Professional Documents

Culture Documents

Ar15 HK Data ON USE AND MODIFICATIONS

Uploaded by

Dennis Klineman0 ratings0% found this document useful (0 votes)

431 views7 pagesAR15 HK DATA ON USE AND MODIFICATION.

Original Title

Ar15 Hk Data ON USE AND MODIFICATIONS

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAR15 HK DATA ON USE AND MODIFICATION.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

431 views7 pagesAr15 HK Data ON USE AND MODIFICATIONS

Uploaded by

Dennis KlinemanAR15 HK DATA ON USE AND MODIFICATION.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 7

M855A1 SELLING OUT TROOPS?

COLD CALLS ON CUSTOMER SERVICE

HANDLOADING WILSON'S 7.62X40 WT

HIGH ANGLE HUNTING W/ KYLE LAMB

78

I

DPMS

20

I

HK USA

118

I

KNIGHT'S ARMAMENT

68 I LARUE

6 I LWRC

88 I POF USA

94

I

RUGER

50

I

SMITH & WESSON

102

I

WILSON COMBAT

MR 556 A1

USA/CANADA $8.99

DISPLAY UNTIL 05/28/2012

B

O

O

K

O

F

T

H

E

A

R

-

1

5

S

P

R

I

N

G

2

0

1

2

P

R

I

N

T

E

D

I

N

U

.

S

.

A

.

EXPERIENCE CULMINATES

IN THE LONG-ANTICIPATED

HK MR556A1.

BY ERIC R. POOLE

www.gunsandammo.com 21 BOOK OF THE AR-15 20

LEAD PHOTO BY JEFF ROSE

BOOK OF THE AR-15

22

THE FAMILY TREE

The MR556A1 is a direct descendant of the

HK416, and the HK416 started life as a modi-

fed variant of the Colt M4. The most signif-

cant aspect of both the MR556A1 and the

HK416 is a proprietary gas-piston operating

system, which employs a piston and a solid

operating push rod in place of the gas tube

found on a direct-impingement AR. This

short-stroke gas-piston system was derived

from the HK G36, which was inspired by

the ArmaLite AR-18 dating back to 1963.

Although the AR-18 was never adopted by

any nation, it is said to have infuenced his-

torically signifcant small arms, such as the

British SA80 service rife and Steyr AUG.

In response to complaints leveled against

the SA80 family after the Persian Gulf War,

the UK Ministry of Defence (MOD) com-

missioned a report that criticized 50 points

on its standard-issue rife. An extensive

modifcation program was contracted in

2000 to HK, which at that time was owned

by British small arms manufacturer Royal

Ordnance. HK remanufactured more than

200,000 SA80-type rifes, which were des-

ignated the L85A2. Improvements included

a new cocking handle, a modifed bolt and

extractor and a redesigned hammer assem-

bly that improved reliability. The affected

L85A2 rifes were branded with an HK

A2 mark on top of the rife just forward

of the buttplate. The improvements were

well received among British troops. Two

points are specifcally relevant to the de-

velopment of the HK 416: an improved HK

steel 30-round magazine was created for the

L85A2 and the fact that HK walked away

with a coveted capabilities reputation for

its successful fulfllment of a large-scale

government contract.

T

he HK416 has been hailed the most signifcant development to

ever come of the Stoner rife system. It brought international at-

tention to the benefts of a short-stroke gas-piston system, and this

one has been proliferated for service by 16 nations and counting.

The problem was that if you were not a U.S. SOCOM operator or

part of a progressive and well-funded law enforcement agency, you

couldnt get one. No more. A decade has passed since development of

the HK416 began, and the long-awaited civilian variant has fnally arrived.

Everyone, please welcome the MR556A1.

P

H

O

T

O

B

Y

J

E

F

F

R

O

S

E

D

o

D

P

H

O

T

O

BOOK OF THE AR-15

24

Ernst Mauch, former HK CEO, is widely

regarded as the father of the HK416, but the

project started in 2000 with a team including

Jim Schatz, Tom Kivlehan, Bruce Davidson

and U.S. Special Forces operator Larry Vick-

ers. At that time Vickers was still involved

with the U.S. Special Forces Operations as

a weapons research and development NCO,

and during an unrelated visit, a discussion

with Jim Schatz of HK arose regarding how to

improve the M4 carbine. The M4 has always

drawn criticism, but covert operators within

U.S. SOCOM were using this carbine well

beyond its design parameters.

DEVELOPMENT OF THE HK416

During my research for this article, I contacted

Larry Vickers, and he referred me to a com-

prehensive article he wrote for hkpro.com in

2006. In it Vickers reported, If you keep the

M4 lubricated, use only Mil-Spec ball ammo

(M855 and M193), use magazines in good con-

dition and fre it on semiauto, it works very

well. But as soon as you try to push it outside

those limits, such as extreme fring conditions

and extensive full-auto fre, as well as running

it with little or no lube, you will have problems.

In addition, trying to issue versions with short-

er than 14-inch barrels and suppressed fre

are also big problem areas with the as-issued

M4. The design is a carbine modifcation of the

20-inch-barreled AR-15/M16 weapon system.

The M4 is pushing that design as far as it can go

and still have an acceptable degree of service

life and reliability. Any requirements beyond

that design envelope will require a redesign

or a new weapon.

Vickers unit had been searching for an

M4-style carbine that was smaller and more

maneuverable in confned spaces. This has

been an ongoing effort to some degree ever

since we had gone from MP5s to M4s, he

said. A lot of money had been spent on test-

ing every short-barreled AR-style weapon we

could fnd. At the end of the day, we came to

the conclusion that none of them answered

our needs. They may be fne for casual use,

but they were not suitable for the demands we

place on a weapon of that type.

But back then U.S. SOCOM did not have

another viable weapon option. In all honesty,

none of them was even close, Vickers said.

At that time we began our search to other

non-AR-style weapons, such as the G36C and

the SIG SG552. Shortly after these other ef-

forts began, we became aware of the HK offer

of a product improvement program for the

M4 carbine. HK had offered this to other key

organizations in the U.S. military small arms

community, with no takers. HK sought to

borrow M4 carbines to analyze and begin an

improvement process on, much like the SA80

program had proceeded. The program would

be of no cost to the U.S. government with the

understanding at the end of the program that

the government had no obligation to purchase

any product HK brought to the market.

The modifcations process began with

high-speed video of the M4 carbine while it

functioned. After carefully analyzing the fring

cycle, a series of modifcations were put into

motion to address the various issues associated

with the M4. One key improvement had al-

ready been made: the HK steel magazine taken

from the L85A2 program. At the time, these

30-round magazines were revolutionary and

highly coveted. They featured a steel follower

that wouldnt cant during the feeding process,

however, the hard use in the feld by infuen-

tial operators ultimately brought on the more

recent trend for polymer-body magazines with

anti-cant followers. As an aside, an HK insider

reports the company is actively exploring its

own high-reliability polymer magazine.

The main effort from the start of the proj-

ect was to adapt the HK gas tappet system used

Former Master Technician

Robert Hirt of HK GmbH

was the primary demon-

strator in the Over The

Beach (OTB) testing of the

HK416. The impressive

results of these tests at

Yuma Proving Grounds in

2003 immediately caught

the attention of the small

arms community after

pictures and video were

accidentally leaked to

the Internet.

P

H

O

T

O

C

O

U

R

T

E

S

Y

H

K

U

S

A

www.gunsandammo.com 27 BOOK OF THE AR-15 26

in the G36 to the M4 carbine, Vickers said.

Engineers at HK Oberndorf had high regard

for several design features in the AR-type

weapon system, and they vowed to retain as

many positive features as possible. However,

HK engineers felt the direct-impingement gas

system common in the AR community was

less than optimum for military service. It was

felt that the G36 gas system would be a perfect

solution if it could be made to work within

the M4 platform.

By working directly with U.S. SOCOM op-

erators, HK engineers discovered the hidden

killer of critical components, such as the bolt

and extractor. Heat from the gases funneled

into the bolt carrier through its gas key dries

out lubricant and deposits carbon fouling.

Carbon fouling is especially egregious with

military ball ammunition, which uses flthy

powders to achieve its high velocities. This

reality shortens the service life of key operat-

ing components. With the HK G36 gas system,

the operating parts stay much cooler and dis-

play a prolonged service life. Further, carbon

fouling is signifcantly reduced because in the

HK416 operating system there is no gas tube

channeling gas into the chamber area.

I have seen HK416-style weapons with

over 26,000 rounds fred through them with

no parts breakages of any kind and plenty of

serviceable barrel life, Vickers said. As I

have demonstrated many times, the lack of

heat transfer through the pusher rod of the gas

tappet system and into the operating group

is so dramatic that you can easily touch the

pusher rod return spring and handle the bolt

carrier in your bare hands after several maga-

zines of full-auto fre. The distinct advantages

of this gas system over the original gas-direct

system are very impressive and have to be

seen to be fully appreciated.

After working through several prototypes

(a couple still reside on a wall in the HK Grey

Room, in Sterling, Va.), HK fnalized the

adaptation of the gas system and fabricated

the key internal bolt carrier components.

Engineers then focused attention on the re-

movable free-foat rail system. A small unit

within U.S. SOCOM had a requirement that

the rail system allow access to the gas system

for maintenance and return to zero for any

rail-mounted devices, such as IR lasers.

Interestingly, the HKM4 did not feature a

dust cover protecting the ejection port be-

cause HK engineers considered the fact that

the G36 operates reliably without one. But

concerns about American customers per-

ception about cutting corners overrode this

decision, and dust covers were included. (The

MR556A1 features a unique polymer ejection-

port cover.) Innovations that did make it to the

HK416 included a heavier buffer flled with

tungsten powder riding within a stronger

recoil spring and a lower receiver redesigned

to included a beveled magazine well.

The resulting HK416 impressed the end-

users, especially after witnessing an early

HK416 ftted with a 10-inch barrel survive

a 15,000-round endurance test. Vickers unit

placed the very frst order for several hundred

HK416s with 10-inch barrels.

No assault rife in modern history has gone

from development, testing, production and

sustained combat operations more quickly

than the HK416, Vickers said.

In 2006 U.S. Special Operations units in

Joint Special Operations Command (JSOC)

began felding the HK416 as their primary

carbine.

MR556A1: ITS HERE!

Word of the success experienced by the HK416

in the military spread and quickly resulted

in a surprising demand for a commercial

model. For the last half decade, the standard

HK response to inquiries was: Its coming.

Vickers presented a familiarization lecture

on the HK416 to select members of the press

during the 2004 SHOT Show. At that event, he

operated the HK416 without its upper hand-

guard so spectators could view its operation,

and after dumping several magazines through

the rife, he quickly removed the piston rod

and bolt carrier assembly to illustrate physi-

cally how clean and cool the components

were. Unfortunately, HK wasnt ready for the

demand caused by the American reception it

received in the weeks that followed.

The MR designation stands for Match

Rife, and HK eventually used this prefx to

label semiauto-only prototypesthe MR223

and MR308. Sightings of these rifles at

SHOT Show only intensifed the commercial

demand. Not long after the BATF provided HK

with written permission to sell upper receivers

commercially in 2004, a few upper receivers

found their way into the civilian market, draw-

ing unprecedented pricesnearly $5,000 in a

few casesfor years to follow.

Until the production of the MR556A1 began

in 2010, not many upper receivers had made

it to the American market due to import re-

strictions on the commercial sales of uppers.

M4

The HK416 program was frst designated

the HKM4, but Colt fled a lawsuit against

HK for patent infringement on the rife

design and trademark infringement on

the term M4. The suit was settled out

of court under undisclosed terms. Inter-

estingly, Bushmaster won a similar suit in

2005 when the court system ruled that the

term M4 is not proprietary to Colt and

could not be claimed as such.

The HK proprietary gas-

piston operating system

was developed from the

HK G36. It uses a short-

stroke piston that drives

an op rod to force the bolt

carrier to the rear and

cycle the action. This de-

sign prevents hot gas from

entering the receiver.

The MR556A1 includes the

tungsten-flled buffer that

is partly responsible for

the high reliability of the

HK416. It is designed to

slow the bolt carrier dur-

ing operation and reduce

the recoil impulse.

D

o

D

P

H

O

T

O

P

H

O

T

O

B

Y

S

E

A

N

U

T

L

E

Y

P

H

O

T

O

B

Y

S

E

A

N

U

T

L

E

Y

Until these restrictions were met, HK uppers

remained a controlled item that could only be

readily married to certain select-fre lowers.

To adhere to U.S. government regulations, HK

postponed introduction of the MR556A1 until

it could be manufactured in the U.S. using

American- and German-made components.

HK set up production in Columbus, Ga., where

the barrel blanks, bolt assemblies, machined

handguards and fre-control groups arrive

from Germany.

To the satisfaction of those in the know, the

heavy barrel installed on the MR556A1 is the

same German-manufactured product produced

by the companys legendary cold-hammer-

forging process. But unlike the HK416, the

MR556A1 does not use a chrome-lined barrel.

HKs position is, Chrome lining can sometimes

mask bore imperfections and negatively affect

accuracy. Another insiders take is: They

dont want Americans screwing with the bores

of its barrels. Thats why they only allow Ameri-

cans to machine and turn them.

The MR556A1 barrel is the heaviest of all

HK416 profles, to include the recently adopted

M27 used by the Marine Corps. It still features

a 1:7-inch twist suited for popular bullet

weights ranging between 55 and 77 grains and

is moderately swaged with a slightly smaller

internal diameter at the muzzle. This feature

is designed to impart a positive effect on bullet

accuracy and velocity.

The 16-inch barrel is capped with an

A2 birdcage compensator that was designed

decades ago to help minimize rise of the

muzzle during sustained fring and reduce

the dust signature experienced with the A1

fash hider on the M16 when fred from the

prone position.

The bolt carrier group features all of the

updates from the HK416 development, in-

cluding a proprietary plated fnish and an

enlarged rear to address carrier tilt. Carrier

tilt is often encountered with piston conver-

sions when a standard bolt carrier is driven

rearward and binds as it tries to enter the

buffer tube at a slight angle.

On the inside of the bolt carrier assembly,

the fring pin utilizes a spring and a captive

fring pin retaining pin. Each of these features

improves feld maintenance by making parts

easier to clean and more diffcult to lose.

Unique to the MR556A1 is a new fring pin

safety system. An arm locks the fring pin

in place and prevents it from coming into

contact with the primer through the boltface

unless the trigger is pressed. The top of the

hammer disengages the fring pin safety as it

rotates forward and allows the fring pin to

strike the primer. This development was nec-

essary because it was discovered that a heavy

buffer and strong action spring can produce

slamfres from the inertia imparted on the

fring pin as the bolt moves to close and lock.

The bolt is loaded by a coil spring. As the

bolt travels out of battery and moves to the

rear for extraction and ejection, this spring

helps infuence the bolt to remain in a forward

position and the cam pin vertical just after the

bolt unlocks. Normally, gas passed violently

through a gas tube and through the bolt car-

rier gas key to the bolt pushes the bolt forward

from the rear. HK has determined that short-

stroke piston systems need a system like this

to ensure reliable operation.

The HK Free Floating Rail System (FFRS)

never comes in contact with the barrel. The

FFRS is a unique vented handguard featur-

ing four MIL-STD Picatinny rails for the

attachment of accessories. HK states, The

HK rail system can be installed and removed

with simple tools and returns to zero when

reinstalled. (The FFRS is removed and rein-

stalled with a 5mm Allen wrench.) An index

integral to its top rail achieves a tight and

uniform ft with the upper receiver.

Delivered with the MR556A1 is the classic

HK-proprietary diopter sight system. Most

notably, it features a rear sight drum with

a V-notch for targets within 100 meters and

three apertures ready to address point targets

at 200, 300 and 400 meters.

To aid accuracy and consistent function,

the MR556A1 features a precision-machined,

two-stage trigger with minimal creep and

overtravel. It requires an average of 7.6 pounds

of pressure before the hammer is allowed to

fall forward and strike the fring pin. To facili-

tate loading from a closed bolt, each rife car-

ries a charging handle wearing an extended

latch (that can be switched to the opposite

side) for easier manipulation when operating

a rife wearing a low-mounted optic.

The six-position retractable stock and stip-

pled grip have become visual identifers to many

thirsty consumers looking through thousands of

military action photos online. The stock fea-

tures a unique arched recoil-reducing pad for a

more intuitive and optimal shoulder ft, while

a lock release lever engages the buffer tube to

prevent any play with the stock when mounted.

BOOK OF THE AR-15 28

The HK416N went into

service with Norways

armed forces in 2010 and

replaced the Kongsberg

AG-3 (aka HK G3A5) that

had been in service since

1967. With its 16-inch

barrel, the HK416N closely

resembles the MR556A1

and is typically issued with

an Aimpoint CompM4.

PHOTO BY SEAN UTLEY

PHOTO BY SEAN UTLEY

D

o

D

P

H

O

T

O

P

H

O

T

O

S

B

Y

S

E

A

N

U

T

L

E

Y

BOOK OF THE AR-15

30

SPECIFICATIONS

HK MR556A1

TYPE

Gas-operated, short-

stroke piston, semi-

automatic

CALIBER 5.56 NATO

CAPACITY 20, 30 rds.

BARREL

16.5 in., cold-hammer-

forged, 1:7 twist

OVERALL

LENGTH

37.68 in. (extended)

33.9 in. (collapsed)

WIDTH 3.07 in.

HEIGHT 9.45 in.

WEIGHT 9.04 lbs.

STOCK 6-position, collapsible

FINISH

Matte Black anodized

(aluminum), phosphate

(steel)

TRIGGER

Two stage; 7 lbs., 6 oz.

(tested)

SIGHTS

Elevation-adjustable

post (front),

windage and

elevation-adjustable

diopter (rear)

MSRP $3,295

MANUFACTURER

Heckler & Koch

hk-usa.com

706-568-1906

With the fring hand wrapped around the tactile

grip, classic AR-style controls are familiarly lo-

cated. The grip features a waterproof trapdoor

at the bottom for storage of small items, such as

batteries, small tools or other accessories.

Once you get past the color-keyed safety/se-

lector pictograms often seen on HK small arms,

you might notice that, unlike other ARs, the

selector can be engaged to the safe position

whether or not the hammer is cocked. This is

sure to please a number of carbine instructors.

Unlike earlier prototypes and variants ob-

served at industry trade shows and HK train-

ing events, the MR556A1 subassemblies are

fully interchangeable with other high-quality

AR-style frearms. Therefore, a forthcoming

MR556A1 upper receiver kit can be used to

retroft other AR legacy systems. The lower will

accept aftermarket stocks assemblies and pistol

grips, as well as other Mil-Spec magazines.

A LONG-TERM RELATIONSHIP

Ive been in a unique position to see the evo-

lution of the HK416 and have had exclusive

access to a signifcant number of them as the

U.S. government considered them for military

and civilian contracting service. I graduated

from the very frst HK416 armorer school put

on by HK USA in 2006. Blackwater USA as-

sumed training responsibilities for HK that

year, so this countrys largest inventory of

HK416 variants were kept in the care of the

armory where I worked. At the time, HK per-

manently located a custodian to accompany a

cross-section of HK products and oversee their

use by U.S. SOCOM operators and VIPs. I came

to know these rifes quite intimately. At Black-

water, the HK416 family performed extremely

well in training and required noticeably less

maintenance than their M4 counterparts and

impressed each operator that came through the

North Carolina facility to train with it.

Ive had one of these rifes on personal order

for three years and fnally got the call about a

year ago that one was inbound. I wasnt about

to rush to fnish the assignment in a few weeks

just to beat some other gun rags questionable

review to the newsstand. Like any other true

enthusiast who has waited years for some-

thing special, I took it out to the range the

same morning it arrived and chronographed

a variety of loads before fring a baseline set of

100-yard accuracy results for reference.

In the course of the last year, Ive fred 4,000

rounds of surplus M855 green tip through my

MR556A1. It has never malfunctioned. Even

after fring that many rounds, velocity still

averages 3,100 fps, and fve-shot, 100-yard

accuracy results still foat between .90 and

1.3 MOA using this ammunition and a Tri-

jicon TA31. (Of course, I achieve consistent

sub-MOA results when I attach a high-power

optic and use Federal Gold Medal 69-grain

ammunition.) I havent even begun to near

the end of this rifes barrel life.

Fit and fnish of the MR556A1 are superb

quite ftting of the stereotype seemingly ap-

plied to everything German. This rife shoots

tight and feels right. Ive gone through the

entire system many times and can fnd nothing

to complain about. My conclusion, therefore,

is simple: If ever a single carbine was worth

$3,300, the MR556A1 is it. It has no rivals.

VICKERS TAKE

I dont necessarily

believe that a piston

AR is the right platform

for everyone, but I still

think that for short-

barrel applications,

the piston AR has a lot

of merit. [The HK416] is

without question the

one piston AR that has

seen the most combat

and service use. The

HK is the golden yard-

stick that everyone

compares another

piston system to

and for good reason.

Now we have numer-

ous piston systems of-

fered by nearly all AR

manufacturers. And

this all started with the

HK416. This is the gun

used to kill bin Laden,

and its now the M27

IAR chosen for service

with the U.S. Marines.

If you have a need

for a piston gun, the

HK will always be the

standard.

USMC

M27IAR

D

o

D

P

H

O

T

O

You might also like

- Glock 17, 19, 20, 21, 22, 23 & 17L Pistol Armorer's ManualDocument60 pagesGlock 17, 19, 20, 21, 22, 23 & 17L Pistol Armorer's Manualh762x39100% (16)

- Improved M4 - AR15 Carbine Zero Target 50MDocument5 pagesImproved M4 - AR15 Carbine Zero Target 50MDennis Klineman100% (3)

- Small Arms of The World - A Basic Manual of Small ArmsDocument774 pagesSmall Arms of The World - A Basic Manual of Small ArmsAndrea Grazioli100% (7)

- A1 To A2Document45 pagesA1 To A2leeyangseopNo ratings yet

- KMR QRF MCMR: Bravo Company MFG®Document3 pagesKMR QRF MCMR: Bravo Company MFG®Matt KienertNo ratings yet

- Practical Guide to the Operational Use of the MP5 Submachine GunFrom EverandPractical Guide to the Operational Use of the MP5 Submachine GunNo ratings yet

- Ruger P95 Owners ManualDocument40 pagesRuger P95 Owners ManualSeathStevensonNo ratings yet

- Improved AR15 Optic Target 100MDocument5 pagesImproved AR15 Optic Target 100Mbeetho1990No ratings yet

- HK Mp5 Mp5k Mp5ka1 ManualDocument30 pagesHK Mp5 Mp5k Mp5ka1 ManualJoseph BriggsNo ratings yet

- User ManualDocument22 pagesUser Manualliwei0% (1)

- Acts 9 Commentary - Paul's Conversion - BibleGatewayDocument4 pagesActs 9 Commentary - Paul's Conversion - BibleGatewayDennis KlinemanNo ratings yet

- Ak 47 AKM Technical Manual DETAILEDDocument23 pagesAk 47 AKM Technical Manual DETAILEDDennis Klineman100% (4)

- FM 23-71-Rifle Marksmanship Course Trainfire I (1957)Document251 pagesFM 23-71-Rifle Marksmanship Course Trainfire I (1957)Michael CessnaNo ratings yet

- Pistols of The World Ed 3 - Hogg and Weeks 1992Document267 pagesPistols of The World Ed 3 - Hogg and Weeks 1992dichotomystudios92% (12)

- AR-15: RECOIL Magazine’s Collection of Unique and Exceptional ARs: RECOIL Magazine’s Collection of Unique and Exceptional ARsFrom EverandAR-15: RECOIL Magazine’s Collection of Unique and Exceptional ARs: RECOIL Magazine’s Collection of Unique and Exceptional ARsNo ratings yet

- 2006 Bushmaster CatalogDocument84 pages2006 Bushmaster Catalogstjohn45No ratings yet

- Glock Armorers ManualDocument60 pagesGlock Armorers ManualMike Bell100% (1)

- America's Rifle - The ARDocument15 pagesAmerica's Rifle - The ARlsilva171No ratings yet

- AR15 ExtractorDocument1 pageAR15 ExtractorfuriousgaulNo ratings yet

- AR15 Trigger ComparisonDocument16 pagesAR15 Trigger ComparisonIM_JohnnyV100% (1)

- AR-15 Zeroing at 25 MetersDocument2 pagesAR-15 Zeroing at 25 Metersdeolexrex100% (6)

- CFD Approach To Firearms Sound Suppressor Design PDFDocument13 pagesCFD Approach To Firearms Sound Suppressor Design PDFGabriel Albornoz100% (1)

- ListDocument40 pagesListCarlos Ramos100% (1)

- Vortex 9Document12 pagesVortex 9255sectionNo ratings yet

- HK 416C/D & M27 & KAC LMG MarkingsDocument1 pageHK 416C/D & M27 & KAC LMG MarkingsspirasioNo ratings yet

- Present Arms AR-15 Gunners MountDocument18 pagesPresent Arms AR-15 Gunners MountAmmoLand Shooting Sports NewsNo ratings yet

- ASTOar15 m16 Armorer CourseDocument2 pagesASTOar15 m16 Armorer CoursetaylorNo ratings yet

- MP 40 Submachine Gun (NAZI Germany)Document9 pagesMP 40 Submachine Gun (NAZI Germany)blowmeasshole1911No ratings yet

- ACR Owners ManualDocument59 pagesACR Owners ManualguncollectorNo ratings yet

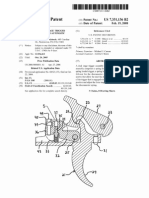

- Mod Firearm Beretta - US Patent 5596162Document9 pagesMod Firearm Beretta - US Patent 5596162luanfunari100% (1)

- Section 03 NomenclatureDocument32 pagesSection 03 Nomenclaturerao_saintNo ratings yet

- Ar15 Lower Machining Instructions PDFDocument5 pagesAr15 Lower Machining Instructions PDFredneckrepairsNo ratings yet

- Improved AR15 OpticTargetDocument5 pagesImproved AR15 OpticTargetbeetho1990No ratings yet

- List of Colt ARDocument39 pagesList of Colt ARDavidArcherNo ratings yet

- Sterling Gun Drill CatalogDocument18 pagesSterling Gun Drill Catalogjkruise100% (1)

- AAC 2012 CatalogDocument96 pagesAAC 2012 CatalogJonathan Berowski100% (1)

- B&T Rifle Suppressor RBS QDN, Cal. 5.56mm / .223Document2 pagesB&T Rifle Suppressor RBS QDN, Cal. 5.56mm / .223Kalmer KaruNo ratings yet

- AR15 Roller Cam Pin - Reducing Friction and Wear vs. Conventional Cam Pins HydraFireAR15RollerCamPinFrictionStudyDocument10 pagesAR15 Roller Cam Pin - Reducing Friction and Wear vs. Conventional Cam Pins HydraFireAR15RollerCamPinFrictionStudyRob ZelNo ratings yet

- 5 8366 PDFDocument68 pages5 8366 PDFguillermoNo ratings yet

- AR15-M16 Magazine FAQDocument28 pagesAR15-M16 Magazine FAQhodhodhodsribdNo ratings yet

- Brownells-2 5LB1911TriggerPullDocument4 pagesBrownells-2 5LB1911TriggerPullRyan ShanksNo ratings yet

- Remington 1100, 11-87 & Super Mag Auto ShotgunsDocument26 pagesRemington 1100, 11-87 & Super Mag Auto ShotgunsPlainNormalGuy2No ratings yet

- Operators Manual: UMP45 (.45 ACP) UMP40 (.40 S&W)Document49 pagesOperators Manual: UMP45 (.45 ACP) UMP40 (.40 S&W)Chad KaplanNo ratings yet

- Heckler and Koch MP5 - SMG - GermanyDocument2 pagesHeckler and Koch MP5 - SMG - GermanyRichard HarigNo ratings yet

- 可调式双级触发机制半自动武器 PDFDocument12 pages可调式双级触发机制半自动武器 PDFJin SongNo ratings yet

- Heckler Koch 40 MM Systems 2010 PDFDocument7 pagesHeckler Koch 40 MM Systems 2010 PDFErikNo ratings yet

- Home Workshop Vol 5 Ar15m16 PDFDocument110 pagesHome Workshop Vol 5 Ar15m16 PDFs.senthil nathan100% (1)

- The Armalite AR-7 Survival RifleDocument6 pagesThe Armalite AR-7 Survival Rifleblowmeasshole1911No ratings yet

- The Complete Book of Assault Rifles 1986 - The Israeli Galil by J.B. WoodDocument6 pagesThe Complete Book of Assault Rifles 1986 - The Israeli Galil by J.B. WoodRSRNo ratings yet

- How To Make and Load All-Brass .410 Shotshells.Document3 pagesHow To Make and Load All-Brass .410 Shotshells.Steven PollardNo ratings yet

- M16 RifleDocument45 pagesM16 Riflepeter_w_l37500% (1)

- Handgun Safety Reference Owner'S Manual: International, IncDocument34 pagesHandgun Safety Reference Owner'S Manual: International, IncpreceptiveinquirerNo ratings yet

- AR15 Barrel Nut IndexingDocument1 pageAR15 Barrel Nut IndexingMike Nichlos100% (3)

- 45 ApcDocument35 pages45 Apcsteved_43No ratings yet

- Operating and Safety Operating and Safety Instruction Manual Instruction ManualDocument16 pagesOperating and Safety Operating and Safety Instruction Manual Instruction Manual.100% (1)

- Kalashnikov AK74 Assault RifleDocument49 pagesKalashnikov AK74 Assault RifleJustin LeeNo ratings yet

- Ar-10 Rifles PDFDocument12 pagesAr-10 Rifles PDFstonefirearmsNo ratings yet

- 螺栓枪口装步枪 PDFDocument7 pages螺栓枪口装步枪 PDFJin SongNo ratings yet

- Thompson/Center Arms Co., Inc. P.O. Box 5002 Rochester, New Hampshire 03866Document28 pagesThompson/Center Arms Co., Inc. P.O. Box 5002 Rochester, New Hampshire 03866johndone100% (1)

- Awc CatalogDocument23 pagesAwc CatalognachosuaveNo ratings yet

- AR-15/M16 INDEX: Orders/TechDocument93 pagesAR-15/M16 INDEX: Orders/TechStan Brittsan100% (1)

- Armalite® AR-50A1™Document37 pagesArmalite® AR-50A1™Jiaqing ZhangNo ratings yet

- H&K Field Stripping NewDocument53 pagesH&K Field Stripping Newkcluer8No ratings yet

- Punching Holes: Buying Ammunition, Gun Accessories, Knives and Tactical Gear at Wholesale PricesFrom EverandPunching Holes: Buying Ammunition, Gun Accessories, Knives and Tactical Gear at Wholesale PricesNo ratings yet

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsFrom EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsNo ratings yet

- Practical Guide to the Operational Use of the UZI Submachine GunFrom EverandPractical Guide to the Operational Use of the UZI Submachine GunNo ratings yet

- Cornelius The CenturionDocument1 pageCornelius The CenturionDennis KlinemanNo ratings yet

- The Fullness of Truth - A Handbo - James M. SeghersDocument198 pagesThe Fullness of Truth - A Handbo - James M. SeghersDennis Klineman100% (1)

- 6 April 2014 - Pastoral Visit To The Roman Parish of - San Gregorio MagnoDocument1 page6 April 2014 - Pastoral Visit To The Roman Parish of - San Gregorio MagnoDennis KlinemanNo ratings yet

- Litany of HumilityDocument2 pagesLitany of HumilityDennis KlinemanNo ratings yet

- The Glories of Mary - Saint Alphonsus LiguoriDocument319 pagesThe Glories of Mary - Saint Alphonsus LiguoriDennis KlinemanNo ratings yet

- Continental Data BookDocument44 pagesContinental Data BookDennis Klineman100% (1)

- BRIDGESTONE r250 BrochureDocument2 pagesBRIDGESTONE r250 BrochureDennis KlinemanNo ratings yet

- The Transformation of Biblical Proper NamesDocument169 pagesThe Transformation of Biblical Proper NamesDennis KlinemanNo ratings yet

- 24 Volt Capacitor For Starting Esm - 24V - DS - 3000915 - en - 2Document2 pages24 Volt Capacitor For Starting Esm - 24V - DS - 3000915 - en - 2Dennis KlinemanNo ratings yet

- R268 Bridgestone Commercial Truck TiresDocument2 pagesR268 Bridgestone Commercial Truck TiresDennis KlinemanNo ratings yet

- Crimsontrace Ar15-M16 Manual LAZER SIGHTDocument9 pagesCrimsontrace Ar15-M16 Manual LAZER SIGHTDennis KlinemanNo ratings yet

- FBI Basic Rifle TrainingDocument19 pagesFBI Basic Rifle TrainingDennis KlinemanNo ratings yet

- M14 Lubrication InstructionsDocument13 pagesM14 Lubrication InstructionsDennis KlinemanNo ratings yet

- SERIAL NUMBER LOOK UP SA, Inc M1A1Document2 pagesSERIAL NUMBER LOOK UP SA, Inc M1A1Dennis Klineman100% (1)

- Operator Maint OF WEAPONSDocument6 pagesOperator Maint OF WEAPONSDennis KlinemanNo ratings yet

- Operations Manual FOR FIELD TESTING OF WEAPONSDocument26 pagesOperations Manual FOR FIELD TESTING OF WEAPONSDennis KlinemanNo ratings yet

- Operations Manual FOR FIELD TESTING OF WEAPONSDocument26 pagesOperations Manual FOR FIELD TESTING OF WEAPONSDennis KlinemanNo ratings yet

- Smle Bolt Thread SizesDocument3 pagesSmle Bolt Thread SizesIvan Duncan100% (1)

- This Quars WarDocument108 pagesThis Quars WarDale Hutchison100% (1)

- Rimfire Ammunition Ballistics Table: Type LoadDocument2 pagesRimfire Ammunition Ballistics Table: Type Loadspey_flyNo ratings yet

- Eric Johnson American Rifleman March 1947Document4 pagesEric Johnson American Rifleman March 1947Roger DiVitoNo ratings yet

- The Ballistic CoefficientDocument7 pagesThe Ballistic Coefficientjvs57No ratings yet

- Anti-Aircraft Journal - Apr 1953Document52 pagesAnti-Aircraft Journal - Apr 1953CAP History LibraryNo ratings yet

- AMCP 700-3-3, Artillery AmmunitionDocument68 pagesAMCP 700-3-3, Artillery Ammunitionlaoba2333333No ratings yet

- 1993 Launcher, Grenade, 40mm, m203, We 199pDocument199 pages1993 Launcher, Grenade, 40mm, m203, We 199pmarc_luscher100% (3)

- SI July 2019 PDFDocument104 pagesSI July 2019 PDFberegond3No ratings yet

- Materials 14 07237 v2Document17 pagesMaterials 14 07237 v2Serhat TüysüzNo ratings yet

- Terrible Sharp Sword (TFL)Document54 pagesTerrible Sharp Sword (TFL)sackeyes100% (3)

- Mary Goldstein Criminal ComplaintDocument17 pagesMary Goldstein Criminal ComplaintGary DetmanNo ratings yet

- Guide To AmmunitionDocument30 pagesGuide To AmmunitionJithin100% (10)

- Hotchkiss Portative - Hotchkiss .303 Portable Mk. 1 Machine Gun - Benet-Mercie Machine Rifle M1909Document3 pagesHotchkiss Portative - Hotchkiss .303 Portable Mk. 1 Machine Gun - Benet-Mercie Machine Rifle M1909blowmeasshole1911No ratings yet

- NYSRPA V Cuomo, Record On Appeal, Volume 1Document298 pagesNYSRPA V Cuomo, Record On Appeal, Volume 1Paloma A. CapannaNo ratings yet

- Diana Stormrider PY-4449-8647 ManualDocument12 pagesDiana Stormrider PY-4449-8647 ManualMr HamakiNo ratings yet

- Caliber Conversions TableDocument5 pagesCaliber Conversions TableVishwas Kumar SinghNo ratings yet

- Paintball Is A Game: Carbon Dioxide HPA N2 Marker Sporting Goods Manufacturers AssociationDocument4 pagesPaintball Is A Game: Carbon Dioxide HPA N2 Marker Sporting Goods Manufacturers AssociationzaharibbNo ratings yet

- Browning 1919Document8 pagesBrowning 1919thermaladvancement1No ratings yet

- Laserlyte Scv4 Fsl-4Document3 pagesLaserlyte Scv4 Fsl-4Twobirds Flying PublicationsNo ratings yet

- Firefight Cheat Sheet: Firearms Difficulty Levels Using FirearmsDocument1 pageFirefight Cheat Sheet: Firearms Difficulty Levels Using FirearmsDiego Amaya0% (1)

- Mauser Rifles - Text PDFDocument36 pagesMauser Rifles - Text PDFFrank Meeker100% (1)

- Battle BrothersDocument5 pagesBattle BrothersAdrianNo ratings yet

- CleosRealm Type10 PDFDocument7 pagesCleosRealm Type10 PDFsupermoto nightNo ratings yet

- CleosRealm Leo1A3Document9 pagesCleosRealm Leo1A3Fnaf YTNo ratings yet

- Specific Parts For The Mil Spec Trigger GroupDocument2 pagesSpecific Parts For The Mil Spec Trigger GroupMauricio Rojas GutierrezNo ratings yet