Professional Documents

Culture Documents

Practical Use of Nanomaterials in Plastics: Innovative Technologies Symposium For Plastics

Uploaded by

aneris10Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Practical Use of Nanomaterials in Plastics: Innovative Technologies Symposium For Plastics

Uploaded by

aneris10Copyright:

Available Formats

Practical Use of

Nanomaterials in Plastics

Innovative Technologies

Symposium for Plastics

J uly 31, 2007

J oseph J . Schwab

www.hybridplastics.com

Hybr i d

Pl ast i c s

What is Nanotechnology?

!Nanotechnology is the understanding and control

of matter at dimensions of roughly 1 to 100

nanometers.

!Nanotechnology involves imaging, measuring,

modeling, and manipulating matter at this length

scale.

!At the nano-scale, the physical, chemical, and

biological properties of materials differ from the

properties of individual atoms and molecules or

bulk matter, creating improved materials,

devices, and systems that exploit these new

properties.

What is Nanotechnology?

A hundred years ago, or even fifty,

nanotechnology would have just been

called chemistry

Economist, 5 July 2001

What is Nanotechnology?

Nanotechnology

Nanodevices

Molecular

Electronics

Mems &

BioMems

Lab on Chip

Sensors &

Detectors

Device

Miniaturization

Nanotools

Fabrication

Techniques

Instrumentation

Metrology &

Analysis

Software

Computation

Simulation

Nanostructured

Materials

Nanoparticles

Supramolecular

Assemblies

Nanocomposites

Representative Types of Nanoparticles

Nanoparticles

Carbon Tubes

-Single Walled

-Multi Walled

Fullerenes

Clays

-Montmorillonite

-Halloysite

-Vermiculite

Metal & Metal Oxides

Silica

POSS

-Molecular Silicas

-Monomers

-Silanols

-Polymers

Nanofibers

Dendrimers

Graphenes

1 mm

0.1 nm

1.0 nm

10 nm

100 nm

1 !m

100 !m

10 !m

Sewing Needle

Razor Blade Thickness

Human Hair

Most Cells & Fibers

Bacteria, Fillers &

Polymer Morphology

Viruses & Nanofillers

Macromolecules

POSS

Building Blocks

Atoms / Small Molecules

0.1-10 nm Defect Nucleation

1-10 nm Critical Nucleus Size

1-10 nm Surface Corrugation

0.5-50 nm Chain Motion Therm-Mech.

1-1000 nm Dislocation Interaction Mechanics

1-100 nm Crack Tip Radius

10-50 nm Entanglement Rad.

0.1-10 nm Primary Structure Polymers

10-1000 nm Secondary Structure

1-100 nm Quantum Well Optical

10-1000 nm Wave Decay

1-100 nm Tunneling Electronics

0.1-5 nm Porosity Control Membranes

1-100 nm Cell Walls Biology

1-10 nm Surface Topology Catalysis

Critical Length Property Field

Why is Nano Important in Materials?

Nanomaterials Are Really Not New

What has been, that will be; what has been done, that will be done.

Nothing is new under the sun. Even the thing which we say, See, this

is new! has already existed in the ages that proceeded us.

Ecclesiastes 1, 9-10

Source: University of Dayton NEST Lab

Carbon Nanotubes

Source:Wikimedia Commons

Source:Peter Harris

Source:Peter Harris

Multi-walled Nanotubes

Source:Hyperion Catalysis

Source:Hyperion Catalysis

Source:Hyperion Catalysis

Carbon Nanotubes

Carbon Nanotubes (CNTs) typically have diameters 1000

times smaller than traditional carbon fibers.

Single-walled CNTs (SWCNTs) consist of a single tubular

graphene sheet and have diameters of 1-2nm.

Multi-walled CNTs (MWCNTs) typically consist of 5-15

tubular graphene layers and have diameters of 10-12nm.

CNTs can be up to 50 times stronger than steel and have

excellent thermal and electrical conductivity.

Fullerenes

RO OR

O O

C

60

Fullerene

Chemically Modified C

60

Fullerene

Endohedral

C

60

Fullerene

Timeline for Fullerenes

(A Cautionary Tale)

In 1985 C

60

is discovered. By 1990 a process for making gram quantities is developed and accelerates

research efforts.

At the end of 2001 Mitsubishi Chemical Corporation and Mitsubishi Corporation establish a joint venture

called the Frontier Carbon Corporation (FCC) with the goal of becoming the world leader in the

commercial production of nano-scale carbon products.

In 2002 FCC claims mass production of 400kg/yr of fullerenes.

By 2003 FCC claims to be operating a 40 tons/year commercial-scale, low-cost plant to produce

fullerenes. FCC claims delivery of fullerene samples at prices ten times lower than 2002 prices. FCC

also claims first commercial product, a bowling ball.

In 2004 FCC claims 400 J apanese companies have purchased samples. Claims that commercial

products in J apan include fiber reinforced composites for badminton rackets, tennis rackets, golf club

shafts, snow boards, ski and snow board wax, lubricants for car air conditioners, and coatings for glass.

In December 2004 FCC establishes Frontier Carbon Corporation of America (FCCA) To meet the

growing commercial demand for nano-scale products in the United States and Europe. FCCA is to

begin production of fullerene materials in the U.S.

In 2005 FCCA announces an agreement with TDA Research to offer a range of fullerene products under

the Nanom product line.

Although many claims about mass production, costs remain high.

Nanoclay

Source:Wikimedia Commons

Source:Southern Clay

Source:Natural Nano

Nanoclay

Almost all nanoclays used in the plastics industry

are minerals which are mined from naturally

occurring deposits.

Montmorillonite is the most widely used clay. It

has a plate-like anisotropic structure and is nano

in only one dimension.

Halloysite is a tube shaped clay having a typical

diameter of 40-200nm and a length of 0.5-10um.

Metal & Metal Oxide Nanoparticles

Source:Nanophase Technologies

Source:Nanophase Technologies

Source:Nanophase Technologies

Metal oxide nanoparticles are actually isolated as

agglomerates, typically over 1,000 nanometers in

size, and behave similarly to conventional powders.

POSS

Nanostructures

One or more reactive

groups for grafting or

polymerization.

Thermally and chemically

robust hybrid

(organic-inorganic)

framework.

Si

Si

O

O

Si

Si

Si

Si

O

O

O

O

Si

O

Si

O

O

O

O

O

R

R

R

R

R

R

R

X

Nanoscopic size

Si-Si distance = 0.5 nm

R-R distance = 1.5 nm.

Precise three-dimensional structure for

molecular level reinforcement of polymer

segments and coils.

Unreactive organic (R)

groups for solubilization

and compatibilization.

Si

Si

O

O

Si

Si Si

O

O

OH

OH

Si

O

Si

O

O

O

O

OH

R

R

R

R

R

R

R

Stable Silanols

Si

Si

O

O

Si

Si

M

Si

O

O

O

O

Si

O

Si

O

O

O

O

O

R

R

R

R

R

R

R

Metal Containing

Why Should We Expect Improvements?

A unique aspect of nanotechnology is the vastly increased ratio of surface

area to volume present in many nano-scale materials.

Nanoparticles in particular have a very high surface area to volume ratio.

For example, montmorillonite nanoclay platelets have a surface area of

750 m

2

/g. This means that ~7g of platelets could cover an area the size

of a football field.

This enormous surface means that in a nanocomposite almost all of the

matrix (polymer) will be in contact with the nanoparticle.

Since the physical properties of the nanoparticles themselves are

generally superior to the polymer matrix this suggests that the properties

of the nanocomposite will trend toward those of the nanoparticle.

Keys to Nanocomposite Polymers

Compatibility: Nanoparticle must have compatibility with matrix.

Dispersion: If good compatibility is achieved, complete dispersion at the

molecular/nano level should occur.

Properties: If dispersion at the molecular/nano level is achieved, improved

optical, physical and mechanical properties should result.

Compatibility ! Dispersion ! Improved Properties

Unfortunately nanoparticles are rarely compatible with polymer matrices

and a tremendous amount of time, money, and effort has gone into trying

to overcome this problem. If the nanoparticle is not acting act the

nanometer level we really should not expect results any different from

those obtained with ordinary macroscopic fillers.

Dispersion of Nanotubes

Poor compatibility between the CNT surface and the matrix lead to difficulty in

exfoliating and debundling CNTs. Poor adhesion of the matrix causes poor

dispersion, phase separation and aggregation of the CNTs making incorporation of

untreated CNTs into polymers difficult.

Several companies have now begun to address these issues by developing

proprietary compatibilizers:

Polymer compatible functionality

CNT Surface compatible functionality

Dispersion of Nanoclay

Clay Particle Clay Platelets

Clay particles consist of groups of stacked platelets. The challenge is to process the

clay nanocomposite so as to achieve complete dispersion of individual platelets.

Dispersion of Nanoclay

Nanoclay must be organically modified in order to achieve compatibility with a

polymer matrix. Long chain alkyl ammonium cations are typically used

N

HO

OH +

Source: Southern Clay Source: Southern Clay

Dispersion of Nanoclay

Source: Southern Clay

Source: Southern Clay

Source: Southern Clay

Good Dispersion,

considered complete

Partial Dispersion,

considered incomplete

Poor Dispersion

Dispersion with POSS

50 wt% loading

and transparent!

phase inversion

Blended into 2 million MW Polystyrene

Si

Si

O

O

Si

Si

Si

Si

O

O

O

O

Si

O

Si

O

O

O

O

O

R

R

R

R

R

R

R R

R = cyclopentyl

Si

Si

O

O

Si

Si

Si

Si

O

O

O

O

Si

O

Si

O

O

O

O

O

R

R

R

R

R

R

R

R = cyclopentyl

Si

Si

O

O

Si

Si

Si

Si

O

O

O

O

Si

O

Si

O

O

O

O

O

R

R

R

R

R

R

R

R = styrenyl

Si

Si

O

O

Si

Si

Si

Si

O

O

O

O

Si

O

Si

O

O

O

O

O

R

R

R

R

R

R

R

R = Phenethyl

partial compatibility

domain formation

Dispersion with POSS

Imaging studies on Nanoreinforced

PP fibers

Molecular Silica dispersion confirmed at molecular level.

* Each black dot represents a 1.5 nm POSS

cage.

Source: Viers - US Air Force Research Laboratory

*scale =50nm.

Si

Si

O

O

Si

Si

Si

Si

O

O

O

O

Si

O

Si

O

O

O

O

O

R

R

R

R

R

R

R

R

Si

O

Si

O

Si

O

Si

O Si

O

Si

O

Si

O

Si

O

Si

O Si

O

Si O

O

Si

R

R

R

O

O

R

R

O

O

O

R

R

R

R

R

R

R

Representative Suppliers of Nanoparticles

Raw materials SWCNTs-HiPco and CNI X Grades Carbon Nanotechnologies, Inc

Raw Material Metal oxides-NanoArc, NanoDur, NanoGard Nanophase

Concentrates CNTs-Kentera Zyvex

Concentrates CNT-Nanoin Nanoledge

Raw Material, Masterbatch CNTs Nanocyl

Raw Material, Masterbatch MWCNTs-Graphistrength Arkema

Raw Material MWCNTs-Baytubes Bayer MaterialScience

Masterbatch MWCNTs-Fibril Hyperion

Compounded products Nanoclay-nanoSEAL Nycoa

Compounded, Concentrates Nanoclay-Nanoblend Polyone

Compounded products Nanoclay, Nanotube RTP Company

Compounded polyolefin Nanoclay-Hyfax Basell

Compounded nylon Nanoclay-Nanomed Foster Corp.

Raw Material Nanoclay-Closite Sothern Clay

Raw Material & Masterbatch Nanoclay-Nanomer, Imperm Nanocor

Raw Material & Masterbatch POSS Hybrid Plastics

How supplied Material supplied Company

Representative Applications of Nanotubes

For the most part, the plastics industry has focused on the use of MWCNTs,

primarily because they are lower cost and the difference in property enhancements

relative to SWCNTs is slight.

Largest use of CNTs is for electrostatic dissipation. Also targeted are improved

mechanical and thermal properties.

In the area of electrostatic dissipation the two largest applications are in automotive

and electronics handling equipment.

In automotive applications CNTs are used in body parts to provide a Class A

surface for electrostatic painting. Another automotive application is fuel line

components such as pumps, lines and housings.

In electronics applications CNTs are used in trays for wafer manufacturing and in

housings for disk drives.

Many applications are in sporting goods to improve mechanical properties of

composites.

Competes with carbon black and carbon fiber.

Representative Applications of Nanoclay

Applications in plastics principally revolve around improving barrier

properties, flame resistance, thermal and structural properties.

Early commercial targets were in automotive and packaging applications.

For automotive applications the target has mainly been weight savings, as

lower loadings of nanoclay can be used to reinforce polymers vs. other

mineral fillers. Clay nanocomposites also provide better surfaces, reduced

CTE and are potentially amenable to recycling.

In packaging the target has been barrier properties. Mainly in the area of

beverages. Other barrier applications have focused on tires and sporting

goods (balls).

Applications for improving fire resistance of plastics also vigorously

pursued.

Competes with traditional inorganic fillers.

Representative Applications of

Metal & Metal Oxides

Primary applications in plastics include antimicrobial, fungal and mold

resistant materials.

Other applications include protection from visible and UV light and

abrasion resistant coatings.

Representative Applications of POSS

Major focus on aerospace and defense applications.

Radiation hardening and shielding.

Food Packaging.

Electronic materials.

Space Resistant materials.

POSS

Barrier in Food Packaging

!POSS

incorporation provides longer product shelf life.

!Improves color printing.

POSS

Oxidation Resistance

MISSE 1 POSS Polyimide Samples: Erosion Depth (m)

POSS

Oxidation Resistance

LER 6.0 nm

Etch Capabilities in Bilayer Resist Design

SLR Resist

Si-based Resist

B

e

f

o

r

e

S

t

r

i

p

A

f

t

e

r

S

t

r

i

p

LER 5.0 nm

LER 6.6 nm

LER 12.9 nm

Much Improved LER after Pattern Transfer due to

Excellent Etch Characteristics of Silicon-based Resist

POSS

Oxidation Resistance

No Pattern Collapse after Etch Transfer

(75 nm line/150nm Pitch)

S i l i c o n b a s e d r e s i s t c a n s u p p o r t

high aspect ratio due to excellent etch selectivity

75nm L/S after dry

development of UL

POSS

Tooth Restoration Products

Examples of Commercial Nanocomposites

Source: Southern Clay

Source: GM

While reports on the use of nanocomposites in

automotive applications were quite frequent as

recently as 2005, there has been a significant

reduction since. Some sources reported that

Nanocomposites would be used in 2006 models,

but it is unclear how much is currently being

used.

Examples of Successful Nanocomposites

Source: Oceanit

Nanotube-containing surfboard

is tested near San Francisco.

Source: Montreal Hockey

Source: Nanoledge

Additional examples include

golf clubs, tennis rackets,

sail boat masts, and skis.

Triton Systems, Inc. - Converse All Star He:01 using ORMLAS polymer

nanocomposite discontinued after initial launch.

InMat, Inc. - Wilson discontinues development of Double Core tennis

ball after initial launch.

Commercial Success can be Short Lived

Honeywell Aegis NC - no longer manufactured. Aegis OX no longer

contains nanocompoite.

Eastman Chemicals Nanocomposites - after significant effort in the area,

intellectual property portfolio for polymer nanocomposites was donated to

the University of South Carolina.

Truths about Nanotechnology

For a successful technology, reality must take precedence

over public relations, for Nature cannot be fooled.

Richard Feynman

US educator & physicist (1918 - 1988)

Truths about Nanomaterials

Nano is not as important as the solution it provides.

Nano has no intrinsic merit other than what it does!

The entry and market capture for nanosolutions

requires vastly more time, capital, and support

than anyone is willing to admit.

Each nanosolution must earn a right to survive

via the application of hard science and economics

rather than reliance on slick marketing.

Trouble Brewing?

Earlier this year DuPont and Environmental Defense combined to launch

a Nano Risk Framework. The framework is designed to provide a

systematic and disciplined process to evaluate and address the potential

risks of nano-scale materials.

In 2005 the EPA announced that it was reclassifying nanosilver as a

pesticide.

In 2005 the Berkeley, CA City Council approved an amendment to their

hazardous materials law to include nano-sized particles which requires

researchers and manufacturers to report what materials they are working

with and how they are handling them. Earlier this year the Cambridge,

MA City Council announced that it is considering a similar law.

Several studies have indicated that carbon nanoparticles might act as

cytotoxins while others have shown that CNTs can have an asbestos like

effect on lung cells. Other studies have found no links between carbon

nanoparticles and cytotoxic effects.

Thank You

Si

Si

O

O

Si

Si

Si

Si

O

O

O

O

Si

O

Si

O

O

O

O

O

R

R

R

R

R

R

R

R

You might also like

- Clay Containing Polymeric NanoComposites, Volume 1, L.A. UtrackiDocument456 pagesClay Containing Polymeric NanoComposites, Volume 1, L.A. Utrackimehrabimajid100% (6)

- 2.natural NaomaterialsDocument2 pages2.natural NaomaterialsNandhini NandhiniNo ratings yet

- Project Report On Synthesis and Characterisation of Fe O - Pva NanocompositeDocument29 pagesProject Report On Synthesis and Characterisation of Fe O - Pva NanocompositeSwagata BanerjeeNo ratings yet

- Characterization of Nano Particles and ApplicationsDocument32 pagesCharacterization of Nano Particles and ApplicationsJiya Zahid100% (1)

- PROJECT CU - CorrectedDocument36 pagesPROJECT CU - CorrectedReshmi MohanNo ratings yet

- GE2023 Fundamentals of Nanoscience L T P C3 0 0 3 Unit I 9Document36 pagesGE2023 Fundamentals of Nanoscience L T P C3 0 0 3 Unit I 9yokeshNo ratings yet

- M5 Nanotechnology and PolynomersDocument6 pagesM5 Nanotechnology and PolynomersMalvika RkNo ratings yet

- NanomaterialsDocument13 pagesNanomaterialsaquib.aquil40036No ratings yet

- Ap 2Document28 pagesAp 2Atif JavaidNo ratings yet

- Clay-Containing Polymer Nanocomposites: From Fundamentals to Real ApplicationsFrom EverandClay-Containing Polymer Nanocomposites: From Fundamentals to Real ApplicationsNo ratings yet

- Fundamental of NanoscienceDocument35 pagesFundamental of NanosciencesrinivasNo ratings yet

- PG Nano Notes Print.Document21 pagesPG Nano Notes Print.vickyNo ratings yet

- Sri Pushpam Nano-New, GCM, PPTDocument48 pagesSri Pushpam Nano-New, GCM, PPTMadhan MohanNo ratings yet

- Faadoo: India'S No.1 Website ForDocument41 pagesFaadoo: India'S No.1 Website ForsunnyNo ratings yet

- Definition of Nano MaterialDocument6 pagesDefinition of Nano MaterialAhmed SobhyNo ratings yet

- Reviewer in Stas (Finals) 2.0Document8 pagesReviewer in Stas (Finals) 2.0A'TINSB19No ratings yet

- Nanochemistry NotesDocument26 pagesNanochemistry Noteswillklinson4No ratings yet

- Additional Presentation For Module 12 NanotechnologyDocument33 pagesAdditional Presentation For Module 12 NanotechnologyKrish TineNo ratings yet

- Nanoscience: NanomaterialsDocument9 pagesNanoscience: NanomaterialsRayan SajibNo ratings yet

- Contemporary Building Material-Unit - 4Document82 pagesContemporary Building Material-Unit - 4architect sowmyaaNo ratings yet

- N S E C A N P B D: Anoscale Cience and Ngineering EnterDocument26 pagesN S E C A N P B D: Anoscale Cience and Ngineering EnterBala SubramanianNo ratings yet

- 2.4 Nanomaterials NotesDocument4 pages2.4 Nanomaterials NotesRalph Rezin MooreNo ratings yet

- Carbon Nanotubes (CNTS) : Presented byDocument27 pagesCarbon Nanotubes (CNTS) : Presented byRakshasa NivatakavachaNo ratings yet

- Project Report On NanoparticlesDocument54 pagesProject Report On Nanoparticlesvijibs83% (6)

- Unit Vii. Engineered Nanomaterials: Page 79 of 83 Modules For CHEM 114 - Chemistry For EngineersDocument5 pagesUnit Vii. Engineered Nanomaterials: Page 79 of 83 Modules For CHEM 114 - Chemistry For EngineersIvyy Joyce BuanNo ratings yet

- Selectedreference - Physics For Engineers (BPH-106) Unit - 4 Advance Material and SynthesisDocument58 pagesSelectedreference - Physics For Engineers (BPH-106) Unit - 4 Advance Material and SynthesisMukesh YadavNo ratings yet

- Topic 7 NanotechnologyDocument8 pagesTopic 7 NanotechnologyAngel Lou DagalaNo ratings yet

- CBM-unit - 4Document74 pagesCBM-unit - 4DEVASHRI ENo ratings yet

- Nanomaterials QD CNTDocument53 pagesNanomaterials QD CNTZeeniakhanNo ratings yet

- Nanomaterials and Their Exotic Properties: Dr. R.Balaji, Thin Film Centre, Department of PhysicsDocument42 pagesNanomaterials and Their Exotic Properties: Dr. R.Balaji, Thin Film Centre, Department of PhysicsGaneshNo ratings yet

- Unit 4 - Advance Material and Synthesis - 2021Document58 pagesUnit 4 - Advance Material and Synthesis - 2021Saurabh Arya RspNo ratings yet

- Carbon Nanotube: Carbon Nanotubes (CNTS) Are Allotropes of Carbon With A Cylindrical NanostructureDocument11 pagesCarbon Nanotube: Carbon Nanotubes (CNTS) Are Allotropes of Carbon With A Cylindrical Nanostructurepraveenkumar_bs2005No ratings yet

- Lecture Notes 3D - Engineered Nanotechnology 2019Document13 pagesLecture Notes 3D - Engineered Nanotechnology 2019Lena BacaniNo ratings yet

- Seminar ReportDocument36 pagesSeminar ReportAbhinav RajNo ratings yet

- Unit Vi Chemistry of Advenced Materials: Rev - Ed. 2014-15Document47 pagesUnit Vi Chemistry of Advenced Materials: Rev - Ed. 2014-15ASumeethKumarNo ratings yet

- Unit 16 - Nano Technology - t1Document41 pagesUnit 16 - Nano Technology - t1dilaroshaNo ratings yet

- Nano FinalDocument40 pagesNano FinalNeelaa BNo ratings yet

- SSJ Campus Almora, Kumaun University: Nanotechnology and Its ApplicationDocument24 pagesSSJ Campus Almora, Kumaun University: Nanotechnology and Its ApplicationSuresh ShahNo ratings yet

- Basic Information About The Carbon Nanotubes (CNTS) : Dr. Dibya Prakash RaiDocument49 pagesBasic Information About The Carbon Nanotubes (CNTS) : Dr. Dibya Prakash RaiArup GhoshNo ratings yet

- Unit3 Carbon NanotubesDocument18 pagesUnit3 Carbon Nanotubestawfigsaeed640No ratings yet

- Development of Nanoparticles: Properties, Applications and UsesDocument18 pagesDevelopment of Nanoparticles: Properties, Applications and UsesrajivNo ratings yet

- Development of Nanoparticles: Properties, Applications and UsesDocument18 pagesDevelopment of Nanoparticles: Properties, Applications and Usesp KumarNo ratings yet

- Applications of NanomaterialsDocument61 pagesApplications of NanomaterialsNikhilNo ratings yet

- Nano MaterialsDocument78 pagesNano MaterialsShiv PatelNo ratings yet

- Nanotechnology Bigthingsfromatinyworld PrintDocument12 pagesNanotechnology Bigthingsfromatinyworld PrintthanhvantvNo ratings yet

- Nano PpsDocument41 pagesNano PpsShravya SirigiriNo ratings yet

- 1 IntroductionDocument10 pages1 IntroductionrevanthkumarreddybNo ratings yet

- Nanochemistry March 2021Document34 pagesNanochemistry March 2021Apeksha SinghNo ratings yet

- Unit - V Nano-Materials Engineering Physics: Origin of Nano TechnologyDocument11 pagesUnit - V Nano-Materials Engineering Physics: Origin of Nano TechnologyKallur Sandilya100% (2)

- Nanomaterials - Wikipedia, The Free EncyclopediaDocument6 pagesNanomaterials - Wikipedia, The Free EncyclopediaGurunath AeroNo ratings yet

- Chapter 1 NTDocument12 pagesChapter 1 NTHarsh ParmarNo ratings yet

- Nithin Seminar ReportDocument19 pagesNithin Seminar Reportmrvishnuraj1999No ratings yet

- Applications of Nano-Catalyst in New Era: Journal of Saudi Chemical SocietyDocument19 pagesApplications of Nano-Catalyst in New Era: Journal of Saudi Chemical SocietyAmit PaulNo ratings yet

- Ashish Rana Singh Regd - 2101287485Document19 pagesAshish Rana Singh Regd - 2101287485pramarth23No ratings yet

- Nanotechnology in NeurosurgeryDocument52 pagesNanotechnology in NeurosurgerybhalNo ratings yet

- Basics of Nano-Materials - Definition, TypesDocument21 pagesBasics of Nano-Materials - Definition, TypesSumit JainNo ratings yet

- 507 Archer BakerDocument11 pages507 Archer BakerWaqas Ahmad KhanNo ratings yet

- Colloidal Foundations of NanoscienceFrom EverandColloidal Foundations of NanoscienceDebora BertiNo ratings yet

- PE6705 Water Flooding and Enhanced Oil Recovery L T P C 3 0 0 3 Objective: Unit I 9Document6 pagesPE6705 Water Flooding and Enhanced Oil Recovery L T P C 3 0 0 3 Objective: Unit I 9Prince ImmanuelNo ratings yet

- Cover Lab ReportDocument5 pagesCover Lab ReportadlenaNo ratings yet

- Pinch Technology/ Process Optimization: 8: Case Study United Refining CompanyDocument80 pagesPinch Technology/ Process Optimization: 8: Case Study United Refining CompanyAnonymous jlLBRMAr3ONo ratings yet

- Background Information: Methodology: ProcedureDocument6 pagesBackground Information: Methodology: ProcedureAlexandra Ramos MNo ratings yet

- Bioinorganic ChemistryDocument12 pagesBioinorganic Chemistrycrisanto valdezNo ratings yet

- Electrochemical Cell LabDocument9 pagesElectrochemical Cell Labribots0% (1)

- Engineering Critical Analyses To BS 7910Document15 pagesEngineering Critical Analyses To BS 7910Mas Arman TewoNo ratings yet

- PWT Aug99 PDFDocument3 pagesPWT Aug99 PDFpanduranganraghuramaNo ratings yet

- Cod and BodDocument57 pagesCod and Boddinesh kumarNo ratings yet

- 3D-QSAR in Drug Design Hugo Kubini Vol. 3Document364 pages3D-QSAR in Drug Design Hugo Kubini Vol. 3vbalaramnavar100% (1)

- Estimate For Water SupplyDocument2 pagesEstimate For Water SupplyAbdulsamad RacmanNo ratings yet

- Kerala PET 2014 PaperDocument40 pagesKerala PET 2014 PaperSonu YadavNo ratings yet

- Structure-Property Relationships of Flexible Polyurethane FoamsDocument10 pagesStructure-Property Relationships of Flexible Polyurethane Foamstoiec hocNo ratings yet

- 3 Effects of Electric Current Physics ProjectDocument20 pages3 Effects of Electric Current Physics ProjectAkshatNo ratings yet

- Mark Scheme (Results) Summer 2016Document31 pagesMark Scheme (Results) Summer 2016NaushinNo ratings yet

- Physics For Scientists and Engineers, 6e: Chapter 41 - Quantum MechanicsDocument15 pagesPhysics For Scientists and Engineers, 6e: Chapter 41 - Quantum MechanicsTom TrầnNo ratings yet

- Densification of Biomass by Briquetting: A Review: October 2017Document9 pagesDensification of Biomass by Briquetting: A Review: October 2017Mauri RangelNo ratings yet

- 26252.9.6. Uniformity of Content of Single-Dose PreparationsDocument1 page26252.9.6. Uniformity of Content of Single-Dose PreparationsMiyyada Aichaoui100% (1)

- Untitled PresentationDocument10 pagesUntitled Presentationanurag singhNo ratings yet

- Stem Gc11cb Iid G 70Document3 pagesStem Gc11cb Iid G 70jeffrey yumang100% (1)

- Ceramic XrayDocument9 pagesCeramic XrayFandi MarcelloNo ratings yet

- Spectrometric Identification of Organic CompoundsDocument466 pagesSpectrometric Identification of Organic CompoundsMarie L100% (5)

- Determination of Dry Rubber Content: 1. ScopeDocument2 pagesDetermination of Dry Rubber Content: 1. ScopeDevender KumarNo ratings yet

- 207 HD 52505 Uv Jam PetrochemicalDocument2 pages207 HD 52505 Uv Jam Petrochemicalriza abdollahyNo ratings yet

- CHAPTER 3c MOLECULAR DIFFUSION IN SOLIDSDocument18 pagesCHAPTER 3c MOLECULAR DIFFUSION IN SOLIDSkiran367No ratings yet

- Chemistry Sample Syllabus 2 Id 1029717v1Document13 pagesChemistry Sample Syllabus 2 Id 1029717v1Wong Weng SiongNo ratings yet

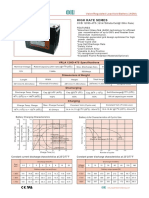

- High Rate Series: CCB 12HD-475Document1 pageHigh Rate Series: CCB 12HD-475orunmila123No ratings yet

- Avogadro ActivityDocument4 pagesAvogadro ActivityShazmie Mohammad NadziriNo ratings yet

- NT Mat 003 - Assessment of Corrosion Protection Classes For Inorganic Coatings On Steel - Nordtest MethodDocument7 pagesNT Mat 003 - Assessment of Corrosion Protection Classes For Inorganic Coatings On Steel - Nordtest MethodCorina StanculescuNo ratings yet

- Is-1479-Part-1.1960-Rapid Examinations of MilkDocument44 pagesIs-1479-Part-1.1960-Rapid Examinations of MilkStacy WilsonNo ratings yet