Professional Documents

Culture Documents

IWESS Chiller Oct06 PDF

Uploaded by

aboumaleOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IWESS Chiller Oct06 PDF

Uploaded by

aboumaleCopyright:

Available Formats

Sep.

28, 2006 Center for Building Performance and Diagnostics, Carnegie Mellon University Page 1

Hongxi Yin, Ph.D.

School of Architecture

Carnegie Mellon University

Ph.D. Committee

Prof. Volker Hartkopf, Ph.D. (Chair)

Prof. David Archer, Ph.D. (CMU)

Prof. David Claridge, Ph.D. (TAMU)

Consultant

Richard Christensen, Ph.D. (OSU)

An Absorption Chiller in a Micro BCHP Application:

Model Based Design and Performance Analysis

0.40

0.50

0.60

0.70

0.80

0.90

1.00

1.10

1.20

1.30

0 2 4 6 8 10 12 14 16 18 20

Actual cooling load (kW)

C

o

e

ff

ic

ie

n

t

o

f

P

e

r

f

o

r

m

a

n

c

e

(

C

O

P

)

.

Thermal COP (measurement) Overall COP (measurement)

Thermal COP (model)

Thermal COP

(model)

Thermal COP

(measurement)

Overall COP

(measurement)

57.39 %

46.22

36.1 92.7 90.65 75.1

T1 T4 T5 T6 T7 T21

T11

44.11

T41

31.5

T42

36.11

T43

38.2

6.35

T32

T31

13.9

62.81 %

156.2

99.97

61.68 %

45.75

T91

57.39 %

48.1

T22

128.8

T20

T51

164

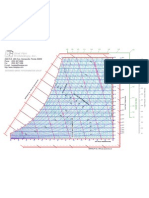

REFRIGERANT TEM

PERATURE, C

SA

T

U

A

T

IO

N

PR

E

SSU

R

E

(P), kPa

SOLUTION TEMPERATURE, C

Equlibrium Chart for A queous Lithium Bromide Solutions

10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180

10

20

30

40

50

60

70

80

90

100

110

120

0

30%

40%

50%

60%

70%

1

2

3

4

5

10

20

30

40

50

100

150

200

0

5

o

o

T52

157.5

Pm, 9.155 kPa

Ph, 85.34 kPa

Pl, 0.7665 kPa 1

4

5

6

20

21

22

7

91

109.6

T54

T53

3.154

T18

95.26

m =0.0073 kg/s 51

m =0.04437 kg/s

21

m =0.04857 kg/s

21

m =0.0042 kg/s 24

m =0.04765 kg/s

4

m =0.09622 kg/s

1 m =0.04434 kg/s

6

m =0.003315 kg/s 10

m =0.007513 kg/s 18

Model solution

Measurement

+ 5 C

o

Refrigerant

Water-LiBr sorbent solution

Steam, cooling water, and chilled water

1

2

3

19

4

5

6

7

8

91

10

11

14

18

20 21

22

23

24

51 52

42 43

32 31 41 42

53

16

17

12

13

25

Q to

Low Temp.

regenerator

Low Temp.

regenerator

High Temp.

heat exchanger

condenser

High Temp.

Low Temp.

condenser

High Temp.

regenerator

Low Temp.

heat exchanger

Absorber

Evaporator

Heat

Recovery

H.X.

Q

By-pass

H.X.

Refrigerant

combiner

expansion

Refrigerant

valve

pump

Recirculation

expansion

Solution

valve pump

Solution

Solution

combiner Splitter

Solution

52

54

9

92

46

45 47

44 41

43

Air

from

City water

600

600

750

Cooling water fill

Cooling tower Chilled water Cooling water

Steam To HRHX

to

Condenser

Absorber

Chilled water

pump

Sept. 28, 2006 Center for Building Performance and Diagnostics, Carnegie Mellon University Page 2

Absorption chiller technology as an integral part of

a Micro BCHP system

BCHP - Building Cooling, Heating, and Power system

Micro scale BCHP - Power generation capacity less than 15 kW

Introduction

Sept. 28, 2006 Center for Building Performance and Diagnostics, Carnegie Mellon University Page 3

Research objectives

The establishment of an experimental environment and

procedures for absorption chiller tests under various

conditions.

The conduct of a comprehensive testing programon a

microscale absorption chiller.

The construction of a comprehensive chiller model based

on the pertinent scientific and engineering principles

The analysis of the measured data, refinement of the

model, and improvement of the chiller design.

The preparation for future chiller design modifications,

system design, evaluation, and integration.

Introduction

Sept. 28, 2006 Center for Building Performance and Diagnostics, Carnegie Mellon University Page 4

ESB

CTW

CR

H

W

R

H

W

S

Absorption

SS

BFT

TLHX

WS

BFP

Chiller

B

A

CHWR

CHWS

PCHWP

ESB

CTW

CR

H

W

R

H

W

S

Absorption

SS

BFT

BCL

CCL

TLHX

WS

BFP

Chiller

Design, engineering, and installation

The absorption chiller and auxiliary system installed

in the intelligent workplace (IW)

B

A

CHWR

CHWS

PCHWP

ESB

CTW

CR

Absorption

SS

BFT

BCL

CCL

WS

BFP

Chiller

Test load

Steam supply

Absorption chiller

Building and grid loads

ESB

CTW

CR

Absorption

SS

BFT WS

BFP

Chiller

Steam supply system

Test load Building load Grid load

Absorption

Chiller

Sept. 28, 2006 Center for Building Performance and Diagnostics, Carnegie Mellon University Page 5

Steam system

Absorption chiller

Test load system

The absorption chiller and auxiliary system installed in IW

Design, engineering, and installation

Eclectrical Steam

boiler

Condensate

receiver tank

Chilled water

system

Test load heat

exchanger

Hot water

supply valve

Sept. 28, 2006 Center for Building Performance and Diagnostics, Carnegie Mellon University Page 6

The test program

Test programs and experimental data

Vary five operating parameters individually

chilled water return temperature (cooling load)

chilled water flow rate

cooling water supply temperature

cooling water flow rate

steam pressure

h enthalpy

m flow rate

Cp heat capacity of water

T temperature

.

) (

_ condensate steam steam input heat

h h m Q = &

) (

sup ply return p CHW cooling

T T C m Q = & input heat

cooling

Q

Q

COP

_

=

Sept. 28, 2006 Center for Building Performance and Diagnostics, Carnegie Mellon University Page 7

Chiller performance under various load conditions

Test programs and experimental data

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

0 2 4 6 8 10 12 14 16 18 20

Actual cooling load (kW)

C

o

e

f

f

i

c

i

e

n

t

o

f

P

e

r

f

o

r

m

a

n

c

e

(

C

O

P

)

.

Thermal COP (measurement) Overall COP (measurement)

Thermal COP

(measurement)

Overall COP

(measurement)

Sept. 28, 2006 Center for Building Performance and Diagnostics, Carnegie Mellon University Page 8

Chilled water loop

Evaporator

Refrigerant

Absorber

Cooling

water

Strong LiBr

solution

Dilute

solution

The chiller performance model

Computational performance model

The model includes

5 major heat transfer components

the evaporator

the absorber

the high temperature regenerator

low temperature regenerator

the condenser

4 minor heat exchanger components

high temperature heat exchanger

low temperature heat exchanger

steam heat recovery exchanger

by-pass heat exchanger

Other associated components include:

cooling tower

pumps

spray nozzles and valves

Schematic diagram

HTRG

LTRG

Condenser

LTHX

HTHX

Steam supply

HRHX

Refrigerant

condensate

Sept. 28, 2006 Center for Building Performance and Diagnostics, Carnegie Mellon University Page 9

1

2

3

19

4

5

6

7

8

91

10

11

14

18

20

21

22

23

24

51 52

42 43

32 31

41 42

53

16

17

12

13

25

Q to

Low Temp.

regenerator

Low Temp.

regenerator

High Temp.

heat exchanger

condenser

High Temp.

Low Temp.

condenser

High Temp.

regenerator

Low Temp.

heat exchanger

Absorber

Evaporator

Heat

Recovery

H.X.

Q

By-pass

H.X.

Refrigerant

combiner

expansion

Refrigerant

valve

pump

Recirculation

expansion

Solution

valve

pump

Solution

Solution

combiner

Splitter

Solution

52

54

9

92

46

45

47

44 41

43

Air

from

City water

600

6

0

0

7

5

0

Cooling water fill

Cooling tower

Chilled water Cooling water

Steam To HRHX

to

Condenser

Absorber

Chilled water

pump

The chiller performance model

The model is based on

fundamental scientific and

engineering principles

mass and energy

balances

thermodynamic property

relations

thermal and phase

equilibrium relations

heat and mass transport

coefficient correlations

The model is a steady-state

model programmed in the

Engineer Equation Solver

(EES)

The basic model has:

409 equations

416 variables

(7 variables as inputs:

5 inputs, 2 primary

measurements)

Computational performance model

Refrigerant

Solution

Equilibrium state

Saturated liquid

Saturated vapor

Sept. 28, 2006 Center for Building Performance and Diagnostics, Carnegie Mellon University Page 10

Diameter of 'lower vessel'

H

i

g

h

t

o

f

'

l

o

w

e

r

v

e

s

s

e

l

'

2

3

2

3

2

3

19 419 19 419

N

u

m

b

e

r

:

1

7

-

1

8

Absorber

tubes

Evaporator

tubes

Separation

blind

Evaporator

Absorber Absorber

LiBr Reservior

Water tray

Spray nozzles

Tube bundles

Spiral

Absorber configuration and its heat transfer

coefficient calculation

( )

( )

( )

( )

+

=

8 . 0

41 42 41

3 1 46 . 0

91 91

, 4

1

3

1

1

m T T f C m T f C

U

abs

Computational performance model

Overall heat transfer coefficient

Ref: Vliet et al; Dittus and Boelter.

CW outlet

CHW outlet

CHW inlet CW inlet

U: heat transfer coefficient

C: constant

T: temperature

m: flow rate

Subscriber:

abs: absorber

Sept. 28, 2006 Center for Building Performance and Diagnostics, Carnegie Mellon University Page 11

The discrepancies between the measurements and the

model solutions due to inaccurate measurements

Temperature sensors mounted on the

external pipe surface

fluctuating measurements of steam

flow due to periodic feedwater

addition to the boiler

cooling water flow measurements due

to space limitations in mounting the

flow sensor

Model based data analysis

Sept. 28, 2006 Center for Building Performance and Diagnostics, Carnegie Mellon University Page 12

0

0.05

0.1

0.15

0.2

0.25

0.3

0.35

0 0.0005 0.001 0.0015 0.002 0.0025 0.003 0.0035 0.004 0.0045 0.005

Refrigerant flow

entering condenser, m24 (kg/s)

V

a

p

o

r

q

u

a

l

i

t

y

(

q

2

4

)

.

Vapor quality of refrigerant entering condenser

Vapor quality of refrigerant

entering Condenser

The adjustment of the model assumptions

Model based data analysis

q24

P

h

P

l

P

m

The quality of the refrigerant leaving LTRG (q24):

0 a linear relation with the differential pressure.

The findings could be used not only to validate the performance model, but also to improve the equipment design.

Sept. 28, 2006 Center for Building Performance and Diagnostics, Carnegie Mellon University Page 13

The deviations between model and measurements

Model based data analysis

0%

2%

4%

6%

8%

10%

12%

14%

16%

0 2 4 6 8 10 12 14 16 18 20

Actual cooling load (kW)

O

v

e

r

a

l

l

a

n

d

w

e

i

g

h

t

e

d

d

e

v

i

a

t

i

o

n

s

.

Overall deviationr Weighted deviation

Overall deviation

Weighted deviation

Sept. 28, 2006 Center for Building Performance and Diagnostics, Carnegie Mellon University Page 14

Future research area - the extended absorption chiller models

Natural gas driven Exhausted gas driven Steam driven Hot water driven

Contributions and areas of future research

Sept. 28, 2006 Center for Building Performance and Diagnostics, Carnegie Mellon University Page 15

Future research area - System Integration and other applications

Integration of the chiller performance and cost models into overall

simulations of microscale BCHP systems to optimize overall system

performance and operating strategies

A cost model including capital cost, operational cost, and

maintenance cost can be integrated with building load simulation

tools to evaluate absorption chiller economic performance under

various types of buildings and weather conditions.

A guideline for applying the microscale absorption chiller in

buildings can be proposed on the basis of the simulation results of the

economical evaluation model.

As a simulation tool, the model should provide a graphic user

interface (GUI) and standard output sheets that can assist the system

designers in implanting BCHP system design and evaluation.

Contributions and areas of future research

You might also like

- Process Heat Transfer: Principles, Applications and Rules of ThumbFrom EverandProcess Heat Transfer: Principles, Applications and Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (11)

- Ho 2022 Variable Importance For Chiller SysDocument21 pagesHo 2022 Variable Importance For Chiller Sys异次元雷少AulayNo ratings yet

- Heat Pumps: Solving Energy and Environmental ChallengesFrom EverandHeat Pumps: Solving Energy and Environmental ChallengesTakamoto SaitoNo ratings yet

- 2015-An Experimental Investigation On A Novel Ejector EnhancedDocument8 pages2015-An Experimental Investigation On A Novel Ejector EnhancedVictor PerezNo ratings yet

- Respiration Calorimeters for Studying the Respiratory Exchange and Energy Transformations of ManFrom EverandRespiration Calorimeters for Studying the Respiratory Exchange and Energy Transformations of ManNo ratings yet

- Cooling Tower Performance Assessment PDFDocument40 pagesCooling Tower Performance Assessment PDFHamid Ariz100% (1)

- 1 s2.0 S0140700723001433 MainDocument37 pages1 s2.0 S0140700723001433 MainimphudaNo ratings yet

- Mostafa SiminarDocument37 pagesMostafa SiminarMostafa HassanainNo ratings yet

- 5.analysisi Chiller Sutem SimulasiDocument14 pages5.analysisi Chiller Sutem SimulasisuryadimalNo ratings yet

- O.2.9.1 Improved Methodology For Testing The Part Load Performance of Water To Water Heat PumpsDocument11 pagesO.2.9.1 Improved Methodology For Testing The Part Load Performance of Water To Water Heat PumpsmaxmanfrenNo ratings yet

- FLAT Heat PipeDocument102 pagesFLAT Heat Pipeafic219473No ratings yet

- The Condenser Performance Test and Thermal Performance Analysis of Variable Conditions in TQNPCDocument4 pagesThe Condenser Performance Test and Thermal Performance Analysis of Variable Conditions in TQNPCrashm006ranjanNo ratings yet

- Prateek Jain Rahul Raj Jadoun Ratnesh Kesari Md. Shamim Siddique Arvind Kumar YadavDocument30 pagesPrateek Jain Rahul Raj Jadoun Ratnesh Kesari Md. Shamim Siddique Arvind Kumar Yadavalokshukla000No ratings yet

- Analysis of Nodalization Effects On The Prediction Er-Ror of Generalized Finite Element Method Used For Dynamic Modeling of Hot Water Storage TankDocument16 pagesAnalysis of Nodalization Effects On The Prediction Er-Ror of Generalized Finite Element Method Used For Dynamic Modeling of Hot Water Storage TankJorge Luis Garcia ZuñigaNo ratings yet

- Optimization of Water-Cooled Chiller SystemDocument21 pagesOptimization of Water-Cooled Chiller SystemNguyễn Thành NamNo ratings yet

- Sunpower's CPT60 Pulse Tube Cryocooler: K. B. Wilson and C. C. FralickDocument10 pagesSunpower's CPT60 Pulse Tube Cryocooler: K. B. Wilson and C. C. FralickNavin DNo ratings yet

- The University of The South Pacific: School of Engineering and PhysicsDocument4 pagesThe University of The South Pacific: School of Engineering and PhysicsRoshiv SharmaNo ratings yet

- Dali Cha Ouch 89Document249 pagesDali Cha Ouch 89Arie JuliantoNo ratings yet

- Performance Analyses of Counter-Flow Closed Wet Cooling Towers Based On A Simplified Calculation MethodDocument15 pagesPerformance Analyses of Counter-Flow Closed Wet Cooling Towers Based On A Simplified Calculation MethodAmir AbbaszadehNo ratings yet

- Design and Performance Analysis of Water Chiller - A ResearchDocument8 pagesDesign and Performance Analysis of Water Chiller - A ResearchDiyar NezarNo ratings yet

- Chang-Hyo Son, Seung-Jun ParkDocument8 pagesChang-Hyo Son, Seung-Jun ParkkamalNo ratings yet

- (translate68.ir مترجم متن) 10.1016 - j.enconman.2012.03.030Document9 pages(translate68.ir مترجم متن) 10.1016 - j.enconman.2012.03.030partoNo ratings yet

- Revolutionizing Turbine Cooling With Micro-Architectures Enabled by Direct Metal Laser SinteringDocument72 pagesRevolutionizing Turbine Cooling With Micro-Architectures Enabled by Direct Metal Laser SinteringMehran MehraniNo ratings yet

- Heat ExchangerDocument5 pagesHeat ExchangerPragya Mehta100% (1)

- Adenariwo AdepojuDocument225 pagesAdenariwo AdepojustarykltNo ratings yet

- Refrigerant in Capillary Tube PDFDocument6 pagesRefrigerant in Capillary Tube PDFMayank Kumar100% (2)

- Advanced Cooling Tower Concept For Commercial and Industrial ApplicationsDocument8 pagesAdvanced Cooling Tower Concept For Commercial and Industrial ApplicationsArun kumarNo ratings yet

- Applied Thermal Engineering: Saad Ayub Jajja, Wajahat Ali, Ha Fiz Muhammad Ali, Aysha Maryam AliDocument7 pagesApplied Thermal Engineering: Saad Ayub Jajja, Wajahat Ali, Ha Fiz Muhammad Ali, Aysha Maryam AliSaad Ayub JajjaNo ratings yet

- Supervisor:-K. Manjunath Assistant Prof., Department of Mechanical Engineering, Delhi Technological UniversityDocument45 pagesSupervisor:-K. Manjunath Assistant Prof., Department of Mechanical Engineering, Delhi Technological UniversityAnkit GuptaNo ratings yet

- SCW NPPS: Layouts and Thermodynamic Cycles: Naidin, M., Mokry, S., Pioro, I.Document12 pagesSCW NPPS: Layouts and Thermodynamic Cycles: Naidin, M., Mokry, S., Pioro, I.Thiago RobertoNo ratings yet

- Yan 2015Document8 pagesYan 2015Anonymous NbnNkxdrRQNo ratings yet

- Design and Dynamic Modeling of PCHE For SCO2 CyclesDocument31 pagesDesign and Dynamic Modeling of PCHE For SCO2 CyclesankitNo ratings yet

- A Design Model For Capillary Tube-Suction Line Heat ExchangersDocument24 pagesA Design Model For Capillary Tube-Suction Line Heat ExchangersDaniel SolesNo ratings yet

- Methane Steam ReformingDocument29 pagesMethane Steam Reformingnganphap67% (6)

- TestReport ThermalDocument12 pagesTestReport ThermalDepri YantriNo ratings yet

- Measurements of Convection Heat Transfer CoefficieDocument7 pagesMeasurements of Convection Heat Transfer CoefficieNatalia SouzaNo ratings yet

- Energy Optimization of A Large Central Plant Chilled Water SystemDocument24 pagesEnergy Optimization of A Large Central Plant Chilled Water Systemmuoi2002No ratings yet

- Cooling Tower JurnalDocument11 pagesCooling Tower Jurnalkumpul tugasNo ratings yet

- Assessment of Heat ExchangersDocument14 pagesAssessment of Heat ExchangersranveerNo ratings yet

- Midas NFX Thermal AnalysisDocument15 pagesMidas NFX Thermal AnalysisGanesh MandpeNo ratings yet

- Journal On Heat TransferDocument47 pagesJournal On Heat TransferjanamuraliNo ratings yet

- Study On Heat Transfer Calculation Method of Ground Heat Exchangers Based On Heat Pump Unit Operation CharacteristicsDocument9 pagesStudy On Heat Transfer Calculation Method of Ground Heat Exchangers Based On Heat Pump Unit Operation CharacteristicsARPITA SINGHNo ratings yet

- Characterization of Energy Efficient Vapor Compression Cycle Prototype With A Linear CompressorDocument6 pagesCharacterization of Energy Efficient Vapor Compression Cycle Prototype With A Linear CompressorManish KumarNo ratings yet

- Optimization of Data Center Chilled Water Cooling System According To Annual Power Consumption CriterionDocument9 pagesOptimization of Data Center Chilled Water Cooling System According To Annual Power Consumption CriterionKhalid JNo ratings yet

- 4 - Discrete Model-Based Operation of Cooling Tower Based On Statistical AnalysisDocument8 pages4 - Discrete Model-Based Operation of Cooling Tower Based On Statistical AnalysisHoàngViệtAnhNo ratings yet

- Experimental and Numerical Analysis of A Cross-Flow Closed Cooling TowerDocument13 pagesExperimental and Numerical Analysis of A Cross-Flow Closed Cooling TowerMontserratt Escobedo ÁlvarezNo ratings yet

- Section AbstractsDocument35 pagesSection AbstractsAgung Satria WarmanNo ratings yet

- Cooling System Cost and Performance Models For Economics CO2 Plant Optimization With Respect To Cold CO2 TemperatureDocument13 pagesCooling System Cost and Performance Models For Economics CO2 Plant Optimization With Respect To Cold CO2 TemperatureOnofreHalberNo ratings yet

- Issn: 2349-3860Document18 pagesIssn: 2349-3860Pat TejNo ratings yet

- CFD Analysis of Feedwater Flow in The HPLWR Pressure Vessel: Helena - Foulonk@iket - Fzk.deDocument4 pagesCFD Analysis of Feedwater Flow in The HPLWR Pressure Vessel: Helena - Foulonk@iket - Fzk.deSlim KanounNo ratings yet

- Iwess Solar Oct06Document17 pagesIwess Solar Oct06limlianpengNo ratings yet

- Increasing Efficiency of Air Conditioning Systems in High Building by Chiller System Load OptimizationDocument7 pagesIncreasing Efficiency of Air Conditioning Systems in High Building by Chiller System Load OptimizationAklilu BahetaNo ratings yet

- Optimization of The Cooling Tower Condenser Water Leaving Temperature Using A Component-Based ModelDocument11 pagesOptimization of The Cooling Tower Condenser Water Leaving Temperature Using A Component-Based ModelNevzatŞadoğlu100% (1)

- Thermal Performance Assessment of Steam Surface CondenserDocument8 pagesThermal Performance Assessment of Steam Surface CondenserJeeEianYannNo ratings yet

- Section 5: Process IntensificationDocument23 pagesSection 5: Process IntensificationPrince EugoNo ratings yet

- Numerical Study On Flow and Heat Transfer Characteristics of Trapezoidal Printed Circuit Heat ExchangerDocument16 pagesNumerical Study On Flow and Heat Transfer Characteristics of Trapezoidal Printed Circuit Heat ExchangerEng Saif MohanadNo ratings yet

- Refrigeration SystemDocument26 pagesRefrigeration Systemwandee2393No ratings yet

- Prescription For Chiller PlantsDocument4 pagesPrescription For Chiller Plantsblack_3289No ratings yet

- Refrigeration LabDocument16 pagesRefrigeration LabFaizal IbrahimNo ratings yet

- Co2report PrimeDocument11 pagesCo2report PrimeNaveen AnnamalaiNo ratings yet

- Natural Ventilation Jose SantiagoDocument13 pagesNatural Ventilation Jose SantiagoRuta PawarNo ratings yet

- Seminar Report On Magnetic RefrigerationDocument24 pagesSeminar Report On Magnetic Refrigerationsanjay dev50% (2)

- 59E Agitator Seals in Chemical-En-18.09.2008Document24 pages59E Agitator Seals in Chemical-En-18.09.2008Daniel CostaNo ratings yet

- Design and Experimental Analysis of An Efficient HVAC Sysyem On An Electric BusDocument12 pagesDesign and Experimental Analysis of An Efficient HVAC Sysyem On An Electric BusEmre EmlekNo ratings yet

- Thermal Conductivity of Composite Wall ManualDocument11 pagesThermal Conductivity of Composite Wall ManualShoaib PathanNo ratings yet

- Refrigeration ClassificationDocument29 pagesRefrigeration ClassificationSakhawat Hossain SumonNo ratings yet

- PED 5 Heat ExchangersDocument74 pagesPED 5 Heat ExchangersDiogo EstevesNo ratings yet

- Thesis 001Document49 pagesThesis 001James Harrill Torres LaydeaNo ratings yet

- Wang 2016Document15 pagesWang 2016Maria Luisa Sandoval OchoaNo ratings yet

- Extended Range Psychrometric ChartDocument1 pageExtended Range Psychrometric Chartapi-3859258No ratings yet

- (BS EN 15423 - 2008) - Ventilation For Buildings. Fire Precaution For Air Distribution Systems in Buildings.Document28 pages(BS EN 15423 - 2008) - Ventilation For Buildings. Fire Precaution For Air Distribution Systems in Buildings.Simon ThaonNo ratings yet

- CIBSE Covid Ventilation Guidance Version 2Document17 pagesCIBSE Covid Ventilation Guidance Version 2Fabina Suso0% (1)

- Ansiariashraeiso13256 2 1998Document16 pagesAnsiariashraeiso13256 2 1998damaso taracenaNo ratings yet

- Ehad Hussainabad HvacDocument4 pagesEhad Hussainabad Hvacashar jafferyNo ratings yet

- Manual Instrucciones Rs 20 20Document3 pagesManual Instrucciones Rs 20 20Armand BasyNo ratings yet

- RAC Assignment 1Document9 pagesRAC Assignment 1basantNo ratings yet

- Instruction Manual PHE PDFDocument78 pagesInstruction Manual PHE PDFzniperxNo ratings yet

- Determine Heat LoadDocument3 pagesDetermine Heat LoadBhawani Pratap Singh PanwarNo ratings yet

- Industrial & Engineering Chemistry Volume 28 Issue 12 1936 (Doi 10.1021/ie50324a027) Sieder, E. N. Tate, G. E. - Heat Transfer and Pressure Drop of Liquids in TubesDocument7 pagesIndustrial & Engineering Chemistry Volume 28 Issue 12 1936 (Doi 10.1021/ie50324a027) Sieder, E. N. Tate, G. E. - Heat Transfer and Pressure Drop of Liquids in Tubesrahulsaini855No ratings yet

- Revision Heating and Cooling 2023Document9 pagesRevision Heating and Cooling 2023Mohib MahmudNo ratings yet

- Pages From ASHRAE HVAC Design Manual For Hospitals & Clinics-2013 (Orignal)Document1 pagePages From ASHRAE HVAC Design Manual For Hospitals & Clinics-2013 (Orignal)3obaydoofNo ratings yet

- Answer - HEat and ThermodyanamicsDocument5 pagesAnswer - HEat and ThermodyanamicsAshik jhaNo ratings yet

- Effect of Moisture On The Thermal Conductivity of Cellulose and Aramid Paper Impregnated With Various Dielectric LiquidsDocument17 pagesEffect of Moisture On The Thermal Conductivity of Cellulose and Aramid Paper Impregnated With Various Dielectric Liquidsnamsaigon316No ratings yet

- FR Gboard Tds21Document1 pageFR Gboard Tds21rangarajan1989100% (1)

- Ice PlantDocument53 pagesIce PlantSandeep MagapuNo ratings yet

- International Journal of Heat and Mass Transfer Volume 102 Issue 2016 (Doi 10.1016/j.ijheatmasstransfer.2016.06.078) Straubhaar, B. Pauchet, J. Prat, M. - Pore Network Modelling of Condensation IDocument11 pagesInternational Journal of Heat and Mass Transfer Volume 102 Issue 2016 (Doi 10.1016/j.ijheatmasstransfer.2016.06.078) Straubhaar, B. Pauchet, J. Prat, M. - Pore Network Modelling of Condensation IRyan Eka JuniawanNo ratings yet

- Batch 5 Study and Analysis of Fluid Flow Rate For Different Concentrate in Compact Heat Exchanger-Converted-1Document68 pagesBatch 5 Study and Analysis of Fluid Flow Rate For Different Concentrate in Compact Heat Exchanger-Converted-1Tirupati Reddy GuduriNo ratings yet

- ABAQUS User SubroutineDocument18 pagesABAQUS User Subroutineknan1100% (1)

- KR - Single Package - R410A - 60Hz - CO - Saudi - MFL67452905 - 6CUK0-01B - 130916-10TRDocument58 pagesKR - Single Package - R410A - 60Hz - CO - Saudi - MFL67452905 - 6CUK0-01B - 130916-10TR1969MAZHARNo ratings yet

- Important Topics For GATE PDFDocument6 pagesImportant Topics For GATE PDFVivek BhatiaNo ratings yet