Professional Documents

Culture Documents

Production Operation Management

Uploaded by

MKPashaPashaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Production Operation Management

Uploaded by

MKPashaPashaCopyright:

Available Formats

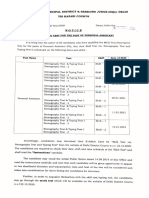

MODULE 1

Engineering

Department

Finance

Department

Human

Resource

Department

Management

Information

System

Department

Raw

Materials

Stores

Materials

Management

Division

Researc

!

Development

"lant

Engineering

Department

Mar#eting

$epartment

%ustomer

In

&arget Mar#et

'en$or(

Suppliers

"ro$uction

Department

)sop floor*

+uality

,ssurance

Department

%ustomer

Support

Department

Sales

Department

Factory

Management

!

Liasioning

, -ir$ view of "ro$uction System

Introduction

Production and operations management (POM) is the

management of an organizations production system.

A production system takes inputs and converts them into

outputs.

The conversion process is the predominant activity of a

production system.

The primary concern of an operations manager is the activities

of the conversion process.

Todays !actors Affecting POM

"#o$a# %ompetition

&.'. (ua#ity) %ustomer 'ervice) and %ost %ha##enges

%omputers and Advanced Production Techno#ogy

"ro*th of &.'. 'ervice 'ector

'carcity of Production +esources

Issues of 'ocia# +esponsi$i#ity

,ifferent -ays to 'tudy POM

Production as a 'ystem

Production as an Organization !unction

,ecision Making in POM

Inputs of a Production 'ystem

./terna#

0ega#) .conomic) 'ocia#) Techno#ogica#

Market

%ompetition) %ustomer ,esires) Product Info.

Primary +esources

Materia#s) Personne#) %apita#) &ti#ities

%onversion 'u$system

Physica# (Manufacturing)

0ocation 'ervices (Transportation)

./change 'ervices (+etai#ing)

'torage 'ervices (-arehousing)

Other Private 'ervices (Insurance)

"overnment 'ervices (!edera#) 'tate) 0oca#)

Production as a 'ystem

Inputs Inputs Inputs Inputs

Outputs Outputs Outputs Outputs

Conversion Conversion

Subsystem Subsystem

Conversion Conversion

Subsystem Subsystem

Production System Production System

Control Control

Subsystem Subsystem

Control Control

Subsystem Subsystem

Outputs of a Production 'ystem

,irect

Products

'ervices

Indirect

-aste

Po##ution

Techno#ogica# Advances

Production as an Organization !unction

1 &.'. companies

cannot compete using marketing) finance) accounting) and

engineering a#one.

1 -e focus on POM as

*e think of g#o$a# competitiveness) $ecause that is *here the vast

ma2ority of a firms *orkers) capita# assets) and e/penses reside.

1 To succeed) a firm

must have a strong operations function teaming *ith the other

organization functions.

,ecision Making in POM

1 'trategic ,ecisions

1 Operating ,ecisions

1 %ontro# ,ecisions

'trategic ,ecisions

1 These decisions are

of strategic importance and have #ong3term significance for the

organization.

1 ./amp#es inc#ude

deciding4

5 the design for a ne*

products production process

5 *here to #ocate a

ne* factory

5 *hether to #aunch a

ne*3product deve#opment p#an

Operating ,ecisions

1 These decisions are

necessary if the ongoing production of goods and services is to

satisfy market demands and provide profits.

1 ./amp#es inc#ude

deciding4

5 ho* much finished3

goods inventory to carry

5 the amount of

overtime to use ne/t *eek

5 the detai#s for

purchasing ra* materia# ne/t month

%ontro# ,ecisions

1 These decisions

concern the day3to3day activities of *orkers) 6ua#ity of products and

services) production and overhead costs) and machine maintenance.

1 ./amp#es inc#ude

deciding4

5 #a$or cost standards

for a ne* product

5 fre6uency of

preventive maintenance

5 ne* 6ua#ity contro#

acceptance criteria

-hat %ontro#s the Operations 'ystem7

1 Information a$out the

outputs) the conversions) and the inputs is fed $ack to management.

1 This information is

matched *ith managements e/pectations

1 -hen there is a

difference) management must take corrective action to maintain

contro# of the system

.at is Operations Management/

Defined

Operations management (OM) is defined as the design) operation)

and improvement of the systems that create and de#iver the firms

primary products and services

1 The !uture of

Operations

5 Outsourcing

everything

5 'mart factories

5 Ta#king inventory

5 Industria# army of

ro$ots

5 -hats in the $o/

5 Mass customization

.y Stu$y Operations

Management/

-usiness E$ucation

Systematic ,pproac

to Org0 "rocesses

%areer Opportunities

%ross1Functional

,pplications

Operations

Management

5 Persona#ized

recommendations

5 'ign here) p#ease

Operations Management Decision &ypes

1 'trategic (#ong3term)

1 Tactica#

(intermediate3term)

1 Operationa# p#anning

and contro# (short3term)

.at is a &ransformation "rocess/

Defined

A transformation process is defined as a use of resources to

transform inputs into some desired outputs Transformations

1 Physica#33

manufacturing

1 0ocation33

transportation

1 ./change33retai#ing

1 'torage33

*arehousing

1 Physio#ogica#33hea#th

care

1 Informationa#33

te#ecommunications

%ore Services "erformance O23ectives

Operations

Management

Fle4i2ility

+uality

Spee$

"rice )or cost

Re$uction*

&e Importance of Operations Management

1 'yner

gies must e/ist *ith other functiona# areas of the organization

1 Operat

ions account for 893:9; of the direct e/penses that $urden a firms

profit.

The Basics of Operations Management

1 Operat

ions Management

5 The

process of managing the resources that are needed to produce an

organizations goods and services.

5 Operat

ions managers focus on managing the <five Ps= of the firms

operations4

1 Peop#e

) p#ants) parts) processes) and p#anning and contro# systems.

The Production 'ystem

1 Input

5 A

resource re6uired for the manufacture of a product or service.

1 %onve

rsion 'ystem

5 A

production system that converts inputs (materia# and human

resources) into outputs (products or services)> a#so the production

process or techno#ogy.

1 Output

5 A

direct outcome (actua# product or service) or indirect outcome (ta/es)

*ages) sa#aries) of a production system.

?asic Types of Production Processes

1 Intermi

ttent Production 'ystem

5 Produc

tion is performed on a start3and3stop $asis) such as for the

manufacture of made3to3order products.

1 Mass

Production

5 A

specia# type of intermittent production process using standardized

Types of Production system

Manufacturing System

Service System

%ontinuous "ro$uction

Intermittent "ro$uction

-atc "ro$uction

5o2 "ro$uction

Mass pro$uction) Flow*

"rocessing "ro$uction

methods and sing#e3use machines to produce #ong runs of

standardized items.

Mass Customization

5 ,esign

ing) producing) and de#ivering customized products to customers for

at or near the cost and convenience of mass3produced items.

5 Mass

customization com$ines high production vo#ume *ith high product

variety.

5 .#eme

nts of mass customization4

1 Modu#

ar product design

1 Modu#

ar process design

1 Agi#e

supp#y net*orks

Continuous Production Processes

5 A

production process) such as those used $y chemica# p#ants or

refineries) that runs for very #ong periods *ithout the start3and3stop

$ehavior associated *ith intermittent production.

5 .norm

ous capita# investments are re6uired for high#y automated faci#ities

that use specia#3purpose e6uipment designed for high vo#umes of

production and #itt#e or no variation in the type of outputs.

Mass Production 'ystem (!#o*)

Continuous Production

1 Anticip

ation of demand

1 May

not have uniform production

1 'tanda

rdized +a* materia#

1 ?ig

vo#ume of #imited product #ine

1 'tanda

rd faci#ity3 high standardization.

1 !i/ed

se6uence of operation

1 Materi

a# hand#ing is easier

1 @igh

ski##ed operator not re6uired

1 More

@uman pro$#em is foreseen

1 @uge

investment.

1 @igh

ra* materia# inventory.

Processing Production System

1 ./tend

ed form of mass production system

1 !." of

one stage is fed to ne/t stage

1 More

automatic machines

1 One

$asic ra* materia# is transferred into severa# products at severa#

stages.

1 0ess

high#y ski##ed *orkers re6uired

1 More

human pro$#ems foreseen

1 @igh#y

standardized system

Batch Production System

1 @igh#y

specia#ized @uman resource is re6uired

1 @igh#y

specia#ized mu#ti tasking machines

1 Machi

nes are shared.

1 Produc

tion in $atches

1 Produc

tion #ots are $ased on customer demand or order.

1 Ao

sing#e se6uence of operation

1 !inish

ed goods are heterogeneous

Custom built / job order production system

1 @igh#y

specia#ized @uman resource is re6uired

1 @igh#y

specia#ized mu#ti tasking machines

1 Machi

nes are shared

1 +a*

materia# is not standardized

1 Proces

s is not standardized

1 Ao

scope for repetition of production

%omparative stu$y of $ifferent pro$uction systems

&ype

"arameter

MassB !#o* Process Co$ ?atch

"er unit

manf0cost

Hig Low Hig Hig

Si6e !

%apital

Invest0

Large

Less

'0 Large

Hig

Small

Low

Me$ium

Hig

Fle4i2ility 7o 7o More More

&ecnical

a2ility S#ills

Less Less Hig Hig

Orgn0

Structure

Line staff Line staff Functional Functional

In$ustrial

application

,utomo2ile

Sugar

Refinery

%emical

"etroleum

Mil# proces0

%onstruction

-ri$ges

S"M

%onsumer

pro$0

M(c0 &ools

%ompetitiveness8 Strategy8 an$ "ro$uctivity

%ompetitiveness9

@o* effective#y an organization meets the *ants and needs of

customers re#ative to others that offer simi#ar goods or services

?usinesses %ompete &sing Marketing

1 Identif

ying consumer *ants and needs

1 Pricing

1 Adverti

sing and promotion

?usinesses %ompete &sing Operations

1 Produc

t and service design

1 %ost

1 0ocati

on

1 (ua#ity

1 (uick

response

?usinesses %ompete &sing Operations

1 !#e/i$i#

ity

1 Invent

ory management

1 'upp#y

chain management

1 'ervic

e

-hy 'ome Organizations !ai#

1 Too

much emphasis on short3term financia# performance

1 !ai#ing

to take advantage of strengths and opportunities

1 !ai#ing

to recognize competitive threats

1 Aeg#ec

ting operations strategy

-hy 'ome Organizations !ai#

1 Too

much emphasis in product and service design and not enough on

improvement

1 Aeg#ec

ting investments in capita# and human resources

1 !ai#ing

to esta$#ish good interna# communications

1 !ai#ing

to consider customer *ants and needs

Strategy

'trategies

P#ans for achieving organizationa# goa#s

Mission

The reason for e/istence for an organization

Mission 'tatement

Ans*ers the 6uestion <-hat $usiness are *e in7=

"oa#s

Provide detai# and scope of mission

Tactics

The methods and actions taken to accomp#ish strategies

MissionB'trategyBTactics

How does mission, strategies and tactics relate to

decision making and distinctive competencies?

Strategy Strategy &actics &actics Mission Mission

Strategy and Tactics

,istinctive %ompetencies

The special attributes or abilities that give an organization a

competitive edge

Price

(ua#ity

Time

!#e/i$i#ity

'ervice

0ocation

P#anning and ,ecision Making

Mission

"oa#s

Organizationa# 'trategies

!unctiona# "oa#s

!inance

'trategies

Marketing

'trategies

Operations

'trategies

Tactics Tactics Tactics

Operating

procedures

Operating

procedures

Operating

procedures

Operations Strategy

1 Operations

strategy 5 The approach) consistent *ith organization strategy) *hich

is used to guide the operations function.

'trategy !ormu#ation

1 ,istinctive

competencies

1 .nvironmenta#

scanning

1 '-OT

1 Order 6ua#ifiers

Banks, ATMs Convenience

ocation ocation

!isneyland

"ordstroms

Superior customer

service

Service Service

Bur#er $in#

Supermarkets

%ariety

%olume

&le'ibility &le'ibility

('press Mail, &ede',

One)*our p*oto, +PS

,apid delivery

On)time delivery

Time Time

Sony T%

e'us, Cadillac

Pepsi, $odak, Motorola

-i#*)per.ormance desi#n

or *i#* /uality Consistent

/uality

0uality 0uality

+1S1 .irst)class posta#e

Motel)2, ,ed ,oo. Inns

o3 Cost

Price Price

./amp#es of ,istinctive

%ompetencies

1 Order *inners

Strategy !ormulation

1 Order 6ua#ifiers

5 %haracteristics

that customers perceive as minimum standards of accepta$i#ity to $e

considered as a potentia# purchase

1 Order *inners

5 %haracteristics

of an organizations goods or services that cause it to $e perceived

as $etter than the competition

"ey #$ternal !actors

1 .conomic

conditions

1 Po#itica#

conditions

1 0ega#

environment

1 Techno#ogy

1 %ompetition

1 Markets

"ey %nternal !actors

1 @uman

+esources

1 !aci#ities and

e6uipment

1 !inancia#

resources

1 %ustomers

1 Products and

services

1 Techno#ogy

1 'upp#iers

&uality and Time Strategies

1 (ua#ity3$ased

strategies

5 !ocuses on

maintaining or improving the 6ua#ity of an organizations products or

services

5 (ua#ity at the

source

1 Time3$ased

strategies

5 !ocuses on

reduction of time needed to accomp#ish tasks

Operations Strategy and Competitiveness

1 Operations

'trategy

1 A !rame*ork

for Operations 'trategy

1 Meeting the

%ompetitive %ha##enge

1 Productivity

Measurement

Operations Priorities

%ost

(ua#ity

,e#ivery 'peed (A#so) Ae* Product Introduction 'peed)

,e#ivery !#e/i$i#ity

"reenness

,e#ivery +e#ia$i#ity

%oping *ith %hanges in ,emand

4

Operations 'trategy 5 'trategic

A#ignment

Customer "eeds Corporate Strate#y

Operations Strate#y

Alignmen

t

Core

Competencie

s

Decision

s

Processes, In.rastructure, and Capabilities

Other Product3'pecific %riteria

OP#'(T%O)S ST'(T#*+ OB,#CT%-#S

u &R,7SL,&E M,R:E& +.(MT' TO 'P.%I!I%

OP.+ATIOA' P+IMA+D MI''IOA'

u ,SSURE O"ER,&IO7S IS %,",-LE TO A%%OMP0I'@

P+IMA+D MI''IOA.

E) '."M.AT MA+F.T ?D P+O,&%T "+O&P'

G) I,.ATI!D P+O,&%T +.(&I+.M.AT'

H) ,.T.+MIA. O+,.+ -IAA.+' AA, (&A0I!I.+'

I) %OAJ.+T O+,.+ -IAA.+' IATO 'P.%I!I% P.+!O+MAA%.

+.(MT'

5

A !rame*ork for Organizationa#

'trategy

Customer

"eeds

"e3 and Current

Products

Per.ormance Priorities

and ,e/uirements

0uality, !ependability,

Service

Speed, &le'ibility, and

Price

Operations 6 Supplier Capabilities

Tec*nolo#y People Systems ,6! CIM 7IT T0M !istribution

Support Plat.orms

&inancial Mana#ement -uman ,esource Mana#ement In.ormation Mana#ement

(nterprise

Capabilities

Strate#ic

%ision

#lements of operation strategy

Positioning the production system

A. Product !ocused

?. Process !ocused

Product B 'ervice p#ans

Out sourcing p#ans

Process techno#ogy p#ans

'trategic a##ocation of resources

!aci#ity p#ans

K%apacity p#ans

K0ocation

.conomic

DE'ELO"I7; "RODU%&IO7 ,7D O"ER,&IO7 S&R,&E;<

%orporate Mission

,ssessment

of 2usiness con$ition

-usiness Strategy

Distinctive %ompetencies

Or .ea#nesses

"ro$uct ( Service "lans

%ompetitive priorities

%ost8 &ime8 +uality !

Fle4i2ility

"ro$uction ( operation Strategy

"ositioning te pro$uction system

"ro$uct ( service plans

"rocess an$ tecnology plans

Strategic allocation of resources

Facility "lan8 %apacity "lan8 Location an$ Layout0

Po#itica#

0ega#

'ocia#

Market

Ana#ysis

%ompetition

-orn out Prod. 'ystem

Automation

'ki##ed @+

@i3tech

Machines

,is 3advantage in

capturing market

0o* prod. cost

,e#ivery performance

@igh 6ua#ity products L

service

%ustomer service L

!#e/i$i#ity

K0ayout

Productivity

A measure of the effective use of resources) usua##y e/pressed as the

ratio of output to input Productivity ratios are used for P#anning

*orkforce re6uirements 'chedu#ing e6uipment

financia# ana#ysis

M%T Commission on %ndustrial Productivity

./01 'ecommendations 2 Still -ery (ccurate Today

1 0ess emphasis on short3term financia# payoffs and

invest more in +L,.

1 +evise corporate strategies to inc#ude responses

to foreign competition.

5 greater investment in peop#e and e6uipment

1 Fnock do*n communication $arriers *ithin

organizations and recognize mutua#ity of interests *ith other

companies and supp#iers.

M%T Commission on Industria# Productivity

./01 'ecommendations

1 +ecognize that the #a$or force is a resource to $e

nurtured) not 2ust a cost to $e avoided.

1 "et $ack to $asics in managing productionB

operations.

5 ?ui#d in 6ua#ity at the design stage.

5 P#ace more emphasis on process innovations

rather than focusing so#e attention on product innovations 3

dramatica##y improve costs) 6ua#ity) speed) L f#e/.

&. '. %ompetitiveness ,rivers

1 "ro$uct(Service Development 3 7"D

5 Teams speed deve#opment and enhance

manufactura$i#ity

1 .aste Re$uction (0.AABCIT Phi#osophy)

5 -IP) space) too# costs) and human effort

1 Improve$ %ustomer1Supplier Relationsips

5 0ook for -in3-inM Taken from Capanese Feiretsu

1 Early ,$option of I& &ecnology Inc#uding

5 P% Techno#ogy 5 --- 3 .+P'

Productivity

Inputs

Outputs

8 ty Productivi

Partia# measures

outputB(sing#e input)

Mu#ti3factor measures

outputB(mu#tip#e inputs)

Tota# measure

outputB(tota# inputs)

Productivity "ro*th Productivity "ro*th

%urrent Period Productivity 5 Previous Period

Productivity

Previous Period Productivity

"ro$uctivity ;rowt =

+nits o. output per kilo3att)*our

!ollar value o. output per kilo3att)

*our

(ner#y

Productivity

+nits o. output per dollar input

!ollar value o. output per dollar input

Capital

Productivity

+nits o. output per mac*ine *our

mac*ine *our

Mac*ine

Productivity

+nits o. output per labor *our

+nits o. output per s*i.t

%alue)added per labor *our

abor

Productivity

./amp#es of Partia# Productivity Measures ./amp#es of Partia# Productivity Measures

!actors Affecting Productivity

%apita

#

(ua#it

y

Techno#og

y

Managemen

t

Other !actors (ffecting Productivity

1 'tandardization

1 (ua#ity

1 &se of Internet

1 %omputer viruses

1 'earching for #ost

or misp#aced items

1 'crap rates

1 Ae* *orkers

1 'afety

1 'hortage of IT

*orkers

1 0ayoffs

1 0a$or turnover

1 ,esign of the

*orkspace

1 Incentive p#ans that

re*ard productivity

Improving Productivity

1 ,eve#op

productivity measures

1 ,etermine critica#

($ott#eneck) operations

1 ,eve#op methods

for productivity improvements

1 .sta$#ish

reasona$#e goa#s

1 "et management

support

1 Measure and

pu$#icize improvements

1 ,ont confuse

productivity *ith efficiency

MO,&0. G

Typical Phases of Product 3evelopment

1 P#anning

1 %oncept ,eve#opment

1 'ystem30eve# ,esign

1 ,esign ,etai#

1 Testing and +efinement

1 Production +amp3up

#conomic (nalysis of Project 3evelopment Costs

1 &sing measura$#e factors to he#p determine4

5 Operationa# design and deve#opment decisions

5 "oBno3go mi#estones

1 ?ui#ding a ?ase3%ase !inancia# Mode#

5 A financia# mode# consisting of ma2or cash f#o*s

5 'ensitivity Ana#ysis for <*hat if= 6uestions

Designing for te %ustomer

+uality Function

Deployment

'alue ,nalysis(

'alue

Engineering

I$eal

%ustomer

"ro$uct

House of +uality

3esigning for the Customer4 &uality !unction 3eployment

1 Interventiona# teams from marketing) design engineering) and

manufacturing

1 Joice of the customer

1 @ouse of (ua#ity

,esigning for the %ustomer4 Ja#ue Ana#ysisBJa#ue .ngineering

1 Achieve e6uiva#ent or $etter performance at a #o*er cost *hi#e

maintaining a## functiona# re6uirements defined $y the customer

5 ,oes the item have any design features that are not

necessary7

5 %an t*o or more parts $e com$ined into one7

5 @o* can *e cut do*n the *eight7

5 Are there nonstandard parts that can $e e#iminated7

,esign for Manufactura$i#ity

1 Traditiona# Approach

5 <-e design it) you $ui#d it= or <Over the *a##=

%oncurrent .ngineering

5 <0ets *ork together simu#taneous#y=

,esign for Manufacturing and Assem$#y

1 "reatest improvements re#ated to ,!MA arise from

simp#ification of the product $y reducing the num$er of separate

parts4

1 ,uring the operation of the product) does the part move re#ative

to a## other parts a#ready assem$#ed7

1 Must the part $e of a different materia# or $e iso#ated from other

parts a#ready assem$#ed7

1 Must the part $e separate from a## other parts to a##o* the

disassem$#y of the product for ad2ustment or maintenance7

Product ,esign

'tandard parts

Modu#ar design

@igh#y capa$#e production systems

%oncurrent

engineering

Measuring "ro$uct Development

"erformance

Measures

&re/1 o. ne3 products introduced

Time to market introduction

"umber stated and number completed

Actual versus plan

Percenta#e o. sales .rom ne3 products

&re/1 o. ne3 products introduced

Time to market introduction

"umber stated and number completed

Actual versus plan

Percenta#e o. sales .rom ne3 products

Time3to3market

Time3to3market

Productivity

Productivity

(ua#ity

(ua#ity

(n#ineerin# *ours per pro9ect

Cost o. materials and toolin# per pro9ect

Actual versus plan

(n#ineerin# *ours per pro9ect

Cost o. materials and toolin# per pro9ect

Actual versus plan

Con.ormance)reliability in use

!esi#n)per.ormance and customer satis.action

:ield).actory and .ield

Con.ormance)reliability in use

!esi#n)per.ormance and customer satis.action

:ield).actory and .ield

Per.ormance

!imension

Process ,esign

'ma## #ot sizes

'etup time reduction

Manufacturing ce##s

0imited *ork in process

(ua#ity improvement

Production f#e/i$i#ity

0itt#e inventory storage

Production !#e/i$i#ity

1 +educe do*ntime $y reducing changeover time

1 &se preventive maintenance to reduce $reakdo*ns

1 %ross3train *orkers to he#p c#ear $ott#enecks

1 &se many sma## units of capacity

1 &se off3#ine $uffers

1 +eserve capacity for important customers

?enefits of 'ma## 0ot 'izes

Re$uces

inventory

Less storage

space

Less

rewor#

"ro2lems are more

apparent

Increases pro$uct

fle4i2ility

Easier to 2alance

operations

&uality %mprovement

1 Autonomation

5 Automatic detection of defects during production

1 Cidoka

5 Capanese term for autonomation

Personnel/Organizational #lements

1 -orkers as assets

1 %ross3trained *orkers

1 %ontinuous improvement

1 %ost accounting

1 0eadershipBpro2ect management

Manufacturing Planning and Control

1 0eve# #oading

1 Pu## systems

1 Jisua# systems

1 %#ose vendor re#ationships

1 +educed transaction processing

1 Preventive maintenance

Pull/Push Systems

1 Pull system 4 'ystem for moving *ork *here a *orkstation pu##s

output from the preceding station as needed. (e.g. Fan$an)

1 Push system 4 'ystem for moving *ork *here output is pushed

to the ne/t station as it is comp#eted

Fan$an Production %ontro# 'ystem

1 "anban 4 %ard or other device that communicates demand for

*ork or materia#s from the preceding station

1 Fan$an is the Capanese *ord meaning <signa#= or <visi$#e

record=

1 Paper#ess production contro# system

1 Authority to pu##) or produce comes

from a do*nstream process.

Kanban Formula

A N Tota# num$er of containers

, N P#anned usage rate of using *ork center

T N Average *aiting time for rep#enishment of parts p#us average

production time for a container of parts

O N Po#icy varia$#e set $y management 3 possi$#e inefficiency in the

system

% N %apacity of a standard container

N =

DT(1+X)

C

Traditiona# 'upp#ier Aet*ork Traditiona# 'upp#ier Aet*ork

Buyer

Buyer

Suppl

ier

Suppl

ier

Suppl

ier

Suppl

ier

Suppl

ier

Suppl

ier

Suppl

ier

Suppl

ier

Suppl

ier

Suppl

ier

Suppl

ier

Suppl

ier

Suppl

ier

Suppl

ier

Product and Service 3esign

Ma2or factors in design strategy

%ost

(ua#ity

Time3to3market

%ustomer satisfaction

%ompetitive advantage

Product and service design 5 or redesign 5 shou#d $e

c#ose#y tied to an organizations strategy

Product or Service 3esign (ctivities

1 Trans#ate customer *ants and needs into product and service

re6uirements

1 +efine e/isting products and services

1 ,eve#op ne* products and services

1 !ormu#ate 6ua#ity goa#s

1 !ormu#ate cost targets

1 %onstruct and test prototypes

1 ,ocument specifications

'easons for Product or Service 3esign

1 .conomic

1 'ocia# and demographic

1 Po#itica#) #ia$i#ity) or #ega#

1 %ompetitive

1 Techno#ogica#

Objectives of Product and Service 3esign

1 Main focus

5 %ustomer satisfaction

1 'econdary focus

5 !unction of productBservice

5 %ostBprofit

5 (ua#ity

5 Appearance

5 .ase of productionBassem$#y

5 .ase of maintenanceBservice

3esigning !or Operations

Taking into account the capa$i#ities of the organization in designing

goods and services

5egal6 #thical6 and #nvironmental %ssues

1 0ega#

5 Product #ia$i#ity

5 &niform commercia# code

1 .thica#

5 +e#easing products *ith defects

1 .nvironmenta#

5 .PA

'egulations 7 5egal Considerations

1 Product 5iability 2 A manufacturer is #ia$#e for any in2uries or

damages caused $y a fau#ty product.

1 8niform Commercial Code 2 Products carry an imp#ication of

merchanta$i#ity and fitness.

Standardization

1 'tandardization

5 ./tent to *hich there is an a$sence of variety in a product)

service or process

1 'tandardized products are immediate#y avai#a$#e to customers

(dvantages of Standardization

1 !e*er parts to dea# *ith in inventory L manufacturing

1 ,esign costs are genera##y #o*er

1 +educed training costs and time

1 More routine purchasing) hand#ing) and inspection procedures

1 Orders fa##i$#e from inventory

1 Opportunities for #ong production runs and automation

1 Aeed for fe*er parts 2ustifies increased e/penditures on

perfecting designs and improving 6ua#ity contro# procedures.

3isadvantages of Standardization

1 ,esigns may $e frozen *ith too many imperfections remaining.

1 @igh cost of design changes increases resistance to

improvements.

1 ,ecreased variety resu#ts in #ess consumer appea#.

1 Mass customization4

5 A strategy of producing standardized goods or services) $ut

incorporating some degree degree of customization

5 ,e#ayed differentiation

5 Modu#ar design

3elayed 3ifferentiation

1 ,e#ayed differentiation is a postponement tactic

5 Producing $ut not 6uite comp#eting a product or service unti#

customer preferences or specifications are kno*n

Modular 3esign

Modular design is a form of standardization in *hich component parts

are su$divided into modu#es that are easi#y rep#aced or interchanged.

It a##o*s4

5 easier diagnosis and remedy of fai#ures

5 easier repair and rep#acement

5 simp#ification of manufacturing and assem$#y

'eliability

1 'eliability 4 The a$i#ity of a product) part) or system to perform its

intended function under a prescri$ed set of conditions

1 !ailure 4 'ituation in *hich a product) part) or system does not

perform as intended

1 )ormal operating conditions 4 The set of conditions under *hich

an items re#ia$i#ity is specified

Improving +e#ia$i#ity

%omponent design

ProductionBassem$#y techni6ues

Testing

+edundancyB$ackup

Preventive maintenance procedures

&ser education

'ystem design

Product 3esign

1 Product 0ife %yc#es

1 +o$ust ,esign

1 %oncurrent .ngineering

1 %omputer3Aided ,esign

1 Modu#ar ,esign

'obust 3esign4 ,esign that resu#ts in products or services that

can function over a $road range of conditions

Taguchi (pproach 'obust 3esign

1 ,esign a ro$ust product

5 Insensitive to environmenta# factors either in manufacturing or

in use.

1 %entra# feature is Parameter 3esign

1 ,etermines4

5 factors that are contro##a$#e and those not contro##a$#e

5 their optima# #eve#s re#ative to ma2or product advances

3egree of )e9ness

1 Modification of an e/isting productBservice

1 ./pansion of an e/isting productBservice

1 %#one of a competitors productBservice

1 Ae* productBservice

,egree of ,esign %hange

Type of ,esign

%hange

Ae*ness of the

organization

Ae*ness to the

market

Modification 0o* 0o*

./pansion 0o* 0o*

%#one @igh 0o*

Ae* @igh @igh

Phases in Product 3evelopment Process

E. Idea generation

G. !easi$i#ity ana#ysis

H. Product specifications

I. Process specifications

P. Prototype deve#opment

8. ,esign revie*

Q. Market test

:. Product introduction

R. !o##o*3up eva#uation

Idea "eneration

Ideas

%ompetitor $ased

'upp#y chain $ased

+esearch $ased

+everse .ngineering

'everse engineering is the dismant#ing and inspecting of a

competitors product to discover product improvements.

'esearch 7 3evelopment :'73;

Organized efforts to increase scientific kno*#edge or product

innovation L may invo#ve4

Basic 'esearch advances kno*#edge a$out a su$2ect

*ithout near3term e/pectations of commercia#

app#ications.

(pplied 'esearch achieves commercia# app#ications.

3evelopment converts resu#ts of app#ied research into

commercia# app#ications.

Manufacturability

Manufactura$i#ity is the ease of fa$rication andBor assem$#y

*hich is important for4

%ost

Productivity

(ua#ity

,esigning for Manufacturing ?eyond the overa## o$2ective to achieve

customer satisfaction *hi#e making a reasona$#e profit is4

,esign for Manufacturing (,!M)

The designers consideration of the organizations manufacturing

capa$i#ities *hen designing a product.

The more genera# term design for operations encompasses services

as *e## as manufacturing

Concurrent #ngineering

Concurrent engineering is the $ringing together of engineering design

and manufacturing personne# ear#y in the design phase.

Computer2(ided 3esign

Computer2(ided 3esign :C(3; is product design using

computer graphics.

increases productivity of designers) H to E9 times

creates a data$ase for manufacturing information on

product specifications

provides possi$i#ity of engineering and cost ana#ysis on

proposed designs

Product design

,esign for manufacturing (,!M)

,esign for assem$#y (,!A)

,esign for recyc#ing (,!+)

+emanufacturing

,esign for disassem$#y (,!,)

+o$ust design

'ecycling

1 +ecyc#ing4 recovering

materia#s for future use

1 +ecyc#ing reasons

5 %ost savings

5 .nvironment

concerns

5 .nvironment

regu#ations

Service 3esign

1 'ervice is an act

1 'ervice de#ivery

system

5 !aci#ities

5 Processes

5 'ki##s

1 Many services are

$und#ed *ith products

1 'ervice design

invo#ves

5 The physica#

resources needed

5 The goods that are

purchased or consumed $y the customer

5 ./p#icit services

5 Imp#icit services

1 'ervice

5 'omething that is

done to or for a customer

1 'ervice de#ivery

system

5 The faci#ities)

processes) and ski##s needed to provide a service

1 Product $und#e

5 The com$ination of

goods and services provided to a customer

1 'ervice package

5 The physica#

resources needed to perform the service

3ifferences bet9een Product and Service 3esign

1 Tangi$#e 5 intangi$#e

1 'ervices created and

de#ivered at the same time

1 'ervices cannot $e

inventoried

1 'ervices high#y visi$#e

to customers

1 'ervices have #o*

$arrier to entry

1 0ocation important to

service

Phases in 'ervice ,esign

1 %onceptua#ize

1 Identify service

package components

1 ,etermine

performance specifications

1 Trans#ate

performance specifications into design specifications

1 Trans#ate design

specifications into de#ivery specifications

Service Blueprinting

1 'ervice $#ueprinting

5 A method used in

service design to descri$e and ana#yze a proposed service

1 A usefu# too# for

conceptua#izing a service de#ivery system

Major Steps in Service Blueprinting

1 .sta$#ish $oundaries

1 Identify steps invo#ved

1 Prepare a f#o*chart

1 Identify potentia#

fai#ure points

1 .sta$#ish a time frame

1 Ana#yze profita$i#ity

Characteristics of <ell 3esigned Service Systems

1 %onsistent *ith the

organization mission

1 &ser friend#y

1 +o$ust

1 .asy to sustain

1 %ost effective

1 Ja#ue to customers

1 .ffective #inkages

$et*een $ack operations

1 'ing#e unifying theme

1 .nsure re#ia$i#ity and

high 6ua#ity

%ha##enges of 'ervice ,esign

1 Jaria$#e re6uirements

1 ,ifficu#t to descri$e

1 @igh customer

contact

1 'ervice 5 customer

encounter

&uality !unction 3eployment

1 (ua#ity !unction

,ep#oyment

5 Joice of the customer

5 @ouse of 6ua#ity

+FD4 An approach that integrates the <voice of the customer= into the

product and service deve#opment process.

Operations 'trategy

E. Increase emphasis on component commona#ity

G. Package products and services

H. &se mu#tip#e3use p#atforms

I. %onsider tactics for mass customization

P. 0ook for continua# improvement

8. 'horten time to market

'horten Time to Market

E. &se standardized components

G. &se techno#ogy

H. &se concurrent engineering

Process 'e#ection

Jariety

@o* much

!#e/i$i#ity

-hat degree

Jo#ume

./pected output

Process Types

Co$ shop

'ma## sca#e

?atch

Moderate vo#ume

+epetitiveBassem$#y #ine

@igh vo#umes of standardized goods or services

%ontinuous

Jery high vo#umes of non3discrete goods

Process design

The comp#ete de#ineation and description of specific steps in the

production process and the #inkage among the steps that *i## ena$#e

the production system to produce products of the

desired 6ua#ity

re6uired 6uantity

at re6uired time

at the economica# cost

./pected $y the customer

Types of Process

Pro2ect

Co$ 'hop

?atch

Assem$#y #ine

%ontinuous

Process ,esign

Interrelationsip of "ro$uct an$ "rocess

Design

Feasi2ility Stu$ies

Feasi2ility Stu$ies

"ro$uct I$ea

"ro$uct I$ea

"ro$uct Design

"ro$uct Design

"rocess Design

"rocess Design

,$vance$ "ro$uct "lanning

,$vance$ Design

"ro$uction "rocess Design

"ro$uct evaluation an$ improvement

"ro$uct use an$ support

,$vance$ "ro$uct "lanning

,$vance$ Design

"ro$uction "rocess Design

"ro$uct evaluation an$ improvement

"ro$uct use an$ support

Organi6ing te process flow

Relation of process Design to

process Flow

Evaluating te "rocess Design

Organi6ing te process flow

Relation of process Design to

process Flow

Evaluating te "rocess Design

&o "ro$uce an$ Mar#et 7ew "ro$ucts

&o "ro$uce an$ Mar#et 7ew "ro$ucts

Production Technology

The method or Techni6ue used in %onverting the +a* materia#

into '!" or !" .conomica##y) .ffective#y and efficient#y is

termed as Production Techno#ogy.

The Selection of Technology

Time

%ost

Type of Product

Jo#ume of production

./pected Productivity

Technica# %omp#e/ity invo#ved

,egree of @uman ski## re6uired

,egree of (ua#ity re6uired

Avai#a$i#ity of Techno#ogy

The ,egree of O$so#escence e/pected.

MO,&0. H

!aci#ity P#anning

0ong range capacity p#anning)

!aci#ity #ocation

!aci#ity #ayout

Strategic %apacity "lanning

Defined

%apacity can $e defined as the a$i#ity to ho#d) receive) store) or

accommodate.

Strategic capacity planning is an approach for determining

the overa## capacity #eve# of capita# intensive resources)

inc#uding faci#ities) e6uipment) and overa## #a$or force size.

%apacity Utili6ation

%apacity uti#ization rate N %apacity used

?est operating #eve#

%apacity used

rate of output actua##y achieved

?est operating #eve#

capacity for *hich the process *as designed

E4ample of %apacity Utili6ation

,uring one *eek of production) a p#ant produced :H units of a

product. Its historic highest or $est uti#ization recorded *as EG9

units per *eek. -hat is this p#ants capacity uti#ization rate7

Ans*er4

%apacity uti#ization rate N %apacity used .

?est operating #eve#

N :HBEG9

N9.8R or 8R;

-est Operating Level

&nderuti#ization

?est

Operating

0eve#

Average

unit cost

of output

Jo#ume

Overuti#ization

Economies ! Diseconomies

of Scale

E993unit

p#ant

G993unit

p#ant

H993unit

p#ant

I993unit

p#ant

Jo#ume

Average

unit cost

of output

.conomies of 'ca#e and the ./perience %urve *orking

,iseconomies of 'ca#e start *orking

Capacity !ocus

The concept of the focused factory ho#ds that production

faci#ities *ork $est *hen they focus on a fair#y #imited set of

production o$2ectives.

P#ants -ithin P#ants (P-P) (from 'kinner)

./tend focus concept to operating #eve#

Capacity !le$ibility

!#e/i$#e p#ants

!#e/i$#e processes

&e E4perience %urve

Tota# accumu#ated production of units

%ost or

price

per unit

As p#ants produce more products) they

gain e/perience in the $est production

methods and reduce their costs per

unit.

!#e/i$#e *orkers

%apacity "lanning

!re6uency of %apacity Additions

./terna# 'ources of %apacity

Determining %apacity Re>uirements

!orecast sa#es *ithin each individua# product #ine.

%a#cu#ate e6uipment and #a$or re6uirements to meet the

forecasts.

Pro2ect e6uipment and #a$or avai#a$i#ity over the p#anning

horizon.

%apacity "lanning9 -alance

Maintaining 'ystem ?a#ance

'tage E 'tage G 'tage H

&nits

per

month

8)999 Q)999 I)P99

E4ample of %apacity Re>uirements

A manufacturer produces t*o #ines of mustard) !ancy !ine and

"eneric #ine. .ach is so#d in sma## and fami#y3size p#astic $ott#es.

The fo##o*ing ta$#e sho*s forecast demand for the ne/t four years.

:ear; < = 4 >

FancyFine

Small ?@@@sA B@ 2@ 5@ <@@

&amily ?@@@sA 4B B@ C@ D@

Generic

Small ?@@@sA <@@ <<@ <=@ <>@

&amily ?@@@sA 5@ D@ <@@ <<@

E4ample of %apacity Re>uirements9 E>uipment an$ La2or

Re>uirements

:ear; < = 4 >

Small ?@@@sA <B@ <C@ =@@ =>@

&amily ?@@@sA <<B <>@ <C@ =@@

Three E99)999 units3per3year machines are avai#a$#e for sma##3$ott#e

production. T*o operators re6uired per machine.

T*o EG9)999 units3per3year machines are avai#a$#e for fami#y3sized3

$ott#e production. Three operators re6uired per machine.

12.= Capacity Planning

(uestion4 -hat are the Dear E va#ues for capacity) machine) and #a$or7

<B@,@@@E4@@,@@@8B@F At < mac*ine .or <@@,@@@, it

takes <1B mac*ines .or <B@,@@@

At = operators .or

<@@,@@@, it takes 4

operators .or <B@,@@@

GThe McGraw-Hill Companies, Inc., 2001

<2

12.> Capacity Planning

(uestion4 -hat are the va#ues for co#umns G) H and I i n the ta$#e $e#o*7

B212CF

<1C@

41>@

B5144F

<1<C

41B@

2212CF

=1@@

>1@@

C@154F

<1>=

>1=B

5@1@@F

=1>@

>15@

54144F

<12C

B1@@

<C

GThe McGraw- Hill Companies, Inc., 2001

Planning Service Capacity

Time

0ocation

Jo#ati#ity of ,emand

Capacity 8tilization 7 Service &uality

?est operating point is near Q9; of capacity

!rom Q9; to E99; of service capacity) *hat do you think

happens to service 6ua#ity7

Capacity Planning

%apacity is the upper #imit or cei#ing on the #oad that an

operating unit can hand#e.

The $asic 6uestions in capacity hand#ing are4

-hat kind of capacity is needed7

@o* much is needed7

-hen is it needed7

%mportance of Capacity 3ecisions

E. Impacts a$i#ity to meet future demands

G. Affects operating costs

H. Ma2or determinant of initia# costs

I. Invo#ves #ong3term commitment

P. Affects competitiveness

8. Affects ease of management

Q. "#o$a#ization adds comp#e/ity

:. Impacts #ong range p#anning

Capacity

,esign capacity

ma/imum output rate or service capacity an operation)

process) or faci#ity is designed for

.ffective capacity

,esign capacity minus a##o*ances such as persona# time)

maintenance) and scrap

Actua# output

rate of output actua##y achieved33cannot

e/ceed effective capacity.

.fficiency and 8tilization

,ctual output

Efficiency =

Effective capacity

,ctual output

Utili6ation =

Design capacity

Both measures e$pressed as percentages

3eterminants of #ffective Capacity

!aci#ities

Product and service factors

Process factors

@uman factors

Operationa# factors

'upp#y chain factors

./terna# factors

Strategy !ormulation

%apacity strategy for #ong3term demand

,emand patterns

"ro*th rate and varia$i#ity

!aci#ities

%ost of $ui#ding and operating

Techno#ogica# changes

+ate and direction of techno#ogy changes

?ehavior of competitors

Avai#a$i#ity of capita# and other inputs

"ey 3ecisions of Capacity Planning

E. Amount of capacity needed

G. Timing of changes

H. Aeed to maintain $a#ance

I. ./tent of f#e/i$i#ity of faci#ities

Capacity cushion ? e$tra demand intended to offset uncertainty

Steps for Capacity Planning

E. .stimate future capacity re6uirements

G. .va#uate e/isting capacity

H. Identify a#ternatives

I. %onduct financia# ana#ysis

P. Assess key 6ua#itative issues

8. 'e#ect one a#ternative

Q. Imp#ement a#ternative chosen

:. Monitor resu#ts

Ma@e or Buy

E. Avai#a$#e capacity

G. ./pertise

H. (ua#ity considerations

I. Aature of demand

P. %ost

8. +isk

,eve#oping %apacity A#ternatives

E. ,esign f#e/i$i#ity into systems

G. Take stage of #ife cyc#e into account

H. Take a <$ig picture= approach to capacity changes

I. Prepare to dea# *ith capacity <chunks=

P. Attempt to smooth out capacity re6uirements

8. Identify the optima# operating #eve#

#conomies of Scale

.conomies of sca#e

If the output rate is #ess than the optima# #eve#) increasing

output rate resu#ts in decreasing average unit costs

,iseconomies of sca#e

If the output rate is more than the optima# #eve#) increasing

the output rate resu#ts in increasing average unit costs

.va#uating A#ternatives

Minimu

m

cost

,

v

e

r

a

g

e

c

o

s

t

p

e

r

u

n

i

t

?

Rate of

output

Production units have an optima# rate of output for minima# cost.

Minimum average cost per unit

Planning Service Capacity

Aeed to $e near customers

%apacity and #ocation are c#ose#y tied

Ina$i#ity to store services

%apacity must $e matched *ith timing of demand

,egree of vo#ati#ity of demand

Peak demand periods

(ssumptions of Cost2-olume (nalysis

. One product is involved

G. .verything produced can $e so#d

H. Jaria$#e cost per unit is the same regard#ess of vo#ume

.va#uating A#ternatives

Minimum cost ! optimal operating rate are

functions of si6e of pro$uction unit0

,

v

e

r

a

g

e

c

o

s

t

p

e

r

u

n

i

t

?

Small

plant

Me$ium

plant Large

plant

Output rate

I. !i/ed costs do not change *ith vo#ume

P. +evenue per unit constant *ith vo#ume

8. +evenue per unit e/ceeds varia$#e cost per unit

!inancial (nalysis

%ash !#o* 3 the difference $et*een cash received from sa#es

and other sources) and cash outf#o* for #a$or) materia#)

overhead) and ta/es.

Present Ja#ue 3 the sum) in current va#ue) of a## future cash

f#o*s of an investment proposa#.

Calculating Processing 'eAuirements

Product

Annua#

,emand

'tandard

processing time

per unit (hr.)

Processing time

needed (hr.)

SE

SG

SH

I99

H99

Q99

P.9

:.9

G.9

G)999

G)I99

E)I99

P):99

Product

Annua#

,emand

'tandard

processing time

per unit (hr.)

Processing time

needed (hr.)

SE

SG

SH

I99

H99

Q99

P.9

:.9

G.9

G)999

G)I99

E)I99

P):99

5ocation Planning and (nalysis

)eed for 5ocation 3ecisions

Marketing 'trategy

%ost of ,oing ?usiness

"ro*th

,ep#etion of +esources

)ature of 5ocation 3ecisions

'trategic Importance

0ong term commitmentBcosts

Impact on investments) revenues) and operations

'upp#y chains

O$2ectives

Profit potentia#

Ao sing#e #ocation may $e $etter than others

Identify severa# #ocations from *hich to choose

Options

./pand e/isting faci#ities

Add ne* faci#ities

Move

Ma@ing 5ocation 3ecisions

,ecide on the criteria

Identify the important factors

,eve#op #ocation a#ternatives

.va#uate the a#ternatives

Make se#ection

5ocation 3ecision !actors

10 Regional Factors

0ocation of ra* materia#s

0ocation of markets

0a$or factors

%#imate and ta/es

@0 %ommunity %onsi$erations

(ua#ity of #ife

'ervices

Attitudes

Ta/es

.nvironmenta# regu#ations

&ti#ities

,eve#oper support

A0 Multiple "lant Strategies

Product p#ant strategy

Market area p#ant strategy

Process p#ant strategy

B0 Site1relate$ Factors

0and

Transportation

.nvironmenta#

0ega#

%omparison of 'ervice and Manufacturing %onsiderations

ManufacturingB,istri$ution 'erviceB+etai#

%ost !ocus +evenue focus

Transportation modesBcosts ,emographics4

age)income)etc

.nergy avai#a$i#ity) costs Popu#ationBdra*ing area

0a$or costBavai#a$i#ityBski##s %ompetition

?ui#dingB#easing costs Traffic vo#umeBpatterns

%ustomer accessBparking

.va#uating 0ocations

%ost3Profit3Jo#ume Ana#ysis

,etermine fi/ed and varia$#e costs

P#ot tota# costs

,etermine #o*est tota# costs

0ocation %ost3Jo#ume Ana#ysis

Assumptions

!i/ed costs are constant

Jaria$#e costs are #inear

Output can $e c#ose#y estimated

On#y one product invo#ved

.va#uating 0ocations

Transportation Mode#

,ecision $ased on movement costs of ra* materia#s or

finished goods

!actor +ating

,ecision $ased on 6uantitative and 6ua#itative inputs

%enter of "ravity Method

,ecision $ased on minimum distri$ution costs

!acility 5ayout

5ayout4 the configuration of departments) *ork centers) and

e6uipment) *ith particu#ar emphasis on movement of *ork

(customers or materia#s) through the system

Importance of 0ayout ,ecisions

+e6uires su$stantia# investments of money and effort

Invo#ves #ong3term commitments

@as significant impact on cost and efficiency of short3term

operations

The )eed for 5ayout 3ecisions

Inefficient

operations

!or ./amp#e4

@igh %ost

?ott#eneck

s

%hanges in the

design

of products or

services

The introduction of

ne*

products or services

Accident

s

'afety

hazards

?asic 0ayout Types

Product #ayouts

Process #ayouts

!i/ed3Position #ayout

%om$ination #ayouts

?asic 0ayout Types

Product #ayout

0ayout that uses standardized processing operations to

achieve smooth) rapid) high3vo#ume f#o*

Process #ayout

0ayout that can hand#e varied processing re6uirements

!i/ed Position #ayout

0ayout in *hich the product or pro2ect remains stationary)

and *orkers) materia#s) and e6uipment are moved as

needed

%hanges in

environmenta

#

or other #ega#

re6uirements

%hanges in vo#ume

of

output or mi/ of

products

%hanges in

methods

and e6uipment

Mora#e

pro$#ems

The Aeed for 0ayout ,esign

(dvantages of Product 5ayout

Advantages of Product 0ayout

@igh rate of output

0o* unit cost

0a$or specia#ization

0o* materia# hand#ing cost

@igh uti#ization of #a$or and e6uipment

.sta$#ished routing and schedu#ing

+outing accounting and purchasing

,isadvantages of Product 0ayout

%reates du##) repetitive 2o$s

Poor#y ski##ed *orkers may not maintain e6uipment or 6ua#ity of

output

!air#y inf#e/i$#e to changes in vo#ume

@igh#y suscepti$#e to shutdo*ns

Aeeds preventive maintenance

Individua# incentive p#ans are impractica#

Raw

materials

or customer

Finished

item

Station

2

Station

2

Station

3

Station

3

Station

4

Station

4

Material

and/or

laor

Station

!

Material

and/or

laor

Material

and/or

laor

Material

and/or

laor

Used for Repetitive or Continuous Processing

Figure 6.4 Product 0ayout

Advantages of Process 0ayouts

%an hand#e a variety of processing re6uirements

Dept. A

Dept. B Dept. D

Dept. C

Dept. F

Dept. E

Used for intermittent processing

Job Shop or Btch

Process Layout

(u!ctio!al)

Figure 6."

Process 0ayout

!or"

Sttion #

!or"

Sttion $

!or"

Sttion %

Pro#uct Layout

(se$ue!tial)

Used for Repetitive Processing

Repetitive or Continuous

Product 0ayout

Aot particu#ar#y vu#nera$#e to e6uipment fai#ures

.6uipment used is #ess cost#y

Possi$#e to use individua# incentive p#ans

,isadvantages of Process 0ayouts

In3process inventory costs can $e high

%ha##enging routing and schedu#ing

.6uipment uti#ization rates are #o*

Materia# hand#ing s#o* and inefficient

%omp#e/ities often reduce span of supervision

'pecia# attention for each product or customer

Accounting and purchasing are more invo#ved

%e##u#ar 0ayouts

%e##u#ar Production

0ayout in *hich machines are grouped into a ce## that can

process items that have simi#ar processing re6uirements

"roup Techno#ogy

The grouping into part fami#ies of items *ith simi#ar design

or manufacturing characteristics

!unctional vs Cellular 5ayouts

Dimension Functional %ellular

Aum$er of moves

$et*een

departments

many fe*

Trave# distances #onger shorter

Trave# paths varia$#e fi/ed

Co$ *aiting times greater shorter

Throughput time higher #o*er

Amount of *ork in

process

higher #o*er

'upervision

difficu#ty

higher #o*er

'chedu#ing

comp#e/ity

higher #o*er

.6uipment #o*er higher

uti#ization

Other 'ervice 0ayouts

-arehouse and storage #ayouts

+etai# #ayouts

Office #ayouts

,esign Product 0ayouts4 0ine ?a#ancing

0ine ?a#ancing is the process of assigning tasks to *orkstations in

such a *ay that the *orkstations have appro/imate#y

e6ua# time re6uirements.

Cycle Time

Cycle time is the ma/imum time a##o*ed at each *orkstation to

comp#ete its set of tasks on a unit.

3etermine Ma$imum Output

!

OT

8 time cycle 8 CT

rate output !esired 8 !

day per time operatin# OT

CT

OT

8 capacity Output

=

3etermine the Minimum )umber of <or@stations 'eAuired

Calculate Percent %dle Time

.fficiency N E 5 Percent id#e time

,esigning Process 0ayouts

Information +e6uirements4

E. 0ist of departments

G. Pro2ection of *ork f#o*s

H. ,istance $et*een #ocations

I. Amount of money to $e invested

P. 0ist of specia# considerations

8. 0ocation of key uti#ities

s task time o. sum 8 t

OT

tA ?!A?

8 "

?"A?CTA

cycle per time Idle

8 time idle Percent

"rocess Layout 1 wor# travels

to $e$icate$ process centers

Millin

g

,ssem2l

y

! &est

;rin$in

g

Drillin

g

"latin

g

Process 0ayout

M"#$%& 4 '() Hours*

+apacit, Management-

7ob !esi#n, (r#onomics,

Met*ods Study and Hork Measurement,

(mployee Productivity,

earnin# Curve, S*ort)term Capacity Plannin#

A##re#ate plannin# and Capacity re/uirement plannin#

?Problems in Hork Measurement and S*ort term Capacity Plannin#A

#esign o.

/ork S,stems

7ob !esi#n, (r#onomics,

Met*ods Study and Hork Measurement,

(mployee Productivity,

0o #esign

Job design involves speci.yin# t*e content and met*ods o. 9ob

H*at 3ill be done

H*o 3ill do t*e 9ob

-o3 t*e 9ob 3ill bob 3ill be done

H*ere t*e 9ob 3ill be done

(r#onomics

#esign o. /ork S,stems

SpecialiIation

Be*avioral Approac*es to 7ob !esi#n

Teams

Met*ods Analysis

Motions Study

Horkin# conditions

0o #esign Success

Successful Job Design must be:

Carried out by e'perienced personnel 3it* t*e necessary trainin# and back#round

Consistent 3it* t*e #oals o. t*e or#aniIation

In 3ritten .orm

+nderstood and a#reed to by bot* mana#ement and employees

Speciali1ation in 2usiness- 3dvantages

Table C1<

#isadvantages

2ehavioral 3pproaches to 0o #esign

7ob (nlar#ement

Jivin# a 3orker a lar#er portion o. t*e total task by *oriIontal loadin#

7ob ,otation

Horkers periodically e'c*an#e 9obs

7ob (nric*ment

Increasin# responsibility .or plannin# and coordination tasks, by vertical

loadin#

For Management

:

10 Simplifies

training

@0 Hig

pro$uctivity

A0 Low wage

costs

For Labor

:

10 Low e$ucation

an$

s#ill

re>uirements

@

0

Minimu

m

responsi2ilitie

s

A

0

Little mental

effort

nee$e

$

For Management:

10

Difficult to motivate

>uality

@0 .or#er $issatisfaction8

possi2ly resulting in

a2senteeism8 ig

turnover8 $isruptive

tactics8 poor attention

to >uality

For Labor:

10 Monotonous wor#

@0 Limite$ opportunities

for a$vancement

A0 Little control over wor#

B0 Little opportunity for

self1fulfillment

Motivation and 4rust

Motivation

In.luences /uality and productivity

Contributes to 3ork environment

Trust

In.luences productivity and employee)mana#ement relations

4eams

Bene.its o. teams

-i#*er /uality

-i#*er productivity

Jreater 3orker satis.action

Sel.)directed teams

Jroups o. empo3ered to make certain c*an#es in t*eir 3ork process

Methods 3nal,sis

Met*ods analysis

AnalyIin# *o3 a 9ob #ets done

Be#ins 3it* overall analysis

Moves to speci.ic details

Methods 3nal,sis

The need for methods analysis can come

from a number of different sources:

C*an#es in tools and e/uipment

C*an#es in product desi#n

or ne3 products

C*an#es in materials or procedures

Ot*er .actors ?e1#1 accidents, /uality problemsA

Methods 3nal,sis 5rocedure

<1 Identi.y t*e operation to be studied

=1 Jet employee input

41 Study and document current met*od

>1 AnalyIe t*e 9ob

B1 Propose ne3 met*ods

21 Install ne3 met*ods

C1 &ollo3)up to ensure improvements *ave been ac*ieved

3nal,1ing the 0o

&lo3 process c*art

C*art used to e'amine t*e overall se/uence o. an operation by .ocusin# on

movements o. t*e operator or .lo3 o. materials

Horker)mac*ine c*art

C*art used to determine portions o. a 3ork cycle durin# 3*ic* an operator

and e/uipment are busy or idle

Motion Stud,

Motion study is t*e systematic study o. t*e *uman motions used to per.orm an operation1

Motion Stud, 4echni6ues

Motion study principles ) #uidelines .or desi#nin# motion)e..icient 3ork

procedures

Analysis of therbligs ) basic elemental motions into 3*ic* a 9ob can be broken

do3n

Micromotion study - use o. motion pictures and slo3 motion to study motions t*at

ot*er3ise 3ould be too rapid to analyIe

Charts

#eveloping /ork Methods

<1 (liminate unnecessary motions

=1 Combine activities

41 ,educe .ati#ue

>1 Improve t*e arran#ement o. t*e 3orkplace

B1 Improve t*e desi#n o. tools and e/uipment

F&'! PR'CESS C(AR)

5o2 Re>uisition of petty cas

Details of Meto$

,7,L<S&

D0 :ol2

",;E

1 of @

O

p

e

r

a

t

i

o

n

M

o

v

e

m

e

n

t

I

n

s

p

e

c

t

i

o

n

D

e

l

a

y

S

t

o

r

a

g

e

Re>uisition ma$e 2y $epartment ea$

"ut in Cpic#1upD 2as#et

&o accounting $epartment

,ccount an$ signature verifie$

,mount approve$ 2y treasurer

,mount counte$ 2y casier

,mount recor$e$ 2y 2oo##eeper

"etty cas seale$ in envelope

"etty cas carrie$ to $epartment

"etty cas cec#e$ against re>uisition

Receipt signe$

"etty cas store$ in safety 2o4

!igure Q3G

/orking +onditions

/ork Measurement

Standard time

Stop3atc* time study

-istorical times

Predetermined data

Hork Samplin#

Temperature L

@umidity

Jenti#ation

I##umination

%o#or

Aoise L

Ji$ration

%auses of

Accidents

'afet

y

-ork

?reaks

+ompensation

Time)based system

Compensation based on time an employee *as 3orked durin# a pay period

Output)based ?incentiveA system

Compensation based on t*e amount o. output an employee produces

durin# a pay period

Form o. 7ncentive 5lan

Accurate

(asy to apply

Consistent

(asy to understand

&air

+ompensation

Individual Incentive Plans

Jroup Incentive Plans

$no3led#e)Based Pay System

Mana#ement Compensation

%earning +urves

Learning curves ; t*e time re/uired to per.orm a task decreases 3it* increasin#

repetitions

%earning &..ect

%earning with 7mprovements

&

i

m

e

p

e

r

r

e

p

e

t

i

t

i

o

n

7um2er of repetitions

3pplications o. %earning +urves

<1 Manpo3er plannin# and sc*edulin#

=1 "e#otiated purc*asin#

41 Pricin# ne3 products

>1 Bud#etin#, purc*asin#, and inventory plannin#

B1 Capacity Plannin#

/orker %earning +urves

&

i

m

e

p

e

r

u

n

i

t

&ime

,verage

Improvements may create a

scallop effect in te curve0

+autions and +riticisms

earnin# rates may di..er .rom or#aniIation to or#aniIation

Pro9ections based on learnin# curves s*ould be vie3ed as appro'imations

(stimates based t*e .irst unit s*ould be c*ecked .or valid times

At some point t*e curve mi#*t level o.. or even tip up3ard

Some improvements may be more apparent t*an real

&or t*e most part, t*e concept does not apply to mass production

3ggregate 5lanning

Operations Plannin# Overvie3

T*e *ierarc*ical plannin# process

A##re#ate production plannin#

('amples; C*ase and evel strate#ies

"perations 5lanning "verview

on#)ran#e plannin#

Jreater t*an t*ree year plannin# *oriIon

+sually 3it* yearly increments

Intermediate)ran#e plannin#

,

)un$er>ualifie$*

-

)average*

%

)over>ualifie$*

&

i

m

e

(

c

y

c

l

e

s

One

wee#

Stan$ar$

time

&raining

time

< to 4 years

+sually 3it* mont*ly or /uarterly increments

S*ort)ran#e plannin#

One year

+sually 3it* 3eekly increments

Hierarchical 5roduction 5lanning

Master Production Sc*edulin#

ProductEService Sc*edule

,esource ,e/uirements Plannin#

MatKls, Capacity, Manpo3er

Order Sc*edulin#

ProductionEPurc*ases

Hork.orce 6

Customer Sc*edulin#

!aily Hork.orce 6

Customer Sc*edulin#

Strate#ic Plannin#

Sales Plannin#

A##re#ate Plannin#

on#)

ran#e

Intermediate)

ran#e

S*ort)

ran#e

3ggregate 5lanning

Joal; Speci.y t*e optimal combination o.

production rate ?units completed per unit o. timeA

3ork.orce level ?number o. 3orkersA

inventory on *and ?inventory carried .rom previous periodA

Product #roup or broad cate#ory ?A##re#ationA

Intermediate)ran#e plannin# period; 2)<5 mont*s

2alancing 3ggregate #emand and 3ggregate 5roduction +apacit,

Annual demand by

item and by re#ion

Mont*ly demand

.or <B mont*s by

product type

Mont*ly demand

.or B mont*s by

item

Forecasts needed

Allocates

production

amon# plants

!etermines

seasonal plan by

product type

!etermines

mont*ly

item production

sc*edules

#ecision 5rocess #ecision %evel

Corporate

Plant mana#er

S*op

superintendent

./hi$it EG.G

./hi$it EG.G

8e, Strategies .or Meeting #emand

C*ase

evel

Some combination o. t*e t3o

S4R34&97&S 3+47:& /R4 #&M3;#

$S& M3R8&47;9 4" SM""4H #&M3;#

(LAMP(S

P,IC(

P,O!+CT

PAC(

P,OMOTIO"

5roactive #emand Management to &6uate Suppl, and #emand

@

=@@@

>@@@

2@@@

5@@@

<@@@@

7an &eb Mar Apr May 7un

>B@@

BB@@

C@@@

<@@@@

5@@@

2@@@

@

=@@@

>@@@

2@@@

5@@@

<@@@@

7an &eb Mar Apr May 7un

>B@@ >@@@

D@@@

5@@@

>@@@

2@@@

'uppose the figure to the

right represents forecast

demand in units.

Ao* suppose this #o*er

figure represents the

aggregate capacity of the

company to meet

demand.

-hat *e *ant to do is

$a#ance out the production

rate) *orkforce #eve#s) and

inventory to make these

figures match up.

5roactive #emand Management to &6uate Suppl, and #emand

0ason &nterprises 3ggregate 5lanning &<amples- $nit #emand and +ost #ata

@

=@@@

>@@@

2@@@

5@@@

<@@@@

@

=@@@

>@@@

2@@@

5@@@

<@@@@

S(ASO"A

!(MA"! )

S"OH S$IIS

CO"T,A)

S(ASO"A

!(MA"! )

MMMMMMMMMMMMMMM

@

=@@@

>@@@

2@@@

5@@@

<@@@@

@

=@@@

>@@@

2@@@

5@@@

<@@@@

C:CICA

!(MA"! )

"(H CA,S

CO"T,A)C:CICA

!(MA"! )

MMMMMMMMMMMMMMMMMM

+apacit, 5lanning

Capacity is t*e upper limit or ceilin# on t*e load t*at an operatin# unit can *andle1

T*e basic /uestions in capacity *andlin# are;

H*at kind o. capacity is neededN

-o3 muc* is neededN

H*en is it neededN

7mportance o. +apacit, #ecisions

<1 Impacts ability to meet .uture demands

=1 A..ects operatin# costs

41 Ma9or determinant o. initial costs

>1 Involves lon#)term commitment

B1 A..ects competitiveness

21 A..ects ease o. mana#ement

C1 JlobaliIation adds comple'ity

51 Impacts lon# ran#e plannin#

+apacit,

!esi#n capacity

Materials O<@@Eunit

-oldin# costs O<@Eunit per mo1

Mar#inal cost o. stockout O=@Eunit per mo1

-irin# and trainin# cost OB@E3orker

ayo.. costs O<@@E3orker

abor *ours re/uired 1 > *rsEunit

Strai#*t time labor costEOT O<=1B@E<51CBE*our

Be#innin# inventory =@@ units

Productive *oursE3orkerEday 51@@

Paid strai#*t *rsEday 5

'uppose *e have the fo##o*ing unit demand and cost information4

!emandEmo 7an &eb Mar Apr May 7un

B@@ 2@@ 2B@ 5@@ D@@ 5@@

!ays per mont* == <D =< =< ==

ma'imum output rate or service capacity an operation, process, or .acility

is desi#ned .or

(..ective capacity

!esi#n capacity minus allo3ances suc* as personal time, maintenance,

and scrap

Actual output

rate o. output actually ac*ieved))cannot

e'ceed e..ective capacity1

&..icienc, and $tili1ation

3ctual output

&..icienc, =

&..ective capacit,

3ctual output

$tili1ation =

#esign capacit,

oth measures e!pressed as percentages

&..icienc,/$tili1ation &<ample

#eterminants o. &..ective +apacit,

&acilities

Actua# output N H8 unitsBday

.fficiency N N R9;

.ffective capacity I9 unitsB day

&ti#ization N Actua# output N H8 unitsBday

N QG;

,esign capacity P9 unitsBday

!esi#n capacity 8 B@ trucksEday

(..ective capacity 8 >@ trucksEday

Actual output 8 42 unitsEday

Product and service .actors

Process .actors

-uman .actors

Operational .actors

Supply c*ain .actors

('ternal .actors

Strateg, Formulation

Capacity strate#y .or lon#)term demand

!emand patterns

Jro3t* rate and variability

&acilities

Cost o. buildin# and operatin#

Tec*nolo#ical c*an#es

,ate and direction o. tec*nolo#y c*an#es

Be*avior o. competitors

Availability o. capital and ot*er inputs

8e, #ecisions o. +apacit, 5lanning

<1 Amount o. capacity needed

=1 Timin# o. c*an#es

41 "eed to maintain balance

>1 ('tent o. .le'ibility o. .acilities

Capacity cus*ion e'tra demand intended to o..set uncertainty

Steps .or +apacit, 5lanning

<1 (stimate .uture capacity re/uirements

=1 (valuate e'istin# capacity

41 Identi.y alternatives

>1 Conduct .inancial analysis

B1 Assess key /ualitative issues

21 Select one alternative

C1 Implement alternative c*osen

51 Monitor results

Make or 2u,

<1 Available capacity

=1 ('pertise

41 0uality considerations

>1 "ature o. demand

B1 Cost

21 ,isk

#eveloping +apacit, 3lternatives

<1 !esi#n .le'ibility into systems

=1 Take sta#e o. li.e cycle into account

41 Take a Pbi# pictureQ approac* to capacity c*an#es

>1 Prepare to deal 3it* capacity Pc*unksQ

B1 Attempt to smoot* out capacity re/uirements

21 Identi.y t*e optimal operatin# level

&conomies o. Scale

(conomies o. scale

I. t*e output rate is less t*an t*e optimal level, increasin# output rate

results in decreasin# avera#e unit costs

!iseconomies o. scale

I. t*e output rate is more t*an t*e optimal level, increasin# t*e output rate

results in increasin# avera#e unit costs

&valuating 3lternatives

&valuating 3lternatives

Minimu

m

cost

,

v

e

r

a

g

e

c

o

s

t

p

e

r

u

n

i

t

?

Rate of

output

Production units have an optima# rate of output for minima# cost.

!igure P.H

Minimum average cost per unit

5lanning Service +apacit,

"eed to be near customers

Capacity and location are closely tied

Inability to store services

Capacity must be matc*ed 3it* timin# o. demand

!e#ree o. volatility o. demand

Peak demand periods

+ost>:olume Relationships

Minimum cost ! optimal operating rate are

functions of si6e of pro$uction unit0

,

v

e

r

a

g

e

c

o

s

t

p

e

r

u

n

i

t

?

Small

plant

Me$ium

plant Large

plant

Output rate

!igure P.I

+ost>:olume Relationships

,

m

o

u

n

t

)

E

*

?

+ )volume in

units*

&

o

t

a

l

c

o

s

t

=

'

%

F

F

%

&

o

t

a

l

v

a

r

i

a

2

l

e

c

o

s

t

)

'

%

*

Fi4e$ cost

)F%*

+ost>:olume Relationships

2reak>&ven 5rolem with Step Fi<ed +osts

,

m

o

u

n

t

)

E

*

+ )volume in

units*

?

&

o

t

a

l

r

e

v

e

n

u

e

,

m

o

u

n

t

)

E

*

+ )volume in units*

?

-E" units

"

r

o

f

i

t

&

o

t

a

l

r

e

v

e

n

u

e

&

o

t

a

l

c

o

s

t

+uantity

F

%

F

'

%

=

&

%

F

%

F

'

%

=

&

%

F

%

F

'

%

=

&

%

Step fi4e$ costs an$ varia2le costs0

1 macine

@ macines

A macines

2reak>&ven 5rolem with Step Fi<ed +osts

3ssumptions o. +ost>:olume 3nal,sis

<1 One product is involved

=1 (veryt*in# produced can be sold

41 %ariable cost per unit is t*e same re#ardless o. volume

>1 &i'ed costs do not c*an#e 3it* volume

B1 ,evenue per unit constant 3it* volume

21 ,evenue per unit e'ceeds variable cost per unit

Financial 3nal,sis

Cas* &lo3 ) t*e di..erence bet3een cas* received .rom sales and ot*er sources,

and cas* out.lo3 .or labor, material, over*ead, and ta'es1

Present %alue ) t*e sum, in current value, o. all .uture cas* .lo3s o. an investment

proposal1

+alculating 5rocessing Re6uirements

E

&

%

&

%

&

%

-E

"

@

-E"

A

&

R

+uantit

y

1

@

A

Multiple 2rea#1even

points

Product

Annua#

,emand

'tandard

processing time

per unit (hr.)

Processing time

needed (hr.)

SE

SG

SH

I99

H99

Q99

P.9

:.9

G.9

G)999

G)I99

E)I99

P):99

Product

Annua#

,emand

'tandard

processing time

per unit (hr.)

Processing time

needed (hr.)

SE

SG

SH

I99

H99

Q99

P.9

:.9

G.9

G)999

G)I99

E)I99

P):99