Professional Documents

Culture Documents

Checklist For Inspecting Vessels Loading Propylene Oxide PO

Uploaded by

morgoths100%(1)100% found this document useful (1 vote)

171 views7 pagesChecklist for Inspecting vessels loading propylene oxide PO

Original Title

Checklist for Inspecting vessels loading propylene oxide PO

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentChecklist for Inspecting vessels loading propylene oxide PO

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

171 views7 pagesChecklist For Inspecting Vessels Loading Propylene Oxide PO

Uploaded by

morgothsChecklist for Inspecting vessels loading propylene oxide PO

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 7

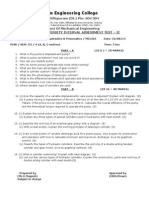

PROPYLENE OXIDE SURVEY QUESTIONAIRE

(COMPLIANCE WITH DOW BULK HANDLING GUIDELINES)

Vessel name: Vessel owner:

Date of inspection: Inspection location:

Inspector:

CERTIFICATES:

Ref A.1.a Applicable U.S. Coast Guard Letter of Compliance or te I!" Certificate for te

carria#e must be current prior to te loadin# and for te duration of te $o%a#e.

Certificate of &itness includes '.". (es )o

Date Issued: *+piration Date:

Issued b%:

Date of ne+t

annual sur$e%

USCG Letter of Compliance:

Date issued: *+piration date:

List of car#o tan,s appro$ed for '.".

Conditions of carria#e of '.". per certificates -attac a cop%.:

Does $essel meet tese conditions/ (es )o )0A

If not1 note reasons below:

DOW GAS RULES:

If th !""# $" % &%" !""#' ()" $t *)+,#- .$th D)./" G%" R0#"1

Vessel 2%pe: SR Gas &R Gas Cem "ter:333333333333333333333333333333333

Y" N) N2A

TANK TIGHTNESS CERTIFICATES (R30$4( %t ")+ U5S5 "$t"' "0*h %" F4,)4t2H)0"t)6):

D)" th !""# h%! t%67 t$&ht6"" *4t$f$*%t" f)4 %## t%67" %,,4)!( f)4 PO1

Note: Vessel must provide a copy of these to the terminal prior to the transfer

Y" N) N2A

If 8YES9' $" !""# $6 *)+,#$%6* .$th th %660%# t"t$6& 430$4+6t1

Date of last test:3333333333333333333

Y" N) N2A

If 8NO9' ()" !""# h%! ,4)*(04"2,%,4.)472,#%6" t) *)+,#t th t"t ,4$)4 t) %44$!%# t) t4%6"f4

*%4&)1

Y" N) N2A

4*' 0 5 September 6778

669:77685.doc

'a#e 1 of 9

P4!$)0" *%4&)" : f)4 t%67" %,,4)!( f)4 *%44$%& )f PO:

2an, Last Car#o 6

nd

Last ;

rd

Last

'lan to use

for Dow '"

tis trip

Ad<acent

car#oes "=

per USCG

!eets '"

Guidelines

PREPARATION FOR LOADING:

Car#o will be loaded usin# $apor return1 discar#ed under nitro#en blan,et

(es )o

Car#o tan,s and pipin# s%stem must be pur#ed wit nitro#en to an o+%#en content of less tan 7.> ? ->1777 ppm.

o+%#en before loadin# is commenced. &or some sipments -Dow 'ol%uretane business.1 te $apor space of car#o

tan,s are pur#ed to less tan 7.7>? ->77 ppm. o+%#en before te sip departs. It is recommended to add nitro#en

trou# te li@uid line -nitro#en bubblin#. to stabiliAe pressure durin# te $o%a#e.

(es )o

Void spaces around car#o tan,s must be pur#ed wit nitro#en to B6? -671777 ppm. o+%#en.

(es )o )0A

Void spaces on #as tan,ers1 wit independent t%pe C tan,s must 6)t be pur#ed1 unless re@uired b%

re#ulation or '" andlin# manual. "n tese #as tan,ers a functionin# #as monitorin# s%stem must be

installed in te $oid space.

(es )o )0A

4*' 0 5 September 6778

669:77685.doc

'a#e 6 of 9

CARGO SYSTEM:

Car#o tan,s1 car#o pipin#1 and support s%stems drawin#s are a$ailable on board/

(es )o

Vessel as a '" Se#re#ation 'lan a$ailable -per Dow bul, #uidelines. wic includes remo$al of spool pieces and

installation of blind flan#es to se#re#ate te '" from oter products/

Note: The use of a modified Seutelven (SEUT) Blind lan!e Valve is accepta"le as an isolatin! device for

propylene o#ide car!o in marine shipments$ The term modified refers to the use of a valve disc assem"ly

that has t%o permanently attached pins of sufficient len!th and diameter to prevent the installation of "oth

the valve flan!e cover and drain plu! %hen the valve is "ein! used as an isolatin! device$

(es )o

2an, was s%stem pipin# internal to te car#o tan,s must be self drainin# and must be se#re#ated from te

Al,%lene "+ides car#o s%stem b% remo$al of spool pieces or b% insertion of blan,in# de$ices prior to loadin#.

(es )o

Vessel as a closed samplin# s%stem for eac tan,/ 2%pe:3333333333333333333333333333333333333333

(es )o

Val$ed $apor sample points installed at eac tan,/

(es )o

MATERIALS OF CONSTRUCTION:

Acceptable?

List MOC Yes No

Car#o 2an,s

Cinc based coatin#s are normall% acceptable. Dut te% need to be $erified b% te

Eualit% Assurance Coordinator -EAC. or is desi#nated representati$e before

loadin#. "ter tan Ainc based coatin#s are not acceptable. Stainless steel is

preferred.

Li@uid lines

Vapor lines

Strippin# lines

Val$es0flan#es0fittin#s

Accessor% e@uipment

LIQUID LINE SYSTEM:

Does te $essel a$e dedicated lines for eac tan,/

&f not' descri"e %hich tan( systems have dedicated lines' and the method for se!re!ation)isolation$

(es )o

Identif% te t%pe of $al$es tat te $essel as in te li@uid line -ball1 butterfl%1 plu#1 etc..:

Automatic $al$es

!anual $al$es

D)" th !""# h%! % "%+,# ,)$6t %t th "h$,/" 4%$# f)4 t%7$6& % *%4&) #$6 "%+,#1

(es )o )0A

Does te load line contain suitable lowFpoint bleeds/ (es )o )0A

4*' 0 5 September 6778

669:77685.doc

'a#e ; of 9

VAPOR RETURN LINE SYSTEM:

Does te $essel a$e dedicated lines for eac tan,/

&f not' descri"e %hich tan( systems have dedicated lines' and the method for se!re!ation)isolation$

(es )o

Identif% te t%pe of $al$es tat te $essel as in te $apor return line -ball1 butterfl%1 plu#1 etc..:

Automatic $al$es

!anual $al$es

Does te $apor return line contain suitable lowFpoint bleeds/ (es )o )0A

MONITORING SYSTEM:

2an, le$el de$ices:

Readout

Drid#e Car#o Control Room

2%pe location

"ter -specif%.

"ter de$ices -list.:

Are all of te tan, le$el de$ices GclosedH s%stems/ (es )o )0A

2an, temperature de$ices:

2%pe I J Readout

Drid#e Car#o Control Room

Location 2op !iddle Dottom location

"ter -specif%.

'ressure sensors I #au#es:

Sensor:

2%pe I J Readout

Drid#e Car#o Control Room

Gau#es:

2%pe I J

location

"ter -specif%.

Alarms:

2%pe Setpoint 2%pe alarm 2%pe of s%stem ta,in# action

Ki# le$el ? Audio Visual Sutdown Computer Independent Dot

Ki# Ki# le$el ? Audio Visual Sutdown Computer Independent Dot

Ki# temp.

L

&i+ed

Variable Audio Visual Sutdown Computer Independent Dot

Ki# Ki# temp.

L

&i+ed

Variable Audio Visual Sutdown Computer Independent Dot

&or $ariable settin#s Ki# temperature Low 'ressure Ki# 'ressure

Setpoint for '.". L

4*' 0 5 September 6778

669:77685.doc

'a#e M of 9

COOLING SYSTEM:

Does te $essel a$e a coolin# plant/

(es )o

Copies of te sipNs lo#s used to record information about te 'rop%lene "+ide car#o and tan,s utiliAed for tat

car#o will be furnised to Carters for re$iew at te discar#e point

(es )o

Keatin# coils operated wit steam are to be blown dr% and blinded upon arri$al and prior to loadin#. Include

cec,s for possible lea,s durin# preFload inspections. Keatin# coils operated wit a eatin# fluid -e.#. termal

oil. are to be se#re#ated b% means of spool pieces or b% insertion of blan,in# de$ices upon arri$al and prior to

loadin#.

(es )o )0A

Vessel aware tat Al,%lene "+ide temperatures must not e+ceed 6> LC durin# carria#e or loadin# (es )o

Vessel aware tat a cop% of te carria#e lo# must be attaced to te sur$e%orNs report at discar#e. 2e

carria#e lo# sould at least contain $esselNs name1 $o%a#e from 0 to1 D"O reference number1 product name1

tan, number1 initial loadin# temperature1 date and time wen measurements are ta,en1 respecti$e tan,

temperature1 and an% e+ceptions.

(es )o

Vessel understands tat $apor reFcompression of Al,%lene "+ides will not be allowed1 and suc s%stems are

se#re#ated from tan, and $ent s%stems b% remo$al of spool pieces and b% insertion of blan,in# de$ices

(es )o )0A

Ad<acent car#o tan,s tat sare a common bul,ead sould not be eated abo$e a ma+imum of P;7 LC. -)ote

te $apor pressure of 'rop%lene "+ide is 987 mm K# at P;M.> LC..

(es )o )0A

Acceptable car#o coolin# s%stems are tose usin# RF161 RF661 RF1;Ma or #l%colFwater s%stem. "ter

refri#erants are onl% acceptable if te% a$e been appro$ed b% te C"G 2ecnolo#% Center.

(es )o )0A

Ref I.A.M Vessels intended to be used for carr%in# 'rop%lene "+ide and wic are not e@uipped wit an onFboard car#o

refri#eration s%stem can onl% be utiliAed if te followin# re@uirements are full% met:

2e Vessel "wner warrants tat Vessels used are appro$ed -Certificate of &itness. for

carria#e of 'rop%lene "+ide in tan,s a$in# at least 7.8 bar pressure ratin#.

(es )o )0A

2at te respecti$e Classification Societ% and1 wen enterin# United States ports1 te

United Coast Guard appro$e usin# sea water spra% dec, coolin#.

(es )o )0A

2at te Vessel to be used is e@uipped wit a separate independent sea water pump and

lines for dec, coolin#1 to ensure tat primar% firefi#tin# s%stem is not relied upon for

coolin#.

(es )o )0A

'ro$ide details describin# te coolin# plant and0or dec, coolin# s%stem:

PRESSURE RELIEF DEVICES:

Does eac tan, a$e a pressure relief $al$e/ (es )o

Does eac tan, a$e a $acuum relief $al$e/ (es )o )0A

Does eac $entmast include an installed flame arrestor/ (es )o )0A

Settin#s: 'ressure: bar

&i+ed

Variable

Vacuum: bar

&i+ed

Variable

Car#o tan, pressure relief $al$es must be set to relie$e witin 7.1> to 17 bar #au#e. 2e relief pressure

must not be #reater tan te desi#n pressure of te car#o tan,.

(es )o

INSULATION:

Are te car#o tan,s insulated/ -if so describe. (es )o

*ar!o tan( insulation' if installed' must "e a closed cell non+a"sor"ent insulation such as urethane'

foam !lass' ceramic foam or a "loc( perlite type insulation system$ ,a!nesia insulations are not

accepta"le$

(es )o )0A

*ar!o systems must "e a"le to maintain carria!e temperature limits$ Uninsulated car!o tan(s may "e

fitted %ith coolin! systems$ -"ove dec( car!o tan(s must "e insulated and may "e fitted %ith coolin!

systems$

(es )o )0A

4*' 0 5 September 6778

669:77685.doc

'a#e > of 9

CARGO PUMPS:

Cargo pumps must be deepwell pumps of the centrifugal type and constructed of steel or

stainless steel. Approved types of hydraulically operated submerged pumps are acceptable.

(es )o )0A

ype of fluid in pumps!

ype of seals in pumps!

NITROGEN PAD SYSTEM:

Capabilit% of pro$idin# positi$e i# purit% nitro#en pad durin# te entire transit. (es )o )0A

Combustion t%pe inert #as s%stem sall not be utiliAed and must be se#re#ated

from Al,%lene "+ides car#o s%stem prior to loadin#.

(es )o )0A

Car#o tan,s must be fitted wit an automatic nitro#en pad s%stem to maintain te car#o tan,s at a pressure

not less tan 7.79 bar #au#e durin# te entire $o%a#e. 2e setpoint sould be between 7.1> and > bar

#au#e.

(es )o )0A

Ki# purit% nitro#en must be used as te pad for Al,%lene "+ides sipments. "+%#en content in te nitro#en

must be less tan 7.7>? ->77 ppm..

(es )o )0A

A lo# of nitro#en pad controls sall be maintained b% deepFsea $essels transportin# Al,%lene "+ides.

(es )o )0A

)onFreturn $al$es sould be installed to pre$ent bac,flow of product into te pad s%stem.

(es )o )0A

A cop% of te carria#e lo# must be attaced to te sur$e%orNs report at discar#e. 2e carria#e lo# sould at

least contain $esselNs name1 $o%a#e from 0 to1 D"O reference number1 product name1 tan, number1 initial

tan, pressure1 date and time wen measurements are ta,en1 respecti$e tan, pressure1 nitro#en supplied

%es 0 no1 and an% e+ceptions.

(es )o )0A

Describe te nitro#en pad s%stem -fi+ed or #enerator.1 t%pe of pipin# to tan,s1 t%pe of se#re#ation1 and

#enerator details -i.e. purit%1 rate1 buffer tan, siAe and pressure ratin#1 bac,Fup s%stem1 outlet pressures

to ballast tan,s0$oids0car#o tan,s0li@uid lines0pump cofferdams..

GASKETS (&64%# 430$4+6t" f)4 ,$,$6& %6( h%t*h"):

Gas,ets trou#out te Al,%lene "+ides car#o s%stems must be spiral wound stainless steel wit '2&* fill.

"ter fluorocarbon fill or #rapite fiber on steel supports t%pe #as,ets are acceptable pro$ided te% meet

applicable I!" or U.S. Coast Guard re#ulations.

(es )o )0A

Double -use of 6. wo$en '2&* #as,ets installed on manoles and cleanin# openin#s are onl% acceptable if

te inner #as,ets are new or dedicated to al,%lene o+ide and te outer #as,ets are #asFti#t and suitable for

al,%lene o+ides. Sin#le wo$en '2&* #as,ets are not acceptable.

(es )o )0A

Gas,et sealin# surfaces must be uniform and present a #ood sealin# surface. Doltin# must be e$enl%

tor@ued and $al$e pac,in# sould be ti#t.

(es )o )0A

KA2CK*S0GAS=*2S:

Describe te #as,etin# on atces. Specific @uestions to answer include:

Is tere a sin#le or double #as,etin# arran#ement1 and wat t%pes are used/

Are tere sufficient s%stems in place to secure te atc in a pressure condition as re@uired for '"/

Are smaller atces of te same or different desi#n/ If different1 describe below.

Describe te #as,et arran#ement.

4*' 0 5 September 6778

669:77685.doc

'a#e 8 of 9

CARGO SYSTEM ISOLATION:

Describe te t%pe of se#re#ation used to isolate te listed s%stem from te product.

Remo$e

spool

pieces

Insertion

of

Dlan,s

)o

fi+ed

connection

)0A "ter -describe.

Inert #as #enerator

2an, was macines and s%stem

Vapor recompression s%stem

Li@uid lines to oter car#o tan,s

Strippin# lines to oter car#o tan,s

Vapor return lines to oter car#o tan,s

Keatin# coils

Steam lines

"ters:

SHUT DOWN FUNCTIONS:

Describe te actions tat occur for eac t%pe of sutdown

Close all

$al$es

Sut off

runnin# car#o

pumps )0A "ter -describe.

KiFKi Le$el

Ki# 'ressure

Low 'ressure

"ters:

Remote sutdown s%stem a$ailable to

place on sore

Remote sutdown s%stem a$ailable to

be connected to sore

BALLAST TANKS AND VOID SPACES:

'ressure relief settin# of ballast tan,s -bar.

!etod of pur#in# ballast tan,s

Special pur#in# re@uirements -i.e. pur#e ballast water pumps0pumproom1 pur#e freswater tan,s1 etc..

Vessel as a cop% of te '.". Dul, Kandlin# Guidelines on board/

(es )o

Kas te $essel e$er carried '."./

(es )o

Kas te !aster or anoter ran,in# crewmember e+perienced in andlin# '.".

(es )o

!aster and Cief "fficer a$e been briefed in te aAards of andlin# '.".1 co$erin# te followin# ,e%

items: 1. '" is i#l% soluble in water1 and spra%in# water into '" can result in $acuum dama#e to te

car#o tan, -muc li,e Ammonia.Q 6. &lammabilit% and broad flammabilit% ran#eQ ;. It is critical to follow te

$esselNs '" manual in andlin# and cleanin# '"Q M. Vessel personnel a$e re$iewed te !SDS.

(es )o

OTHER NOTES OR COMMENTS:

)ame of !aster:

)ame of Cief !ate:

4*' 0 5 September 6778

669:77685.doc

'a#e 9 of 9

You might also like

- Naval Mechanical Engineering: Gas Turbine Propulsion, Auxiliary, and Engineering Support SystemsFrom EverandNaval Mechanical Engineering: Gas Turbine Propulsion, Auxiliary, and Engineering Support SystemsNo ratings yet

- Practical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentFrom EverandPractical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentNo ratings yet

- Asme Boiler and Pressure Vessel Code, Section I Design GuideDocument11 pagesAsme Boiler and Pressure Vessel Code, Section I Design Guidepeach5No ratings yet

- (131056537) Manual Centrala VestoWIN - enDocument21 pages(131056537) Manual Centrala VestoWIN - enviltermNo ratings yet

- Turn Over Notes For Third OfficerDocument6 pagesTurn Over Notes For Third OfficerMariaAnthessaGalay100% (4)

- Hydrotest Exemption DetailsDocument4 pagesHydrotest Exemption Detailsjoseph.maquez24No ratings yet

- Alaska energy tank farm design guidelinesDocument2 pagesAlaska energy tank farm design guidelinesSigit BintanNo ratings yet

- Power Grid Components and Protection DevicesDocument39 pagesPower Grid Components and Protection DevicesPhani KumarNo ratings yet

- 230529Document8 pages230529thanh_79No ratings yet

- 4.1 Catalyst Support MaterialDocument5 pages4.1 Catalyst Support MaterialRisky Astia LianyNo ratings yet

- 1 A Master HT Eu 2014specDocument9 pages1 A Master HT Eu 2014specapi-17442293No ratings yet

- Low Voltage Motor Control Centers Section 26 24 19 16443Document8 pagesLow Voltage Motor Control Centers Section 26 24 19 16443Nardi VallejoNo ratings yet

- As Lab Manual NEWDocument43 pagesAs Lab Manual NEWJagdish KumarNo ratings yet

- Quality Control Procedure for Hot Tap Tie-inDocument9 pagesQuality Control Procedure for Hot Tap Tie-inarockiyathassNo ratings yet

- Understanding octane ratings and their importance for enginesDocument13 pagesUnderstanding octane ratings and their importance for enginesekyroskianaNo ratings yet

- Annex Xi: (Stipulations in Exemption of Sections 356C (2), 356E and 356F of M.S. Act)Document4 pagesAnnex Xi: (Stipulations in Exemption of Sections 356C (2), 356E and 356F of M.S. Act)Eshwar BabuNo ratings yet

- Arabian Drilling Company Rig Specific Procedure AD - 32 Prepare CasingDocument6 pagesArabian Drilling Company Rig Specific Procedure AD - 32 Prepare CasinginfonexusNo ratings yet

- Mechanical Maintenance MECASIGN MECAPRO - Ang - CN7000Document16 pagesMechanical Maintenance MECASIGN MECAPRO - Ang - CN7000Alexandru BurcaNo ratings yet

- Rupture Disk+Safety Valve CombinationDocument5 pagesRupture Disk+Safety Valve CombinationHamza NoumanNo ratings yet

- TERMS AND ABBREVIATIONS FOR CHARTERINGDocument8 pagesTERMS AND ABBREVIATIONS FOR CHARTERINGVivek JhaNo ratings yet

- Notes On Parts ListDocument18 pagesNotes On Parts Listplan2222100% (1)

- Optimal Ratio For Steel Tanks For StorageDocument7 pagesOptimal Ratio For Steel Tanks For Storagenelly del pilarNo ratings yet

- Energy Conversion Lab Manual NewDocument50 pagesEnergy Conversion Lab Manual NewRavi TejNo ratings yet

- The Jacket - A Path To Deeper Waters: AdvantagesDocument6 pagesThe Jacket - A Path To Deeper Waters: AdvantagesjiokoijikoNo ratings yet

- Old Hot InsulationDocument9 pagesOld Hot InsulationNehal VaghelaNo ratings yet

- Bulk Grain Carriage2 CargoDocument4 pagesBulk Grain Carriage2 Cargowaleedyehia100% (1)

- 105 Transformer Installation Instructions enDocument3 pages105 Transformer Installation Instructions enSujit AdhyaNo ratings yet

- Barring GearDocument30 pagesBarring GearJeffrey MuellerNo ratings yet

- It-Ii AhpDocument1 pageIt-Ii AhpVignesh KumarNo ratings yet

- Safety and First Aid for PipelinesDocument14 pagesSafety and First Aid for PipelinesNishad JoshiNo ratings yet

- 3 Comments On Line Pipe Specifications 2013 08 27 RespuestasDocument3 pages3 Comments On Line Pipe Specifications 2013 08 27 Respuestasluisbazan7055No ratings yet

- Motor Volkswagen GolfDocument22 pagesMotor Volkswagen GolfcarbutzNo ratings yet

- Rehabilitation of Street Lights Along Saraki RoadDocument47 pagesRehabilitation of Street Lights Along Saraki RoadAbdulyekini AhmaduNo ratings yet

- DW Horizontal AbovergroundDocument3 pagesDW Horizontal AbovergroundMohammed EljammalNo ratings yet

- 009 Lifting PlanDocument2 pages009 Lifting PlanmossamorrisNo ratings yet

- API 650 ChecklistDocument3 pagesAPI 650 Checklistjacquesmayol100% (2)

- Lesson Globe Valves: Sub-ObjectiveDocument9 pagesLesson Globe Valves: Sub-Objectivemister pogiNo ratings yet

- 1999 Q2-Advanced Maintenance Techniques For The 757-300Document8 pages1999 Q2-Advanced Maintenance Techniques For The 757-300tlnrsNo ratings yet

- How To Fix Your Car AcDocument13 pagesHow To Fix Your Car AcElaineWilliamsNo ratings yet

- 3rd Class Old Part B Paper 1 Review Questions and AnswersDocument143 pages3rd Class Old Part B Paper 1 Review Questions and AnswersVirgilMaroNo ratings yet

- KSRTC Report Doc Format NsDocument32 pagesKSRTC Report Doc Format NsAndrea Perry50% (2)

- How To - Transmission Fluid Change On The Aisin Warner AWTF-80SC (06+ Aero Automatic) - SaabCentral ForumsDocument17 pagesHow To - Transmission Fluid Change On The Aisin Warner AWTF-80SC (06+ Aero Automatic) - SaabCentral ForumsOscar VillaseñorNo ratings yet

- 25 Details of Asphalt Institute Method of Design of Flexible PavementspptxDocument55 pages25 Details of Asphalt Institute Method of Design of Flexible PavementspptxRijan MrtNo ratings yet

- Sec 660Document4 pagesSec 660sab_veer2913No ratings yet

- API Standard 653 - Tank Inspection, Repair, Alteration, and ReconstructionDocument15 pagesAPI Standard 653 - Tank Inspection, Repair, Alteration, and ReconstructionMuhammad Nasir SiddiqueNo ratings yet

- Verify Correct Version Before Use.: PRC-5002 Rev. EDocument9 pagesVerify Correct Version Before Use.: PRC-5002 Rev. EkonazoiNo ratings yet

- Drilling - Introduction: Subjects Being TreatedDocument23 pagesDrilling - Introduction: Subjects Being Treatedamramazon88No ratings yet

- 6 6 KV APFC Panel SpecificationDocument8 pages6 6 KV APFC Panel Specificationjoydeep_d3232No ratings yet

- AUSOTSDocument26 pagesAUSOTSEulogio Campos GonzalezNo ratings yet

- OISD STANDARD-117 Amended Edition August 2000 for Restricted Circulation: Fire Protection Facilities for Petroleum Depots, Terminals and Pipeline InstallationsDocument34 pagesOISD STANDARD-117 Amended Edition August 2000 for Restricted Circulation: Fire Protection Facilities for Petroleum Depots, Terminals and Pipeline InstallationsManish Tukaram DeshpandeNo ratings yet

- اسئلة تشريعات- A1Document38 pagesاسئلة تشريعات- A1wagih83115100% (1)

- Checklist Tank NewDocument11 pagesChecklist Tank NewamevaluacionesNo ratings yet

- BOV (Bug Out Vehicle) BasicsDocument4 pagesBOV (Bug Out Vehicle) BasicsMLogan01No ratings yet

- O&M Manual For FCUDocument30 pagesO&M Manual For FCUBeatrice Li50% (2)

- Exhaust BackpressureDocument4 pagesExhaust Backpressurecatalin555No ratings yet

- Nglo Astern Roup Ship/ Shore Safety Checklist - Tankers: MT "Atlantic Grace"Document6 pagesNglo Astern Roup Ship/ Shore Safety Checklist - Tankers: MT "Atlantic Grace"Sardar Sirajul IslamNo ratings yet

- Air Conditioning System: Section 15 / 1Document12 pagesAir Conditioning System: Section 15 / 1Ahmed Yousri AhmedNo ratings yet

- During Cargo-Ballast Operations Checklist (Tanker)Document2 pagesDuring Cargo-Ballast Operations Checklist (Tanker)opytnymoryak100% (2)

- Flange Leakage Checking in Caesar II Using ASME Section VIII MethodDocument10 pagesFlange Leakage Checking in Caesar II Using ASME Section VIII MethodMichael RobinsonNo ratings yet

- Cessna 152 Pre-Solo ExamDocument7 pagesCessna 152 Pre-Solo ExamrayduxNo ratings yet

- CDI Best Practice Portable Electronic Equipment 31-01-2023 PDFDocument7 pagesCDI Best Practice Portable Electronic Equipment 31-01-2023 PDFmorgothsNo ratings yet

- RT FlexDocument15 pagesRT FlexprasadcshettyNo ratings yet

- CDI A5 Flyer PDFDocument2 pagesCDI A5 Flyer PDFmorgothsNo ratings yet

- The Benefits of CDI A5 Flyer PDFDocument2 pagesThe Benefits of CDI A5 Flyer PDFmorgothsNo ratings yet

- Interpretations For SOLASDocument331 pagesInterpretations For SOLASmorgothsNo ratings yet

- CDI A5 Flyer PDFDocument2 pagesCDI A5 Flyer PDFmorgothsNo ratings yet

- CDI Best Practice Dosing Paper 31-01-2023 PDFDocument7 pagesCDI Best Practice Dosing Paper 31-01-2023 PDFmorgothsNo ratings yet

- CDI Best Practice Dosing Paper 31-01-2023 PDFDocument7 pagesCDI Best Practice Dosing Paper 31-01-2023 PDFmorgothsNo ratings yet

- CDI Best Practice Static Container Hazards 31-01-2023Document5 pagesCDI Best Practice Static Container Hazards 31-01-2023morgothsNo ratings yet

- Nautical Publication ChecklistDocument1 pageNautical Publication ChecklistmorgothsNo ratings yet

- CDI Best Practice Static Container Hazards 31-01-2023Document5 pagesCDI Best Practice Static Container Hazards 31-01-2023morgothsNo ratings yet

- Mesqac 2010 Rev.01Document55 pagesMesqac 2010 Rev.01akivko100% (1)

- CDI Best Practice Portable Electronic Equipment 31-01-2023 PDFDocument7 pagesCDI Best Practice Portable Electronic Equipment 31-01-2023 PDFmorgothsNo ratings yet

- The Benefits of CDI A5 Flyer PDFDocument2 pagesThe Benefits of CDI A5 Flyer PDFmorgothsNo ratings yet

- IMO Publication Catalogue 2014Document117 pagesIMO Publication Catalogue 2014morgothsNo ratings yet

- IRCA Auditor: Requirements For Certification As AnDocument61 pagesIRCA Auditor: Requirements For Certification As AnRiadh TaktakNo ratings yet

- OvitReport Incident ECDISDocument94 pagesOvitReport Incident ECDISЕвгений Стародубов100% (2)

- Assessment of Protective Coatings in Ballast TanksDocument12 pagesAssessment of Protective Coatings in Ballast Tanksmorgoths100% (1)

- Understanding DIS 9001-2014 - 72D CQI - DIS - 9001 - Main - ReportDocument64 pagesUnderstanding DIS 9001-2014 - 72D CQI - DIS - 9001 - Main - Reportmorgoths100% (1)

- MEPC 157 (55) Rate of DischargeDocument3 pagesMEPC 157 (55) Rate of Dischargefineeq100% (3)

- Abs Hsqe PDFDocument53 pagesAbs Hsqe PDFTakis RappasNo ratings yet

- Paris-Tokyo MOU - CIC STCW Hours of Rest - and QuestionnaireDocument4 pagesParis-Tokyo MOU - CIC STCW Hours of Rest - and QuestionnairemorgothsNo ratings yet

- Snap Back Zones - MGM 308Document8 pagesSnap Back Zones - MGM 308morgoths100% (1)

- Project Horizon - Sleepiness & Watchkeepers - Research-Report-2012Document8 pagesProject Horizon - Sleepiness & Watchkeepers - Research-Report-2012morgothsNo ratings yet

- ECDIS - Industry Recommendations For ECDIS FamiliarisationDocument8 pagesECDIS - Industry Recommendations For ECDIS FamiliarisationmorgothsNo ratings yet

- Costa Concordia Casualty ReportDocument181 pagesCosta Concordia Casualty ReportToni Pons0% (1)

- Final Impa Pilot Ladder PosterDocument1 pageFinal Impa Pilot Ladder Posterdassi99No ratings yet

- MGN 426 - External Access To Means of EscapeDocument5 pagesMGN 426 - External Access To Means of EscapemorgothsNo ratings yet

- PSC DeficienciesDocument17 pagesPSC DeficienciesmorgothsNo ratings yet

- Technology Guide No. 19: SSPC: The Society For Protective CoatingsDocument3 pagesTechnology Guide No. 19: SSPC: The Society For Protective CoatingsMia AndinoNo ratings yet

- Selective MediaDocument10 pagesSelective Mediaprincess_likemist4No ratings yet

- Induction Sealing - Wikipedia, The Free EncyclopediaDocument6 pagesInduction Sealing - Wikipedia, The Free EncyclopediaSohail ShaikhNo ratings yet

- ArcelorMittal Projects Steel Pipe ProductionDocument20 pagesArcelorMittal Projects Steel Pipe Productionanil-kumar-singh-6674No ratings yet

- Gnaser H., Huber B., Ziegler C. - Nanocrystalline TiO2 For Photocatalysis (2004) PDFDocument32 pagesGnaser H., Huber B., Ziegler C. - Nanocrystalline TiO2 For Photocatalysis (2004) PDFoscuraNo ratings yet

- Dynamic Balancing of Hydronic SystemsDocument65 pagesDynamic Balancing of Hydronic Systems黃偉哲100% (4)

- Profile Prince Decoware Furniture HandlesDocument54 pagesProfile Prince Decoware Furniture HandlesRushabh ShahNo ratings yet

- Astm 1351 1 REPLICADocument6 pagesAstm 1351 1 REPLICAmaheshNo ratings yet

- Rigaku Nex QCDocument12 pagesRigaku Nex QCLuis ReyesNo ratings yet

- Cosmetics 09 00063 v2Document44 pagesCosmetics 09 00063 v2maizhafiraNo ratings yet

- Spectroscopy Primer AnswersDocument13 pagesSpectroscopy Primer AnswersjayshreeNo ratings yet

- The Changing World of OleochemicalsDocument9 pagesThe Changing World of OleochemicalsMarta Szymańska100% (1)

- Hydrogen BondsDocument2 pagesHydrogen BondsJohnNo ratings yet

- Cassida Chain Oil 150-SdsDocument5 pagesCassida Chain Oil 150-SdsInggil Budi PekertiNo ratings yet

- BS en 12396-2-1999Document10 pagesBS en 12396-2-1999DoicielNo ratings yet

- Synthesis and Discriminative Stimulus Properties of N(6)-Alkyl Norlysergic Acid DerivativesDocument4 pagesSynthesis and Discriminative Stimulus Properties of N(6)-Alkyl Norlysergic Acid Derivativesmik100% (1)

- Application News: Infrared Spectra of Polyvinyl ChlorideDocument2 pagesApplication News: Infrared Spectra of Polyvinyl ChlorideRudiyansah RudiyansahNo ratings yet

- Power Distribution at NFC EeeDocument70 pagesPower Distribution at NFC EeeTeEbhan ChAnthira SeEkaranNo ratings yet

- Chapter-1 Classification of MaterialsDocument46 pagesChapter-1 Classification of MaterialstrfuawlachewNo ratings yet

- Chemical, Physical, and Baking Properties of Apple FiberDocument4 pagesChemical, Physical, and Baking Properties of Apple FiberHector FloresNo ratings yet

- Steps in Balancing Redox ReactionsDocument28 pagesSteps in Balancing Redox ReactionsRUZCHEMISTRYNo ratings yet

- Packed bed axial thermal conductivityDocument7 pagesPacked bed axial thermal conductivityAdriano HenriqueNo ratings yet

- Unit 1 - Construction Materials - WWW - Rgpvnotes.inDocument21 pagesUnit 1 - Construction Materials - WWW - Rgpvnotes.inmadhavi likharNo ratings yet

- A Review On Development of Stereolithography (SLA) 3D Printing in Additive Manufacturing For Biomedical IndustryDocument4 pagesA Review On Development of Stereolithography (SLA) 3D Printing in Additive Manufacturing For Biomedical IndustryFirdaus Mat SoibNo ratings yet

- Limites condenatorios aceite en MeritorDocument4 pagesLimites condenatorios aceite en MeritorJavier H Durán ValeroNo ratings yet

- World Fertilizer Trends and Outlook To 2020Document38 pagesWorld Fertilizer Trends and Outlook To 2020SudhirNo ratings yet

- COC-Dosing Skid - NalcoDocument11 pagesCOC-Dosing Skid - NalcodeyprasenNo ratings yet

- Groundwater ContaminationDocument25 pagesGroundwater ContaminationjoshjethNo ratings yet

- Atracurium BesylateDocument4 pagesAtracurium BesylateStill DollNo ratings yet

- Filter Elements, Parts for Compressors and EnginesDocument2 pagesFilter Elements, Parts for Compressors and Enginespgm900No ratings yet