Professional Documents

Culture Documents

Anchor Bolts

Uploaded by

mukeshkumarjCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Anchor Bolts

Uploaded by

mukeshkumarjCopyright:

Available Formats

HPM AND PPM

ANCHOR BOLTS

Version 03/2009

Benets of HPM and PPM Anchor Bolts

Wide variety of capacities available

Forged heads allow for shallow foundations

Bolt Connection No Welding at the Site

HPM/L Anchor Bolts Have ETA-Approval

Right to Use CE-Marking

Free Use of the Product Without Commercial Limitations

Standardized Products

Precalculated Design Parameters Available

Fast Delivery Time

Available in Stainless St eel and Hot Dip Gavanized

HPM AND PPM

ANCHOR BOLTS

Peikkos benets:

Reliable: passed demanding test program

Competitive price and delivery time

Economical and easy to use in designing,

manufacturing and installation of the

elements

For technical support, please contact

us at 1-888-PEIKKO-1

Printed in Canada

SAFETY CONSIDERATIONS

Read, understand and follow the information in this publication

before using any of the Peikko product displayed herein. When

in doubt about the proper use or installation of any Peikko lifting

product, immediately contact the Peikko Engineering Services for

clarication.

Peikko guarantees the products it manufactures only when

used by qualied, experienced and properly supervised workmen

adhering to the safety factor standards detailed below. Misuse,

misapplication or lack of proper supervision and/or inspection can

result in serious accidents. If you have unusual applications or are

uncertain about a product application, contact Peikkos Engineering

Services for clarication and carefully eld test the application prior

to general use.

The user of a Peikko product must evaluate the product application

to determine the safe working load and control all eld conditions

to prevent application of loads in excess of a products safe

working load. The Safety Factors Table shown in this publication

are approximate minimum values. The data used to develop

safe working loads for products displayed in this publication is a

combination of actual testing and/or other industry sources.

Recommended safe working loads given for the products in the

publication must never be exceeded. Safety factors are determined

by the degree of risk involved in the use of the product and are

established by the American Concrete Institute (ACI), Occupational

Safety and Health Administration (OSHA) and American National

Standards Institute (ANSI).

All products displayed in this publication have the applicable

safety factor used to derive their safe working loads. This does

not relieve the user of the responsibility to carefully calculate and

determine the actual loads that will be applied in a specic product

application.

WORN WORKING PART

For safety, concrete accessories must be properly used and

maintained. Concrete accessories shown in this publication may

be subject to wear, overloading, deformation, intentional alteration

and other factors that may affect the devices performance. All

reusable accessories must be inspected regularly by the user to

determine if they may be used at the rated safe working load or

removed from service. The frequency of inspections depends

upon factors such as (but not limited to) the amount of use, period

of service and environment. It is the responsibility of the user

to schedule hardware inspections for wear and to remove from

service when wear is noted.

WELDING CONSIDERATIONS

Peikko cannot control eld conditions or eld workmanship;

therefore it cannot guarantee any Peikko product that has been

altered in any ways after it has left the manufacturing facility. This

includes welding, bending, ling, etc. Never weld to a casting

unless authorized by a lisenced metallurgical engineer. Welding to a

casting can cause localized embrittlement that greatly reduces the

load-carrying capacity of the casting. Tack welding to wire products

can have the same effect.

PRODUCT DESIGN AND SAFE WORKING LOAD

CHANGES

As a manufacturer of quality concrete accessories, Peikko reserves

the right to change product designs and/or product safe working

load ratings at any time without prior notice to prospective users.

Any such changes will only be made to improve the product or to

increase product safety.

CORROSION OF THE PRODUCTS

Corrosion may occur on exposed metal products when architectural

precast members are etched or acid washed. The amount of

corrosion will depend on the acidity of the wash and/or the type of

chemicals used.

EMBRITTLEMENT

Carbon steels, cold-worked steels and heat treated steels are

susceptible to embrittlement in both electroplating and hot dip

galvanizing operations. Any severely cold-worked steel must be

stress-relieved from strain aging by baking prior to electro-plating

or hot dip galvanizing. Any steel with signicant high strength or

high carbon content is susceptible to hydrogen embrittlement

during electro-plating or hot dip galvanizing.It must be baked

after the coating is applied to drive out excessive hydrogen.

WARNING : Products manufactured from high carbon steel that are

electro-plated or hot dip galvanized must be properly heat treated

to minimize embrittlement. Failure to properly heat treat these

products may cause a compromise of their safe working loads and

result in a premature failure of the product.

CAPACITIES

Please note that the information contained in graphs, tables and

gures is provided only as a guideline. Local authorities having

jurisdiction should be consulted prior to plan submission.

Improper Use of the Peikko Products Can Cause Severe Injuries or Death

1. DESCRIPTION OF THE SYSTEM ...........................................5

2. DIMENSIONS AND MATERIALS ...........................................5

3. MANUFACTURING ...............................................................6

3.1 Manufacturing method ................................................................................... 6

3.2 Manufacturing tolerances .............................................................................. 6

3.3 Manufacturing markings ................................................................................ 6

3.4 Quality control ............................................................................................... 7

4. CAPACITIES .........................................................................7

4.1 Capacity values .............................................................................................. 7

4.2 Interaction of tensile and shear forces .......................................................... 7

4.2.1 Formula for tension ..................................................................... 7

4.2.2 Formula for shear ......................................................................... 7

4.2.3 Formula for tension and shear ..................................................... 7

5. APPLICATION ......................................................................8

5.1 Limitations for application ............................................................................. 8

5.2 Design principles ............................................................................................ 8

5.2.1 Principle of application .................................................................................... 8

5.2.2 Calculation principles ...................................................................................... 8

5.2.3 Requirements for concrete bedding .............................................................. 8

5.2.4 Minimum edge distances, centres and attachment bedding

reinforcement for long Bolts .......................................................................... 8

5.2.5 Minimum edge distances, centres and attachment bedding

reinforcement for short Bolts ........................................................................ 9

5.2.6 The correction factors of capacity values ..................................................... 11

5.2.7 Joining to foundations and column to column connections ...................... 11

5.3 Erection notice .............................................................................................. 11

6. INSTALLATION ....................................................................13

6.1 Appliance and equipment ............................................................................. 13

6.2 Bolt installation and installation tolerances ................................................. 14

6.3 Bending the Bolts .......................................................................................... 14

6.4 Welding of the Bolts ...................................................................................... 14

6.5 Installing the columns ................................................................................... 14

7. INSTALLATION CONTROL ...................................................14

7.1 Instructions for controlling Bolt installation ................................................ 14

7.2 Instructions for controlling column installation ........................................... 15

CONTENTS

5

www.peikko.com

1. DESCRIPTION OF THE SYSTEM

The Peikko

PPM and HPM Anchor Bolts transfer the tension, compression and

shear forces to the reinforced concrete base structure.

There are two types of PPM and HPM Anchor Bolts:

Long Anchor Bolts (HPM/P and PPM/P) for splices

Short Anchor Bolts (HPM/L and PPM/L) for anchoring

The long Anchor Bolts transfer the compression and tension forces

through the bond of the ribbed bars.

The short Anchor Bolts transfer the forces through the bond of the

ribbed bars and headed studs.

Concrete blow out failure generally denes the tensile capacity of the

Bolt.

Use range:

in concrete element column joints with Column Shoes

in steel column joints

in concrete element wall joints with PSK Wall Shoes

(Note: AL washers to be used)

in concrete element beam joints with Beam Shoes

in xing machines to the concrete

Note: The capacities and reinforcements specied in this bro-

chures tables are provided as guidelines. Local authorities hav-

ing jurisdiction should be consulted prior to plan submission.

Figure 1. Bolts in reinforced concrete column joint

2. DIMENSIONS AND MATERIALS

Materials and standards:

Ribbed Bars A500HW SFS 1215 / B500B

SFS-EN 10080-1:2005

Threaded Bars High strength steel fyk 112 ksi (770 MPa) (t < 1-3/8 (35 mm))

fyk 101 ksi (770 MPa) (t > 1-3/8 (35 mm))

Washers S355J2 + N SFS-EN 10025 / DIN 7349

Nuts property class 8.8 SFS-EN ISO 4032 / SFS-EN 24032 / DIN 934

6

HPM AND PPM ANCHOR BOLTS

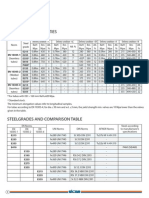

Table 1. Dimensions, Weights, Stress areas of the threads and Colors of the HPM Anchor Bolts

M

A

Stress

area of the

thread

Ribbed

Bar

Washer

HPM/P HPM/L

Color

Thread Type L Weight L Weight

[US*] [ SI] [in] [ mm] [in

2

] [ mm

2

] [SI] [ US*] [in] [ mm] [in] [ mm] [lb] [kg] [in] [ mm] [lb] [kg]

HPM 16 5/8 M16 5-1/2 140 0.243 157 M16 #5 1-1/2-1/4 38- 6 31-7/8 810 3.75 1.7 11 280 1.98 0.9 yellow

HPM 20 3/4 M20 5-1 140 0.379 245 M20 #6 1-13/16-1/4 46- 6 39-3/8 1000 6.39 2.9 13-3/4 350 3.09 1.4 blue

HPM 24 7/8 M24 6-11/16 170 0.545 352 M25 #8 2-13/16-1/4 56- 6 45-5/8 1160 10.80 409 16-15/16 430 4.85 2.2 grey

HPM 30 1-1/8 M30 7-1/2 190 0.869 561 M32 #10 2-1/2-5/16 65-8 55-7/8 1420 21.61 9.8 19-11/16 500 9.04 4.1 green

HPM 39 1-1/2 M39 7-7/8 200 1.512 976 M40 #11 3-1/2-3/8 90-10 78-3/4 2000 48.06 21.8 27-9/16 700 20.28 9.2 orange

* Imperial values converted from metric standards

L L

HPM P HPM L

A A

M M

Table 2. Dimensions, Weights, Stress areas of the threads and Colors of the PPM Anchor Bolts

M

A

Stress

area of the

thread

Ribbed Bar

Washer

PPM/P PPM/L

Color

Thread Type L Weight L Weight

[US*] [ SI] [in] [ mm] [in

2

] [ mm

2

] [in] [ mm] [in] [ mm] [in] [ mm] [lb] [kg] [in] [ mm] [lb] [kg]

PPM 22 7/8 M22 6-1/4 160 0.469 303 2#6 220 2-1/4-1/4 56- 6 46-7/8 1190 13.67 6.2 20 510 6.39 2.9 light. blue

PPM 27 1 M27 6-11/16 170 0.711 459 2#8 225 2-9/16-5/16 65-8 55-3/4 1415 25.35 11.5 25-9/16 650 12.57 5.7 black

PPM 30 1-1/8 M30 7-1/2 190 0.869 561 2#8 225 2-9/16-5/16 65-8 67-1/8 1705 31.09 14.1 26-3/8 670 13.67 6.2 -

PPM 36 1-1/4 M36 7-1/2 190 1.266 817 4#6 420 80-5/16 80-8 57 1450 35.27 16.0 29-1/8 740 20.72 9.4 red

PPM 39 1-1/2 M39 7-1/2 190 1.512 976 3#8 325 3-1/2-13/32 90-10 71-1/2 1815 51.81 23.5 34-5/8 880 28.00 12.7 brown

PPM 45 1-3/4 M45 6-21/32 220 2.023 1306 4#8 425 3-15/16-13/32 100-10 71-7/8 1825 69.23 31.4 38-9/16 980 41.00 18.6 purple

PPM 52 2 M52 9-7/8 250 2.723 1758 4#10 432 3-15/16-1/2 100-12 76 1930 114.86 52.1 44-7/8 1140 71.87 32.6 white

PPM 60 2-1/4 M60 12-1/4 310 3.659 2362 4#10 432 4-1/2-19/32 115-15 98 2490 156.53 71.0 52-3/8 1330 92.59 42.0 -

* Imperial values converted from metric standards

L

PPM P PPM L

A

M

L

A

M

3. MANUFACTURING

3.1 Manufacturing method

Ribbed Bars Mechanical cutting

Threads Mechanical machining

Welding MAG by hand or robot

Forging Hot forging or similar anchoring

Welding class C (SFS-EN 25817)

3.2 Manufacturing tolerances

Length 3/8 (10 mm)

Thread length +3/16 , -0 (+5 mm, -0 mm)

3.3 Manufacturing markings

Products are marked with the mark of Inspecta, the emblem of Peik-

ko Group, the type of the product, the year and the week of manufac-

turing. The Bolt is marked with the same color as the corresponding

Column Shoes. Studded Bolts have either PG or Peikko

emblem

on the headed studs. HPM L Anchor Bolts have CE-marking.

7

www.peikko.com

3.4 Quality control

Peikko is under the Inspecta Certication for quality

control. HPM and PPM Anchor Bolts have certied prod-

uct declarations. PPM/L Anchor Bolts have certied product

declaration. HPM/L Anchor Bolts are ETA approved.

4. CAPACITIES

4.1 Capacity values

All values in table 3 are obtained from steel capacity of the

bolt as being the governing failure mode. In order to make

sure that the steel failure will be the governing failure mode,

the minimum compressive strength of the concrete used in

the bolt (fc 4500 psi (30 MPa)), the minimum edge distance

(1,5 X hef) and the thickness of the slab of at least 2,25 X hef

must be respected.

If a bolt is located at less than 1,5 times the embedment

length; for an edge or if the minimum concrete compres-

sive strenght is lower than specied, all possible failures

modes must be checked.

Shear capacities presented in Table3. are factored accord-

ing to bolt material limits only. Buckling and bending of the

bolt should be noted in situation occuring during erection

time and installation. An exemple of calculation is given

above in section 5.3.

Designer must provide to erectors instructions for tighten-

ing the nuts. If needed, Peikkos technical support will give

advice.

In the event that high shear loads must be transfered to

the Anchor bolts, the shear should be transfered by another

mecanism such as a shear dowel.

4.2 Interaction of tensile and shear forces

Anchors or Anchor Groups that are subjected to bolt shear

and axial loads shall be designed to satisfy the requirements

of clauses 4.2.1 through 4.2.3.

The value of Nr (factored resistance in tension) shall be the

smallest of the steel resistance of the Anchor in tension,

concrete breakout resistance of the Anchor in tension, pull-

out resistance of the Anchor in tension and side-face blow-

out resistance.

The value of Vr (factored shear resistance) shall be the small-

est of the steel resistance of the Anchor in shear, the con-

crete breakout resistance of the Anchor in shear and the

pryout resistance.

Nf

= factored axial load normal to the cross-section occur-

ring simultaneously with vf, including effects of tension due

to creep and shrinkage (taken as positive for tension and

negative for compression).

Vf = factored shear force according to bolt material

capacities

Table 3. Design values for tensile(N

S

) and shear capacities(V

S

)

Bolt

ACI 318-05 CSA A23.3-04

Ns

[kips]

Vs

[kips]

Nsr

[kN]

Vsr

[kN]

HPM 16 12.6 6.9 51.3 28.6

HPM 20 19.6 10.9 80.1 44.6

HPM 24 28.2 15.6 115.1 64.1

HPM 30 45.0 24.9 183.5 102.2

HPM 39 78.4 43.4 319.4 177.9

PPM 22 38.1 22.1 155.0 86.3

PPM 27 57.7 31.9 234.9 130.8

PPM 30 70.6 39.1 287.1 159.9

PPM 36 102.8 56.9 418.1 232.9

PPM 39 122.9 68.0 499.4 278.3

PPM 45 164.4 91.0 668.3 372.3

PPM 52 221.3 122.6 899.6 501.2

PPM 60 297.3 164.7 1208.6 673.4

4.2.1 Formula for tension

If Vf 0.2Vr ,full resistance in tension shall be permitted, as

follows (see gure 2)

N

R

N

F

4.2.2 Formula for shear

If Nf 0.2Nr ,full resistance in shear shall be permitted, as

follows (see gure 2)

V

R

V

F

4.2.3 Formula for tension and shear

If Vf > 0.2Vr and Nf > 0.2Nr , the following shall apply

(see gure 2)

N

N

f f

r r

V

V

+

1.2

0,0

0,2

0,2

0,4

0,6

0,8

1,0

1,0

1,2

Trilinear

Interaction

Approach

Figure 2. Shear and tensile load interaction equation

The capacity of the normal force of a Bolt cast in concrete

is the same in tension and compression. The bending and

buckling of the Bolt should be noted in situations occurring

during assembly. Such a situation can be dimensioned with

HPM AND PPM ANCHOR BOLTS

the PeikCol dimensioning program that can freely be down-

loaded from Peikkos website www.peikko.com.

5. APPLICATION

5.1 Limitations for application

The capacities of the Anchor Bolts have been calculated for

static loads. In the case of dynamic and fatigue loads, grea-

ter safety factors have to be used individually for each

case.

5.2 Design principles

5.2.1 Principle of application

HPM/P Ribbed Bar Anchor Bolts are used as overlapping

Bolts in precast columns and as foundation Bolts.

HPM/L Ribbed Bar Anchor Bolts are also used as Anchor

Bolts in foundations, and they are suitable for Bolt joints at

the top of concrete beams or on the sides of columns.

PPM/P Ribbed Bar Anchor Bolts are used as overlapping

Bolts in columns. The main reinforcement of the basic Bolt

is attach ed to the reinforcement of the column with an over-

lap.

PPM/L Ribbed Bar Anchor Bolts are used as Anchor Bolts

in foundations.

Figure 3. Using the Bolts

PPM P

-high foundation

columns

HPM P

-column joints

PPM L

-foundation

plates

HPM L

-low foundation

columns

-foundation

plates

5.2.2 Calculation principles

With short Bolts, tension and compression forces create

a concrete cone into the base structure in the situation of

ultimate limit state. To ensure the capacities minimum dis-

tances of the edge and centres, minimum concrete cover

and minimum reinforcement has to be undertaken accor-

ding to section 5.2.4 and 5.2.5.

The normal forces on the long Bolts (PPM/P and HPM/P)

are transferred through the overlapped ribbed bars to the

main reinforcement of the structure.

Table 4. Splice factors for the long Bolts

Bolt type Factor

HPM/P 1.5

PPM/P 2.0

The factors in this table are provided as guidelines, local

authorities having jurisdiction should be consulted prior to plan

submission.

PPM and HPM Anchor Bolts have been designed for rein-

forced concrete 4500 PSI (30 MPa) in bond condition I.

The maximum level of the Anchor Bolts should be accor-

ding to section 6.2.

The effect of the stability forces has been taken into consi-

deration with a reduction factor of 0.8.

5.2.3 Requirements for concrete bedding

PPM and HPM Bolts have been designed for reinforced con-

crete 4500 PSI (30 MPa). The correction factors for lower

grades and also for structure class 1 exist in section 5.2.6.

5.2.4 Minimum edge distances, centers and

attachment bedding reinforcement for long Bolts

The re-resistance period and environment class, in which

the Column Shoes is situated, denes the concrete cover

thickness according to local regulations.

Also centre distances of long Bolts (P-types) are dened

according to local regulations.

Attachment bedding reinforcement

A basic column is reinforced with the amount of reinforce-

ment corresponding to the Bolts bond.

8

Table 5. Reinforcement of column with PPM/P Bolts

PPM P

Rebars of the Bolt

[imperial] [metric]

PPM 22P 2#6 2 M20

PPM 27P 2#8 2 M25

PPM 30P 2#8 2 M25

PPM 36P 4#6 4 M20

PPM 39P 3#8 3 M25

PPM 45P 4#8 4 M25

PPM 52P 4#10 4 M35

PPM 60P 4#10 4 M35

Table 6. The dening criteria for Bolt lengths

HPM/P HPM/P PPM/P

Concrete

[psi] 4000 5000 4000

[MPa] 30 35 30

Bond coefcient

I II I

Splice factor

1.5 1.5 2

Shearing forces

When shearing forces are transferred, the edge distance

has to be at least 1.5 h

ef

and the thickness of the slab must

be at least 2.25 hef. Otherwise, the edge has to be rein-

forced against the shearing forces or the capacity has to be

decreased according to section 5.2.6

5.2.5 Minimum edge distances, centres and

attachment bedding reinforcement for short

Bolts

The minimum edge distance from the edge of the founda-

tion is 1.5 h

ef

and the thickness of the slab must be at least

2.25 hef for short HPM/L and PPM/L Anchor Bolts.

Table 7. The edge distance of short Bolts in footing and the

minimum centre distances, when the joint consists of

four Anchor Bolts

c / c

Nd

Md

1.5 X hef

c/c

[in] [ mm]

HPM 16L

3-1/2 80

HPM 20L

4-1/2 110

HPM 24L

5 120

HPM 30L

8 180

HPM 39L

12 280

PPM 22L

4 100

PPM 27L

4 100

PPM 30L

8 200

PPM 36L

12 280

PPM 39L

12 280

PPM 45L

12 280

PPM 52L

12 280

PPM 60L

12 280

If tensile force is affecting more than two Anchor Bolts, the

centre distances have to be treated as a special case.

9 www.peikko.com

10

HPM AND PPM ANCHOR BOLTS

Tensile forces

A single Bolt can be anchored without the need for pun-

ching reinforcement. A pair of Bolts requires the use of

mesh reinforcement according to the concrete standards.

The reinforcement is distributed evenly in the area of the

concrete cone.

Table 8. Foundation reinforcement

As

lb

Nd

Md

As Min. mesh reinforcement

[in

2

/ft] [ mm

2

/m] [imperial] [metric]

HPM 16L 0.079 167 # 3 @ 8 M10 @ 200

HPM 20L 0.106 225 # 3 @ 8 M10 @ 200

HPM 24L 0.136 288 # 3 @ 6 M10 @ 150

HPM 30L 0.159 336 # 3 @ 6 M10 @ 150

HPM 39L 0.236 500 # 3 @ 6 M10 @ 150

PPM 22L 0.168 355 # 3 @ 6 M10 @ 150

PPM 27L 0.222 470 # 3 @ 6 M10 @ 150

PPM 30L 0.231 490 # 3 @ 6 M10 @ 150

PPM 36L 0.255 539 # 3 @ 6 M10 @ 150

PPM 39L 0.313 663 # 4 @ 6 M15 @ 150

PPM 45L 0.352 745 # 4 @ 6 M15 @ 150

PPM 52L 0.410 869 # 4 @ 4 M15 @ 150

PPM 60L 0.481 1019 # 4 @ 4 M15 @ 150

If necessary, values lower than the edge distances stated in

table 7 can be used if the concrete cone is anchored against

Bolt force by using the following principles.

Figure 4. Alternatives for punching reinforcement

Nd

Nd

PPM L

HPM L

PPM L

HPM L

lb

If necessary, the HPM/L Anchor Bolts can be located closer

to the edge of the structure if the corner of the structure is

reinforced according to the Bolt forces. In that case, with

the HPM/L Anchor Bolts, you can use the minimum edge

distance of 3,1 x M, calculated on the basis of the local

compression fraction of the concrete. Using this small edge

distance (min. 3,1 x M) becomes necessary in beams, co-

lumns and in the edges of other strongly reinforced struc-

tures.

Table 9. The minimum edge distance of the HPM/L Anchor

Bolts according to local compression factor. The reinforcement

of the structure will prevent conical fracture.

3,1xM c / c

splices

Ash Splices

[in

2

] [ mm

2

] [imperial] [metric]

HPM 16L 0.025 52 1 # 3 1 M10

HPM 20L 0.039 82 2 # 3 2 M10

HPM 24L 0.056 118 3 # 3 3 M10

HPM 30L 0.088 187 4 # 3 3 M10

HPM 39L 0.153 325 5 # 3 5 M10

Compression forces

The compression anchoring of short Bolts requires a suf-

cient concrete layer (h) underneath the Bolts forged head,

11

www.peikko.com

so that the anchor piece does not cause a blowout failure

under the Anchor Bolt. If (h) in the structure is lower than

the required (hrequired,) the structure has to be reinforced.

Shearing forces

When shearing forces are transferred, the edge distance

has to be 1.5 h

ef

and the thickness of the slab must be at

least 2.25 hef at the most. Oterwise, the edge has to be

reinforced against the shearing forces or the capacity has

to be decreased according to section 5.2.6.

5.2.6 The correction factors of capacity values

Concrete grade

Correction factor for concrete 3000 psi (25 MPa) = 0.83

Edge distances for shearing force

The shearing force capacity requires an edge distance

of 1.5 h

ef

and the thickness of the slab must be at least

2.25 hef. If this requirement is not in place, reinforcement

must be used to make sure the edge of the concrete

structure will not break. Alternatively, the capacities must

be reduced in relation to the edge distances.

Table 10. Reinforcing the blowout failure under the Bolt

As

Nd

l

b

h

Reinforcement, if h < h

required

h

required

As

[in] [ mm] [in

2

] [ mm

2

]

HPM 16L 3-1/8 80 0.045 96

HPM 20L 3-15/16 100 0.067 141

HPM 24L 4-1/2 115 0.088 186

HPM 30L 5-11/16 145 0.147 311

HPM 39L 7-1/2 190 0.240 508

PPM 22L 3-1/2 90 0.070 149

PPM 27L 4-1/8 105 0.072 152

PPM 30L 4-3/4 120 0.141 298

PPM 36L 6-11/16 170 0.278 588

PPM 39L 7-11/16 195 0.340 720

PPM 45L 8-1/16 205 0.454 961

PPM 52L 8-11/16 220 0.484 1024

PPM 60L 11 280 0.713 1510

Correction Factor=

2

10

M

C

C = Distance from structure section to the centre of the Bolt (mm)

M = Thread Size (metric)

5.2.7 Joining to foundations and column to

column connections

Figure 5. Column joint of two different size columns

Ash

B

H

Ash

Table 11. The expansion of the (min) and splitting stirrups

Concrete grade

(column)

[psi] 6000 7500 8000 8000 12000

[MPa] 40 50 60 60 80

Concrete grade

(foundation)

[psi] 4500 4500 4500 6000 6000

[MPa] 30 30 30 40 40

The Bolts of the

tension side yield

[in] 0.13 x H 0.26 x H 0.38 x H 0.20 x H 0.38 x H

[ mm] 0.13 x H 0.26 x H 0.38 x H 0.20 x H 0.38 x H

Cross section

compressed

[in] 0.24 x H 0.43 x H 0.61 x H 0.33 x H 0.61 x H

[ mm] 0.24 x H 0.43 x H 0.61 x H 0.33 x H 0.61 x H

Diametric

reinforcement

(BSt500S)

Ash > A

[in

2

]

A

=

B

x

H

/

4

3

0

A

=

B

x

H

/

2

4

0

A

=

B

x

H

/

1

7

0

A

=

B

x

H

/

2

7

8

A

=

B

x

H

/

1

5

3

[ mm

2

]

A

=

B

x

H

/

4

3

0

A

=

B

x

H

/

2

4

0

A

=

B

x

H

/

1

7

0

A

=

B

x

H

/

2

7

8

A

=

B

x

H

/

1

5

3

The concrete strength of the lower column, in the column

to column connection should be at least the same as the

concrete strength of the upper column.

5.3 ERECTION NOTICE

Erection time

For program must calculate:

Gd

= Weight of column

M

d

= Bending moment (caused by wind)

Warning: Joint is not grouted - bolts analisis is similar to

cantilever columns.

12

HPM AND PPM ANCHOR BOLTS

Imperial Metric

Diameter of thread

1,388 in

1,513 X 4

A X 4

d

sp

sp

=

=

mm 3 , 35

976 X 4

A X 4

d

sp

sp

=

=

Lever arm of shear force ( jmax 3,75 in or 100 mm)

4,2 in 1,388 5 , 0 2,5

2

2

d 5 , 0 j

2

t

a

sp b

= + + = + + =

( ( ( (

mm 6 , 102 3 , 35 5 , 0 60

2

50

d 5 , 0 j

2

t

sp

= + + = + + =

( ( ( (

a

b

Forces per bolt; centre distance of bolt:

19 in 2,5 2 24 E 2 b c = = = mm 480 60 2 600 E 2 b c = = =

Normal force of single bolt

kips 9 , 17

kips 6 , 48

583 , 1 2

73 , 104

4

61,0

c

2

n

M

n

G

N

d d

d , b

+

=

kN 7 , 79

kN 2 , 216

48 , 0 2

00 , 142

4

00 , 273

c

2

n

M

n

G

N

d d

d , b

+

=

Shear force of single bolt

0,75 kips

4

3,0

n

V

V

d

d , b

= = = kN 58 , 3

4

30 , 14

n

V

V

d

d , b

= = =

Bending moment of single bolt

13 kipsXft , 0

0 , 2

35 , 0 75 , 0 a V

M

M

b d , b

d , b

=

= kNm 184 , 0

0 , 2

103 , 0 58 , 3 a V

M

M

b d , b

d , b

=

=

Elastic section modulus S

3

3 3

sp

b

0,340 in

32

1,513

32

d

S =

=

=

3

3 3

sp

b

mm 4318

32

3 , 35

32

d

S =

=

=

Stress due to normal force

sp

b

d , Nb

32190 psi

1,51

48,6

A

N

= = =

2

3

sp

b

d , Nb

mm

N

5 , 221

976

10 2 , 216

A

N

=

= =

Stress due to bending moment

b

b

d , Mb

4588 psi

0,340

1,56

S

M

= = =

2

6

b

b

d , Mb

mm

N

6 , 42

4318

10 184 , 0

S

M

=

= =

Combined stresses of one single bolt

d , Mb d , Nb d , b

36778 psi 4588 32190 = + = + =

2 d , Mb d , Nb d , b

mm

N

1 , 264 6 , 42 5 , 221 = + = + =

Design value factored according:

ACI 318-05 CSA A23.3-04

uk yd 0,65 f f = = X 51851 psi

2 uk yd

mm

N

0,70 f f X 0,85 = = X 327

Requirement

51851 psi 36778 psi f

ud d , b

<

mm

N

327

mm

N

1 , 264 f

2 2 ud d , b

<

N

V

M

Figure 6. Static Model of the Anchor Bolt during erection

Table 12. Bolt design during erection

Figure 7. Forces on bolts during erection

13

www.peikko.com

Static model of bolt:

Bolt will transfer the loads like a small cantilever or mast

column.

Column connection:

Column cross section bXh = 24X35 in

2

or

600X900 mm

2

With 4 HPKM 39 Column Shoes

With 4 HPM 39 Anchor Bolts n = 4

Thread cross section Asp = 1,513 in

2

or 976 mm

2

Design Values of actions / forces:

Gd= 61,0 kips or 273 kN

Vd= 3,0 kips or 14,3 kN

Md= 104,73 kipsft or 142 kNm

These values are according to information of civil engineer/

client .

Information for design:

Bottom plate thickness t = 2 in or 50 mm

Joint thickness j=2,5in or 60mm (jmax

3,75in or 100mm)

Edge distance of bolt E = 2,5 in or 60 mm

Figure 8. Forces on bolts at the bottom of a column during

erection

t

j

dsp/2

a

Design Values of actions / forces for one bolt:

Nb,d = -48,6 kips or -216,5 kN

Vb,d = 0,75 kips or 3,58 kN

Mb,d = 1,56 kipsft or 0,184 kNm

6. INSTALLATION

6.1 Appliance and equipment

Compiling the Bolts to Bolt groups is done with the PPK

installation frame.

By using the installation frame, the right c/c distance as

well as the verticality of the Anchor Bolts is secured. Cen-

tre lines marked on the installation frame make it easier

to measure the Anchor Bolt groups to their location accor-

ding to module line. With the help of the installation frame,

the Anchor Bolts can be grouped easily for direct use in

reinforcement. Use of the welded Anchor Bolt groups, or

grillages, is unnecessary.

The frame is installed by tightening it between the nuts.

During casting, the frame protects the threads. By grea-

sing the threads before casting it helps in the removal of

the frame. The installation frame is attached by nailing it to

the mould with a support timber and by binding the Anchor

Bolt group into the reinforcement. An open frame makes

casting and compacting the concrete with mechanical vibra-

tors easier. After casting, the frame is detached and can be

reused.

Figure 9. Using the PPK installation frame

Table 13. Wrench to be used for Peikko Bolts

Thread Wrench ( mm) Compatible Wrench (in)

M16 24 1

M20 30 1-3/16

M22 34 1-3/8

M24 36 1-7/16

M27 41 1-5/8

M30 46 1-13/16

M36 55 2-3/16

M39 60 2-3/8

M45 70 2-13/16

M52 80 3-1/4

M60 90 3-5/8

14

HPM AND PPM ANCHOR BOLTS

6.2 Bolt installation and installation

tolerances

The Anchor Bolts are installed at the level according to the

gures in table 13. The level is measured from the sur-

face of the rough casting, and the level tolerance is 3/4

(20 mm).

Table 14. Installation tolerances and the Anchoring Bolts

height level from the surface of concrete when

HPKM, PPKM and PEC Column Shoes are used.

Installation tolerance T

I

n

s

t

a

l

l

a

t

i

o

n

t

o

l

e

r

a

n

c

e

T

location tolerance

of bolt group

3/8 (10 mm)

Anchor

Bolts

Column

Shoes

Grouting

Bolt height

from cast

level

Installation

tolerance

for the Bolt

(T)

[in] [ mm] [in] [ mm] [in] [ mm]

HPM 16 HPKM 16 2 50 4-1/8 105 1/8 3

HPM 20 HPKM 20 2 50 4-1/2 115 1/8 3

HPM 24 HPKM 24 2 50 5-1/8 130 1/8 3

HPM 30 HPKM 30 2 50 6 150 1/8 3

HPM 39 HPKM 39 2-3/8 60 7 180 1/8 3

PPM 22 PEC 24 2 50 5-1/8 130 1/8 3

PPM 27 PEC 30 2 50 6-1/4 160 1/8 3

PPM 30 2 50 5-7/8 150 1/8 3

PPM 36 PPKM 36 2-5/32 55 6-5/8 170 5/32 4

PPM 39 PPKM 39 2-3/8 60 7-1/16 180 5/32 4

PPM 45 PPKM 45 2-9/16 65 7-5/8 195 5/32 4

PPM 52 PPKM 52 2-3/4 70 8-7/8 225 3/16 5

PPM 60 3-1/8 80 10-1/4 260 3/16 5

When the Anchor Bolt group for the PPK installation frame

is formed, a reciprocal location tolerance of 1/8 (3 mm)

is achieved for the Anchor Bolts. The location tolerance

of the Bolt groups frame has to be 3/8 (10 mm) in

concrete element installation. The location of the center of

each Anchor Bolt must be positioned at a maximum of 3/8

(10 mm) from the position specied in the plan drawing.

6.3 Bending the Anchor Bolts

The HPM Anchor Bolts and the rebars or Anchor Bars of the

PPM Anchor Bolts are made of BSt500S (A500HW) ribbed

steel.

6.4 Welding of the Anchor Bolts

Welding of the Anchor Bolts should be avoided, although all

materials used in HPM and PPM Anchor Bolts are weldable

(except the nuts).

6.5 Installing the columns

Column installation is done on top of washers adjusted to

the right level with the nuts and by using installation pieces

(shims or packers) under the columns. The verticality of the

column is checked and the nuts are screwed on tight. Joint

grouting must be done prior to installing the upper struc-

tures. Using shims is not mandatory. However, you can also

install precast columns with shims.

7. INSTALLATION CONTROL

7.1 Instructions for controlling Bolt

installation

Before casting

ensure that the right frame is being used (c/c standards,

thread size). HPKM and PPKM Column Shoes have a col-

umn side measurement of 4 (100 mm) (M16 - M36) or

4-3/4 (120 mm) (M39 M52) greater than the Anchor

Bolts c/c standards.

ensure the location of the Anchor Bolt group in relation to

the module lines

15

www.peikko.com

ensure that the reinforcement required by the Anchor

Bolts has been installed

ensure that the Anchor Bolts are in planned, correct and

right level

ensure that the installation frame did not rotated

After casting

ensure the location of the Anchor Bolt group (the tole-

rance for concrete element column joints are portrayed

in section 6.2). Greater variations must be reported to the

structural designer.

protect the thread until the installation of the column

(tape, plastic tube etc.)

7.2 Instructions for controlling column

installation

The joints have to be made according to the installation plan

drawn by the designer (construction

engineer). If needed, Peikkos techni-

cal support will give advice.

In particular, check the follow-

ing:

installation order

support during installation

instructions for tightening the nuts

instructions for joint casting

Peikko Group www.peikko.com

You might also like

- Engineering Design of Lifting LugsDocument1 pageEngineering Design of Lifting LugsadammzjinNo ratings yet

- Code Cases Boilers and Pressure VesselsDocument994 pagesCode Cases Boilers and Pressure VesselsmateoNo ratings yet

- TechnipFMC Project MobilizationDocument9 pagesTechnipFMC Project MobilizationJobJob100% (8)

- Precast Concrete Frames GuideDocument58 pagesPrecast Concrete Frames GuideibrahimrobertNo ratings yet

- Claim LetterDocument1 pageClaim LetterAshis Pal RonyNo ratings yet

- Presentation GirderDocument53 pagesPresentation GirderIrfan KhanNo ratings yet

- Method Statement - ASPHALT CONCRETE WORKS PDFDocument10 pagesMethod Statement - ASPHALT CONCRETE WORKS PDFTAHER AMMAR100% (6)

- 3 Is GRC A Green Building MaterialDocument7 pages3 Is GRC A Green Building MaterialJuliano. PQMNo ratings yet

- Reconditioning of ValvesDocument6 pagesReconditioning of ValvesPaul PhiliphsNo ratings yet

- Composites BLDG Mtrls For Green BuildingDocument74 pagesComposites BLDG Mtrls For Green Buildingabinash SethiNo ratings yet

- PIP STS05130 (Erection of Structural & Miscellaneous Steel Specification)Document11 pagesPIP STS05130 (Erection of Structural & Miscellaneous Steel Specification)Hui Liu100% (2)

- Precast Concrete SolutionsDocument27 pagesPrecast Concrete SolutionsMohammed IkramaliNo ratings yet

- Pre-Load and Tightening Torques For Steel Fasteners - Standard Metric ThreadsDocument3 pagesPre-Load and Tightening Torques For Steel Fasteners - Standard Metric ThreadsmukeshkumarjNo ratings yet

- Precast Concrete Specifications for Resort SpaDocument9 pagesPrecast Concrete Specifications for Resort SpaTEC PlantNo ratings yet

- Precast Construction: Prepared By: Parth S. Patel SD1510Document55 pagesPrecast Construction: Prepared By: Parth S. Patel SD1510Gireesh Gowda GiriNo ratings yet

- Piping Course هام جداDocument206 pagesPiping Course هام جداMohamed Ibrahim100% (1)

- Method Statement For Erection of PanelDocument13 pagesMethod Statement For Erection of PanelNadeem Afzal100% (1)

- Noise CalculatorDocument9 pagesNoise CalculatormukeshkumarjNo ratings yet

- Precast Concrete PDFDocument160 pagesPrecast Concrete PDFSandi AslanNo ratings yet

- Precast Concrete AccessoriesDocument93 pagesPrecast Concrete AccessoriesSimone BonelliNo ratings yet

- Fire Protection System Specification for Government HousingDocument44 pagesFire Protection System Specification for Government Housingmon MagbualNo ratings yet

- Andamios PDFDocument69 pagesAndamios PDFleonciomavarez100% (1)

- HPM (1) BoltDocument16 pagesHPM (1) BoltRani HendrikusNo ratings yet

- Essential Concrete Curing MethodsDocument4 pagesEssential Concrete Curing MethodsrmdarisaNo ratings yet

- The Safe Handling Transportation and Erection of Precast ConcreteDocument45 pagesThe Safe Handling Transportation and Erection of Precast Concreteespanolal100% (3)

- Formenta Product CatalogueDocument28 pagesFormenta Product CatalogueEmanuel KrznarNo ratings yet

- Prestressed Concrete: By: Lois B. BernarinoDocument27 pagesPrestressed Concrete: By: Lois B. BernarinoloisNo ratings yet

- Geto Aluminium Formwork User ManualDocument35 pagesGeto Aluminium Formwork User ManualbsudhareddyNo ratings yet

- Compaction of Concrete Using Immersion and Surface Vibrators PDFDocument12 pagesCompaction of Concrete Using Immersion and Surface Vibrators PDFmehdi_hoseinee0% (1)

- MDF Safety For CarpentersDocument4 pagesMDF Safety For CarpentersTudorache RaduNo ratings yet

- DC PT Contractors Role Responsibilities PTIA IEAust NewcastleDocument30 pagesDC PT Contractors Role Responsibilities PTIA IEAust NewcastleSree NivasNo ratings yet

- BhandupDocument69 pagesBhandupMrudulaNo ratings yet

- Structural Steel Shapes and StandardsDocument5 pagesStructural Steel Shapes and Standardsnazlie1707No ratings yet

- EABASSOC Lightweight Foamed ConcreteDocument4 pagesEABASSOC Lightweight Foamed ConcreteAr Aayush GoelNo ratings yet

- Constructing The Future: Built Environment and Transport Panel Construction Associate ProgrammeDocument31 pagesConstructing The Future: Built Environment and Transport Panel Construction Associate ProgrammeBijoy AVNo ratings yet

- Prefab Install Manual 051520Document113 pagesPrefab Install Manual 051520jackcan501No ratings yet

- Lg933 Wheel Loader Parts Catalog: Shandong Lingong Construction Machinery Co.,LtdDocument147 pagesLg933 Wheel Loader Parts Catalog: Shandong Lingong Construction Machinery Co.,LtdЭрнест БекировNo ratings yet

- Precast Meadow Burke Manual Inserts in PrecastDocument184 pagesPrecast Meadow Burke Manual Inserts in Precastgemotorres0% (1)

- Ultra High Performance Concrete Panels For Prefabricated Wall AssembliesDocument22 pagesUltra High Performance Concrete Panels For Prefabricated Wall AssembliesDebasish DeyNo ratings yet

- ErectionDocument7 pagesErectiondtuan8150% (2)

- Corrosion Control of Reinforcement BarsDocument6 pagesCorrosion Control of Reinforcement BarsBhaskar ReddyNo ratings yet

- Specific Experience - PCLDocument15 pagesSpecific Experience - PCLGboyega AwelewaNo ratings yet

- Kosovo - Terms of Reference LandfillsDocument28 pagesKosovo - Terms of Reference Landfillsrimi7alNo ratings yet

- Installation Manual - Chain Link FenceDocument2 pagesInstallation Manual - Chain Link FenceChase GietterNo ratings yet

- 2020-05-08 SVKM'S, Shirpur, Maharashtra - DBR-R0Document26 pages2020-05-08 SVKM'S, Shirpur, Maharashtra - DBR-R0Sheikh_MutaharNo ratings yet

- Rebar Impalement HazardsDocument2 pagesRebar Impalement HazardsamizanNo ratings yet

- Peiko Wall Shoe PDFDocument20 pagesPeiko Wall Shoe PDFjoyson232542No ratings yet

- 4,100-Villa Abu Dhabi Project Built with Precast ConcreteDocument25 pages4,100-Villa Abu Dhabi Project Built with Precast ConcreteVîkÅš VìČkýNo ratings yet

- Report Site VisitDocument4 pagesReport Site VisitFaiz SalimNo ratings yet

- Precast Concrete - Sandwich Panel ConstructionDocument16 pagesPrecast Concrete - Sandwich Panel Constructionalberto5791No ratings yet

- Permanent Formwork Systems: For In-Situ Ground Beams & Pile CapsDocument12 pagesPermanent Formwork Systems: For In-Situ Ground Beams & Pile CapsbrechtNo ratings yet

- K017-T12-0003 - 0 Method Statement For Extension Work of Temporary JettyDocument16 pagesK017-T12-0003 - 0 Method Statement For Extension Work of Temporary JettyBayu PutraNo ratings yet

- Petroleum Development Oman Signs Catalogue SpecificationDocument97 pagesPetroleum Development Oman Signs Catalogue SpecificationSiva ShankarNo ratings yet

- Hazardous Material StorageDocument2 pagesHazardous Material Storageone8283841553No ratings yet

- TI 801-02 Volume 2 - Statement of WorkDocument81 pagesTI 801-02 Volume 2 - Statement of WorkMohamed FathiNo ratings yet

- Erectors ManualDocument5 pagesErectors ManualPurushoth Marley0% (1)

- WisDOT Bridge Manual Chapter 13 - Piers Design and AnalysisDocument166 pagesWisDOT Bridge Manual Chapter 13 - Piers Design and Analysisrohit kumarNo ratings yet

- Engineered Cementitious Composites PDFDocument11 pagesEngineered Cementitious Composites PDFseshNo ratings yet

- International Journal PrecastDocument3 pagesInternational Journal Precastraghuveer11No ratings yet

- 9 Questions Before Making Shotcrete Mix DesignDocument2 pages9 Questions Before Making Shotcrete Mix DesignMuhammadIqbalMughalNo ratings yet

- Traffic Management Plan: ContractDocument9 pagesTraffic Management Plan: Contractm.ispasNo ratings yet

- Self-Compacting Concrete: The Benefits of SCCDocument4 pagesSelf-Compacting Concrete: The Benefits of SCCKhaja MohiddinNo ratings yet

- JPRCP Manual FullDocument243 pagesJPRCP Manual FullHanuman BuildersNo ratings yet

- RMCDocument40 pagesRMCFiroj AlamNo ratings yet

- ABB Proteção Elétrica - Plugs e Tomadas IndustriaisDocument120 pagesABB Proteção Elétrica - Plugs e Tomadas IndustriaisalexandrewsfNo ratings yet

- EXTER T150-st: Installation ManualDocument24 pagesEXTER T150-st: Installation ManualdwdawadNo ratings yet

- Lokring Application GuideDocument26 pagesLokring Application GuideMarcos KlaynNo ratings yet

- Modular Structure Assembly Manual and Safety: Pág. 1 Edic.03.01.04.2014.01Document194 pagesModular Structure Assembly Manual and Safety: Pág. 1 Edic.03.01.04.2014.01steve branchNo ratings yet

- COM-BLD SSR24 Installation ManualDocument94 pagesCOM-BLD SSR24 Installation ManualAelfwine EinshpiedNo ratings yet

- BP Variable Catalog 09VDocument52 pagesBP Variable Catalog 09VPetros IosifidisNo ratings yet

- Manual SismoDocument36 pagesManual SismoDiego PeñaNo ratings yet

- 1 25Document18 pages1 25Charu ChhabraNo ratings yet

- AISI304Document2 pagesAISI304tony_abNo ratings yet

- Fan TerminologyDocument12 pagesFan TerminologymukeshkumarjNo ratings yet

- Tray Support 2Document28 pagesTray Support 2pankajskecNo ratings yet

- Motor Bus Transfer Techniques for Maintaining Process ContinuityDocument14 pagesMotor Bus Transfer Techniques for Maintaining Process ContinuityMohamed Abdel KhalekNo ratings yet

- Catalogue - EasySteel - Steel Book 2012 PDFDocument112 pagesCatalogue - EasySteel - Steel Book 2012 PDFIvan BuhiinzaNo ratings yet

- Basic Noise CalculationsDocument15 pagesBasic Noise Calculationsapi-270822363No ratings yet

- Use of Dissipative SilencersDocument9 pagesUse of Dissipative SilencersmukeshkumarjNo ratings yet

- Noise SourcesDocument22 pagesNoise SourcesmukeshkumarjNo ratings yet

- Mechanical Properties and Steel Grades Comparison TableDocument1 pageMechanical Properties and Steel Grades Comparison TablemukeshkumarjNo ratings yet

- Achieving the Impossible in 11 MonthsDocument5 pagesAchieving the Impossible in 11 MonthsmukeshkumarjNo ratings yet

- Gandhi Special Tubes ISO 9001 2008Document6 pagesGandhi Special Tubes ISO 9001 2008mukeshkumarjNo ratings yet

- Dear Smriti, A Very Happy New Year!!!! With Love, AadishreeDocument1 pageDear Smriti, A Very Happy New Year!!!! With Love, AadishreemukeshkumarjNo ratings yet

- ANSI B36.10 - Pipe Dimension With Wt.Document1 pageANSI B36.10 - Pipe Dimension With Wt.RAVI1972No ratings yet

- Metric - Cap and Domed Nuts Hex Dome NutsDocument1 pageMetric - Cap and Domed Nuts Hex Dome NutsmukeshkumarjNo ratings yet

- Flu/P: D. K. Instruments Pvt. LTDDocument3 pagesFlu/P: D. K. Instruments Pvt. LTDmukeshkumarjNo ratings yet

- Metal Grade Equivalents ChartDocument1 pageMetal Grade Equivalents ChartmukeshkumarjNo ratings yet

- Airtel 2014-02-07Document2 pagesAirtel 2014-02-07mukeshkumarjNo ratings yet

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Document1 pageIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)mukeshkumarjNo ratings yet

- Structural Analysis of ICS 3d PanelDocument32 pagesStructural Analysis of ICS 3d PanelajivakkomNo ratings yet

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Document1 pageIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)mukeshkumarjNo ratings yet

- Rotary Actuated Switches HDLS SeriesDocument2 pagesRotary Actuated Switches HDLS SeriesmukeshkumarjNo ratings yet

- Tourist ChecklistDocument2 pagesTourist ChecklistmukeshkumarjNo ratings yet

- Boarding PassDocument1 pageBoarding PassmukeshkumarjNo ratings yet

- Ticket ReturnDocument1 pageTicket ReturnmukeshkumarjNo ratings yet

- SteelTubeHandbook February201211111Document1 pageSteelTubeHandbook February201211111mukeshkumarjNo ratings yet

- Acoustic ExplanationDocument1 pageAcoustic ExplanationmukeshkumarjNo ratings yet

- KENCO CHEMICAL INJECTORS for Natural Gas & Oil IndustriesDocument2 pagesKENCO CHEMICAL INJECTORS for Natural Gas & Oil IndustriesMEHDINo ratings yet

- AS 4100/amdt 1/2012-02-29Document28 pagesAS 4100/amdt 1/2012-02-29luiscr3806No ratings yet

- PTS-1028 Ra FC Operation ManualDocument32 pagesPTS-1028 Ra FC Operation ManualOrlando PWRNo ratings yet

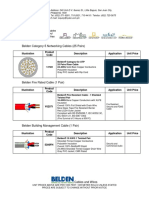

- Sytec Belden Cables and Accessories List 2016 Eff May 1Document15 pagesSytec Belden Cables and Accessories List 2016 Eff May 1Mitch PareñoNo ratings yet

- 2018 Verity Brochure v1Document2 pages2018 Verity Brochure v1RatkoMRNo ratings yet

- Jib Cranes Brochure PDFDocument28 pagesJib Cranes Brochure PDFJESUSCALVILLONo ratings yet

- Tyrolean Rendering Texture GuideDocument2 pagesTyrolean Rendering Texture GuidenanoNo ratings yet

- Tesla R32 Heat Pump Air To Water TGTP-8HMDA1 Spec 2023 ENGDocument1 pageTesla R32 Heat Pump Air To Water TGTP-8HMDA1 Spec 2023 ENGAnonymous LDJnXeNo ratings yet

- Essentials of Materials Science and Engineering Si Edition 3rd Edition Askeland Solutions ManualDocument26 pagesEssentials of Materials Science and Engineering Si Edition 3rd Edition Askeland Solutions Manualhanhgloria0hge5100% (30)

- Vulkem NEM - Data SheetDocument2 pagesVulkem NEM - Data SheetRobertNo ratings yet

- Yamuna Sports ComplexDocument37 pagesYamuna Sports ComplexHimanshu GoodwaniNo ratings yet

- 2019-05-28 - DA - RSLF Artillery Brigade - Volume 2 PDFDocument490 pages2019-05-28 - DA - RSLF Artillery Brigade - Volume 2 PDFDusngi MoNo ratings yet

- Transformation of Vernacular Houses in Coastal Andhra PradeshDocument17 pagesTransformation of Vernacular Houses in Coastal Andhra PradeshRachit AgarwalNo ratings yet

- Evaluation of Modified Truss Model Approach For Beam in ShearDocument10 pagesEvaluation of Modified Truss Model Approach For Beam in ShearKinjal DaveNo ratings yet

- Design of Guyed Mast TowerDocument5 pagesDesign of Guyed Mast TowerShai KoiNo ratings yet

- Submission: Document No Received Date Review Date NotesDocument1 pageSubmission: Document No Received Date Review Date NotesMahmoud AbbassNo ratings yet

- Works) : SABS 1200Document10 pagesWorks) : SABS 1200Palesa TshetlanyaneNo ratings yet

- Series LFN45B-M1 Specification SheetDocument2 pagesSeries LFN45B-M1 Specification SheetWattsNo ratings yet

- T-ZED Homes, Whitefield, BengaluruDocument5 pagesT-ZED Homes, Whitefield, BengaluruHello ShraaNo ratings yet

- ABEL SH Solids Handling Pumps GB-web-02 2020Document6 pagesABEL SH Solids Handling Pumps GB-web-02 2020ha liNo ratings yet

- Sikafloor - 161 PDFDocument5 pagesSikafloor - 161 PDFShaik FazilNo ratings yet