Professional Documents

Culture Documents

Dewinter Software Catalogue

Uploaded by

Shivraman ThapliyalOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dewinter Software Catalogue

Uploaded by

Shivraman ThapliyalCopyright:

Available Formats

ItaIy

Dewinter TechnoIogies

admin@dewinteritaly.com

Hong Kong

Dewinter(HK) Instruments

hongkong@dewintermicroscope.com

Germany

Dewinter Labortechnik

germany@dewintermicroscope.com

Canada

Dewinter Microtek(Canada) Ltd.

canada@dewintermicroscope.com

India

Dewinter OpticaI Inc.

admin@dewinterindia.com

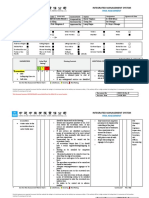

Weld Check

Weld Penetration Analysis

Software

Weld Check software is a powerful easy-to-use tool that enhances your ability to quickly and efficiently handle your most critical

welding measurement and documentation software needs. Your workflow and productivity are greatly improved. Weld Check has

been designed with your welding cross-section measurement needs in mind. Weld Check's measurement module allows you to

quickly measure items such as your fillet welds, throat, leglengths andpenetration.

Use Weld Check Measurement Tolerance indicator to improve performance by having the software automatically tell you if a

measurement is out of the tolerance range.

The following report concerns the analysis of a fillet weld, a weld of approximately triangular cross section joining two surfaces at

approximately right angles to each other. lmportant measurements made by the distance from the root if the fillet to the center of the

face (or throatj, the distance from the root of the joint to the junction between the exposed surface of the weld and the base metal (or

legj, the angles and the root penetration. Measurements that could have been done with the same ease or similar sample are among

others : depth of HAZ (heat affectedzonej, area of HAZ, joint penetration, phase counting, etc.

The measurement remain uneffected if the image is zoomed for better accuracy. T he magnifier tool is also available which can be

switchedon any part of image. The tool zooms only the region surroundingthe cursor allowingtoincrease the drawingprecision while

still seeingthe whole sample.

lmage analysis system can measure a sequence of specific characteristics or welded parts. The system brings the good tool with the

goodcolor when it's the time for the operator touse it.

Spec|f|cat|crs

Hardness Pro

Hardness Analysis

Software

Microhardness testing applied in areas including metallography, precision mechanics, electroplating, material testing and material

science. ln order to determine microhardness, different shaped indents are pressed into flat material samples with a defined force.

Three methods available are :

Brinell Hardness

ln Brinell hardness test, an indentation hardness test in which a hardmetal ball is forcedintothe surface of a test piece, mean diameter

of the indentation is left on the surface after removal of the test force is measured.

The Brinell hardness HBW is obtainedby software.

vickers Hardness

The vickers hardness test, measure length of the diagonals of indentation left in the surface in which a Square-based diamond

pyramid, having an angle of 136 degree between the opposite faces at the vertex, is forced. The vickers hardness is obtained by

dividingthe test force by the area of the slopingfaces of the indentation. The vickers hardness Hv is displayedby software.

KnoopHardness

The Knoophardness test is an indentation hardness test in which a rhombic-baseddiamondpyramid, havingan includedlongitudinal

edge angle of 172.5 degree and an included transverse edge angle of 130 degree, is forced into the surface of a test piece. The length

of the long diagonal of the indentation left in the surface after removal of the test force. The Knoop hardness HK is calculated by

software.

Spec|f|cat|crs

Pharma Pro

Particle Size lmage

Analysis Software

The use of microscopic image analysis system is the most reliable technique to characterize particle shape and to characterize a

particle size and volume distribution. Tradition method, such as laser diffraction, although efficient, gives limited information on

particle shape. The particle size, distribution and shape of the particles can effect bulk properties, product performance, process

ability, stability andappearance of the endproduct in Pharma industry.

The software is useful to measure and analyse the particle size, particle shape, particle count, foreign particle detection, particle

structure, homogeneity, surface coatings thickness. For spherical particles (which are rarely encountered in pharmaceutical

powdersj the diameters are sufficient to describe the particle size. For non-spherical particles, feret's diameter, Particle orientation,

Particle shape, elongation, convexity, circularity, circle equivalent diameter are measured.

This software is also useful to study the polarizing effects which study the cross section through pharmaceutical tablets by preparing

thin-sections on slide with Uv curing adhesive for final polishing. The cross section reveal the spatial distribution of components in

the tablets so that any post compression change (e.g. polymorph conversions or change in the hydration state of components can be

investigated.

Spec|f|cat|crs

Caliper Pro

Micro Measurements

Software

This software is powerful for acquiring, organizing, storing, retrieving and editing any image. lt handles different image formats BMP,

TlFF, lMG, lMF, GlF, PCX, JPEG, PlC. lt support many cameras, frame grabbers andother USB-1, USB-2 &Twain input devices.

Cut, Copy and Paste, Selected copy by free hand AOL controlled by four arrow keys available on keyboard or mouse with zoom

preview. Floodfill or spray with selected color at selected portion. Drawing tool curve, line, square and circle, with node control and

provision to change color and thickness of the line. Write text in any color or font. Pointer to place on an object in four directions with

provision to change its color and thickness. Eraser works only on lines, arrows or on any drawing tool. (Not on original imagej, Useful

tomerge different focuses of same image.

(aj Sportial Calibration (bj Line Measurements for Distance, Length, Width, Perimeter, Angle Three point Radius. (cj Area by enclosed

line controlled by four arrow keys available on the keyboard arrow with zoomed preview. The Line measurement is not effected on

zoomedimages

Reportinghas three options :

Direct Print out with Original image &Tabular Results.

Export toMS Office

Excel for further modification.

Spec|f|cat|crs

Micro Measurement

lmage Analysis & Live

Measurements Software

The software provides real time full Screen Display. lt also does real time live measurements due to which large number of

samples can be handled.

The new capture wizard developed under the technical guidance of lead tool, USA support Microsoft formats available for cameras

and frame Grabbers, Most of the input devices with USB 1, USB 2, lEEE, TWAlN can be easily used. The on-Line measurements &

calculation available are length, width, perimeter, three point radius, Angle between two lines. Three point Angle, Length of a chord,

and Distance between circle and point, curved area, area by polygon, Area by circle, area by rectangle, Distance between centers of

two circles, Distance between two parallel lines etc. The various other measurements & calculations available on captured images

are, Ferrite length Min/ Max Radius, Thread width, Shape, Orientation, Elongation, Equal circular Diameter, Equal, Sphere volume

Box Area, centroidX &Y, Major &Minor X1, X2, Y1, Y2, Centroid X &Y, Major &Miner X1, X2, Y1, Y2.

Report Direct printout is available with original image andtabulatedresults. lt can alsobe exportedtoMS Excel.

Spec|f|cat|crs

Foundry Plus

Cast lron Analysis Software

The Software is totally Automatic and provides complete analysis of microstructure of Cast lron.

Choice to get analysis report in ASTM 247-67, lSO 945-1, lSl - 945-1, DlN EN 945, JlS G 5504 standards.

Nodules touching boundries are excluded in analysis.

Artifacts less than 10 Micron are not excluded in analysis.

Nodules are separated from Non-Nodules on predefined Spheroidicity.

The Nodules form ( Designated by Roman no. l to vl j & Size ( Designated Arabic no. 1 to 8 j is reported.

The Flakes occuring in Cast lron in the form l, reported on the basis of type of distribution ( designated by capital letter Ato E

on the basis of orientation j and size ( designated by Arabic no. 1to 8 j.

The percentage of PEARLlTE is calculated by excluding the GRAPHlTE area.

The Matrix of PEARLlTE, FERRlTE, GRAPHlTE & CARBlDE are reported in etched sample.

Report is generated with specific lnternational standard choosen by user.

F% is reported in JlS method.

Spec|f|cat|crs

Textile Pro

Textile Analysis

Software

This new program with our polarizing microscope is very useful for quality control or textile testing laboratories for the analysis, micro-

measurement of fiber, yarn, threads, textile Material, non-woven fabrics etc.

The real full screen display of image, acquisition, annotations, enhancement with hundred of filters, measurements, statistical processing

of measureddata are few of the capability of Textile Pro.

Photographs of all Fibers view are pre loaded in the software to identify fibers without prior knowledge in the same. The library can be

created&retrievedwithin the same programme.

Few of common usage of Textile Proare:

Microanalysis of yarns andfiber sections.

Measurements of length, surfaces, perimeters, angles, distance between twopoints or lines or objects.

Fast andeasy way the fineness analysis of single fiber.

Check the purchased material can be identify the type of fiber, comparing it with the fiber pictures stored in the Data bank with the

longitudinal andthe sectional views.

Check andmeasure the quality andshape of Lycra or synthetic Multifilament single threads.

Analyse the compactness of non-woven Fabrics.

Analyse the Yarn structure anddetect possible defects.

Detect, identify andmeasure possible impurities containedin textile materials.

Analyse the compactness of non-woven fabrics.

Measure section surfaces andperimeters.

Analyse mechanical parts like needle points spinnerets etc.

Macroanalysis of a yarn section.

Reduce the fabric warpandweft density toa cm or inch.

Spec|f|cat|crs

Biowizard

lmage Processing &

Micromeasurement Software

BlOWlZARD is a new generation image analysis software meant for scientist to do analysis in the simplest way. This is a single screen window

based system. The system is flexible, independent to adopt any capture card, camera and Microscopes.The software can handle

monochrome (8 bitsj and color (24 bitsj images. Multiple images of any size can be opened and displayed on the screen for analysis or

comparison. The software support most common formats BMP, JPEG, TlFF, PNG, and GlP & PSD. The full screen real time image can be

observed and captured on the same platform. Since system is made in window environment, graphs and charts displayed on the monitor can

be quickly transferred into other window-based program like MS Word, MS Excel or any other commercial window based software for the use

in reports andpresentation.

Measurements

(aj Sportial Calibration (bj Line Measurements for Distance, Length, Width, Perimeter, Angle, Three point Radius. (cj Area by enclosed line

controlledby four arrow keys available on the keyboardarrow with zoomedpreview. The Line measurement is not effectedon zoomedimages.

Count &Classification

ldentification of objects in an image, count them, obtain several features measurements. Objects identification by user or automatically. User

definedclassification on basis of size or intensity.

Particle Size

Manual, Autobright anddark methods toidentify intensity range definedobject tobe measured. various calculation &measurements available

for selectedParticle are: Dimensions, Area, Perimeter, Ferrite Length, Min/ Max Radius, Thread(Length, Widthj, Fiber (Length, Widthj.

Morphometery

Roundness, shape, Orientation, Elongation, Equal Circular Diameter, Equal Sphere volume.

Locational

Centroid X, Centroid Y, Major X1, MajorY1, Minor X1, MinorY1, Major X2, MajorY, Major X2, MinorY2, Box X1, X2, Box Y, Y2 & Box Area.

Measure area fraction &volume fraction.

Report

(aj Three Options: Direct Print out with Original image &Tabular Results.

(bj Export toMS Office (cj Excel for further modification.

Spec|f|cat|crs

Material Plus

METALLURGlCAL MlCROSTRUCTURE

ANALYSlS SOFTWARE

Material Plus is a comprehensive micrographic solution for metallographic studies. The available software modules conform to all

equivalent national andinternational standards. The available wizards are :

Grain Size

ASTM E-112, E-930, E-1181, lSO 643-03, JlS G 0551-05 BS 490 DlN 643-03, lS-4748-88, SlS 111101 GOST 5639-82.Determine

feritic and austerritic Grain Size in Steel. The available methods are : 1. Automatic & Semi automatic Lineal Heyn lntercept method. 2.

Jeffries Planimetric Method. 3. Automatic and Semiautomatic Snyder and Graff Open Scale lntercept Method. 4. Comparison

Method. 5. ALA Grain Size. 6. SelectedGrain Size 7. Manual Count etc.

Lamellar Graphite

Lamellar Graphite module is simple andstraight forward. You needonly to describe the sample andtaken the image of the sample rest

is supported by powerful and complex image analysis algorithms. This module evaluate and quantity in a fully automatic and

consistent way FORM(Designatedby Roman no l to vlj, size (Designatedby Arabic no 1 to 8j &type A to E. The Graphite is determined

at a magnification of 100 and recommended area size is 80mm. Results and images may be displayed and stored in either the industry

standards Microsoft access database, where search facility can quickly find the results of a particular analysis using unique

information such as customer, specimen type, data, operator etc.

Phase Segmentation

Segmentation module in a sample measures the volume percentage of phases in a fully automatic way and is associated to a knew

constitute of the specimen. Since a phase is detected and its area is estimated on the basis of its intensity/grayscale, an option for

delineating phases from the histogram is also provided. Multiple phases are identified by colored overlays and can be simultaneously

displayed for the same field of view. The area percentage data for each phase are displayed in class table. You can process and

measures the unlimitednumber of images andall statistical data (areaj will be accumulatedin the class table.

Case Depth

ASTM lSO 2639-02, BS-6479-84, lS-6416-88 JlS G0557 DlN 50790. The test determine the depth of hardened surface under low

magnification by measuringthe distance from the surface tothe point shavinga different coloration towards core.

Spec|f|cat|crs

Porosity ASTM247

Pores in castingare estimatedandreportedon the basis of intensity. The percentage is calculated.

Non-Metallic lnclusion

ASTME-1245 E ASTME45-97, lSO 4163-82, DlN50602. The wizard determine contents of Non-metallic. lnclusion in rolled or forged

steel products. According to ASTM, expression of results are in GroupA, B, C, D along with segmentation of thick/thin andits severity

level.

Spheroidal Graphite

Spheroidal Graphite (Nodulesj in cast iron are analysed by identifying the appropriate industry standards. The software determines

proportion of graphite of non-round shape, for instance vermicular graphite. Nodules for (designated by Arabic no 1 to 8j is reported

along with calculated Nodules/sqmm. Artifact can be recognized and ignored. Following graphite measurement and classification,

the software presents the result in both graphical and statistical formats. The full morphological analysis raw data is also displayed.

Results and images may be displayed and stored in either the industry standard Microsoft access database format, or in an

integrateddatabase alongwith unique information such as customer, specimen type, data, operator etc.

Decarburization

ASTM E1077, lSO 3887, JlS-0557-98 BS-6617-1, lS-7754 DlN 50192. Decarburization module intended to measure decarburized

depth of steel due to heating at elevated temperatures during hot working or by detecting changes in the microstructure, hardness or

carbon content at the surface. The decarburized depth is taken as the depth where a uniform microstructure, hardness or carbon

content of the base material is observed. The microscope image analysis system is accurate for-as hot rolled, as forged, as annealed,

and as normalized sample. The software performs interactive measurement of complete, partial or total decarburization conforming

toindustry standards.

CoatingThickness

The test method covers measurement of the local thickness of metal and oxide coatings by microscopical examination of cross

sections.

You might also like

- Research Paper On Coordinate Measuring MachineDocument4 pagesResearch Paper On Coordinate Measuring MachineafeaoebidNo ratings yet

- Geometrical Dimensioning and Tolerancing for Design, Manufacturing and Inspection: A Handbook for Geometrical Product Specification Using ISO and ASME StandardsFrom EverandGeometrical Dimensioning and Tolerancing for Design, Manufacturing and Inspection: A Handbook for Geometrical Product Specification Using ISO and ASME StandardsRating: 4.5 out of 5 stars4.5/5 (3)

- 13 5Document5 pages13 5jaiganeshv1991No ratings yet

- Three-Dimensional Laser Imaging System For Measuring Wound GeometryDocument7 pagesThree-Dimensional Laser Imaging System For Measuring Wound GeometryLata DeshmukhNo ratings yet

- Home WorkDocument14 pagesHome WorkIlyasse ChemlalNo ratings yet

- Comparison Corrosion Mapping Solutions Using PDFDocument10 pagesComparison Corrosion Mapping Solutions Using PDFfabian barraganNo ratings yet

- Comparison Corrosion Mapping Solutions Using Phased Array, Conventional UT and 3D ScannersDocument10 pagesComparison Corrosion Mapping Solutions Using Phased Array, Conventional UT and 3D ScannersSooraj RajanNo ratings yet

- Fischer X-Ray Florescence TesterDocument10 pagesFischer X-Ray Florescence TesterTravis WoodNo ratings yet

- DV07PUB5 Study GuideDocument5 pagesDV07PUB5 Study Guideantonio87No ratings yet

- An Investigation On Surface Characteristics of Micro Turned ComponentsDocument28 pagesAn Investigation On Surface Characteristics of Micro Turned Components04066002No ratings yet

- Pitting Corrosion MeasurementDocument8 pagesPitting Corrosion Measurementclarence8bacligNo ratings yet

- Three-Dimensional Semi-Automated Volumetric AssessDocument12 pagesThree-Dimensional Semi-Automated Volumetric AssessDinesh RokayaNo ratings yet

- Medição Dimensional A Laser Na LaminaçãoDocument11 pagesMedição Dimensional A Laser Na LaminaçãoWaldir Monteiro de OliveiraNo ratings yet

- Stiffness TesterDocument6 pagesStiffness TesterTJPRC PublicationsNo ratings yet

- Faculty Orientation Programme-2017 SAE, Mechanical Department, Kondhwa, PuneDocument57 pagesFaculty Orientation Programme-2017 SAE, Mechanical Department, Kondhwa, Puneraghav maskeNo ratings yet

- Models For Emulating The Human Quality Assessment of Laser 2021 Procedia CIDocument6 pagesModels For Emulating The Human Quality Assessment of Laser 2021 Procedia CIlelag96085No ratings yet

- Inimize Your Cost For Phased Array and TOFDDocument12 pagesInimize Your Cost For Phased Array and TOFDJhoseph RoqueNo ratings yet

- Micro RulerDocument2 pagesMicro RulerFawwaz KhayyatNo ratings yet

- Model Contura G2 Manufactured by Carl Zeiss Same YearDocument4 pagesModel Contura G2 Manufactured by Carl Zeiss Same YearB VarunNo ratings yet

- Thesis MetrologyDocument5 pagesThesis Metrologyybkpdsgig100% (2)

- D 133 Id-523 PDFDocument10 pagesD 133 Id-523 PDFkulihat_hijauNo ratings yet

- 3-D Measurements On PistonsDocument4 pages3-D Measurements On PistonsRajaSekarsajjaNo ratings yet

- Optical 3D Surface MetrologyDocument24 pagesOptical 3D Surface MetrologyBuluc GheorgheNo ratings yet

- 1 s2.0 S030057122200210X MainDocument10 pages1 s2.0 S030057122200210X MainFlávia de Souza BastosNo ratings yet

- Thesis On Surface RoughnessDocument6 pagesThesis On Surface Roughnesshmnxivief100% (2)

- Profile Measurement in The Tyre IndustryDocument7 pagesProfile Measurement in The Tyre IndustryHartwig SuhrNo ratings yet

- 2D - DicDocument22 pages2D - Dicitsnothing at the endNo ratings yet

- Preliminary Feasibility Torque Mechanical Evaluation For 3D Printed Orthodontic Springs With Different Parameters - in Vitro Study - SpringerLinkDocument21 pagesPreliminary Feasibility Torque Mechanical Evaluation For 3D Printed Orthodontic Springs With Different Parameters - in Vitro Study - SpringerLinkDr.Prakher SainiNo ratings yet

- Flexural Behaviour of ABS 3D Printed Parts On Professional Printer Stratasys Fortus 900mcDocument5 pagesFlexural Behaviour of ABS 3D Printed Parts On Professional Printer Stratasys Fortus 900mcLeyton DanyNo ratings yet

- Clemex: Welding AnalysisDocument8 pagesClemex: Welding Analysisemirson_samatNo ratings yet

- Surface Roughness Parameters - ENDocument14 pagesSurface Roughness Parameters - ENNarcisDanielPetreaNo ratings yet

- NDT Ut SumDocument9 pagesNDT Ut Sumuthiyacharan_1400961No ratings yet

- Trueness of Milled Prostheses According To Number of Ball-End Mill BursDocument6 pagesTrueness of Milled Prostheses According To Number of Ball-End Mill Bursabdulaziz alzaidNo ratings yet

- Close Range Photogrammetry For Industrial ApplicationsDocument12 pagesClose Range Photogrammetry For Industrial ApplicationsDoc2005No ratings yet

- ACCRETECH E Book Tactile Vs Contactless ENGDocument24 pagesACCRETECH E Book Tactile Vs Contactless ENGpatrikcncNo ratings yet

- 3d Machine Vision SystemsDocument9 pages3d Machine Vision SystemsAnonymous KIUgOYNo ratings yet

- IDM Lab2Document8 pagesIDM Lab2gudursrinath11No ratings yet

- NDTDocument6 pagesNDTYasir SiddiquiNo ratings yet

- WeeklyReport QualityofPrintsDocument7 pagesWeeklyReport QualityofPrintsantony1993No ratings yet

- Automatic X-Ray Crack Inspection For Aircraft Wing Fastener HolesDocument8 pagesAutomatic X-Ray Crack Inspection For Aircraft Wing Fastener HolesRamakrishnan AmbiSubbiahNo ratings yet

- EGR242 Lecture02 Measurement 2012Document17 pagesEGR242 Lecture02 Measurement 2012mukesh3021No ratings yet

- Real-Time Laser Profile Edge Detection by VotingDocument8 pagesReal-Time Laser Profile Edge Detection by Votingharsha3250No ratings yet

- Laser Scanning ThesisDocument7 pagesLaser Scanning Thesisamyholmesmanchester100% (2)

- Jurnal Pti Printer OutputDocument6 pagesJurnal Pti Printer OutputFathullahNo ratings yet

- Non-Destructive Testing of Continuously Cast Billets by Means of The Laser Triangulation MethodDocument8 pagesNon-Destructive Testing of Continuously Cast Billets by Means of The Laser Triangulation MethodSyed HasniNo ratings yet

- Bachelor Thesis Drucken DarmstadtDocument4 pagesBachelor Thesis Drucken Darmstadtmarianaarnoldmadison100% (2)

- Noncontact Roughness Measurement of Turned Parts Using Machine VisionDocument10 pagesNoncontact Roughness Measurement of Turned Parts Using Machine VisionmayilsamythangarajuNo ratings yet

- Edited CT Pres GRP 3Document37 pagesEdited CT Pres GRP 3sanyengereNo ratings yet

- Magnification GellerDocument2 pagesMagnification GellerVrusGogNo ratings yet

- 14 Holloway.Document14 pages14 Holloway.MAYUR RAVATNo ratings yet

- Gom Argus Brochure ENDocument8 pagesGom Argus Brochure ENMissael GarciaNo ratings yet

- 62 It Imp 09Document3 pages62 It Imp 09hayumbe08No ratings yet

- NDT AmtDocument26 pagesNDT AmtRammohan YSNo ratings yet

- Pitting Corrosion MeasurementDocument8 pagesPitting Corrosion MeasurementHazimNo ratings yet

- Ch5 CMM CondensedDocument10 pagesCh5 CMM CondensedRisikkesh SNo ratings yet

- Mechanical Systems and Signal Processing: Kunpeng Zhu, Xiaolong YuDocument12 pagesMechanical Systems and Signal Processing: Kunpeng Zhu, Xiaolong YuRodrigo CabralNo ratings yet

- QA Lab ReportDocument26 pagesQA Lab ReportAliNo ratings yet

- Development of A Desktop Universal Testing Machine With A Full-Field Optical ExtensometerDocument12 pagesDevelopment of A Desktop Universal Testing Machine With A Full-Field Optical ExtensometerDaniel Alejandro La ValleNo ratings yet

- Startup ShutdownDocument4 pagesStartup ShutdownPit_mkluNo ratings yet

- Vrviii - Brochure - Pcvuse11-02b - Daikin AcDocument28 pagesVrviii - Brochure - Pcvuse11-02b - Daikin AcDarko JuricNo ratings yet

- Review of Plant Leaf Disease Detection Using Image ProcessingDocument5 pagesReview of Plant Leaf Disease Detection Using Image ProcessingInternational Journal of Application or Innovation in Engineering & Management100% (1)

- Industrial Training ReportDocument19 pagesIndustrial Training ReportRam PandeyNo ratings yet

- 91 91 Issue 7 AMD 3 2Document38 pages91 91 Issue 7 AMD 3 2andre_jvcNo ratings yet

- Royal 77Document131 pagesRoyal 77victorNo ratings yet

- Datasheet Ls 7222Document4 pagesDatasheet Ls 7222Martín NestaNo ratings yet

- Multi Storey Building FramesDocument24 pagesMulti Storey Building Framespriyanka0% (2)

- So5000334g01 R00Document5 pagesSo5000334g01 R00carlosoriNo ratings yet

- Bus Switching Scheme PDFDocument6 pagesBus Switching Scheme PDFJAYKUMAR SINGHNo ratings yet

- HS22186Document4 pagesHS22186daviNo ratings yet

- bsc25-n0363 Flyback - HR 80435Document3 pagesbsc25-n0363 Flyback - HR 80435Romell Estaba Salazar100% (2)

- Extended Aeration Treatment System 22Document13 pagesExtended Aeration Treatment System 22ashe zinab0% (1)

- Urban Transport Guidelines - Geometric Design of Urban Colloctor RoadsDocument26 pagesUrban Transport Guidelines - Geometric Design of Urban Colloctor RoadsCharl de Reuck100% (1)

- An Introduction To Project Logistics Management: ArticleDocument9 pagesAn Introduction To Project Logistics Management: ArticleCh Tushar BhatiNo ratings yet

- CSCEC HSE-F-01 Risk Assessment Form - Excavation& Backfilling - RA-02Document12 pagesCSCEC HSE-F-01 Risk Assessment Form - Excavation& Backfilling - RA-02Dan SarmientoNo ratings yet

- Pinch, Sound StudiesDocument14 pagesPinch, Sound StudieshjhjhjhjhNo ratings yet

- HIAB 390 L Chapter 3 BoomDocument14 pagesHIAB 390 L Chapter 3 BoomsengottaiyanNo ratings yet

- A Survey of Serviceable Spacecraft Failures PDFDocument8 pagesA Survey of Serviceable Spacecraft Failures PDFjuanra3171No ratings yet

- Fendolite Proofing PDFDocument4 pagesFendolite Proofing PDFShaji MathewNo ratings yet

- Dowsil 51 AdditiveDocument5 pagesDowsil 51 AdditiveYến HoàngNo ratings yet

- UAES 473F Engine Electronic Fuel Injection Section PDFDocument81 pagesUAES 473F Engine Electronic Fuel Injection Section PDFjardenNo ratings yet

- Ep-15 CCTV, Telephone Fdas Riser DiagramDocument1 pageEp-15 CCTV, Telephone Fdas Riser DiagramNyel ArmstrongNo ratings yet

- Lenox TA Serie 6 A 20 TRDocument40 pagesLenox TA Serie 6 A 20 TRjose antonioNo ratings yet

- APIs and Business Functions GuideDocument104 pagesAPIs and Business Functions GuideSindhu RamNo ratings yet

- General Thread: No Flavor Hard Math Bad ArtDocument4 pagesGeneral Thread: No Flavor Hard Math Bad ArtAnonymous q9PRRY25% (4)

- Smart Factory For Industry 4.0: A Review: January 2015Document9 pagesSmart Factory For Industry 4.0: A Review: January 2015aisyah ai aisyahNo ratings yet

- BAF-ball Valves Rev 1 PDFDocument40 pagesBAF-ball Valves Rev 1 PDFJack ChavanNo ratings yet

- SO-0031 - T316 Fs0in - 023Document131 pagesSO-0031 - T316 Fs0in - 023Krum Kashavarov100% (2)

- Grafico Miller 1965 PDFDocument1 pageGrafico Miller 1965 PDFJaviera AlejandraNo ratings yet