Professional Documents

Culture Documents

Indexable: Center Drill

Uploaded by

skidamdnevnoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Indexable: Center Drill

Uploaded by

skidamdnevnoCopyright:

Available Formats

http://www.jic-tools.com.

tw

indexable

Center Drill

i-center indexable center drill (patent pending)

First Indexable center drill in the world.

Shortens set up time and center drilling time.

Increases tool life which reduces tooling costs.

Special forms are possible.

Highly Efficient Tools

No Re-setting, No Resharpening

Time Saving

Long Tool Life

Improve your Process Performance

2009-08

Cat. No.01

i-center indexable center drill

The i-center is a trademark of Nine9,

the developer of the first indexable center drill.

For the first time, Nine9s i-center patent-pending design provides

the benefit of solid carbide cutting parameters while delivering High Speed, High Feed Rate

High Performance speed and feed can be reached thanks to the special ground insert

and ridged holder design. For example, for drilling alloy steel is 6000 rpm and Feed rate

600 mm/min. (0.1mm/rev.)

Easy Tool Length Setting

Application on turning machine.

The axial position accuracy of the insert is 0.05 mm. It is not necessary to reset

the tool length again while changing insert or cutting edge.

Excellent Repeatability

The insert is position by two fixed pin and clamped by one insert screw at the center.

The positioning repeatability of the insert within 0.02 mm in radial direction, thus

ensuring conformity to any National Standard.

Extended Tool Life

Coolant can be supplied through the center of the holder to increase performance and

extend tool life. Insert geometry, grades and coating process are specifically

engineered for centering applications.

Universal and Easily Integrated with Special Tools

High pressure coolant can be

supplied through center directly

to tip of center drill insert.

The tool holder is made of high alloy steel, hardened and ground to h6 tolerances with a

flat. Its easy for stationary tool and rotating tool. Special combinations tools available

upon request. (see page 6)

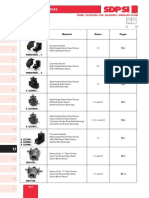

Tool holder

Made of High alloy steel and hardened.

Special holders are available on request.

d

d

Features:

L2

Order No.

Part No.

IC

L1

L2

Screw

Key

00-99616-IC12-16

SB16-IC12

12

16

48

36

21

NS-30072

2.0 Nm

NK-T9

00-99616-IC16-16

SB16-IC16

16

16

48

43

27

NS-35080

2.5 Nm

NK-T15

00-99616-IC20-20

SB20-IC20

20

20

50

60

32

NS-50120

5.5 Nm

NK-T20

00-99616-IC25-25

SB25-IC25

25

25

56

65

43

NS-50120

5.5 Nm

NK-T20

Order No.

Part No.

IC

L1

L2

Screw

Key

00-99616-IC12-5/8

SB5/8"-IC12

12

5/8"

48

36

21

NS-30072

2.0 Nm

NK-T9

00-99616-IC16-5/8

SB5/8"-IC16

16

5/8"

48

43

27

NS-35080

2.5 Nm

NK-T15

00-99616-IC20-3/4

SB3/4"-IC20

20

3/4"

50

60

32

NS-50120

5.5 Nm

NK-T20

00-99616-IC25-1

SB1"-IC25

25

1"

56

65

43

NS-50120

5.5 Nm

NK-T20

i-center indexable center drill

Indexable center insert

Features:

NC 2033: K20F grade carbide insert and TiAlN coated for carbon steel,

alloy steel, high alloy steel, cast iron and Al, Al-alloy, Cu, Cu-alloy.

2 cutting edges, high performance for center drilling.

Metric sizes: DIN 332 A+B, DIN 332 R , 2~10 mm

Inch sizes: ANSI (BS) #2 ~10

Special forms are available on request.

2 cutting edges

DIN332 Form R

d1

Parts No.

I9MT12T2R0200-NC2033

2.00

I9MT12T2R0250-NC2033

2.50

I9MT12T2R0315-NC2033

3.15

I9MT1603R0400-NC2033

4.00

I9MT1603R0500-NC2033

5.00

I9MT2004R0630-NC2033

6.30

I9MT2004R0800-NC2033

8.00

I9MT2506R1000-NC2033

10.00

+0.22

0

L1

L2

5.0

5.3

6.3

8.0

R

min.

max.

6.72

5.0

6.3

6.7

8.29

6.3

8.0

8.5

9.94

8.0

10.0

10.0

10.6

12.84

10.0

12.5

12.5

13.2

14.78

12.5

16.0

+0.14

0

+0.18

0

d2

IC

12

16.0

17.0

18.83

16.0

20.0

20.0

21.2

21.2

20.0

25.0

25.0

26.5

26.5

25.0

31.5

16

20

25

d3

DIN332 Form A+B

d1

I9MT12T2B0200-NC2033

2.00

I9MT12T2B0250-NC2033

2.50

I9MT12T2B0315-NC2033

3.15

I9MT1603B0400-NC2033

4.00

I9MT1603B0500-NC2033

5.00

I9MT2004B0630-NC2033

6.30

I9MT2004B0800-NC2033

8.00

I9MT2506B1000-NC2033

10.00

+0.14

0

d2

d3

4.25

6.3

2.5

5.3

3.1

6.7

10

3.9

8.5

12.5

5.0

10.6

16

6.3

+0.18

0

+0.22

0

L1

L2

L3

+0.8

0

4.3

4.9

+1.0

0

5.5

6.8

7.4

9.0

+1.2

0

IC

12

9.5

10.6

11.7

13.3

13.2

18

8.0

14.6

15.9

17.0

20

10.1

18.6

19.4

21.2

25

12.8

23.2

24.3

+1.4

0

L3

L2

L1

Parts No.

16

20

25

ANSI 60

d2

L1

mm

I9MT12T2A2-NC2033

#2

5/64

1.98

I9MT12T2A3-NC2033

#3

7/64

2.78

I9MT12T2A4-NC2033

#4

1/8

3.18

I9MT1603A5-NC2033

#5

3/16

4.76

mm

+0.14

0

+0.18

0

3/16

4.76

5/64

1.98

+0.8

0

4.4

1/4

6.35

7/64

2.78

+1.0

0

5.9

5/16

7.94

1/8

3.18

7/16

11.11

3/16

4.76

I9MT2004A6-NC2033

#6

7/32

5.56

1/2

12.7

7/32

5.56

I9MT2004A7-NC2033

#7

1/4

6.35

5/8

15.88

1/4

6.35

3/4

19.05

5/16

7.94

0.98

25.0

3/8

9.53

I9MT2004A8-NC2033

#8

5/16

7.94

I9MT2506A10-NC2033

#10

3/8

9.53

+0.22

0

L2

IC

mm

7.3

10.3

+1.2

0

16

11.8

14.6

+1.4

0

12

20

17.6

22.9

25

L1

d1

Size

L2

Parts No.

i-center indexable center drill

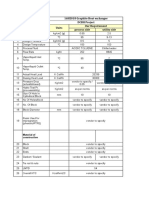

Cutting data

Attention:

For d1< 4 mm or size #5, be sure the center misalignment is less than 0.05mm.

If the mislignment of the turret center of the CNC lathe is above 0.15mm,

please use the Center Height Adjusting Sleeve ( see page 6.)

For low spindle speed special purpose machines or lathes,

lower spindle speed is allowed but the feed rate should be kept.

2~4 (#2~#5)

f

Work piece

material

Vc

d1

(m/min)

f (mm/rev)

Cutting

2 (#2)

2.5 (#3)

3.15 (#4)

4 (#5)

fluid

Carbon steel

C<0.3%

60-70-80

(S=11140 rpm)

0.03-0.05-0.06

(S=8912 rpm)

0.04-0.06-0.08

(S=7073 rpm)

0.08-0.10-0.12

(S=5570 rpm)

0.08-0.12-0.14

emulsion

Carbon steel

C>0.3%

50-60-70

(S=9549 rpm)

0.03-0.04-0.05

(S=7639 rpm)

0.04-0.06-0.08

(S=6063 rpm)

0.08-0.10-0.12

(S=4774 rpm)

0.08-0.12-0.14

emulsion

Low alloy steel

C<0.3%

45-55-65

(S=8753 rpm)

0.02-0.03-0.05

(S=7002 rpm)

0.03-0.05-0.07

(S=5557 rpm)

0.06-0.08-0.10

(S=4376 rpm)

0.06-0.08-0.10

emulsion

High alloy steel

C>0.3%

40-50-60

(S=7957 rpm)

0.01-0.02-0.04

(S=6366 rpm)

0.02-0.04-0.06

(S=5052 rpm)

0.04-0.06-0.08

(S=3978 rpm)

0.04-0.06-0.08

emulsion

Cast iron

50-60-70

(S=9549 rpm)

0.02-0.04-0.06

(S=7639 rpm)

0.04-0.06-0.08

(S=6063 rpm)

0.06-0.08-0.10

(S=4774 rpm)

0.06-0.08-0.10

dry

100-150-200

(S=23873 rpm)

0.01-0.02-0.04

(S=19098 rpm)

0.02-0.03-0.05

(S=15157 rpm)

0.02-0.04-0.06

(S=11936 rpm)

0.02-0.04-0.06

emulsion

Al, and

non-ferrous metal

5~10 (#6~#10)

f

Work piece

material

Vc

d1

(m/min)

f (mm/rev)

5 (#6)

6.3 (#7)

8 (#8)

Cutting

10 (#10)

fluid

Carbon steel

C<0.3%

60-70-80

(S=4456 rpm)

0.10-0.12-0.16

(S=3536 rpm)

0.10-0.14-0.16

(S=2785 rpm)

0.12-0.15-0.18

(S=2228 rpm)

0.14-0.18-0.20

emulsion

Carbon steel

C>0.3%

50-60-70

(S=3819 rpm)

0.10-0.12-0.16

(S=3031 rpm)

0.10-0.14-0.16

(S=2387 rpm)

0.12-0.15-0.18

(S=1909 rpm)

0.14-0.18-0.20

emulsion

Low alloy steel

C<0.3%

45-55-65

(S=3501 rpm)

0.08-0.10-0.12

(S=2778 rpm)

0.08-0.12-0.14

(S=2188 rpm)

0.10-0.14-0.16

(S=1750 rpm)

0.12-0.16-0.20

emulsion

High alloy steel

C>0.3%

40-50-60

(S=3183 rpm)

0.06-0.08-0.10

(S=2526 rpm)

0.08-0.10-0.12

(S=1989 rpm)

0.10-0.14-0.16

(S=1591 rpm)

0.10-0.14-0.16

emulsion

Cast iron

50-60-70

(S=3819 rpm)

0.08-0.10-0.12

(S=3031 rpm)

0.08-0.12-0.14

(S=2387 rpm)

0.10-0.14-0.16

(S=1909 rpm)

0.12-0.16-0.18

dry

100-150-200

(S=9549 rpm)

0.04-0.06-0.08

(S=7578 rpm)

0.04-0.06-0.08

(S=5968 rpm)

0.06-0.08-0.10

(S=4774 rpm)

0.06-0.08-0.10

emulsion

Al, and

non-ferrous metal

i-center indexable center drill

Undeniable benefits of

Example of comparison:

3.15

7.2mm

i-center is the unique solution in the world to up grade the center drill

process into the indexable generation leaving HSS and

solid carbide centering as ancient history.

Work piece: Low carbon alloy steel, 850 N/mm2

Diameter of tool: 3.15 mm Depth of drilling: 7.2 mm

Machine: Vertical Machining Center, BT40 with internal coolant

Cutting speed

m/min.

Spindle speed

r.p.m.

i-center

HSS

Center drill

Solid carbide

center drill

i-center

HSS Center drill

Solid carbide

center drill

65

17

65

6570

1718

6570

Feed rate f =

mm/rev.

0.1

0.02

0.1

Feed rate F=

mm/min.

657

34.4

657

Emulsion

External / Internal

External

External

sec.

0.65

12.5

0.65

Holes of drilling per edge

3000

200

2000

Coolant

Drilling time

Profit by making the right choice

High speed and feed rates of the i-center reduce cutting time.

The unique design of i-center increases tool life and reduces

change over time.

Together these attributes lower cost and increase your profits!

Nine9 i-center

Feed rate

HSS center drill

Solid carbide center drill

Tool life per edge

Tool setting time

Cost saving

i-center indexable center drill

i-cen

Application of

For shaft end machining.

C

F

Center Height Adjusting Sleeve

Clamping

Principle:

For use on

CNC lathes

Designed for adjusting Center Height of center drills, NC spot drills,

reamers and taps on the CNC lathes.

Applications:

Used when the CNC lathes is needed to adjust the center height.

For clamping 16 mm side lock shank tool holder or cutting tool, and

this sleeve can be clamped in VDI 40, VDI 50 E2 tool holders, and

other type of internal turning tool holders.

Center height adjusting range: 0.15 mm.

Total axial movement is 6mm.

Adjusting

Dust protection

wiper

95~101

90

90

16

Adjusting

range

0.15 mm

40

40

Dia. 16 mm

Cutting tool holder

Locking Screw: M8

Order No.:

00-99600-400

Distributor :

International Corp.

2009.08 Cat. No.:NIC 01:1000PC

You might also like

- Untitled 1 PDFDocument35 pagesUntitled 1 PDFRAVI KANT BARANWALNo ratings yet

- 15 Rotating Toolholders WNT2013Document177 pages15 Rotating Toolholders WNT2013Natrajj SivakumarNo ratings yet

- ARTY - Aubert Et Duval - Produits - Longs - GB PDFDocument6 pagesARTY - Aubert Et Duval - Produits - Longs - GB PDFScott_B4UNo ratings yet

- MachiningDocument12 pagesMachiningwardendavid5591100% (1)

- Accouplement MecDocument19 pagesAccouplement MecAli Ben Belgacem MahroukNo ratings yet

- 05 MachiningDocument12 pages05 MachiningVisvas RajyaguruNo ratings yet

- SPECIFICATIONSDocument9 pagesSPECIFICATIONSRicardo VelozNo ratings yet

- SpecificationsDocument9 pagesSpecificationsAbdul Syukur ZNo ratings yet

- Mitsu End MillDocument20 pagesMitsu End MillTrịnh Văn PhậnNo ratings yet

- MK-Dent Highspeed HandpiecesDocument12 pagesMK-Dent Highspeed HandpiecesPaul LairdNo ratings yet

- CA65 PR11: For Stainless Steel MachiningDocument12 pagesCA65 PR11: For Stainless Steel MachiningmachineCanNo ratings yet

- 1 ATI Stellram U INCIMA DimenzijeDocument8 pages1 ATI Stellram U INCIMA DimenzijeBosko LukavicNo ratings yet

- MKT11 Ed01 Rev01 11Document96 pagesMKT11 Ed01 Rev01 11João RangelNo ratings yet

- E76 Ac510 - 520uDocument4 pagesE76 Ac510 - 520uFabianoKovalechenNo ratings yet

- 12 - Right Angle Drives: Catalog Series Material Pages RatiosDocument16 pages12 - Right Angle Drives: Catalog Series Material Pages RatiosODG_290473No ratings yet

- Okuma Simul Turn 400Document11 pagesOkuma Simul Turn 400paulkupasNo ratings yet

- Ringlok RingfederDocument5 pagesRinglok RingfederHector MaldonadoNo ratings yet

- Scule HidrauliceDocument34 pagesScule HidraulicelucianbordeutNo ratings yet

- NTK General MillingDocument14 pagesNTK General Millingswathi_ipeNo ratings yet

- Special Steel Sheet: Cat - No.B1E-005-05Document16 pagesSpecial Steel Sheet: Cat - No.B1E-005-05wahyuNo ratings yet

- Tinnerman PalnutDocument53 pagesTinnerman Palnutjeffls68688No ratings yet

- Tool Steel Alloy Cr12MoVDocument5 pagesTool Steel Alloy Cr12MoVMujjo Sahb100% (1)

- Kyocera Catalog CeramicDocument36 pagesKyocera Catalog CeramicJoel Alexandre Santiago AlmeidaNo ratings yet

- Alberg Cutting Tool 2002 PDFDocument28 pagesAlberg Cutting Tool 2002 PDFApichat1967No ratings yet

- Special Steel Sheet: Cat - No.B1E-005-04Document16 pagesSpecial Steel Sheet: Cat - No.B1E-005-04Arnaldo Macchi MillanNo ratings yet

- Twin Shaft ShredderDocument88 pagesTwin Shaft ShredderZach Loves Sana0% (1)

- Turning X: TAC Toolholders For Super High Feed TurningDocument4 pagesTurning X: TAC Toolholders For Super High Feed TurningArizal AyRevNo ratings yet

- Turbine Blade MachiningDocument36 pagesTurbine Blade Machiningyh1.yuNo ratings yet

- KOBELCO-Copper-Alloy Tubes For Heat ExchangersDocument20 pagesKOBELCO-Copper-Alloy Tubes For Heat Exchangerssumant.c.singh1694No ratings yet

- Ss 400Document4 pagesSs 400A Rahim A Bakar100% (1)

- Classif AçosDocument7 pagesClassif AçoslavascudoNo ratings yet

- Koike Portabel KatalogDocument65 pagesKoike Portabel KatalogAnonymous 4e7GNjzGWNo ratings yet

- Rotork 300 Quarter TurnDocument4 pagesRotork 300 Quarter TurngullenariNo ratings yet

- RAD-6 MRX Radius Milling CutterDocument14 pagesRAD-6 MRX Radius Milling Cutterangkot_01No ratings yet

- Peeled Round Steel BarsDocument9 pagesPeeled Round Steel BarsaxgasaNo ratings yet

- Mesin BubutDocument34 pagesMesin BubutAhmad Amril NurmanNo ratings yet

- Europa 10TH Edition Catalogue PDFDocument530 pagesEuropa 10TH Edition Catalogue PDFnozzon7No ratings yet

- MPVN BrochureDocument32 pagesMPVN Brochurefernando_naciamentNo ratings yet

- Cutting ToolsDocument143 pagesCutting ToolsTone RatanalertNo ratings yet

- AMRI ISORIA 16 Type Series Booklet DataDocument20 pagesAMRI ISORIA 16 Type Series Booklet Datarudiskw456No ratings yet

- Tubular Products From Special MetalsDocument26 pagesTubular Products From Special Metalskaveh-bahiraeeNo ratings yet

- Threading Tools (SST Series)Document8 pagesThreading Tools (SST Series)Gilberto ManhattanNo ratings yet

- 93 Camry SERVICE SPECIFICATIONS - STANDARD BOLTDocument72 pages93 Camry SERVICE SPECIFICATIONS - STANDARD BOLTdgc513No ratings yet

- Service SpecificationDocument95 pagesService SpecificationLoc TruongNo ratings yet

- Sds Eng PDFDocument8 pagesSds Eng PDFdaviko313No ratings yet

- Catalogo - Cilindros Hidraulicos VEGADocument24 pagesCatalogo - Cilindros Hidraulicos VEGARaul Izquierdo MoralesNo ratings yet

- NPA205 Black Rush TaeguTecDocument6 pagesNPA205 Black Rush TaeguTecpchakkrapaniNo ratings yet

- Cold Rolled 2010 DUNAFER HungriaDocument12 pagesCold Rolled 2010 DUNAFER HungriaBeatriz RizzoNo ratings yet

- The Most Economical Solution For Drilling!: Indexable DrillDocument20 pagesThe Most Economical Solution For Drilling!: Indexable DrillapulavartyNo ratings yet

- CDA110 Specifaction SheetDocument5 pagesCDA110 Specifaction SheetGendakensNo ratings yet

- Series: PR13 /PR13 /PR13Document8 pagesSeries: PR13 /PR13 /PR13machineCanNo ratings yet

- Insertos KYOCERA RoscadoDocument3 pagesInsertos KYOCERA RoscadoCristian AlonsoNo ratings yet

- 2 ATI Steellram U INCIMA DimenzijeDocument4 pages2 ATI Steellram U INCIMA DimenzijeBosko LukavicNo ratings yet

- HNK NT VTC Vert Lathes PDFDocument16 pagesHNK NT VTC Vert Lathes PDFs_barriosNo ratings yet

- No 1 20 - 866Document8 pagesNo 1 20 - 866sunanNo ratings yet

- Globe Motor Spec SheetDocument4 pagesGlobe Motor Spec Sheetargh112No ratings yet

- 16MnCr5 SteelDocument3 pages16MnCr5 SteelaravindhNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- TraubDocument28 pagesTraubskidamdnevno0% (1)

- DORMER Product Selector: Tool Recommendation Cutting DataDocument1 pageDORMER Product Selector: Tool Recommendation Cutting DataskidamdnevnoNo ratings yet

- T4 - Svrdlo Fi 10.2Document1 pageT4 - Svrdlo Fi 10.2skidamdnevnoNo ratings yet

- T5 - Svrdlo Fi 15.5 PDFDocument1 pageT5 - Svrdlo Fi 15.5 PDFskidamdnevnoNo ratings yet

- T12 - Glodalo Fi 18 G-TMDocument1 pageT12 - Glodalo Fi 18 G-TMskidamdnevnoNo ratings yet

- Servo DesingDocument2 pagesServo DesingskidamdnevnoNo ratings yet

- Disaster Recovery Planning Template RevisedDocument36 pagesDisaster Recovery Planning Template RevisedSatria Ardi Perdana100% (1)

- T12 - Glodalo Fi 18 G-TMDocument1 pageT12 - Glodalo Fi 18 G-TMskidamdnevnoNo ratings yet

- DORMER Product Selector: Data SheetDocument1 pageDORMER Product Selector: Data SheetskidamdnevnoNo ratings yet

- Full Page PhotFulloDocument1 pageFull Page PhotFulloskidamdnevnoNo ratings yet

- T5 - Svrdlo Fi 15.5Document1 pageT5 - Svrdlo Fi 15.5skidamdnevnoNo ratings yet

- DORMER Product Selector: Data SheetDocument1 pageDORMER Product Selector: Data SheetskidamdnevnoNo ratings yet

- Fi17.5 Za M20 - ČelikDocument1 pageFi17.5 Za M20 - ČelikskidamdnevnoNo ratings yet

- Spell Lists PDFDocument10 pagesSpell Lists PDFskidamdnevnoNo ratings yet

- CATIA Cloud of PointsDocument141 pagesCATIA Cloud of Points4953049530100% (1)

- Full Page PhotoDocument1 pageFull Page PhotoskidamdnevnoNo ratings yet

- Ed 06 (EN)Document8 pagesEd 06 (EN)skidamdnevnoNo ratings yet

- Ed 02Document58 pagesEd 02skidamdnevnoNo ratings yet

- Web FibreglassGuideDocument40 pagesWeb FibreglassGuideskidamdnevnoNo ratings yet

- Bosion BX410Document21 pagesBosion BX410skidamdnevnoNo ratings yet

- How To Use Enc28j60 Ethernet Shield With Arduino Mega 2560Document5 pagesHow To Use Enc28j60 Ethernet Shield With Arduino Mega 2560skidamdnevnoNo ratings yet

- PrefacesDocument7 pagesPrefaceslaleye_olumideNo ratings yet

- Force, Torque, and PowerDocument2 pagesForce, Torque, and PowerskidamdnevnoNo ratings yet

- App ADocument3 pagesApp ASigit Eka Duwi TamaNo ratings yet

- Serveri PDFDocument83 pagesServeri PDFskidamdnevnoNo ratings yet

- Cymill Cyspeed enDocument111 pagesCymill Cyspeed enskidamdnevnoNo ratings yet

- 6.3.1 Gear Terms Lesson Rev3Document19 pages6.3.1 Gear Terms Lesson Rev3meg77717No ratings yet

- Moment of InertiaDocument1 pageMoment of Inertiavimalraj93No ratings yet

- Command Line v10.4Document304 pagesCommand Line v10.4skidamdnevnoNo ratings yet

- p12 EnglischDocument8 pagesp12 EnglischskidamdnevnoNo ratings yet

- ASH ReportDocument3 pagesASH ReportChandra SekharNo ratings yet

- SAP Lot Sizing ParameterDocument1 pageSAP Lot Sizing ParameterWilliam HolidiNo ratings yet

- M.Tech. 2nd (Non CBCS) May 2018 - 9 - 5 - 18Document2 pagesM.Tech. 2nd (Non CBCS) May 2018 - 9 - 5 - 18doob marroNo ratings yet

- Software Project Engineer in Richland Kennewick Pasco WA Resume Robert VeklotzDocument2 pagesSoftware Project Engineer in Richland Kennewick Pasco WA Resume Robert VeklotzRobertVeklotzNo ratings yet

- Introduction To Boltzmann LearningDocument2 pagesIntroduction To Boltzmann LearningnvbondNo ratings yet

- 01-RH124 Red Hat System Administration IIDocument4 pages01-RH124 Red Hat System Administration IIpimentel-diogo2056No ratings yet

- Tutorial 9Document4 pagesTutorial 9fawwazfauzi2004No ratings yet

- Erita Astrid - UPBDocument25 pagesErita Astrid - UPBmas_kinooooNo ratings yet

- COOLANT Komatsu PDFDocument16 pagesCOOLANT Komatsu PDFdarwin100% (1)

- Director Talent Acquisition HR in Fargo ND Resume Tom FennellDocument2 pagesDirector Talent Acquisition HR in Fargo ND Resume Tom FennellTomFennellNo ratings yet

- TDSC Tpus420 enDocument23 pagesTDSC Tpus420 encatalind_cdNo ratings yet

- Press Working OperationsDocument23 pagesPress Working OperationsKanagaraj Ganesan100% (1)

- HILTI Typical Plumbing ApplicationsDocument140 pagesHILTI Typical Plumbing ApplicationskuraimundNo ratings yet

- TIBCO Hawk Rulebase Standard GuidelinesDocument9 pagesTIBCO Hawk Rulebase Standard GuidelinesAshish ShrivastavaNo ratings yet

- Sony Blitz h36 - ManualDocument212 pagesSony Blitz h36 - ManualBohorc Ivica JerryNo ratings yet

- 16HE018 Graphite Heat Exchanger DCBH Project Sr. No. Particulars Units Our Requirement Process Side Utility SideDocument2 pages16HE018 Graphite Heat Exchanger DCBH Project Sr. No. Particulars Units Our Requirement Process Side Utility SideBhaumik BhuvaNo ratings yet

- 1.5-7 Power Distribution Systems Reference Data: Motor ProtectionDocument1 page1.5-7 Power Distribution Systems Reference Data: Motor ProtectionMiguel Augusto Donayre CarbajalNo ratings yet

- Jobs Movie ReviewDocument2 pagesJobs Movie ReviewSaleh RehmanNo ratings yet

- Characterization and Application of Cerium Fluoride Film in InfraredDocument4 pagesCharacterization and Application of Cerium Fluoride Film in InfrarednguyenthanhhopNo ratings yet

- Esna CatalogDocument12 pagesEsna Catalogbalaji_jayadeva9546No ratings yet

- Pioneer pdp-424mv Pdp-42mve1 (ET)Document122 pagesPioneer pdp-424mv Pdp-42mve1 (ET)Manuel PeraltaNo ratings yet

- Full Marks: 50 Duration: 3 HoursDocument2 pagesFull Marks: 50 Duration: 3 HoursK JaiswalNo ratings yet

- Electrica QC Check ListDocument21 pagesElectrica QC Check Listmakana qc100% (1)

- 8098 Spare Parts ListDocument29 pages8098 Spare Parts ListJuan Gomez67% (3)

- Bou-Llusar Et Al 2009 EFQM Excellence ModelDocument22 pagesBou-Llusar Et Al 2009 EFQM Excellence Modelfastford14No ratings yet

- HS GB 3109 PQ 12 Drive ElectronicsDocument7 pagesHS GB 3109 PQ 12 Drive Electronicsphankhoa83No ratings yet

- Installation Operation Maintenance 7200CB en USDocument140 pagesInstallation Operation Maintenance 7200CB en USEleno RibeiroNo ratings yet

- Appendix 1: Lesson Plan (Template)Document4 pagesAppendix 1: Lesson Plan (Template)Anonymous X7u8sMNo ratings yet

- Bituthene Mastic - Data SheetDocument2 pagesBituthene Mastic - Data SheettamilnishaNo ratings yet

- Built in Classes in JavaDocument104 pagesBuilt in Classes in JavaarchanaNo ratings yet