Professional Documents

Culture Documents

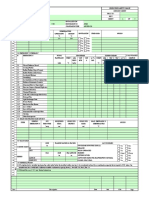

DehydrationTEG Unit

Uploaded by

Jermaine Heath0 ratings0% found this document useful (0 votes)

153 views2 pagesThis document provides specifications for several glycol dehydration units including minimum and maximum operating parameters. Key details include:

- Unit locations and gas characteristics at absorber inlets including minimum pressures, maximum temperatures, and gas flow rates.

- Required water dew points and dry gas water content specifications.

- Calculations of the maximum water content of inlet gas and amount of water to be removed by each unit.

- Determination of minimum lean glycol concentrations and selection of main process parameters for the absorption process.

- Sizing of major equipment including absorber diameter, reboiler heat duties, and glycol circulation rates.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides specifications for several glycol dehydration units including minimum and maximum operating parameters. Key details include:

- Unit locations and gas characteristics at absorber inlets including minimum pressures, maximum temperatures, and gas flow rates.

- Required water dew points and dry gas water content specifications.

- Calculations of the maximum water content of inlet gas and amount of water to be removed by each unit.

- Determination of minimum lean glycol concentrations and selection of main process parameters for the absorption process.

- Sizing of major equipment including absorber diameter, reboiler heat duties, and glycol circulation rates.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

153 views2 pagesDehydrationTEG Unit

Uploaded by

Jermaine HeathThis document provides specifications for several glycol dehydration units including minimum and maximum operating parameters. Key details include:

- Unit locations and gas characteristics at absorber inlets including minimum pressures, maximum temperatures, and gas flow rates.

- Required water dew points and dry gas water content specifications.

- Calculations of the maximum water content of inlet gas and amount of water to be removed by each unit.

- Determination of minimum lean glycol concentrations and selection of main process parameters for the absorption process.

- Sizing of major equipment including absorber diameter, reboiler heat duties, and glycol circulation rates.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 2

DGEP J ob : Unit :

Service : Date : Rev.:

GLYCOL (TEG) DEHYDRATION UNIT CHARACTERISTICS

Unit Yadana Tunu north Alwyn Timimoun

GAS CHARACTERISTICS at absorber inlet

Minimun pressure bar abs 105.5 66 68.5 80

Maximun temperature C 49 45 32 60

Maximun gas flowrate (1 Sm3=35,383 SCF) 10^6 SCFD 495.36 495.36 318.44 106.15

Maximun gas flowrate 10^6 Sm3/day 14 14 9 3

WATER DEW POINT REQUIRED

Water dew temperature required C -4.2 10 -11

Reference pressures bar abs 105 66 68

Dry gas water content kg/10^3 Sm3 0.0642 0.219 0.055

Dry gas water content lb/10^6 Scuft 4.00 13.65 3.43

AMOUNT OF WATER TO BE REMOVED

Maximun water content of inlet gas (Fig.IV-A1) Wi kg/10^3 Sm3 1.25 1.6 0.72 1

Design water dew temp. of dry gas ( dew temp.required - 5C ) -9.2 5 -16 -5

Maxi water content of dry gas ( Fig. IV-A1) Wo kg/10^3 Sm3 0.046 0.16 0.04 0.05

Amount of water to be removed by TEG unit kg/h 772.57 840.00 255.00 118.75

(With the margin of 10% recommended in SPEC GS ECP 101)

Minimun lean TEG concentration

Equilibrium water dew temp. (design water dew temp.-10 C) C -19.2 -5 -26 -15

Minimun lean TEG concentration (Fig.VII-B2) C % w 99.65 98.8 99.55 99.55

Activity coefficient ( Fig.VII-B3) Gamma 0.617 0.667 0.63 0.57

Main process parameters of the absorption

Lean TEG concentration adopted (range : 98,8 - 99,9) C % w 99.7 98.85 99.8 99.5

Activity coefficient correspondent (Fig. VII-B3) Gamma 0.617 0.667 0.58 0.59

Lean TEG / removed water ratio adopted r ( kg/kg ) 27 24 35.4 28

Minimun specified by SPEC GS ECP 101( Average value:27,5 kg/kg ; range:15 - 35 ) 23.63 22.20 27.28 25.00

Number of theoritical plates for the absorber adopted n 2.2 2 1.5 2

Absorption factor calculated A 5.16 4.21 7.01 5.60

R 329.66 86.08 504.38 194.19

Lean TEG concentration calculated C % w 99.70 98.85 99.80 99.49

( C adopted is modified untill its value is equal to the C calculated)

Glycol (TEG) unit Process characteristics

Lean TEG circulation rate kg/hour 18963 20160 9027 3325

Lean TEG density kg/liter 1.1 1.105 1.115 1.1

Lean TEG circulation rate liters/hour 17239 18244 8096 3023

Minimun rich TEG concentration c % w 96.14 94.90 97.06 96.06

Number of theoritical plates for the stripping column (usual max =1) 1 1 1 1

Stripping gas flowrate ( Fig.VII -B6) Sm3/m3 TEG 14 0 22 22

Stripping gas flowrate Sm3/hour 241 0 178 67

Reboiler minimun heat duty (SPEC GS ECP 101) kcal/kg 1970.00 1857.50 2285.00 2007.50

Reboiler minimun heat duty (SPEC GS ECP 101) 10^6 kcal/h 1.52 1.56 0.58 0.24

Reboiler installed heat load ( oversizing included ) 10^6 kcal/h 1.85 1.96 0.87 0.32

MAIN EQUIPMENT SIZING

ABSORBER

Gas density @ drying process conditions kg/m3 87.20 62.90 73.00 63.00

Gas molar mass kg/kmol 20.28 20.28 20.64 18.00

Absorber diameter with bubble caps plates (with an over design of 10%) m 3.69 3.98 3.10 1.74

Absorber diameter with structured packing m 2.84 3.06 2.39 1.34

Glycol flowrate with structured packing ( mini =1m/h ) m/hour 2.71 2.47 1.81 2.15

Timimoun

50

0.64

275000

0.55

You might also like

- Process Calculation Sheet Tag No.: 1. PurposeDocument10 pagesProcess Calculation Sheet Tag No.: 1. PurposeAJAY1381No ratings yet

-  Process Calculation: CRU Revamp Project Heavy Naphtha Splitter Btms Pumps (6104J/JA)Document16 pages Process Calculation: CRU Revamp Project Heavy Naphtha Splitter Btms Pumps (6104J/JA)KalpeshJadhavNo ratings yet

- DDG-T-P-03310 Condensate StripperDocument11 pagesDDG-T-P-03310 Condensate StripperCristinaNo ratings yet

- DJM-MBA-PCS-CA-008 Low Temperature Separator REV-BDocument6 pagesDJM-MBA-PCS-CA-008 Low Temperature Separator REV-BDIANTORONo ratings yet

- Steam CoilDocument6 pagesSteam CoilMyung Ho SynNo ratings yet

- Shell K.O.drum SeparatorDocument11 pagesShell K.O.drum SeparatorChitu Ionut LaurentiuNo ratings yet

- 8-0241-4503-Flare System Design PDFDocument8 pages8-0241-4503-Flare System Design PDFVinothrajaNo ratings yet

- Rigorous Method For Fire CaseDocument4 pagesRigorous Method For Fire CaseFlorin Daniel AnghelNo ratings yet

- Flare Stack Design PDF ReportDocument2 pagesFlare Stack Design PDF Reportrutuja100% (2)

- BDVDocument3 pagesBDVJason ThomasNo ratings yet

- Sample Sheet: Supply of PF Process Calculation Spreadsheet (Excel Forma)Document15 pagesSample Sheet: Supply of PF Process Calculation Spreadsheet (Excel Forma)Mustafa AhsanNo ratings yet

- FlareTot - Total Flare AnalysisDocument8 pagesFlareTot - Total Flare AnalysisArjun KapoorNo ratings yet

- Pipe Distributor Sizing Calculations - 07-08-2013Document26 pagesPipe Distributor Sizing Calculations - 07-08-2013pelotoNo ratings yet

- Heat Exchanger Sizing AC-6050 #1Document2 pagesHeat Exchanger Sizing AC-6050 #1Luis Enrique Leyva OvalleNo ratings yet

- MP Separator1Document2 pagesMP Separator1ToyinNo ratings yet

- 4 - 02. Section II - 4420003405Document137 pages4 - 02. Section II - 4420003405JonesNo ratings yet

- R1111-DSH-PL-00-021 - DATA SHEET FOR PIG LAUNCHER-Rev 0ADocument4 pagesR1111-DSH-PL-00-021 - DATA SHEET FOR PIG LAUNCHER-Rev 0AAHMED AMIRANo ratings yet

- KIRK Sep-Calc SoftwareDocument4 pagesKIRK Sep-Calc Softwaredhl_tuNo ratings yet

- 720-C-001 (Vent Wash Column)Document4 pages720-C-001 (Vent Wash Column)idilfitriNo ratings yet

- 31-MBD-127 Inlet Separator-Rev.0 (On Pile)Document53 pages31-MBD-127 Inlet Separator-Rev.0 (On Pile)Didi Hadi RiantoNo ratings yet

- 140 V 023Document4 pages140 V 023Goutam GiriNo ratings yet

- Distillation Theoretical Stages CalculatorDocument1,557 pagesDistillation Theoretical Stages Calculatorgautam_96948069No ratings yet

- SeparatorDocument23 pagesSeparatorLeonardo Ramirez GuzmanNo ratings yet

- Fire Heat Flux To Un-Wetted VesselDocument0 pagesFire Heat Flux To Un-Wetted VesselImtinan MohsinNo ratings yet

- Spreadsheet To Design SeparatorsDocument21 pagesSpreadsheet To Design SeparatorsreninbabaskiNo ratings yet

- Gas Liquid Seperation by VesselsDocument2 pagesGas Liquid Seperation by VesselszapspazNo ratings yet

- Unlock Separator SizingDocument42 pagesUnlock Separator SizingmortezasabetiNo ratings yet

- PSV D-103Document24 pagesPSV D-103DIANTORONo ratings yet

- Korf Tutorial PDFDocument17 pagesKorf Tutorial PDFAadi Khan100% (1)

- Petronas Design Manual: Column SizingDocument10 pagesPetronas Design Manual: Column SizingHazizi AkmarNo ratings yet

- Training CaseDocument15 pagesTraining CaseThái Xuân QuangNo ratings yet

- 31.PEAK Depressurization RATEDocument1 page31.PEAK Depressurization RATEDILIP MATALNo ratings yet

- PROII 8.1 Getting Started GuideDocument139 pagesPROII 8.1 Getting Started Guidekingcobra008100% (2)

- Gpsa PDFDocument4 pagesGpsa PDFmehdiNo ratings yet

- Relief and Blowdown Report: Page 1 of 21Document21 pagesRelief and Blowdown Report: Page 1 of 21TarekNo ratings yet

- Pump CalcDocument1 pagePump CalcMoch WildanNo ratings yet

- HMB For Preheat TrainDocument8 pagesHMB For Preheat TrainHassaanNo ratings yet

- 3Ph Vert Sep 2010 Weir VerA FPS PDFDocument5 pages3Ph Vert Sep 2010 Weir VerA FPS PDFhaiderNo ratings yet

- M-01-DS-0003 Specification Sheet: Date REV Prepared by Checked by Approved by DescriptionDocument2 pagesM-01-DS-0003 Specification Sheet: Date REV Prepared by Checked by Approved by DescriptionAJAY1381No ratings yet

- Routine Is Based On API 521 Recommended Practice For Sizing of Relief KO DrumsDocument3 pagesRoutine Is Based On API 521 Recommended Practice For Sizing of Relief KO DrumsMohamed Sayed AbdoNo ratings yet

- Section 7 - Separation EquipmentDocument9 pagesSection 7 - Separation Equipmentlulis171No ratings yet

- DJM MBA PCS CA 011 de Butanizer Accumulator REV 1Document6 pagesDJM MBA PCS CA 011 de Butanizer Accumulator REV 1DIANTORONo ratings yet

- Revised Process Datasheet For Deaerator Ma-1018 - Rev 001 - SignedDocument10 pagesRevised Process Datasheet For Deaerator Ma-1018 - Rev 001 - SignedAnonymous bHh1L1No ratings yet

- Control Valve Sizing - Gas Rev 3.1bDocument3 pagesControl Valve Sizing - Gas Rev 3.1bLuis RamirezNo ratings yet

- Line ListDocument1 pageLine Listهيمنت بيلودياNo ratings yet

- Line Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Document12 pagesLine Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Engr TheyjiNo ratings yet

- Process Engineer - PSV SizingDocument3 pagesProcess Engineer - PSV SizingLaorenciaNo ratings yet

- Control Valve Hydraulics-GasDocument6 pagesControl Valve Hydraulics-GasganeshdhageNo ratings yet

- Tank Emisiion CalcDocument16 pagesTank Emisiion CalcAdhe GedeNo ratings yet

- Tube Rupture (Two Phase-Omega Method) PDFDocument1 pageTube Rupture (Two Phase-Omega Method) PDFAmin RoisNo ratings yet

- Calculation Sheet - Working Volume - Piping UpdateDocument4 pagesCalculation Sheet - Working Volume - Piping UpdateamiyachemNo ratings yet

- Psvcalculationsflare 130225000902 Phpapp02 UnprotectedDocument116 pagesPsvcalculationsflare 130225000902 Phpapp02 UnprotectedMike DukasNo ratings yet

- No Yes No Yes No Yes No Yes No Yes No YesDocument8 pagesNo Yes No Yes No Yes No Yes No Yes No YesEkundayo JohnNo ratings yet

- Set Depressuring Model Dimensions To Get More Accurate Results - AutosavedDocument4 pagesSet Depressuring Model Dimensions To Get More Accurate Results - Autosavedoverlord5555No ratings yet

- Vertical Separator SizingDocument3 pagesVertical Separator SizingIRVINGNo ratings yet

- NKGSB-PRS-CL-007-A4-A Fire Water Demand Calculation2 (Autosaved-26-01-20)Document15 pagesNKGSB-PRS-CL-007-A4-A Fire Water Demand Calculation2 (Autosaved-26-01-20)ahmad santoso100% (1)

- Coal Gas Urea Complex DesignDocument23 pagesCoal Gas Urea Complex DesignOsama HasanNo ratings yet

- 1500 TPD Ammonia ProductionDocument178 pages1500 TPD Ammonia ProductionRana Uzair100% (1)

- Bio Gas G3516 Technical Data - S02!35!03Document2 pagesBio Gas G3516 Technical Data - S02!35!03Fatah FatanNo ratings yet

- Material Stream: Gas Mainfold: ConditionsDocument4 pagesMaterial Stream: Gas Mainfold: ConditionsMohammed Gad-AllahNo ratings yet

- Chart TitleDocument1 pageChart TitleJermaine HeathNo ratings yet

- Vessel (Drum) SizingDocument1 pageVessel (Drum) Sizingzamijaka100% (1)

- Horizontal 2 Phase Separator SizingDocument10 pagesHorizontal 2 Phase Separator SizingJermaine Heath100% (1)

- Knock Out KO Drum SizingDocument10 pagesKnock Out KO Drum SizingJermaine HeathNo ratings yet

- Vertical 2 Phase Separator SizingDocument5 pagesVertical 2 Phase Separator SizingJermaine Heath100% (1)

- Visualizing The Mccabe-Thiele Diagram: Reactions and SeparationsDocument9 pagesVisualizing The Mccabe-Thiele Diagram: Reactions and SeparationsMicheal BrooksNo ratings yet

- SIL Selection SpreadsheetDocument21 pagesSIL Selection SpreadsheetJermaine Heath100% (4)

- 4 Guidance On Valve Type SelectionDocument86 pages4 Guidance On Valve Type SelectionKrista OneillNo ratings yet

- TP - Heat Exchanger Design BasisDocument42 pagesTP - Heat Exchanger Design BasisduurkahinNo ratings yet

- P&id Slug CatcherDocument1 pageP&id Slug CatcherewfsdNo ratings yet

- Be Smart About Column DesignDocument7 pagesBe Smart About Column DesignJermaine HeathNo ratings yet

- Calling A Fortran DLL From ExcelDocument7 pagesCalling A Fortran DLL From ExcelJermaine HeathNo ratings yet

- SVPL PDFDocument68 pagesSVPL PDFSales SVPLNo ratings yet

- Em01d29 PDFDocument4 pagesEm01d29 PDFJack CardiagNo ratings yet

- Floating Head Heat Exchanger MaintenanceDocument15 pagesFloating Head Heat Exchanger MaintenanceAbdullah Dinsuhaimi100% (8)

- Poison Test PlanDocument29 pagesPoison Test PlanDinesh KumarNo ratings yet

- Week 4 Disc Brake System - Lecture PDFDocument76 pagesWeek 4 Disc Brake System - Lecture PDFamr yosryNo ratings yet

- FMC Hydraulic ActuatorsDocument2 pagesFMC Hydraulic ActuatorsLuciano Fucello57% (7)

- Manual - CompAir Hydrovane HV11-15 (2006)Document34 pagesManual - CompAir Hydrovane HV11-15 (2006)Muzakki Putra83% (6)

- Tata Steel Strip Product Range Catalogue 2018Document232 pagesTata Steel Strip Product Range Catalogue 2018OmkarNo ratings yet

- 132 30422 182 PDFDocument10 pages132 30422 182 PDFJJNo ratings yet

- Operation of Centrifugal Clutch: Presented ByDocument12 pagesOperation of Centrifugal Clutch: Presented BybilalfocusNo ratings yet

- C5-21B B777 CapabilitiesDocument8 pagesC5-21B B777 CapabilitiesPablo Restrepo OssaNo ratings yet

- ItemsDocument204 pagesItemsfattaninaveed786100% (1)

- Mercado 2001 Modeling Flow and Heat Transfer in Tubes Using A Fast CFD FormulationDocument10 pagesMercado 2001 Modeling Flow and Heat Transfer in Tubes Using A Fast CFD FormulationeliastorcaNo ratings yet

- 1T 8l qbY498zmSUk-zDBJXfZWsKEjcu5 PDFDocument58 pages1T 8l qbY498zmSUk-zDBJXfZWsKEjcu5 PDFANH LÊ100% (1)

- Motores EficienciaDocument35 pagesMotores EficienciapatricioNo ratings yet

- HW#5 SolutionDocument5 pagesHW#5 Solutionmtydaics100% (2)

- SR Energy Services: No. 24, 6th Street, Iyyappa Nagar, Madipakkam, Chennai-600091Document1 pageSR Energy Services: No. 24, 6th Street, Iyyappa Nagar, Madipakkam, Chennai-600091sadhanaNo ratings yet

- 200kN-TW Trailer Mounted - 2009 Until 31-12-2009Document1 page200kN-TW Trailer Mounted - 2009 Until 31-12-2009Adakole ObekaNo ratings yet

- 00 Catalogue Update UK PDFDocument7 pages00 Catalogue Update UK PDFhepcomotionNo ratings yet

- 9 Types of Maintenance - How To Choose The Right Maintenance StrategyDocument10 pages9 Types of Maintenance - How To Choose The Right Maintenance StrategydejanNo ratings yet

- COF069115 05 Systemlosungen Broschure en RZ WebDocument11 pagesCOF069115 05 Systemlosungen Broschure en RZ WebAnonymous TThmYKFpNo ratings yet

- Dozer: 10 50J Waste HandlerDocument6 pagesDozer: 10 50J Waste Handlerwalk01No ratings yet

- Restoration of The Contact Surface in The HLL-Riemann SolverDocument10 pagesRestoration of The Contact Surface in The HLL-Riemann SolverRafael HenriqueNo ratings yet

- Actuadores Field Devices Spare Parts Catalogue 2010Document34 pagesActuadores Field Devices Spare Parts Catalogue 2010Héctor IbáñezNo ratings yet

- 329E IntroDocument48 pages329E IntromouhsineNo ratings yet

- Eaton Lubricant Suppliers TCMT0020 EN-US: Lubrication GuideDocument13 pagesEaton Lubricant Suppliers TCMT0020 EN-US: Lubrication Guideluis_dominguezeNo ratings yet

- I Removal of TurbochargerDocument6 pagesI Removal of TurbochargerDavid QuispeNo ratings yet

- Looking After Your Rotax 912 Series EngineDocument20 pagesLooking After Your Rotax 912 Series EngineDimitris SarmasNo ratings yet

- Hw10-Projectreport BellDocument11 pagesHw10-Projectreport Bellapi-306934489No ratings yet