Professional Documents

Culture Documents

IB Topic How To Cut Internal Threads

Uploaded by

redneckrepairs0 ratings0% found this document useful (0 votes)

53 views11 pageslathe threading

Original Title

IB Topic How to Cut Internal Threads

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentlathe threading

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

53 views11 pagesIB Topic How To Cut Internal Threads

Uploaded by

redneckrepairslathe threading

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 11

Please Help support the forums.....we need subscribers to help keep us online.

Recommend this on Google

Roderus Custom Gunworks :: Home Gunsmith Forums

Home Gunsmithing Forums

Welcome RedneckRepairs

[ Your Control Panel :: Log Out :: Notes :: New Posts ] Your messenger (2 new)

Home Gunsmith Forums Main Forums Home Machine Shop How to cut internal threads

Pages: (4) < [1] 2 3 4 >

[ Track this topic :: Email this topic :: Print this topic ]

Topic: How to cut internal threads, ...in case you wanted to know < Next Oldest | Next Newest >

GeneT

LIFE MEMBER

Group: Community Pillar

Posts: 3579

J oined: April 2005

Posted: Dec. 23 2008,14:50

In this exercise we'll cut some internal threads. I nternal threading is very much like external threading, but with two additional

challenges:

1.Getting over your fear of cutting internal threads.

2.Remembering to dial the cross-slide in the opposite direction to back out of the cut at the end.

As you can see, that's only one 'real' challenge, and it's not a difficult one to overcome.

Required Tools:

1.A bench grinder with course and fine stones

2.A sharpening stone

3.A lathe with change gears or a quick- change gear box

4.A 60* threading gage ('fishtail' gage)

5.A thread pitch gage.

Required Materials

1.A threading tool these are numerous in design and any internal tool will work, they may be

1.Ground from a single piece

2.A High Speed Steel (HSS) bit, appropriately ground and placed in a boring bar

3.A carbide insert type. (Not recommended for your first attempts, unless you don't mind ruining $25 inserts when you mess up...)

2.A piece of metal with a hole in it to bore

Process:

Let's start by preparing a tool. I f you're using a manufactured tool, you can skip down to lathe setup. We'll detail creating a tool to fit

in a boring bar. We'll use a commercial boring bar, but don't be afraid to make one, they're no more complex than a piece of bar

with a hole cross-drilled through it and and a center hole drilled and tapped to hold the cutter in place. Generally speaking you want

to use the largest boring bar that will fit into the hole to be threaded but remember you must leave room for the threading tip as

well! If you make a bar, it should be cross-drilled for a specific size toolbit, select a size that is wide enough to cut your full thread.

One nice thing about grinding internal threading tools is that they generally use a smaller tool bit, so grinding is faster.

Gather your boring bar, tool bit and fishtail gage. Your tool bit will be quite a bit too long, but leave it that way for now it'll give

you something to hold on to while grinding.

Attached Image

67 people like this. Sign Up to see whatyour friends like. Like Like Share Share

iB::Topic::How to cut internal threads http://www.homegunsmith.com/cgi-bin/ib3/ikonboard.cgi?s=778386e4bd...

1 of 11 2/15/2014 6:55 AM

Create PDF files without this message by purchasing novaPDF printer (http://www.novapdf.com)

--------------

50 BMG Site

Firearms Designer

Back to top

Report this post to a moderator

GeneT

LIFE MEMBER

Group: Community Pillar

Posts: 3579

J oined: April 2005

Posted: Dec. 23 2008,14:51

Set your grinder tool rest at about a 5* angle, which will impart side clearance, and holding the cutter at about 30* grind in from

both sides until you reach a point. Check the point in the fishtail gage and correct the angle until it is exactly 60*.

Attached Image

iB::Topic::How to cut internal threads http://www.homegunsmith.com/cgi-bin/ib3/ikonboard.cgi?s=778386e4bd...

2 of 11 2/15/2014 6:55 AM

Create PDF files without this message by purchasing novaPDF printer (http://www.novapdf.com)

--------------

50 BMG Site

Firearms Designer

Back to top

Report this post to a moderator

GeneT

LIFE MEMBER

Group: Community Pillar

Posts: 3579

J oined: April 2005

Posted: Dec. 23 2008,14:52

When you have achieved a perfect 60*, it's time to add the front clearance. If this were an external cutting tool, the front clearance

produced by grinding the angle would probably be sufficient, but this tool will go inside a hole, so some additional front clearance is

necessary at the base of the tool (not all the way to the top). This 'compound front clearance' will allow threading inside a smaller

hole. How much depends on how tight the hole to be threaded is. You just want to make sure that the bottom of the bit doesn't

contact the work.

Attached Image

iB::Topic::How to cut internal threads http://www.homegunsmith.com/cgi-bin/ib3/ikonboard.cgi?s=778386e4bd...

3 of 11 2/15/2014 6:55 AM

Create PDF files without this message by purchasing novaPDF printer (http://www.novapdf.com)

--------------

50 BMG Site

Firearms Designer

Back to top

Report this post to a moderator

GeneT

LIFE MEMBER

Group: Community Pillar

Posts: 3579

J oined: April 2005

Posted: Dec. 23 2008,14:52

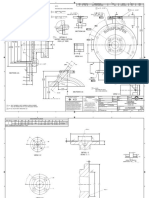

Here's a drawing that I hope better illustrates the clearance we're after.

Attached Image

iB::Topic::How to cut internal threads http://www.homegunsmith.com/cgi-bin/ib3/ikonboard.cgi?s=778386e4bd...

4 of 11 2/15/2014 6:55 AM

Create PDF files without this message by purchasing novaPDF printer (http://www.novapdf.com)

--------------

50 BMG Site

Firearms Designer

Back to top

Report this post to a moderator

GeneT

LIFE MEMBER

Group: Community Pillar

Posts: 3579

J oined: April 2005

Posted: Dec. 23 2008,14:53

Now cut the bit to a reasonable length (just enough that the tip sticks out of the boring bar fully and the back is flush, or a little

proud). You can cut the bit with a dremel and cutting wheel. I nstall the tool in the boring bar so it points back toward you when it's

in the lathe. (Your mom probably told you never to point cutting tools at yourself, so make sure she's locked out of the shop before

continuing.)

Attached Image

iB::Topic::How to cut internal threads http://www.homegunsmith.com/cgi-bin/ib3/ikonboard.cgi?s=778386e4bd...

5 of 11 2/15/2014 6:55 AM

Create PDF files without this message by purchasing novaPDF printer (http://www.novapdf.com)

--------------

50 BMG Site

Firearms Designer

Back to top

Report this post to a moderator

GeneT

LIFE MEMBER

Group: Community Pillar

Posts: 3579

J oined: April 2005

Posted: Dec. 23 2008,14:54

I should have mentioned that the top of the bit should be flat and level when set up in the boring bar.

Lathe setup

Set the compound to 29.5*. That is, if 0* is pointing straight away from you, the compound gets rotated to the far end is 29.5* away

from that centerline and pointed toward the headstock. The important thing here is that it's a little less than 30*, use the graduations

provided it doesn't have to be super accurate.

Attached Image

iB::Topic::How to cut internal threads http://www.homegunsmith.com/cgi-bin/ib3/ikonboard.cgi?s=778386e4bd...

6 of 11 2/15/2014 6:55 AM

Create PDF files without this message by purchasing novaPDF printer (http://www.novapdf.com)

--------------

50 BMG Site

Firearms Designer

Back to top

Report this post to a moderator

GeneT

LIFE MEMBER

Group: Community Pillar

Posts: 3579

Joined: April 2005

Posted: Dec. 23 2008,14:55

Run the compound forward, so you have enough room to back into the cut.

Now setup the workpiece. You may be threading an existing hole (in which case you'll need to center it) or drilling a hole in order

to thread. I f you drill, centering is taken care of. You may need to use a standard boring bar to open the hole to the desired size.

I f you don't know what hole size to start with, consult a reference like Machinery's Handbook. Even if you're cutting a non-standard

diameter, there are tables that tell you what diameters are appropriate for a given thread engagement. I f you are cutting a

standard size, you want your hole to be as big as the minor diameter to start with. Remember, unlike external threading you're

making the thread bigger with each pass.

Give some thought to setting up the workpiece. There are two basic internal threads, through and blind. The through thread is the

easiest, because it's not critical where the cutter stops, just sometime after you've cut through the work. I f your lathe is big enough

to 'swing' it, cutting an AR-15 buffer tower is one of the easiest internal threads you can do. When cutting through threads, be sure

there is room to stop before the boring bar crashes into the back of the lathe chuck. Blind threads are those that stop somewhere

inside the hole, and it's more critical that you stop where you should, to avoid crashing the cutter into a 'step' if the diameter is

smaller after the thread ends. Cut a thread relief the depth of the thread at the back of the hole. I f the part allows it, make it 0.1

long to give you plenty of time to stop the lathe.

The AR buffer tower is a through thread...

Attached I mage

iB::Topic::How to cut internal threads http://www.homegunsmith.com/cgi-bin/ib3/ikonboard.cgi?s=778386e4bd...

7 of 11 2/15/2014 6:55 AM

Create PDF files without this message by purchasing novaPDF printer (http://www.novapdf.com)

--------------

50 BMG Site

Firearms Designer

Back to top Report this post to a moderator

GeneT

LIFE MEMBER

Group: Community Pillar

Posts: 3579

J oined: April 2005

Posted: Dec. 23 2008,14:56

Threading the tube for a silencer (where the thread minor diameter is larger than the tube diameter) is a 'blind thread'.

Attached Image

iB::Topic::How to cut internal threads http://www.homegunsmith.com/cgi-bin/ib3/ikonboard.cgi?s=778386e4bd...

8 of 11 2/15/2014 6:55 AM

Create PDF files without this message by purchasing novaPDF printer (http://www.novapdf.com)

--------------

50 BMG Site

Firearms Designer

Back to top

Report this post to a moderator

GeneT

LIFE MEMBER

Group: Community Pillar

Posts: 3579

J oined: April 2005

Posted: Dec. 23 2008,14:57

With the workpiece set up and ready to thread, install the boring bar in the lathe. Make sure it extends deep enough to cut the

thread depth, but not much deeper. (The less the boring bar sticks out, the more rigid the setup.) Set the cutter height at or just a

bit below center. Now square the cutter to the workpiece. The fishtail gage can be used for this, though I sometimes cheat and just

square the boring bar to the work.

Attached Image

iB::Topic::How to cut internal threads http://www.homegunsmith.com/cgi-bin/ib3/ikonboard.cgi?s=778386e4bd...

9 of 11 2/15/2014 6:55 AM

Create PDF files without this message by purchasing novaPDF printer (http://www.novapdf.com)

--------------

50 BMG Site

Firearms Designer

Back to top

Report this post to a moderator

GeneT

LIFE MEMBER

Group: Community Pillar

Posts: 3579

J oined: April 2005

Posted: Dec. 23 2008,14:58

Now it's pretty much like normal threading. Run the boring bar inside the bore, dial the cross-slide back until the cutter touches and

zero it. Double check that there's enough clearance at the bottom of the cutter. Run the cutter back to the thread relief, or

stopping point and zero the X axis. Now bring the cutter out, dial the cross-slide to zero.

Set up the lathe to cut your desired thread pitch and engage the threading dial. At the end of each cut you will want to

simultaneously disengage the half-nut and back the cutter out of the cut. To do this have one hand on the half-nut and one hand on

the cross-slide dial. Now, if you've cut a lot of external threads your hand knows which way to spin the cross-slide for an external

thread, but this is backwards and those habits can mean the death of the cutter (especially if it's carbide) or the workpiece. You must

remember to run the cross-slide forward. A tip that works for me is to draw an arrow on the cross-slide dial indicating which way to

turn, make sure your hand is 'cocked' to turn in that direction before engaging the half-nut with each pass.

Attached Image

iB::Topic::How to cut internal threads http://www.homegunsmith.com/cgi-bin/ib3/ikonboard.cgi?s=778386e4bd...

10 of 11 2/15/2014 6:55 AM

Create PDF files without this message by purchasing novaPDF printer (http://www.novapdf.com)

--------------

50 BMG Site

Firearms Designer

Back to top

Report this post to a moderator

35 replies since Dec. 23 2008,14:50 < Next Oldest | Next Newest >

[ Track this topic :: Email this topic :: Print this topic ]

Pages: (4) < [1] 2 3 4 >

Forum Jump

Quick Reply: How to cut internal threads

iB Code Buttons B I U http:// @ Quote Code Image Flash

You are Posting as:

RedneckRepairs

Do you wish to enable

your signature for this post?

Do you wish to enable

emoticons for this post?

Track this topic

View All Emoticons

View iB Code

Quick Post Preview

Home Gunsmith Forums Main Forums Home Machine Shop How to cut internal threads

2004 Roderus Productions, LLC

Powered by Ikonboard 3.1.2a 2003 Ikonboard

iB::Topic::How to cut internal threads http://www.homegunsmith.com/cgi-bin/ib3/ikonboard.cgi?s=778386e4bd...

11 of 11 2/15/2014 6:55 AM

Create PDF files without this message by purchasing novaPDF printer (http://www.novapdf.com)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Jeff Cooper's Commentaries - Vol. 8, 00Document78 pagesJeff Cooper's Commentaries - Vol. 8, 00redneckrepairsNo ratings yet

- Jeff Cooper's Commentaries - Vol. 7, 99Document73 pagesJeff Cooper's Commentaries - Vol. 7, 99redneckrepairsNo ratings yet

- Jeff Cooper's Commentaries - Vol. 9, NoDocument29 pagesJeff Cooper's Commentaries - Vol. 9, NoredneckrepairsNo ratings yet

- 1911 12 REM UMC Retail CatalogDocument189 pages1911 12 REM UMC Retail CatalogredneckrepairsNo ratings yet

- Home Made TanneriteDocument9 pagesHome Made TanneriteVimace67% (9)

- Snail Bullet TrapDocument4 pagesSnail Bullet TrapredneckrepairsNo ratings yet

- AR 15 Lower Receiver Step by StepDocument81 pagesAR 15 Lower Receiver Step by StepNorm96% (27)

- Grinding Your Own Lathe ToolsDocument9 pagesGrinding Your Own Lathe ToolsredneckrepairsNo ratings yet

- Fast and Dirty WeldingDocument2 pagesFast and Dirty WeldingredneckrepairsNo ratings yet

- 5278 Manual - Mini Metal LatheDocument26 pages5278 Manual - Mini Metal Latheredneckrepairs50% (2)

- Grinding Lathe Tools On A Belt Sander - Part 2 - MachinistBlogDocument7 pagesGrinding Lathe Tools On A Belt Sander - Part 2 - MachinistBlogredneckrepairsNo ratings yet

- Grinding Lathe Tools On A Belt Sander - For The New Guy - MachinistBlogDocument13 pagesGrinding Lathe Tools On A Belt Sander - For The New Guy - MachinistBlogredneckrepairs100% (1)

- How To - DIY Anodising - Aussie Street BikesDocument8 pagesHow To - DIY Anodising - Aussie Street BikesredneckrepairsNo ratings yet

- Uputstvo Za Obijanje Brava (Englseki)Document18 pagesUputstvo Za Obijanje Brava (Englseki)Nermin SelicNo ratings yet

- Grinding Lathe Tools On A Belt Sander - Part 3 - MachinistBlogDocument11 pagesGrinding Lathe Tools On A Belt Sander - Part 3 - MachinistBlogredneckrepairsNo ratings yet

- Eddie The Wire-The Complete Guide To LockpickingDocument83 pagesEddie The Wire-The Complete Guide To Lockpickingapi-3777781100% (5)

- Uputstvo Za Obijanje Brava (Englseki)Document18 pagesUputstvo Za Obijanje Brava (Englseki)Nermin SelicNo ratings yet

- Silencer Threadless Connector - US Patent 3698747Document4 pagesSilencer Threadless Connector - US Patent 3698747ArchdukePotterNo ratings yet

- Farm BuildingsDocument198 pagesFarm Buildingsredneckrepairs100% (1)

- FM 999 3 Counter Zombie Operations at The Fireteam LevelDocument21 pagesFM 999 3 Counter Zombie Operations at The Fireteam LevelMike LambNo ratings yet

- The Geezer CookbookDocument83 pagesThe Geezer CookbookDarren WhiteleyNo ratings yet

- Prison Camp LatheDocument6 pagesPrison Camp LatheChukwuRapNo ratings yet

- Free 12 X 8 Shed Plan - Step by Step DIYDocument24 pagesFree 12 X 8 Shed Plan - Step by Step DIYgo2top2No ratings yet

- DHS: Rightwing Extremism ReportDocument10 pagesDHS: Rightwing Extremism ReportTucsonSentinel50% (2)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Dumy Rack RXP501 PDFDocument1 pageDumy Rack RXP501 PDFTuyenNo ratings yet

- We Will Cover:: Machine Guarding PrinciplesDocument32 pagesWe Will Cover:: Machine Guarding PrinciplesChaitanya MyneniNo ratings yet

- Engines Kid InstructionsDocument1 pageEngines Kid InstructionsBruce BelvinNo ratings yet

- SBCF Ils-T-Rwy-16 Iac 20200102 PDFDocument1 pageSBCF Ils-T-Rwy-16 Iac 20200102 PDFMatheus Ekermann PachecoNo ratings yet

- Iaito English CatalogDocument44 pagesIaito English CatalogAntonio Maza GamboaNo ratings yet

- Lecture Note 12+13 (Actuators) - Mechanical ActuationDocument42 pagesLecture Note 12+13 (Actuators) - Mechanical ActuationBăng Trương Thanh100% (1)

- Tikka - T1x - 3x - Instruction Manual - S34065180 - v5.1 - WEB PDFDocument128 pagesTikka - T1x - 3x - Instruction Manual - S34065180 - v5.1 - WEB PDFLevchenko IvanNo ratings yet

- M240LWDocument2 pagesM240LWHenry ArnoldNo ratings yet

- Product Data Sheet: Duct Detector, Single Pipe UniversalDocument2 pagesProduct Data Sheet: Duct Detector, Single Pipe UniversalAndrei PantaNo ratings yet

- Weapon Tags: Slug Thrower PistolDocument6 pagesWeapon Tags: Slug Thrower PistolAndrés MattNo ratings yet

- Amarpreet Hotel (Aurangabad) : A Basement S.No Description QTYDocument22 pagesAmarpreet Hotel (Aurangabad) : A Basement S.No Description QTYrafroz_87No ratings yet

- Hydraulic Bolt TensioningDocument19 pagesHydraulic Bolt Tensioningadarsh100% (1)

- Maximum Metal 2Document114 pagesMaximum Metal 2Mr.Karma100% (2)

- Gear Grinding: Software UpdateDocument92 pagesGear Grinding: Software UpdategrazianogirottoNo ratings yet

- Man Rider - Fa150 Kgi PartsDocument24 pagesMan Rider - Fa150 Kgi PartsLIVIANo ratings yet

- SSR Instruction ManualDocument12 pagesSSR Instruction Manualgrandmas developerNo ratings yet

- css9-ppt Hand ToolsDocument43 pagescss9-ppt Hand ToolsCleo Angelique BañaresNo ratings yet

- Botox QuotationDocument4 pagesBotox QuotationCatherine ZamudioNo ratings yet

- S05 Drilling CompartmentDocument62 pagesS05 Drilling CompartmentPeetNo ratings yet

- A E B G: CasingDocument2 pagesA E B G: CasingAgnel StanleyNo ratings yet

- Actuator F Series PDFDocument11 pagesActuator F Series PDF0303tatanNo ratings yet

- Masterkidz Toys Catalog Lite Version 2024 SpringDocument61 pagesMasterkidz Toys Catalog Lite Version 2024 Springicc.willyNo ratings yet

- David PisotDocument4 pagesDavid PisotLucy AmallNo ratings yet

- Minnesota Deer Permit Areas 2022Document2 pagesMinnesota Deer Permit Areas 2022inforumdocsNo ratings yet

- Enerpac LPHT312: Operation & Maintenance ManualDocument26 pagesEnerpac LPHT312: Operation & Maintenance ManualMohammed Al-BayatiNo ratings yet

- Meritor Service Manual DUCO - MM1127Document83 pagesMeritor Service Manual DUCO - MM1127LUKASNo ratings yet

- Boat Scarf JigDocument1 pageBoat Scarf JigFrancois VaaltynNo ratings yet

- Modern Further Thoughts - RAPID FIRE!Document2 pagesModern Further Thoughts - RAPID FIRE!jensenrontNo ratings yet

- Milling Machines: - Column-And-Knee Milling Machines - Bed Type Milling Machines - Machining CentersDocument10 pagesMilling Machines: - Column-And-Knee Milling Machines - Bed Type Milling Machines - Machining Centersrk_kamatchi3483No ratings yet

- 4A Detailed Lesson Plan in Hand ToolsDocument10 pages4A Detailed Lesson Plan in Hand ToolsRuel John Barrientos ClamianoNo ratings yet