignmentDocument6 pagesPlastic Analysis AssignmentLeo DoeNo ratings yet

- Proposed Two Storey Residence ReportDocument27 pagesProposed Two Storey Residence ReportchorgedNo ratings yet

- Manual of Basic Air Flow BenchDocument24 pagesManual of Basic Air Flow BenchPung Kang Qin100% (1)

- SIM Metrology SchoolDocument56 pagesSIM Metrology SchoolDaniNo ratings yet

- ASBMB Science Book List: Title Author Publisher IsbnDocument4 pagesASBMB Science Book List: Title Author Publisher IsbnjitendramataNo ratings yet

- Various Analyses of An Elbow Bracket: Solved With Comsol Multiphysics 3.5ADocument3 pagesVarious Analyses of An Elbow Bracket: Solved With Comsol Multiphysics 3.5Atomica06031969No ratings yet

- Student Book Answers Paper 1 Questions: Answers Extra Information MarkDocument6 pagesStudent Book Answers Paper 1 Questions: Answers Extra Information MarkEngwarwickNo ratings yet

- Electric Machines and Transformers E-615Document4 pagesElectric Machines and Transformers E-615etaNo ratings yet

- Armstrong-High Strain Rate Properties Int Mat. RevDocument24 pagesArmstrong-High Strain Rate Properties Int Mat. RevAnthony LeungNo ratings yet

- Discussion - Strengthening of Existing Composite Beams Using LRFD ProceduresDocument2 pagesDiscussion - Strengthening of Existing Composite Beams Using LRFD ProceduresCaesar JJNo ratings yet

- 000 in DTS 401Document6 pages000 in DTS 401zsmithNo ratings yet

- Discretization Considerations in Moving Load Finite Element Beam ModelsDocument16 pagesDiscretization Considerations in Moving Load Finite Element Beam ModelsEugene CommerellNo ratings yet

- Question Bank Centroid&MIDocument13 pagesQuestion Bank Centroid&MIrubyNo ratings yet

- P 846 Ps 1Document3 pagesP 846 Ps 1betjodaNo ratings yet

- CHAPTER 6 - ELE290 INDUCTION MotorDocument10 pagesCHAPTER 6 - ELE290 INDUCTION MotorKamaruz DanialNo ratings yet

- Synthesis and Consolidation of Boron Carbide - A ReviewDocument37 pagesSynthesis and Consolidation of Boron Carbide - A ReviewEvandro SilvaNo ratings yet

- NumecDocument14 pagesNumecDinie Abdullah ZamawiNo ratings yet

- 1 Gibbsite CIFDocument5 pages1 Gibbsite CIFDjohra BEDGHIOUNo ratings yet

- Equilibrium Worksheet 2Document9 pagesEquilibrium Worksheet 2haileyNo ratings yet

- Ansys Maxwell Egtm IcerigiDocument2 pagesAnsys Maxwell Egtm IcerigiFeyza KaragözNo ratings yet

- Profile LevelingDocument3 pagesProfile LevelingShealtiel Regine Cinco-AyalaNo ratings yet

- Crystal Defects PDFDocument1 pageCrystal Defects PDFJohan Steven Rivera RomeroNo ratings yet

- ANP1 Zeeman EffectDocument12 pagesANP1 Zeeman Effectmdilshadshigri1000No ratings yet

- T1-T7Q Ee2005 NtuDocument10 pagesT1-T7Q Ee2005 NtuamosmarongshengNo ratings yet

- Mohrscirclebysanjaykumawat 170912050937Document22 pagesMohrscirclebysanjaykumawat 170912050937ravi maskeNo ratings yet