Professional Documents

Culture Documents

Selecting the Right Press Brake and Tooling

Uploaded by

Lingarajan RamasamyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Selecting the Right Press Brake and Tooling

Uploaded by

Lingarajan RamasamyCopyright:

Available Formats

64 The FABRICATOR August 2013

By Steve Benson

S

electing the press brake and tooling for a

particular job involves much more than

just making sure theres enough brute force.

Make one miscalculation, and pieces of tooling

can y while, at the same time, you may exceed

the ram center load, causing the press brake ram

and bed to bend. If you dont believe this can hap-

pen, look at almost any high-mileage mechanical

press brake and count the number of shims be-

tween the die and the bed.

To avoid these problems, take a look at your ton-

nage and load limits.

How Much Tonnage

Does a Job Require?

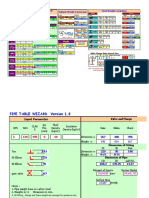

Start by looking at a standard tonnage chart (see

Figure 1) that relates the workpiece thickness with

the width of the die opening. Where the two inter-

sect gives you the approximate tonnage per foot

required for the job, based on 60,000-PSI tensile

cold-rolled steel.

Tonnage charts can be inaccurate, though. So

to nd the tonnage a job requires quickly and ac-

curately every time, consider using the following

formula, which solves for tonnage per inch when

air forming 60,000-PSI-tensile AISI 1035 cold-rolled

steel over a given die width: Tonnage per inch =

{[(575 Material thickness

2

) / Die width] / 12}.

Multiply this value by the bend length, and youll

get the total tonnage required for the application.

Still, in any job shop, material types vary, and

each has its own tensile strength. Tensile strength

is dened as the ability of a material to bear weight

without breaking or being pulled apart under a

smooth load, not a sudden impact.

To incorporate diferent materials into the ton-

nage calculation, you include a material factor in

the tonnage formula. Here are some common ma-

terial factors:

AISI 1035 cold-rolled steel = 1

304 Stainless = 1.4 to 6

Aluminum 6061 T6 = 1.28

Aluminum 5052 H32 = 0.50

We use the 60,000-PSI-tensile AISI 1035 (the

most common type of cold-rolled steel used) as

a baseline and so give it a value of 1. To obtain a

factor for a specic material, you can perform a

simple comparison of tensile strengths, working

with 60,000-PSI tensile as the baseline. For example,

if youre working with a material with a specied

maximum tensile strength of 120,000 PSI, divide

that by 60,000 to get 2, which becomes your mate-

rial factor in the tonnage formula.

Considering all this, here is the tonnage calcula-

tion you can use to determine the amount of ton-

nage you need for a job:

Tonnage per inch = {[(575 Material thickness

2

)

/ Die width] / 12} Material factor

Total tonnage needed for the job = Tons per

inch Length of bend in inches

Tese formulas apply to air forming. If youre

bottoming or coining, you need to take this into

account. Bottoming and coining tonnage calcula-

Why tonnage

matters

Nevereverexceed

the load limits for your

tooling or press brake

Figure 1

Tonnage charts relate workpiece thicknesses with the width of the die opening. Note that tonnage charts can be inaccurate for the job at hand.

Thickness

of Metal

Width of Female Die Opening

Approximate pressure in tons per linear foot required to make a 90-degree air bend in mild steel (60,000 PSI tensile)

Gauge Dec.

1

4"

5

16"

3

8"

1

2"

5

8"

3

4"

7

8" 1" 1

1

8" 1

1

4" 1

1

2" 2" 2

1

2" 3" 3

1

2" 4" 5" 6" 7" 8" 10" 12"

20 0.036 2.6 2.2 1.6 1.2 1.0

18 0.048 3.5 2.8 2.1 1.7 1.3

16 0.060 5.3 3.7 2.8 2.2 1.7

14 0.075 5.5 4.6 3.5 3.0 2.5 2.1

13 0.090 6.4 5.5 4.3 3.6 3.2 2.8

12 0.105 9.2 6.9 6.2 5.0 4.3 3.9 3.1

11 0.120 10.1 8.0 7.0 6.1 5.3 4.3 2.9

10 0.135 10.3 8.7 7.8 6.9 5.7 3.9

9 0.150 11.9 9.8 8.8 7.0 5.0 3.7

7 0.188 16.9 13.9 11.2 8.3 6.7 4.9

1

4" 0.250 27.5 22.1 15.0 11.6 9.6 7.9 6.7

5

16" 0.312 39.2 26.5 19.3 15 12.5 10.4 7.7

3

8" 0.375 42.7 31.2 23.8 19.5 16.3 12.4 9.6

7

16" 0.437 45.5 35.2 28.5 24.4 17.4 15.0 11.5

1

2" 0.500 48.5 39.5 33.2 24.6 19.5 16.1 13.4

5

8" 0.625 65.5 57.9 42.8 33.1 27.3 23.3 17.0

3

4" 0.750 92.3 68.1 53.0 36.2 36.2 26.9 21.0

7

8" 0.875 103.1 79.9 52.3 52.3 39.2 31.2

1 1.00 112.1 90.4 75.5 55.7 43.7

DANGER ZONE

Aug13FAB_PressBrakes.indd 64 7/23/13 11:18 AM

August 2013 The FABRICATOR 65

tions are rough approximations at best, because

they can vary depending on the machine operator.

But these bending methods do increase required

tonnage substantially. If youre bottoming, you

need to multiply your calculated tonnage per inch

by at least a factor of 5; if youre coining, the factor

can be 10 or even more.

Also note that the maximum tonnage doesnt

happen all at once; it builds along a steep curve.

Under close observation, you will notice that 80

percent of the total tonnage is developed in the

rst 20 degrees of bend, so even a small bend angle

can produce enormous pressures on the tooling

and equipment.

Teres also more tonnage to consider than just

what it takes to bend the sheet. Workpiece size also

can afect tonnage requirements. When you are

working with a small part, this force is extremely

small. But for larger parts, the force can be signi-

cant. Supporting the materialbe it with a lot of

manpower, material lifters on the brake itself, or a

cranecan help mitigate this efect.

Whether you are using a tonnage chart or cal-

culating the tonnage requirements manually, you

need to know how to apply the information. Te

jobs tonnage requirements should not exceed the

tonnage capacity of the press brake or the tooling.

Press Brake Tonnage Capacity

Before continuing, we need to dene some terms,

the rst being deection. Deection is the tempo-

rary deformation of the press brakes ram and bed

that occurs naturally under a load (see Figure 2).

When the pressure is removed, so is the deection

present under load, and the ram and bed return to

their original positions. In other words, deection is

normal and to be expected.

Te second term is upset, which occurs when

you exceed the maximum deection of the press

brake ram. When this happens, the ram and bed

stay permanently deected (bent); once upset, the

press brake ram and the bed become difcult and

expensive to repair.

Most press brakes are designed for centerline

loading; that is, they are designed for work in the

center of the press brake bed. Te ram power

comes from the cylinders on either side of the bed,

60%

When Reversed

Loses Center Maintains Center

Figure 2

Deection is the temporary deformation of the press

brake ram and bed that occurs naturally under a load.

An overtonnage situation can push a brake beyond its

deection limit, causing upset, where the ram and bed

stay in a permanently deected, or bent, state.

Figure 3

Generally, you should never apply full machine tonnage

over an area thats less than 60 percent of the distance

between the side frames.

Figure 4

Standard American tooling (left) is reversible as far as

pressure ow is concerned, but it can lose its center in

the die. Note the small space that appears between the

punch and right-hand die face. European-style tooling

(on the right) is completely reversible as far as centers

are concerned, but the pressure ow changes, as shown

in Figure 5.

Figure 5

European-style tooling can be reversed, but the pressure

ow changes. As shown on the right, the pressure ows

past the ram and onto the mounting bolts. Tis creates a

very dangerous situation.

Make one miscalculation, and pieces of tooling can y

while, at the same time, you may exceed the ram center

load, causing the press brake ram and bed to bend.

If you dont believe this can happen, look at almost

any high-mileage mechanical press brake and count the

number of shims between the die and the bed.

Aug13FAB_PressBrakes.indd 65 7/23/13 11:18 AM

You might also like

- How To Compute Tonnage RequirementsDocument5 pagesHow To Compute Tonnage RequirementsPrabhat SharmaNo ratings yet

- 1488644012final Bending - Forming, DrawingDocument31 pages1488644012final Bending - Forming, DrawingasifNo ratings yet

- Runners, Gates and Feed System Data PDFDocument27 pagesRunners, Gates and Feed System Data PDFBade BhausahebNo ratings yet

- Unigraphics Nx7 5 Mold Wizard PDFDocument23 pagesUnigraphics Nx7 5 Mold Wizard PDFyuwrajc100% (1)

- OSHA and steel beam worksheet linksDocument464 pagesOSHA and steel beam worksheet linksWill SmithNo ratings yet

- 00000-Metri-Imperial Unit ToolsDocument4 pages00000-Metri-Imperial Unit ToolsPop JiNo ratings yet

- FORMULAS For CALCULATING RATES1 PDFDocument4 pagesFORMULAS For CALCULATING RATES1 PDFBasara MladenNo ratings yet

- Polymer Journal ListDocument4 pagesPolymer Journal ListAnish KumarNo ratings yet

- Bending and DrawingDocument14 pagesBending and DrawingStelwin FernandezNo ratings yet

- LPG STORAGE TANK DESIGN CALCULATIONSDocument2 pagesLPG STORAGE TANK DESIGN CALCULATIONSRamesh GanapathyNo ratings yet

- Recommended Speed For Turning: Free Machining, Plain Carbon SteelsDocument11 pagesRecommended Speed For Turning: Free Machining, Plain Carbon Steelsjsk_senNo ratings yet

- Basic part numbers and codesDocument37 pagesBasic part numbers and codesMani Rathinam RajamaniNo ratings yet

- Service Philips 2005Document188 pagesService Philips 2005acostaricciNo ratings yet

- Cable List SEAS 70Document381 pagesCable List SEAS 70phankhoa83No ratings yet

- Modelo (Battenfeld) Unidades HM 40/60 (14) HM 100/210 (25) HM 210/525 (35) Clamping UnitDocument1 pageModelo (Battenfeld) Unidades HM 40/60 (14) HM 100/210 (25) HM 210/525 (35) Clamping UnitGerardo ArroyoNo ratings yet

- (Products Data) Calculation of Punch Strength - Misumi, The Catalog Press Die ComponentsDocument5 pages(Products Data) Calculation of Punch Strength - Misumi, The Catalog Press Die Componentsmonu991No ratings yet

- Using The ASME VIII-1 Nozzle F Factor (UG-37)Document7 pagesUsing The ASME VIII-1 Nozzle F Factor (UG-37)stalin_83No ratings yet

- Academic Project PresentationDocument20 pagesAcademic Project Presentationkishore pm100% (1)

- Key Points To Specified A Injection Moulding MachineDocument2 pagesKey Points To Specified A Injection Moulding MachineNIKHIL PATHADENo ratings yet

- E-Design Tools For Friction Stir Welding - Cost Estimation ToolDocument72 pagesE-Design Tools For Friction Stir Welding - Cost Estimation ToolEDIZONNo ratings yet

- ByStar Fiber Datasheet Eng Original 14278Document2 pagesByStar Fiber Datasheet Eng Original 14278Trần Ngọc ThànhNo ratings yet

- Detector CO2 ParcajeDocument93 pagesDetector CO2 ParcajeStratulat Lucian-IonutNo ratings yet

- Dimensionless Designator of Pipe Size PDFDocument1 pageDimensionless Designator of Pipe Size PDFleoscbdNo ratings yet

- Procedures For Costing Projects With Quantities - MaterialsDocument2 pagesProcedures For Costing Projects With Quantities - MaterialsTran Kim Thanh-VuNo ratings yet

- Cable Sizing SheetDocument76 pagesCable Sizing Sheetprathamesh sawantNo ratings yet

- 725-24-600-12 Cylinder DetailsDocument2 pages725-24-600-12 Cylinder DetailsramabhplNo ratings yet

- Design of Two-Way Slab: GivenDocument21 pagesDesign of Two-Way Slab: GivenJohn Pierce GumapacNo ratings yet

- Linatex Premium Rubber Spec SheetDocument1 pageLinatex Premium Rubber Spec Sheet_Asylum_No ratings yet

- Jigs and Fixtures DesignDocument9 pagesJigs and Fixtures Designazizmaarof100% (4)

- Calculation of Punch StrengthDocument1 pageCalculation of Punch StrengthTolga KurbanNo ratings yet

- Excel Project Schedule Template: Mar-30 Apr-6 Apr-13 Apr-20 Apr-27 May-4 May-11 26-Mar-2018 (Monday) 1Document3 pagesExcel Project Schedule Template: Mar-30 Apr-6 Apr-13 Apr-20 Apr-27 May-4 May-11 26-Mar-2018 (Monday) 1Mary Rose MejillanoNo ratings yet

- CH03. Sheet Metal ProcessesDocument73 pagesCH03. Sheet Metal ProcesseshizanorhudaNo ratings yet

- Plastic Injection Moulding MachinesDocument2 pagesPlastic Injection Moulding MachinesFelipe Doria RibeiroNo ratings yet

- Part/Material Inputs: Injection Molding Technical Cost Model MIT - Materials Systems LaboratoryDocument13 pagesPart/Material Inputs: Injection Molding Technical Cost Model MIT - Materials Systems LaboratoryEmba MadrasNo ratings yet

- Costing calculations for India hall buildingDocument8 pagesCosting calculations for India hall buildingRakesh SharmaNo ratings yet

- Tailor Welded BlanksDocument52 pagesTailor Welded BlanksYuvaraj YuvarajNo ratings yet

- Material Properties ChartDocument2 pagesMaterial Properties ChartNick PieperNo ratings yet

- 132 - 33 KV TRF Paenl Cabel Termination ScheduleDocument7 pages132 - 33 KV TRF Paenl Cabel Termination ScheduleMathur DineshNo ratings yet

- 住友1705版Document192 pages住友1705版费凌翔No ratings yet

- Shearing Process GuideDocument29 pagesShearing Process GuideSriram MuruganNo ratings yet

- Industrial Practical Training Report General Tyre and Rubber CompanyDocument19 pagesIndustrial Practical Training Report General Tyre and Rubber Companysalman6625No ratings yet

- General Notes: S Piping and Instrument Diagram - Gen1 - System 0000Document1 pageGeneral Notes: S Piping and Instrument Diagram - Gen1 - System 0000sanjay masoodNo ratings yet

- Plate Shear Strength Calculation DetailsDocument6 pagesPlate Shear Strength Calculation DetailsvenkateswaranNo ratings yet

- Shaft Design and CalculationDocument4 pagesShaft Design and CalculationHugo Mario Ariza PalacioNo ratings yet

- Cutter GuideDocument1 pageCutter GuideCarlos RamirezNo ratings yet

- Section 2 Gmaw Fundamentals: 2-1. Basic InformationDocument9 pagesSection 2 Gmaw Fundamentals: 2-1. Basic InformationEnriquinoNo ratings yet

- MP SheetMetal PDFDocument48 pagesMP SheetMetal PDFNhan LeNo ratings yet

- Weight CalculatorDocument2 pagesWeight CalculatorenjoygurujiNo ratings yet

- Welding Cost Estimation For 12 Joints in 8 NPS SCH 80 PDFDocument1 pageWelding Cost Estimation For 12 Joints in 8 NPS SCH 80 PDFAnonymous VRspXsmNo ratings yet

- Drawing PracticesDocument60 pagesDrawing Practicespverma02No ratings yet

- CircuitvcbDocument8 pagesCircuitvcblalit92112760No ratings yet

- Strengthening MechanismsDocument43 pagesStrengthening MechanismsZahra KaylNo ratings yet

- Gantt Chart LDocument8 pagesGantt Chart LRobin WeigoldNo ratings yet

- Drawing Office Calculation Version 2.8 Tubular Weight Conversion Steel Weight Caculation Convert Imperial & MetricDocument7 pagesDrawing Office Calculation Version 2.8 Tubular Weight Conversion Steel Weight Caculation Convert Imperial & MetricJp Tobias0% (1)

- Cylinder Force For PunchingDocument4 pagesCylinder Force For PunchingAntehun MekonnenNo ratings yet

- F= Π X Dt3 X Τk 8Xdmxk: Technical InformationDocument6 pagesF= Π X Dt3 X Τk 8Xdmxk: Technical InformationaleaubrNo ratings yet

- Air Bend Force Chart - SheetMetal PDFDocument4 pagesAir Bend Force Chart - SheetMetal PDFsunilbholNo ratings yet

- D15 Integral Journal BearingsDocument9 pagesD15 Integral Journal BearingsSuresh Kumar MittapalliNo ratings yet

- Menges CrowningDocument8 pagesMenges CrowningTarun GuptaNo ratings yet

- Surface TreatmentDocument24 pagesSurface TreatmentLingarajan RamasamyNo ratings yet

- Quality - Induction ProgramDocument2 pagesQuality - Induction ProgramLingarajan RamasamyNo ratings yet

- Continuity - Level III 9TH DEC2015Document2 pagesContinuity - Level III 9TH DEC2015Lingarajan RamasamyNo ratings yet

- List of Instruments: S.No Instrument Name Instrumnet ID NoDocument2 pagesList of Instruments: S.No Instrument Name Instrumnet ID NoLingarajan RamasamyNo ratings yet

- Change Over Process Check ListDocument1 pageChange Over Process Check ListLingarajan RamasamyNo ratings yet

- Odering Information - Stainless Steel PipeDocument4 pagesOdering Information - Stainless Steel PipeLingarajan RamasamyNo ratings yet

- ISO DocumentsDocument6 pagesISO DocumentsLingarajan RamasamyNo ratings yet

- K1013471870 18Document2 pagesK1013471870 18comphackNo ratings yet

- Quality - Induction ProgramDocument2 pagesQuality - Induction ProgramLingarajan RamasamyNo ratings yet

- COC Air Liquide FastenersDocument3 pagesCOC Air Liquide FastenersLingarajan RamasamyNo ratings yet

- Paints and Varnishes: ISO Standards HandbookDocument5 pagesPaints and Varnishes: ISO Standards Handbookshankar.ouctNo ratings yet

- COC Air Liquide FastenersDocument4 pagesCOC Air Liquide FastenersLingarajan RamasamyNo ratings yet

- JSC - Se S 0073GDocument216 pagesJSC - Se S 0073GLingarajan RamasamyNo ratings yet

- Tolerance As Per ISO 2768-1Document1 pageTolerance As Per ISO 2768-1Lingarajan RamasamyNo ratings yet

- Hot Dip Galvanized CoatingDocument28 pagesHot Dip Galvanized CoatingOci Rizal100% (6)

- Permissible Tolerance as SS-ISO-2768-CDocument1 pagePermissible Tolerance as SS-ISO-2768-CLingarajan RamasamyNo ratings yet

- Induction For New WelderDocument1 pageInduction For New WelderLingarajan RamasamyNo ratings yet

- Profile Metalice HEA-Caracteristici GeometriceDocument1 pageProfile Metalice HEA-Caracteristici GeometriceCristi PopNo ratings yet

- 7QC Tools BBDocument188 pages7QC Tools BBLingarajan Ramasamy100% (2)

- Issues To Address... : Chapter 14/15-1Document11 pagesIssues To Address... : Chapter 14/15-1Alex Nico JhoentaxsNo ratings yet

- Astm A283Document2 pagesAstm A283Ahmad Udin100% (1)

- 3074 PDFDocument18 pages3074 PDFsunil srivastavaNo ratings yet

- (2017) Review On Mechanical Properties of Banana FiberDocument5 pages(2017) Review On Mechanical Properties of Banana Fiberdeepen_banoriyaNo ratings yet

- Dental Casting Alloys FinalDocument175 pagesDental Casting Alloys FinalNiaz Ahammed0% (1)

- Universal Testing MachineDocument26 pagesUniversal Testing MachineAlyan YousafNo ratings yet

- QA Plan Polyethylene Pipes Supply Gaseous Fuel IS 14885Document3 pagesQA Plan Polyethylene Pipes Supply Gaseous Fuel IS 14885Gururaj P KundapurNo ratings yet

- PugalenthiDocument7 pagesPugalenthiTHANI ORUVANNo ratings yet

- Formiga P Materials en 0Document23 pagesFormiga P Materials en 0Mihajilo TosicNo ratings yet

- General Properties of Dental MaterialsDocument7 pagesGeneral Properties of Dental Materialsalaa jaleelNo ratings yet

- Thin-Walled Pressure VesselsDocument43 pagesThin-Walled Pressure VesselsAdonis C. BibatNo ratings yet

- Hand Operated Can CrusherDocument60 pagesHand Operated Can CrusherParen Trivedi100% (2)

- AISI1040Document2 pagesAISI1040Anonymous qRbPsLpuNNo ratings yet

- Seamless Carbon Steel Pipe For High-Temperature ServiceDocument25 pagesSeamless Carbon Steel Pipe For High-Temperature ServiceMauricio AdameNo ratings yet

- S Chambro N 2008Document7 pagesS Chambro N 2008Jose Luis Ubilla ⎝⏠⏝⏠⎠No ratings yet

- Concrete PropertiesDocument32 pagesConcrete PropertiesEldho CaNo ratings yet

- Effect of Weld Parameters On Mechanical Properties of The Friction Stir Welding Aa6063-T5Document9 pagesEffect of Weld Parameters On Mechanical Properties of The Friction Stir Welding Aa6063-T5HUỲNH HOÀNG TÚNo ratings yet

- Nickel-Chromium-Molybdenum-Tungsten-Alloys (UNS N06110) Welded PipeDocument5 pagesNickel-Chromium-Molybdenum-Tungsten-Alloys (UNS N06110) Welded PipeNav TalukdarNo ratings yet

- Ce 201 PDFDocument141 pagesCe 201 PDFMuntashir MunimNo ratings yet

- Giroud 1981 and Noiray Unpaved Road Design Corrected OCRDocument39 pagesGiroud 1981 and Noiray Unpaved Road Design Corrected OCRDanny Lam100% (1)

- Def Stan 00-970Document11 pagesDef Stan 00-970stefan.vince536No ratings yet

- Chlorimet 2 (N-7M) and Chlorimet 3 (CW-6M)Document6 pagesChlorimet 2 (N-7M) and Chlorimet 3 (CW-6M)gullenariNo ratings yet

- Is 15652Document14 pagesIs 15652girish19100% (1)

- Is 1897Document9 pagesIs 1897Yuvaraj SathishNo ratings yet

- OTW MaterijalDocument29 pagesOTW Materijalb_0102_7891No ratings yet

- Astm f1470Document5 pagesAstm f1470mombarreNo ratings yet

- Steel Wire For Mechanical Springs DIN: European Standard EN 10270-1: 2001 Has The Status of A DIN StandardDocument27 pagesSteel Wire For Mechanical Springs DIN: European Standard EN 10270-1: 2001 Has The Status of A DIN StandardDiego CamargoNo ratings yet

- ElasticityDocument80 pagesElasticityRisa M. LimNo ratings yet

- RilemDocument78 pagesRilemسارة المالكيNo ratings yet