Professional Documents

Culture Documents

Exp 2

Uploaded by

prop_kcpOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Exp 2

Uploaded by

prop_kcpCopyright:

Available Formats

Exercise

3

The MOSFET

Four-Quadrant

chopper

Drive

OBJECTIVE

.TobecomefamiliarwiththeuseofaMosFETfour-quadrantchopperdriving

a dc motor

.

To achieve open-loop

and closed-loop

control

DISCUSSION

ln this exercise we will study the operation of a four-quadrant

chopper driver' This

type of driver altows ;p;ah ot t'he machine in each of the four

quadrants of the

converter V-l plane, ,! .no*n in Figure 3-1. so far in this manual,

we were able

to control a macnine in quadrants I and + (or, by reversing the connections

on

the armature of the dc motor, in quadrants 2 and 3)'

Figure 3-1. Four'quadrant

operalion of the chopper drive'

To allow four-quadrant

operation, the driver must

permit the current to flow in

either direction and tne pbLrity oi the voltage to be reversed'.Figure

3-2 shows

a simplified torr-qraOrlnt

.nopp"t drivd using an H-bridge

configuration'

3-1

The

MOSFET

Four-Quadrant

Chopper

Drive

Figure3-3showsthesymbolusedinthismanualtorepresentthesameconverter

configuration.

Flgure

3'2' Simplilied

four-quadrant

chopper

drive'

lnthefour-quadrantchopper'MO:FET'areswitchedinpairs;Q'andQu'Q'and

Qo.

when

one

pair

"i-rri5sirrs

is on,- tnt

.ii."i'1.

ott'

rn"

dc voltage

at the

output

of the touuqu"jr"rli

.nopp", rv.io"p"nos

on tne duty

cycle

of the

switching

control

.ignrl..

The following

"qLrtibn

expresses

the

relation

between

V, and

Vo.

Vo

=

V,x

(2co, -

1)

Theclosed-loopspeedcontrolwillbeachievedusingaSpeedSensorl

tr"nom"t"r

and a P'l'D'

controller'

D4

osJ

POilER UOSrgrs

(a8Sz)

o

FOUR-OUADR^}II

CHOPPER

- L-

I rtos

iY cffi

1nE

@

Figure

3-3. Symbol

represenling

the lour'quadranl

chopper'

['*

3-2

_E

The

MOSFET

Four-Quadrant

Chopper

Drive

Procedure

summary

lnthefirstpartoftheexercise,youwillsetuptheequipmentrequiredtocarryout

this

experiment'

ln the second

part of this exercise'

yoy

-Yll

use the circuit

shown

in Figure

3-4 to

.i,Jvop"n-,qep::ti:lf,iXg-".,{?"..;1;;1"*ffi S','H:rXH[:T:*lIf:!!i

b; *iil be attached

to the d"

lY::::':::i':""*1"' ,-nr'"t,"ture

current

and

of the

system'

vou

*iff'o[J*

on the

oscilloscope

the

armz

votage

waveforms

til';iff

;ltor

acceleration

and

deceleratton'

ln the last

part of the exercise'

yoy wil]'implement

closed-loop

speed

control

of

the dc motor

u.ing'f

;r;:;ir;rr"r.

vor"*jiit

"ov

tn" response

of the svstem

to speed

variations'ii;;;g

ih" ot

191i'

t"'ine

svncnronous

generator'

you will

also

study

'n"

'"toJnt;';i

th; system

to load

variations'

EOUIPMENT

HEOUIRED

Refertothe

Equipment

Utilisation

Chart'

Apq?n1":-^?]this

manual'

to obtain

the

tist of the

"q'ipm"ni'ilquit"o

to carry

out this

exercrse'

PR..EDUBE

cAurloN!

Hishvortasesarepre_sent;HT"":X?"#:3"tri;T:'0"?"",'$

make

or modity

anY ba-nant

unless

otherwise

sPecilieo!

Setting

uP the equiPment

tr

1' lnstall

the

Power

Supply'

-the

Enclosure

l'?Y"t

Supply'

the DC

Motor/Generator'

the Power

'iSsiiii'ir'"

oc voltmeter/

Ammeter'

and

,n"

=*lTifii,i;iil;;i"ts

in tne Mobile

workstation'

lnstalltheChopper/lnverterControlUnit,theCurrentlsolatorandthe

Vort'g"'ft"]""Ii"

the Enclosure

/

Power

Supply'

n2'lnstallthelnertiaWheelon.theshaftoftheDcj/otor/Generator'Verify

that

th; rnertia

wheer

i. ,rt"rv=.".ii"J

on the Dc Motor

shaft'

tr3'MakesurethatthemainpowerswitchofthePowerSupplyissettothe

o

(oFF)

position'

conn"t'*t]i""

po*"i Supply

to a three-phase

wall

receptacle'

Set the rocker

switch

of'the

Enclosure

/

Power

Supply

to the

O (OFF)

position.

Plug

the

en"ro.I,,!',i;;;;

suppty-tine

cord

into

a wall

recePtacle'

The MOSFET Four-Quadrant Chopper Drive

tr 4. Connect the modules as shown in Figure 3-4.

X' SYI*. O'JTPUI OF Il+E

POTEF I'('SFETS TOUIE

TO CI'RTENI

ISCTIIfi OUIPUT

IO \OLTTCE

60ut(n oumrt

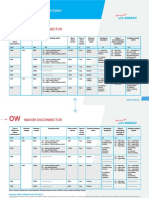

trs.

LINL.

VOLIAGE

(voc)

L1

(H)

E

1dc

lldc

(A)

et

(v)

l1

(A)

120 0.2 r50 5.0 500 !0

220 0.8 300 2.5 600 5

240 0.8 500 2,5 600 5

Figure 3-4. Circuil ot rhe MOSFET tour-quadrant chopper driving a DC Motor.

Set the rocker switch of the Enclosure / Power Supply to the I

position and make the following settings:

On the Power Supply

(oN)

VoltageSelector

......7-N

On the POWER MOSFETS

lnterconnection switch S, . . .

On the Chopper

/ lnverter Control Unit

DC SOURCE 1 mid position

DC SOURCE? . . mid position

MODE CHOP. PWM

CHoPPER

/

INVERTER

CONTROL UNIT

3-4

The MOSFET

Four-Quadrant

chopper

Drive

On the OscilloscoPe

Channel-1 SensitivitY

Channel-2

SensitivitY

s V/DIV.

(DC couPled)

2 V/DIV.

(DC couPled)

Vertical Mode .

CHOPPed

0.2 ms/DlV.

Time Base

Trigger Source

EKIernal

TriggerSloPe

,.

'

positive (+

)

TriggerCouPling

...

HF REJection

The four-quadrant

chopper driving a dc motor with an inertia wheel

tr 6. on the Power supply, make sure that the voltage control knob is set to

the0position,thensettne24-Yacpowerswitchand.themainpower

switch to the l' (oN) position. Adiust the voltage control

knob to the 100

Position

(1OO% of line voltage)'

Set the DC Motor/Generator

lield current to its nominalvalue

using the

field rheostat'

tr 7. on the oscilloscope, make the appropriate settings to position the traces

ofchannels,land2intheupperandlowerhalvesofthescreen,

respectively

tr 8. Use the Dc souRcE 1 (Duty cycle) knob on the chopper / lnverter

control unit to slowly vary the ipeeo of the dc motor. observe the

voltage and current signais. What happens during acceleration and

deceleration?

n9.

Note: An over-current

protection circuit built into the Power

MOtrEls module will limit the peak current, during abrupt

acc eleratio n or d ec ele ratio n, to an acceptab le value' Wtho ut this

protection, the current surge coutd damage the motor and/orthe

diwr.

lnstall a P.l.D. Controller in the Mobile workstation. You will modify your

circuit to add filtering to the voltage and current isolator outputs' as

shown in Figure 3-5.

The MosFET

Four-Quadrant

chopper

Drive

ro cuinHr Fourltn

o('lft'T

ro vurr6E Eq.lrn

drr?ttl

Figure 3-5. Oscllloscope

connectlons'

tl 10. Make the following settings:

On the P.l.D. Controller

LOWPASS FILTER-1 CUTOFF FREOUENCY

. , .

LOWPASS FILTER.2 CUTOFF FREQUENCY

. . .

On the OscilloscoPe

0.s v/Dlv.

Channel-1 SensitivitY

Channel-2 SensitivitY

1 V/DIV.

MAX

MAX

(GND)

(GND)

Venical Mode...

Time Base

Adjust the FILTER-1 and FILTER-2 cutoff frequencies

to filter the voltage

and current signals'

A dot shoulcl appear on the oscilloscope

screen. set the horizontal

and

vertical

position controls on the oscilloscope

to centre

_the

dot on the

screen, ihen set the input coupling switches of the x and Y channels to the

DC position.

X-Y

X-Y

trll.TurntheDcSoURcEl(DutyCycle)knobfullyclockwiseonthe

Chopper/lnverterControlUnit.WaituntilthemotorspeedStabilizes.

Observe the oscilloscope screen and describe what happens while slowly

turning the DC SOURCE 1 control knob lully counterclockwise'

Explain'

3-6

The MOSFET Four-Quadrant Chopper Drive

tr 12. Adjust the DC SOURCE 1 control to its mid position to stop the motor.

Turn the control knob on the Power Supply to zero (completely

counterclockwise) and turn off the power. Turn off the Enclosure / Power

Supply.

Closed-loop speed control

tr 13. Remove the lnertia Wheel from the DC Motor shaft. lnstall the Three-

Phase Synchronous Motor / Generator and the Resistive Load in the

Mobile Workstation. Use the Timing Beh to link the DC Motor to the

Synchronous Generator. Connect the modules as shown in Figure 3-6.

tr 14. Set the rocker switch of the Enclosure / Power Supply to the | (ON)

position and make the following settings:

On the Chopper / lnverter Control Unit

DCSOURCE1 ... midpos.

DCSOURCE} ....,................. MAXimum

MODE . CHOP. PWM

On the Three-Phase Synchronous Motor/Generator

Toggle Switch I (close)

Field-Current control knob reference position

On the P.l.D. Controller

LOW-PASS FILTER-2 CUTOFF FREOUENCY . . . mid pos.

FEEDBACK AMPLIFIER GAIN . 1/3 of range

PROPORT1ONAL GAIN LOW, MAXmum

INTEGML GAIN .

'ti3

of range

UPPERLIMIT .,. MAXimum

LOWERLIMIT. ,. MAXimum

ANTI-RESET ......I

tr 15. Ori the Power Supply, make sure that the voltage control knob is set to

the 0 position, then set the 24-V ac power switch and the main power

switch to the I (ON) position. Adiust the voltage control knob to the 100

position (100% of line voltage).

tr 16. lncrease the dc motor speed to maximum by turning the DC SOURCE 1

control knob, on the Chopper / lnverter Control Unit, fully clockwise. Use

the FEEDBACK AMPLIFIER GAIN to ser rhe maximum speed of the dc

motor to looo r/min.

3-7

Circuit Diagram Symbols

SYMBOL EQUIPMENT AND CONNECTIONS

o

@

o

o

@

@

@

@

@

@

@

o

THREE.PI{ASE

WATTMETER

/

VARMETER

@

+l

I

r,

l"ry 6

ll

cou.l

@

CURRENT ISOUTOR

o

*l

|

",

ls{l, o

tt

cou.l

@

VOLTAGE ISOLATOR

g-1-ry.,

I cuRRENr I I

l"Fr''iSbtLT

*'-'l

lo

@U'

r Note: Sclcct the terminol which

corrcsponds to the desired scole

g-1-ry.,

I vor-rrce I I

l*""''i8bt''T

*'*'l

f@

@U'

r Notc: Sclcct thc tcrminol which

coresponds to the dcsired scole.

A-5

Circuit Diagram Symbols

SYMBOL

OC INOEPENOANT-RELO

MOTOR

EQUIPMENT AND CONNECTIONS

OC MOTOR

,/ GENEMTOR

(E2l 1

)

LINL

VOLTAGE

(voc)

lFdc

(mA)

120 500

220 500

240 500

SYNCHRONOUS

MOTOR ,/ GENERATOR

(az+ t

)

r---

---l

oo

SYNCHRONOUS

MOTOR

o

@

o

SPEEo SENSOR

/

TACHOMETER

A-7

Circuit

Diagram

Symbols

@

o

o

@

SYMBOL

@

BUCK/B@ST

CHOPPER

FOUR.QUAORA.II

CHOPPER

EQUIPMENT

AND CONNECTTONS

POWER MOSFm (8857)

t---

i

o,

-l

L--

-___t

I srrc+rm

9Il cornq-

'l lFrrts

@

o

@

o

@

POWER MOSFETS (8857)

A-11

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Exp 1: SCR SwitchDocument4 pagesExp 1: SCR Switchprop_kcpNo ratings yet

- Disassembling System Unit Procedure and Safety PrecautionsDocument28 pagesDisassembling System Unit Procedure and Safety PrecautionsLourent Villy Conlu Casayuran100% (5)

- Experiment 3 Buck ConverterDocument8 pagesExperiment 3 Buck Converterprop_kcpNo ratings yet

- Experiment 2 BJT SwitchDocument6 pagesExperiment 2 BJT Switchprop_kcp50% (2)

- Experiment 2 BJT SwitchDocument6 pagesExperiment 2 BJT Switchprop_kcp50% (2)

- Exp 1Document11 pagesExp 1prop_kcpNo ratings yet

- 4 ARM Parallelism PDFDocument10 pages4 ARM Parallelism PDFjehuNo ratings yet

- Lab. Experiment 1: Verification of Mesh Analysis Date:27/09/2021 Lab. Slot: L31+L32 Name: Ayush Giri Reg. No.: 21BDS0031Document11 pagesLab. Experiment 1: Verification of Mesh Analysis Date:27/09/2021 Lab. Slot: L31+L32 Name: Ayush Giri Reg. No.: 21BDS0031psNo ratings yet

- Statcom PDFDocument38 pagesStatcom PDFيوسف خضر النسورNo ratings yet

- 3 Transmission Line Modelling and PerformanceDocument22 pages3 Transmission Line Modelling and PerformanceDharamNo ratings yet

- B-63494EN - 01 - Fin (Dual Check Safety Ops Man)Document268 pagesB-63494EN - 01 - Fin (Dual Check Safety Ops Man)nzbradNo ratings yet

- Valliammai Enginering College Department of Mechanical EngineeringDocument6 pagesValliammai Enginering College Department of Mechanical EngineeringMani KandanNo ratings yet

- lm2940 NDocument33 pageslm2940 NFly Jesus Yesca PrzNo ratings yet

- 05a3 - E70 Comfort AccessDocument18 pages05a3 - E70 Comfort AccessAlwyn KalapuracanNo ratings yet

- Propagation Analysis of Radio Frequency (RF) Signal of Love FM Transmitter in Port Harcourt, NigeriaDocument9 pagesPropagation Analysis of Radio Frequency (RF) Signal of Love FM Transmitter in Port Harcourt, NigeriaAzuka ObiNo ratings yet

- Assignment#1 (Computer) D18E141 HAMZA JAVEDDocument5 pagesAssignment#1 (Computer) D18E141 HAMZA JAVEDHamza JavedNo ratings yet

- 2SC458Document6 pages2SC458mei jonieNo ratings yet

- Am25ck PDFDocument2 pagesAm25ck PDFLogan Marquez AguayoNo ratings yet

- SonoAce X8 v2.03.00-01 E PDFDocument476 pagesSonoAce X8 v2.03.00-01 E PDFDario BriceñoNo ratings yet

- Resistor Transistor LogicDocument3 pagesResistor Transistor LogicRAJESHKUMAR SNo ratings yet

- QuadCopter FlightDocument60 pagesQuadCopter Flightasso2412100% (1)

- RRUS 32 DatasheetDocument2 pagesRRUS 32 DatasheetLeo DuranNo ratings yet

- BSC, BSC16 SW - DXAlarmsDocument191 pagesBSC, BSC16 SW - DXAlarmselmoustaphaelNo ratings yet

- Television: Operating InstructionsDocument32 pagesTelevision: Operating InstructionsAsantha Buddhi HerathNo ratings yet

- Simatic S7-400HDocument23 pagesSimatic S7-400HSyariefNo ratings yet

- Order Specification OWDocument3 pagesOrder Specification OWdabyvjxpNo ratings yet

- EMTP Simulation Lightning MV PDFDocument4 pagesEMTP Simulation Lightning MV PDFCarlos Lino Rojas AgüeroNo ratings yet

- CT SizingDocument62 pagesCT SizingNoli OtebaNo ratings yet

- Design of A Cost Effective Micro Hydro Power Generation System Using The Discharge Water of The Central Steam Power PlantDocument159 pagesDesign of A Cost Effective Micro Hydro Power Generation System Using The Discharge Water of The Central Steam Power PlantNobel Engzen Du BermoyNo ratings yet

- DSPDocument5 pagesDSPKarishma SavNo ratings yet

- 7 5 ConnectorsDocument17 pages7 5 ConnectorsRonal Quispe HuamanNo ratings yet

- List of 7400 Series Integrated Circuits PDFDocument22 pagesList of 7400 Series Integrated Circuits PDFduriiNo ratings yet

- Semiconductor DiodesDocument42 pagesSemiconductor DiodesHieu DinhNo ratings yet

- The Most Complete Starter Kit For UNO V1.0.19.09.18Document223 pagesThe Most Complete Starter Kit For UNO V1.0.19.09.18Kuldeep SinghNo ratings yet

- Datasheet PDFDocument3 pagesDatasheet PDFSamvel KhachatryanNo ratings yet