Professional Documents

Culture Documents

A 632 - 02 Qtyzmi0wmke

Uploaded by

LUISALBERTO060119850 ratings0% found this document useful (0 votes)

11 views4 pagesThis specification covers grades of stainless steel tubing in sizes under 1 / 2 down to 0.050 in. (12. To 1. Mm) in outside diameter and wall thicknesses less than 0.065 in. Down to 0.005 in. (1. To 0. Mm) for general corrosion-resisting and lowor high-temperature service. The values stated in inch-pound units are to be regarded as the standard.

Original Description:

Original Title

A 632 – 02 ;Qtyzmi0wmke

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis specification covers grades of stainless steel tubing in sizes under 1 / 2 down to 0.050 in. (12. To 1. Mm) in outside diameter and wall thicknesses less than 0.065 in. Down to 0.005 in. (1. To 0. Mm) for general corrosion-resisting and lowor high-temperature service. The values stated in inch-pound units are to be regarded as the standard.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views4 pagesA 632 - 02 Qtyzmi0wmke

Uploaded by

LUISALBERTO06011985This specification covers grades of stainless steel tubing in sizes under 1 / 2 down to 0.050 in. (12. To 1. Mm) in outside diameter and wall thicknesses less than 0.065 in. Down to 0.005 in. (1. To 0. Mm) for general corrosion-resisting and lowor high-temperature service. The values stated in inch-pound units are to be regarded as the standard.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

Designation: A 632 02a

Standard Specication for

Seamless and Welded Austenitic Stainless Steel Tubing

(Small-Diameter) for General Service

1

This standard is issued under the xed designation A 632; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope *

1.1 This specication covers grades of stainless steel tubing

in sizes under

1

2 down to 0.050 in. (12.7 to 1.27 mm) in outside

diameter and wall thicknesses less than 0.065 in. down to 0.005

in. (1.65 to 0.13 mm) for general corrosion-resisting and low-

or high-temperature service, as designated in Table 1.

NOTE 1The grades of austenitic stainless steel tubing furnished in

accordance with this specication have been found suitable for low-

temperature service down to 325F (200C) in which Charpy notched-

bar impact values of 15 ftlbf (20 J), minimum, are required and these

grades need not be impact tested.

1.2 Optional supplementary requirements are provided and,

when desired, shall be so stated in the order.

1.3 The values stated in inch-pound units are to be regarded

as the standard.

2. Referenced Documents

2.1 ASTM Standards:

A 262 Practices for Detecting Susceptibility to Intergranu-

lar Attack in Austenitic Stainless Steels

2

A 1016/A 1016M Specication for General Requirements

for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stain-

less Steel Tubes

3

E 165 Test Method for Liquid Penetrant Examination

4

E 527 Practice for Numbering Metals and Alloys (UNS)

3

2.2 SAE Standard:

SAE J 1086 Practice for Numbering Metals and Alloys

(UNS)

5

3. Ordering Information

3.1 Orders for product under this specication should in-

clude the following, as required, to describe the desired

material adequately:

3.1.1 Quantity (feet or number of lengths),

3.1.2 Name of product (seamless or welded tubes),

3.1.3 Grade (see Table 1),

3.1.4 Size (only two of the following: outside diameter,

inside diameter, and average wall),

3.1.5 Length (specic or random),

3.1.6 Optional requirements (check analysis, see Section 7;

hydrostatic, air underwater pressure test, or nondestructive

electric test, see Section 13),

3.1.7 Test report required,

3.1.8 Specication designation, and

3.1.9 Special requirements or any supplementary require-

ments selected, or both.

4. General Requirements

4.1 Tubing furnished under this specication shall conform

to the applicable requirements of the current edition of Speci-

cation A 1016/A 1016M, unless otherwise provided herein.

5. Manufacture

5.1 ManufactureThe tubes shall be cold nished and shall

be made by the seamless or welded process.

5.2 Heat TreatmentAll material shall be furnished in the

heat-treated condition. The heat-treatment procedure shall

consist of heating the material to a minimum temperature of

1800F (980C) and quenching in water or rapidly cooling by

other means.

6. Chemical Composition

6.1 The steel shall conform to the requirements as to

chemical composition as specied in Table 1.

7. Product Analysis

7.1 When specied on the purchase order, an analysis of

either one billet or one length of at-rolled stock or one tube

shall be made from each heat. The chemical composition thus

determined shall conform to the specied requirements.

7.2 If the analysis made in accordance with 7.1 does not

conform to the specied requirements, an analysis of each

billet or length of at-rolled stock or tube from the same heat

may be made and all billets, stock, or tubes thus conforming to

the requirements shall be accepted so far as chemical compo-

sition is concerned.

1

This specication is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.10 on Stainless and Alloy Steel Tubular Products.

Current edition approved Sept. 10, 2002. Published November 2002. Originally

published as A 632 69. Last previous edition A 632 02.

2

Annual Book of ASTM Standards, Vol 01.03.

3

Annual Book of ASTM Standards, Vol 01.01.

4

Annual Book of ASTM Standards, Vol 03.03.

5

Available from Society of Automotive Engineers (SAE), 400 Commonwealth

Dr., Warrendale, PA 15096-0001.

1

*A Summary of Changes section appears at the end of this standard.

Copyright ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

8. Mechanical Properties

8.1 Tensile RequirementsThe material shall conform to

the requirements as to tensile properties specied in Table 2.

These mechanical properties apply to tubing

1

8 in. (3.2 mm)

and larger in outside diameter by 0.015 in. (0.38 mm) in wall

thickness and heavier. Smaller sizes are available meeting the

minimum tensile strength specied in Table 2; however, yield

strength is not generally determined on such sizes, and the

minimum elongation shall be 25 %.

9. Permissible Variations in Dimensions

9.1 Variations in diameter and wall thickness from those

specied shall not exceed the amounts specied in Table 3.

10. Surface Condition

10.1 The tubes shall be pickled free of scale. When bright

annealing is used, pickling is not required.

11. Number of Tests

11.1 For each lot of 100 nished tubes or fraction thereof,

two tubes shall be selected at random for the aring test (see

Note 2).

11.2 One tension test shall be made on a specimen for lots

of not more than 50 tubes. Tension tests shall be made on

specimens from two tubes for lots of more than 50 tubes (see

Note 3).

NOTE 2For aring requirements, the term lot applies to all tubes of

the same nominal size and wall thickness that are produced from the same

heat of steel and subjected to the same nishing treatment in a continuous

furnace; when nal heat treatment is in a batch-type furnace, the lot shall

include only those tubes that are heat treated in the same furnace charge.

NOTE 3For tensile requirements, the term lot applies to all tubes prior

to cutting, of the same nominal diameter and wall thickness that are

produced from the same heat of steel. When nal heat treatment is in a

batch-type furnace, a lot shall include only those tubes of the same size

and the same heat that are heat treated in the same furnace charge. When

the nal heat treatment is in a continuous furnace, a lot shall include all

tubes of the same size and heat, heat treated in the same furnace at the

same temperature, time at heat and furnace speed.

11.3 When more than one heat is involved, the test require-

ments prescribed in 12.1 shall apply to each heat.

11.4 Each tube shall be subjected to a pressure test or the

nondestructive test described in Section 13.

12. Flaring Test

12.1 Flaring TestA section of tube approximately 4 in.

(101.6 mm) in length shall stand being ared with a tool having

a 60 included angle until the tube at the mouth of the are has

been expanded to the following percentages without cracking

or showing aws:

Ratio of Inside Diameter

to Outside Diameter

Minimum Expansion of

Inside Diameter, %

0.9 21

0.8 22

0.7 25

0.6 30

0.5 39

0.4 51

0.3 68

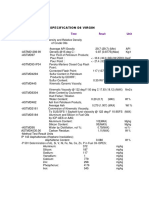

TABLE 1 Chemical Requirements

Element

Composition, %

Grade TP 304 TP 304L TP 310 TP 316 TP 316L TP 317 TP 321 TP 347 TP 348

UNS

Designation

A

S30400 S30403 S31000 S31600 S31603 S31700 S32100 S34700 S34800

Carbon, max 0.08 0.030 0.15 0.08 0.030 0.08 0.08 0.08 0.08

Manganese max 2.00 2.00 2.00 2.00 2.00 2.00 2.00 2.00 2.00

Phosphorus, max 0.045 0.045 0.045 0.045 0.045 0.045 0.045 0.045 0.045

Sulfur, max 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030

Silicon, max 0.75 0.75 0.75 0.75 0.75

B

0.75 0.75 0.75 0.75

Nickel 8.011.0 8.013.0 19.022.0 11.014.0

C

10.015.0 11.014.0 9.013.0 9.013.0 9.013.0

Chromium 18.020.0 18.020.0 24.026.0 16.018.0 16.018.0 18.020.0 17.020.0 17.020.0 17.020.0

Molybdenum ... ... ... 2.003.00 2.003.00 3.004.00 ... ... ...

Titanium ... ... ... ... ... ...

D

... ...

Columbium + tantalum ... ... ... ... ... ... ...

E E

Tantalum, max ... ... ... ... ... ... ... ... 0.10

A

New designation established in accordance with Practice E 527 and SAE J 1086, Practice for Numbering Metals and Alloys (UNS).

B

For seamless TP316L tubes, the silicon maximum shall be 1.00 %.

C

For welded TP 316 tubes, the nickel range shall be 10.014.0 %.

D

Grade TP 321 shall have a titanium content of not less than ve times the carbon content and not more than 0.60 %.

E

Grades TP 347 and TP 348 shall have a columbium plus tantalum content of not less than ten times the carbon content and not more than 1.0 %.

TABLE 2 Tensile Requirements

Tensile strength, min, ksi (MPa) 75

A

(515)

A

Yield strength, min, ksi (MPa) 30

A,B

(205)

A,B

Elongation in 2 in. or 50 mm, min, % 35

B

A

Grades TP 304L and TP 316L shall have a minimum tensile strength of 70 ksi

(485 MPa) and a minimum yield strength of 25 ksi (170 MPa).

B

Yield strength is not generally determined on tubing sizes smaller than

1

8 in.

(3.2 mm) in outside diameter or thinner than 0.015 in. (0.38 mm) wall, so yield

strength is not required on such sizes. Also, the minimum elongation required on

these smaller or thinner sizes is 25 %.

TABLE 3 Permissible Variations in Dimensions

Outside Diameter Range

Outside

Diameter,

in. (mm)

Inside

Diameter,

in. (mm)

Wall,

plus

and

minus, %

Up to, but not including

3

32

(0.094) in. (2.38 mm)

+0.002 (0.05)

0.000

+0.000

0.002 (0.05)

10

3

32 (0.094) in. (2.38 mm) but

not including

3

16(0.188)

in. (4.76 mm)

+0.003 (0.08)

0.000

+0.000

0.003 (0.08)

10

3

16 to, but not including,

1

2

(0.500) in. (12.70 mm)

+0.004 (0.10)

0.000

+0.000

0.004 (0.10)

10

A 632 02a

2

NOTE 4These are tests shall not be required on sizes under 0.093 in.

(2.38 mm) in inside diameter.

13. Hydrostatic, Air Underwater Pressure Test, or

Nondestructive Electric Test

13.1 Each tube shall be subjected to the hydrostatic test, air

underwater pressure test, or nondestructive electric test. The

type of test to be used shall be at the option of the manufac-

turer, unless otherwise specied in the purchase order.

13.2 Hydrostatic Test:

Each tube shall be subjected to a hydrostatic test at a test

pressure not exceeding 1000 psi (6.89 Mpa).

13.3 Air Underwater Pressure Test:

Each tube shall be subjected to an air underwater pressure

test, at a test pressure as given by the following equation or 500

psi (3.4 Mpa), whichever is less:

P 5 2St / D (1)

where:

P = air pressure, psi or MPa

S = allowable ber stress of 16,000 psi (110.3 MPa),

t = specied wall thickness, in. or mm, and

D = specied outside diameter, in. or mm.

13.4 Nondestructive Electric Test:

13.5 Each tube shall be subjected to a nondestructive

electric test that is capable of detecting imperfections with a

depth exceeding 10 % of the wall thickness or 0.002 in. (0.05

mm), whichever is greater. Testing will not be required on sizes

under 0.125 in. (3.18 mm) in outside diameter. However, at the

option of the purchaser, tubing to be drawn to a diameter under

0.125 in. may be tested while in the range from 0.156 in. (3.97

mm) to 0.125 in. outside diameter, and any defects that are

found shall be culled out before any further reductions are

made.

14. Keywords

14.1 austenitic stainless steel; seamless tube; small diam-

eter; stainless steel tube; steel tube; welded steel tube

SUPPLEMENTARY REQUIREMENTS

The following supplementary requirements shall apply only when specied by the purchaser in the

inquiry, contract, or order.

S1. Dye Penetrant Inspection

S1.1 Each tube shall be submitted to a visible dye or

uorescent dye penetrant examination. The procedure for this

specication shall conform to Test Method E 165. The type

penetrant and the acceptance level shall be agreed upon

between the purchaser and manufacturer.

S2. Embrittlement Test

S2.1 Tubing shall be capable of meeting the intergranular

corrosion test specied in Practice E of Practices A 262 in the

as-shipped condition. Stabilized and low-carbon grades shall

be capable of meeting the requirements of this test in the

sensitized condition (1 h at 1240F [675C]).

S3. Cleanliness

S3.1 When specied, tubing shall be supplied thermocouple

clean on the inside surface. Thermocouple clean is dened as

being free of all drawing compounds, carbon, dirt, dust, visible

surface oxides, scale, and other contaminants.

S3.1.1 Verify the freedom from inside visible surface oxides

and scale by cutting two short lengths of tubing as specimens

and longitudinally sectioning both. Pickle one of the specimens

and then wash both. Visually, without magnication, compare

the pickled and unpickled specimens to conrm that neither

exhibits surface oxides or scale on their inside surfaces.

S3.1.2 Verify cleanliness and freedom from contaminants,

such as drawing compounds, carbon, dirt, and dust, by passing

a solvent-saturated swatch of lint-free yarn or cloth, or a felt

plug through the tube. Isopropyl alcohol, methanol, ethanol,

denatured alcohol, or acetone followed by alcohol are accept-

able solvents. Because acetone leaves a residual lm, cleaning

with acetone alone is not acceptable. While a heavy discolora-

tion of the swatch or plug is unacceptable, a light discoloration

is acceptable unless particles of grit or metallic akes are

visually detectable without the use of magnication.

S3.2 After cleaning, the tubing shall be capped or otherwise

protected to ensure cleanliness upon arrival at its destination.

The producer and purchaser shall agree on the method of

protection.

S4. Unstraightened Tubes

S4.1 When the purchaser species tubes unstraightened

after nal heat treatment (such as coils), the minimum yield

strength of Table 2 shall be reduced by 5 ksi.

S4.2 On the certication, and wherever the grade designa-

tion for unstraightened tubing appears, it shall be identied

with the suffix letter U (for example, 304-U, 321-U, and so

forth.).

A 632 02a

3

SUMMARY OF CHANGES

This section identies the location of changes to this specication that have been incorporated since the last

issue, A 632 02.

(1) Reference to Specication A 1016/A 1016M has been

added.

(2) References to Test Methods and Denitions A 370, Termi-

nology A 941, and Test Methods A 751 have been deleted from

Section 2 and throughout the standard.

(3) Section 12 was renamed from Manipulation Test to

Flaring Test.

(4) Section on Terminology was deleted.

(5) Section on General Requirements was added.

(6) Paragraphs 7.1 and 7.2 were revised.

(7) Sections on Retests, Retreatment, Test Specimens and Test

Methods, Inspection, Rejection, Certication, and Product

Marking were deleted.

(8) Section 13 was revised.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every ve years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

A 632 02a

4

You might also like

- A 632 - 01 Qtyzmi0wmqDocument4 pagesA 632 - 01 Qtyzmi0wmqLUISALBERTO06011985No ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- QTIWOS9BMJA5TQDocument3 pagesQTIWOS9BMJA5TQquiensabe0077No ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Seamless Medium-Carbon Steel Boiler and Superheater Tubes: Standard Specification ForDocument3 pagesSeamless Medium-Carbon Steel Boiler and Superheater Tubes: Standard Specification ForJoshua SteigerwaldNo ratings yet

- Fundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationFrom EverandFundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationNo ratings yet

- Steel Tubes, Carbon and Carbon Manganese, Fusion Welded, For Boiler, Superheater, Heat Exchanger and Condenser ApplicationsDocument4 pagesSteel Tubes, Carbon and Carbon Manganese, Fusion Welded, For Boiler, Superheater, Heat Exchanger and Condenser ApplicationsSriniramu SriniramuNo ratings yet

- A270 PDFDocument5 pagesA270 PDFHansSarmientoNo ratings yet

- Electric-Resistance-Welded Ferritic Alloy-Steel Boiler and Superheater TubesDocument4 pagesElectric-Resistance-Welded Ferritic Alloy-Steel Boiler and Superheater TubesVishal SharmaNo ratings yet

- Proceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014From EverandProceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014No ratings yet

- Seamless and Welded Carbon and Alloy-Steel Tubes For Low-Temperature ServiceDocument6 pagesSeamless and Welded Carbon and Alloy-Steel Tubes For Low-Temperature ServiceAlphaEcc EngineeringTeamNo ratings yet

- Steel Tubes, Carbon and Carbon Manganese, Fusion Welded, For Boiler, Superheater, Heat Exchanger and Condenser ApplicationsDocument3 pagesSteel Tubes, Carbon and Carbon Manganese, Fusion Welded, For Boiler, Superheater, Heat Exchanger and Condenser ApplicationshamidharvardNo ratings yet

- A 953Document3 pagesA 953José Ramón GutierrezNo ratings yet

- A 953 - 96 Qtk1my05ngDocument3 pagesA 953 - 96 Qtk1my05ngsachinguptachdNo ratings yet

- A 269 - 02 Qti2os0wmke - PDFDocument6 pagesA 269 - 02 Qti2os0wmke - PDFMan98No ratings yet

- Seamless Medium-Carbon Steel Boiler and Superheater Tubes: Standard Specification ForDocument3 pagesSeamless Medium-Carbon Steel Boiler and Superheater Tubes: Standard Specification ForJuan Pablo BautistaNo ratings yet

- Seamless and Welded Ferritic/Austenitic Stainless Steel PipeDocument6 pagesSeamless and Welded Ferritic/Austenitic Stainless Steel PipeJosé Ramón GutierrezNo ratings yet

- A210-A210m - 02Document3 pagesA210-A210m - 02vmonrroy7450No ratings yet

- A 1020 - A 1020m - 01 QtewmjavqtewmjbnlvjfraDocument4 pagesA 1020 - A 1020m - 01 QtewmjavqtewmjbnlvjfraPatricio SantisNo ratings yet

- A 210 - A 210M - 96 R01 Qtixmc05nliwmqDocument3 pagesA 210 - A 210M - 96 R01 Qtixmc05nliwmqStuartNo ratings yet

- A 822 - 90 r00 Qtgymi9bodiyts1sruqDocument5 pagesA 822 - 90 r00 Qtgymi9bodiyts1sruqsachinguptachdNo ratings yet

- A 953 - 96 Qtk1my1sruqDocument4 pagesA 953 - 96 Qtk1my1sruqsachinguptachdNo ratings yet

- Steel Tubes, Carbon and Carbon Manganese, Fusion Welded, For Boiler, Superheater, Heat Exchanger and Condenser ApplicationsDocument3 pagesSteel Tubes, Carbon and Carbon Manganese, Fusion Welded, For Boiler, Superheater, Heat Exchanger and Condenser ApplicationsCharlie ChongNo ratings yet

- A 250 - A 250M - 04 Qti1mc9bmjuwtq - PDFDocument4 pagesA 250 - A 250M - 04 Qti1mc9bmjuwtq - PDFMan98No ratings yet

- A688A688 ASS Feed WaterDocument6 pagesA688A688 ASS Feed Waterkhot2000No ratings yet

- A334Document6 pagesA334Aleksei AvilaNo ratings yet

- Asme SA 249Document10 pagesAsme SA 249gst ajahNo ratings yet

- Astm A356Document6 pagesAstm A356Srinivasan KrishnamoorthyNo ratings yet

- ASTM A426 Centrifugally Cast Ferritic Alloy Steel Pipe For High - Temperature ServiceDocument4 pagesASTM A426 Centrifugally Cast Ferritic Alloy Steel Pipe For High - Temperature ServiceSumedh ParadkarNo ratings yet

- A 872 - 91 R02 Qtg3mi05mviwmgDocument3 pagesA 872 - 91 R02 Qtg3mi05mviwmgsachinguptachdNo ratings yet

- Astm A269Document6 pagesAstm A269Leonardo Borsari SixelNo ratings yet

- A 789 - A 789M - 04 Qtc4os9bnzg5tqDocument4 pagesA 789 - A 789M - 04 Qtc4os9bnzg5tqAhmad HajeerNo ratings yet

- A1014Document3 pagesA1014malika_00No ratings yet

- A 949 - A 949M - 01 Qtk0os9botq5tqDocument4 pagesA 949 - A 949M - 01 Qtk0os9botq5tqsachinguptachdNo ratings yet

- T000003407 - FileName1 - 6079A-B-590-006 Vol-2Document32 pagesT000003407 - FileName1 - 6079A-B-590-006 Vol-2kanchanabalajiNo ratings yet

- A 135 - 01 Qteznq - PDFDocument9 pagesA 135 - 01 Qteznq - PDFStuartNo ratings yet

- A192A192M-02 (2012) Standard Specification For Seamless Carbon Steel Boiler Tubes For High - Pressure Service PDFDocument2 pagesA192A192M-02 (2012) Standard Specification For Seamless Carbon Steel Boiler Tubes For High - Pressure Service PDFValli Raju100% (1)

- Astm A269 PDFDocument5 pagesAstm A269 PDFjairoyvNo ratings yet

- Astm A179 1990Document4 pagesAstm A179 1990DhruvNambiarNo ratings yet

- A1020A1020M-02 (2012) Standard Specification For SteeDocument4 pagesA1020A1020M-02 (2012) Standard Specification For SteeRony YudaNo ratings yet

- A 814 - A 814m - 01 Qtgxnc9bode0ts1sruqDocument7 pagesA 814 - A 814m - 01 Qtgxnc9bode0ts1sruqsachinguptachdNo ratings yet

- Steel Line Pipe, Black, Plain End, Longitudinal and Helical Seam, Double Submerged-Arc WeldedDocument6 pagesSteel Line Pipe, Black, Plain End, Longitudinal and Helical Seam, Double Submerged-Arc WeldedOrkun OrhanNo ratings yet

- A269Document5 pagesA269Jeffrey StokesNo ratings yet

- A 954 - 96 QTK1NC05NGDocument4 pagesA 954 - 96 QTK1NC05NGsachinguptachdNo ratings yet

- A 268 - A 268M - 01 Qti2oc0wmq - PDFDocument6 pagesA 268 - A 268M - 01 Qti2oc0wmq - PDFMan98No ratings yet

- Astm A 178 A 178M 2002Document4 pagesAstm A 178 A 178M 2002AnamulKabir0% (1)

- A 949 - A 949M - 00 Qtk0os0wmeeDocument4 pagesA 949 - A 949M - 00 Qtk0os0wmeesachinguptachdNo ratings yet

- A105-2010 Flange ACDocument5 pagesA105-2010 Flange ACbmalbertNo ratings yet

- A847Document5 pagesA847Sallemi GuafrachNo ratings yet

- Asme Section II A Sa-249 Sa-249mDocument10 pagesAsme Section II A Sa-249 Sa-249mAnonymous GhPzn1xNo ratings yet

- A500/a500m - 09Document5 pagesA500/a500m - 09Jeff GallandNo ratings yet

- Seamless Carbon Steel Boiler Tubes For High-Pressure ServiceDocument2 pagesSeamless Carbon Steel Boiler Tubes For High-Pressure ServiceالGINIRAL FREE FIRENo ratings yet

- A 872 - 91 r02 Qtg3mi9bodcyts1sruqDocument6 pagesA 872 - 91 r02 Qtg3mi9bodcyts1sruqsachinguptachdNo ratings yet

- Astm A333Document7 pagesAstm A333Luis Evangelista Moura Pacheco100% (3)

- Asme Section II A Sa-376 Sa-376mDocument10 pagesAsme Section II A Sa-376 Sa-376mAnonymous GhPzn1xNo ratings yet

- A 822 - 90 r00 Qtgymi9bodiytqDocument3 pagesA 822 - 90 r00 Qtgymi9bodiytqsachinguptachdNo ratings yet

- A 789 - A 789MDocument4 pagesA 789 - A 789MJGD123No ratings yet

- Cartridge Brass Sheet, Strip, Plate, Bar, and Disks (Blanks)Document5 pagesCartridge Brass Sheet, Strip, Plate, Bar, and Disks (Blanks)LUISALBERTO06011985No ratings yet

- B 570 - 96 Qju3mc05ngDocument4 pagesB 570 - 96 Qju3mc05ngLUISALBERTO06011985No ratings yet

- B 302 - 00 Qjmwmi1sruqDocument7 pagesB 302 - 00 Qjmwmi1sruqLUISALBERTO06011985No ratings yet

- B 140 - B 140M - 01 Qje0mc9cmtqwtqDocument3 pagesB 140 - B 140M - 01 Qje0mc9cmtqwtqLUISALBERTO06011985No ratings yet

- B 99 - B 99m - 96 Qjk5l0i5ou0tukveDocument5 pagesB 99 - B 99m - 96 Qjk5l0i5ou0tukveLUISALBERTO06011985No ratings yet

- Copper-Cobalt-Beryllium Alloy and Copper-Nickel-Beryllium Alloy Strip and SheetDocument4 pagesCopper-Cobalt-Beryllium Alloy and Copper-Nickel-Beryllium Alloy Strip and SheetLUISALBERTO06011985No ratings yet

- A 787 - 01 QTC4NWDocument6 pagesA 787 - 01 QTC4NWLUISALBERTO06011985No ratings yet

- B 643 - 00 Qjy0my1sruqDocument8 pagesB 643 - 00 Qjy0my1sruqLUISALBERTO06011985No ratings yet

- B 698 - 97 Qjy5oc1sruqDocument3 pagesB 698 - 97 Qjy5oc1sruqLUISALBERTO06011985No ratings yet

- B 176 - 04 Qje3ngDocument4 pagesB 176 - 04 Qje3ngLUISALBERTO06011985No ratings yet

- B 135m - 96 Qjeznu0totyDocument5 pagesB 135m - 96 Qjeznu0totyLUISALBERTO06011985No ratings yet

- A 453 - A 453M - 00 Qtq1my0wmeuxDocument5 pagesA 453 - A 453M - 00 Qtq1my0wmeuxLUISALBERTO06011985No ratings yet

- Mercurous Nitrate Test For Copper and Copper AlloysDocument3 pagesMercurous Nitrate Test For Copper and Copper AlloysLUISALBERTO06011985No ratings yet

- A 1014 - 03 QtewmtqDocument3 pagesA 1014 - 03 QtewmtqLUISALBERTO06011985No ratings yet

- A 988 - 98 Qtk4oc05oaDocument11 pagesA 988 - 98 Qtk4oc05oaLUISALBERTO06011985No ratings yet

- Astm A179-A179m PDFDocument2 pagesAstm A179-A179m PDFMostafaRockNo ratings yet

- A 181 - A 181M - 01 Qte4ms9bmtgxtqDocument3 pagesA 181 - A 181M - 01 Qte4ms9bmtgxtqLUISALBERTO06011985No ratings yet

- A 758 - A 758M - 00 Qtc1oc9bnzu4tqDocument5 pagesA 758 - A 758M - 00 Qtc1oc9bnzu4tqLUISALBERTO06011985No ratings yet

- A 795 - 00 QTC5NS9BNZK1TQDocument6 pagesA 795 - 00 QTC5NS9BNZK1TQsachinguptachdNo ratings yet

- A 778 - 01 Qtc3oaDocument4 pagesA 778 - 01 Qtc3oaLUISALBERTO06011985No ratings yet

- A 928 - A 928M - 00 Qtkyoc0wmaDocument5 pagesA 928 - A 928M - 00 Qtkyoc0wmaLUISALBERTO06011985No ratings yet

- A 369 - A 369M - 01 Qtm2os0wmqDocument4 pagesA 369 - A 369M - 01 Qtm2os0wmqLUISALBERTO06011985No ratings yet

- A 369 - A 369M - 01 Qtm2os0wmqDocument4 pagesA 369 - A 369M - 01 Qtm2os0wmqLUISALBERTO06011985No ratings yet

- A 192 - A 192M - 02 Qte5mi9bmtkytqDocument3 pagesA 192 - A 192M - 02 Qte5mi9bmtkytqLUISALBERTO06011985No ratings yet

- A 771 - A 771M - 95 R01 QTC3MS9BNZCXTQDocument5 pagesA 771 - A 771M - 95 R01 QTC3MS9BNZCXTQLUISALBERTO06011985No ratings yet

- A 498 - 98 Qtq5oc05oaDocument3 pagesA 498 - 98 Qtq5oc05oaLUISALBERTO06011985No ratings yet

- A 453 - A 453M - 00 Qtq1my0wmaDocument5 pagesA 453 - A 453M - 00 Qtq1my0wmaLUISALBERTO06011985No ratings yet

- A 403 - A 403M - 03 Qtqwmy0wm0eDocument7 pagesA 403 - A 403M - 03 Qtqwmy0wm0eLUISALBERTO06011985No ratings yet

- A 409 - A409m - 95 Qtqwos05nuffmqDocument6 pagesA 409 - A409m - 95 Qtqwos05nuffmqLUISALBERTO06011985No ratings yet

- A 403 - A 403M - 03 Qtqwmy0wmwDocument7 pagesA 403 - A 403M - 03 Qtqwmy0wmwLUISALBERTO06011985No ratings yet

- Din 8559Document1 pageDin 8559Kamal MulchandaniNo ratings yet

- Astm B 366Document13 pagesAstm B 366AVINASH CHAVANNo ratings yet

- Chinook-Services-Wellsite GeologyDocument6 pagesChinook-Services-Wellsite Geologyincharge geologistNo ratings yet

- Bioscrn PDFDocument69 pagesBioscrn PDFNicolas CancioNo ratings yet

- SorptionDocument44 pagesSorptionluckyprimeNo ratings yet

- Raghavendra Bhat. GPUC High School Section, MegaravalliDocument8 pagesRaghavendra Bhat. GPUC High School Section, Megaravallisyedyaseen39375No ratings yet

- COMEDK Important Topics and Revised SyllabusDocument49 pagesCOMEDK Important Topics and Revised SyllabusVishal VermaNo ratings yet

- Particulate Nature of MatterDocument4 pagesParticulate Nature of MatterSandy ItabNo ratings yet

- Analysis Synthesis and Design of Chemical Processes 3rd Edition Turton Solutions ManualDocument21 pagesAnalysis Synthesis and Design of Chemical Processes 3rd Edition Turton Solutions ManualdarrenrichncogbpizjkNo ratings yet

- 2022 - Hyd 443 - 1Document201 pages2022 - Hyd 443 - 1api-620585842No ratings yet

- Module - 8 Primary-TreatmentDocument26 pagesModule - 8 Primary-TreatmentARSLAN MASOODNo ratings yet

- AlkanolamideDocument5 pagesAlkanolamidebellesuperNo ratings yet

- European Cat 08 2009-10Document92 pagesEuropean Cat 08 2009-10sitiodossitesNo ratings yet

- Brown ApplesDocument4 pagesBrown ApplesChristian PatriceNo ratings yet

- Bunting Powered Bronze Bushings PDFDocument56 pagesBunting Powered Bronze Bushings PDFFitunopNo ratings yet

- Friction Coefficients of Some Common MaterialsDocument2 pagesFriction Coefficients of Some Common MaterialsWanda Hafiz NurzamanNo ratings yet

- ZL 440 Product Data SheetDocument3 pagesZL 440 Product Data SheetVishal ChudasamaNo ratings yet

- Experiment No.1. (Monograph)Document3 pagesExperiment No.1. (Monograph)ayeza.sarwar2021No ratings yet

- Engineering Mechanics: Second PartDocument18 pagesEngineering Mechanics: Second Partاحمد سلمان عزيز , مسائيCNo ratings yet

- Specification D6 Virgin: Method Test Result UnitDocument1 pageSpecification D6 Virgin: Method Test Result UnitClaudio SantellanesNo ratings yet

- Evamarine: Drying Time Set-To-Touch Hard Dry Painting Interval Min MaxDocument1 pageEvamarine: Drying Time Set-To-Touch Hard Dry Painting Interval Min MaxcelescopitoNo ratings yet

- Complete DissertationDocument240 pagesComplete DissertationAriSuandiNo ratings yet

- LPL 322Document2 pagesLPL 322Quality Control BiochemNo ratings yet

- Biofoam: Dosage Rate Application InformationDocument2 pagesBiofoam: Dosage Rate Application InformationDhilNo ratings yet

- Opportunities and Limits of 2k Injection MouldingDocument22 pagesOpportunities and Limits of 2k Injection Mouldingsa_arunkumarNo ratings yet

- Microbiology of Waste Water TreatmentDocument22 pagesMicrobiology of Waste Water TreatmentDevendra SharmaNo ratings yet

- Chemistry Revision Guide For IGCSE Coordinated Science Chemistry Revision Guide For IGCSE Coordinated ScienceDocument20 pagesChemistry Revision Guide For IGCSE Coordinated Science Chemistry Revision Guide For IGCSE Coordinated SciencekarlabrooksNo ratings yet

- Food Che. W1-4Document177 pagesFood Che. W1-4mihael jhnsNo ratings yet

- Quiz 1 With AnswerDocument3 pagesQuiz 1 With AnswerAltra ZNo ratings yet

- Gallic AcidDocument28 pagesGallic AcidDolih GozaliNo ratings yet