Professional Documents

Culture Documents

6 Ch09 Joints

Uploaded by

Mumtaz Ahmad QaisraniCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6 Ch09 Joints

Uploaded by

Mumtaz Ahmad QaisraniCopyright:

Available Formats

1

CHAPTER 9:

PRINCIPLES OF JOINTS AND

SEALANTS

Expansion and Contraction Control

Expansion & Contraction Control Introduction

Principles of Joints and Sealants

Joints in Buildings

(a) Joints are a common feature in buildings, particularly on building facades. Some of

these joints are aesthetic joints to provide surface relief, rhythm, patterns, and so on,

while others are provided for performance reasons related to building design and (or)

construction. (b) The fasteners used in the joint in the copper cladding of Burton Barr

Central Library, Phoenix, Arizona, contribute to the rhythm and pattern in the cladding.

(c) The textured surface and the bold horizontal lines in the exterior concrete walls of

the same library building relieve the monotony of a large concrete surface.

Static and Movement Joints

Static joint a nonmoving joint (connection) between

the components.

In the case of the window glass and frame, a static joint

would most likely result in broken glass, broken frame,

or both.

Dynamic joint or movement joint a connection that

allows both materials to move independently and at

the same time hold the window glass securely in the

frame.

Expansion & Contraction Control Types of

Movement Joints

Principles of Joints and Sealants

Types of Movement Joints

Based on the purpose they serve, movement joints

are classified as

Building joints joints between different parts of the

building as a whole

Component joints joints between individual

components of an assembly

2

Types of Movement Joints contd

A building joint divides the entire building into two

or more separate buildings.

Based on the purpose for which it is provided, it is

classified as either a building separation joint or a

seismic joint .

A joint between two adjacent building components

can be an expansion joint , a contraction joint

(commonly called a control joint), or an isolation

joint .

Types of movement joints in a building.

Expansion & Contraction Control Building

Separation Joints and Seismic Joints

Principles of Joints and Sealants

Building Separation Joints

A building separation joint prevents the stresses created in one

part of the building from affecting the integrity of the other

part.

Needed in large buildings.

Rough guide:

Provided at 250-ft (75-m) intervals

Provide building separation joints at the following discontinuities:

Where a low building mass meets a tall mass.

Where the building changes direction, such as in an L-shaped or T-

shaped building.

Where the buildings structural material changes, such as where a

steel frame building meets a concrete frame.

Building Separation Joints contd

A building separation joint should divide the building into smaller, structurally

independent sections (as if they are separate buildings) so that each section is

geometrically simple.

Building Separation Joints contd

A building separation joint runs through the entire building from the ground floor (or the

basement, if provided) up to the roof. Two columns are often used at the separation

joint. However, a combined footing may be used for the two adjacent columns.

3

Building Separation Joints contd

Building separation joint with two columns in a reinforced concrete building. Because

the building is under construction, daylight is showing through the joint between the

columns. In a completed building, the joint is sealed and covered with a joint cover, as

is the case here for the separation joint in the floor.

Building Separation Joints contd

Building separation joint with two columns and two beams in a steel frame building.

Because the building is under construction, daylight is showing through the joint between

the columns. In a completed building, the joint is sealed and covered with a joint cover.

Building Separation Joints contd

Building separation joint using a single column in a reinforced concrete building.

Observe the provision of a beam on each side of the separation joint.

Building Separation Joints contd

Building separation joint in a steel frame building using a single column. Because the

building is under construction, daylight is showing through the separation joint. In a

completed building, the joint is sealed and covered with a joint cover. Observe the

provision of a steel joist on each side of the separation joint.

Seismic Joints vs. Building Separation

Joints

A seismic joint is similar to but also different from a

building separation joint.

Building separation joints accommodate moderate building

movements caused by temperature and moisture changes,

creep, and foundation settlements.

Building separation joints are designed to accommodate

mainly horizontal movement, that is, in the direction

perpendicular to the joint.

Seismic Joints

The purpose of seismic joints is to ensure that one

section of the building does not collide with the

adjacent section during an earthquake.

A seismic joint must accommodate simultaneous

movements in horizontal as well as vertical directions,

that is, in all three principal directions.

A seismic joint is generally much wider than a building

separation joint.

4

Covers Over Building Separation or

Seismic Joints

A typical detail of a building separation joint cover at the floor level. Similar covers

are provided in interior and exterior walls and roofs. Joint cover manufacturers details

and specifications should be strictly followed for structural, fire rating, and other

performance reasons.

Expansion & Contraction Control Movement

Joints in Building Components

Principles of Joints and Sealants

Movement Joints in Building

Components

Movement in a building component can be caused

by several phenomena.

Factors that must be considered in sizing and

detailing movement joints in building components:

Thermal movement

Moisture movement

Elastic deformation and creep

Construction tolerances and other considerations

X indicates the presence of particular movement in the material andindicates the

absence of such movement.

Importance of Movement Joints in

Building Components

Importance of Movement Joints in

Building Components contd

(a) An acrylic sheet in an un-deformed state. (b) Deformation of the same sheet (nearly

4 ft long) shortened by approximately1/16 in. at each end by placing 25-cent coins.

Note that the (lateral) deformation of the sheet (approximately 2 in.) is much larger

than the longitudinal shortening (approximately 18 in.).

5

Expansion & Contraction Control Thermal

Movement

Principles of Joints and Sealants

Thermal Movement

Eq. (1)

BuildingConstruction: Principles, Materials, &Systems, 2e

Mehta, Scarborough, and Armpriest

2013, 2010, 2008 by Pearson Higher Education,

Upper Saddle River, NJ 07458. All Rights Reserved.

Thermal Movement contd Coefficient of Thermal Expansion ( )

Annual Temperature Change (

t

)

Annual temperature change (

t

) to which a building component is subjected in the

United States.

Estimating Thermal Movement

Example 1

6

Estimating Thermal Movement

Example 1 - contd

Estimating Thermal Movement

Example 2

Expansion & Contraction Control Moisture

Movement

Principles of Joints and Sealants

Moisture Movement

Portland cementbased materials shrink due to

moisture loss.

Because the moisture loss continues for several

weeks after construction, portland cementbased

components keep shrinking long after they are

placed in a wall or slab.

Therefore, concrete slabs, concrete and concrete

masonry walls, and stucco require shrinkage joints

more commonly referred to as control joints .

Moisture Movement in Concrete and

Masonry

Clay (brick) masonry units expand on absorption of

water or water vapor. This expansion, which occurs

during and after construction, is irreversible; that is, clay

masonry does not shrink on drying.

In fact, a brick unit is smallest in size when it comes out

of the kiln, after which it grows in size.

Thus, brick masonry walls require expansion joints .

The amount of moisture movement in concrete and

masonry is given by

Eq. (2)

Moisture Movement in Concrete and

Masonry

The amount of moisture movement in concrete and

masonry is given by

= moisture expansion or contraction

of a unit of length L and is the

moisture coefficient of the material.

The values of are given in Table

9.2 . Note that has no units. It is

simply a number.

7

BuildingConstruction: Principles, Materials, &Systems, 2e

Mehta, Scarborough, and Armpriest

2013, 2010, 2008 by Pearson Higher Education,

Upper Saddle River, NJ 07458. All Rights Reserved.

Moisture Movement in Wood

The microstructure of wood

consists of hollow cellular

tubes bundled together.

The walls of the tubes shrink

and swell, depending on

the ambient airs humidity

and temperature, changing

the dimensions of a wood

member.

Estimating Moisture Movement

Example 3

Estimating Moisture Movement

Example 4

Expansion & Contraction Control Elastic

Deformation and Creep

Principles of Joints and Sealants

Elastic Deformation and Creep

Instantaneous (elastic) deflection (A) and creep (inelastic) deflection (B) of a beam. The

dashed lines show the unloaded condition of the beam. Creep is the incremental

deformation of a component caused by sustained loading.

BuildingConstruction: Principles, Materials, &Systems, 2e

Mehta, Scarborough, and Armpriest

2013, 2010, 2008 by Pearson Higher Education,

Upper Saddle River, NJ 07458. All Rights Reserved.

Deflection of Spandrel Beam

If a non-load-bearing wall

is placed directly under a

spandrel beam, an

adequate space between

the beam and the top of

the wall should be provided

to allow the beam to

deflect under the load.

If adequate space is not

provided, the load from the

beam will be transferred to

the wall, damaging it.

The connection between the spandrel beam

and the non-load-bearing wall below must

account for the beams deflection.

8

Expansion & Contraction Control Total Joint

Dimension

Principles of Joints and Sealants

Total Joint Dimension

Factors to be considered when determining joint

dimensions include:

Thermal, moisture, elastic, and creep deformations

Material tolerances (i.e., building components vary from

their specified dimensions).

Construction tolerances

Construction tolerances are a function of quality

control during construction.

Eq. (3)

Width of joint =

with based on temperature,

moisture, and other

movements

+ tolerances

Effect of a Sealant on Joint Dimension

Most joints in building envelope components are filled with elastomeric sealants.

Sealants have a finite ability to cyclically stretch and compress, which is given as the plus-

minus movement ability of the sealant.

The plus value denotes the maximum stretch the sealant can withstand, and the minus value denotes the

maximum compression it can sustain.

Sealants are generally classified based on their movement ability.

A sealant with a movement ability of 25 is called a class 25 sealant . Such a sealant is able to stretch

and compress by 25% of its installed dimension. Similarly, a sealant with a movement ability of 50 is

called a class 50 sealant.

If the width of a joint at the time the sealant is applied to it is 1 in., a class 50 sealant will

safely stretch to 1.5 in. or compress to 0.5 in.

The movement ability of sealants must be included in determining the total joint width of a

sealed joint. Therefore, the total joint width of a sealed joint is given by

Eq. (4)

Joint width of sealed joint =

100

[joint movement] + tolerances

Sealant class

Estimating Total Joint Width Between

Components Example 5

Expansion & Contraction Control Principles of

Joint Detailing

Principles of Joints and Sealants

Principles of Joint Detailing

In detailing a movement joint in a component, it is

important to distinguish between an expansion joint

and a control (shrinkage) joint .

Because the joint width in an expansion joint will

become smaller over time, the filler in an expansion

joint (if used) must be elastomeric to allow

unrestrained movement of the components.

9

Detail of an Expansion Joint

Detail of an expansion joint in a brick veneer wall. The joint is filled with a compres-

sible backer rod and an elastomeric sealant.

Detail of a Control Joint

Detail of a control joint in a concrete masonry wall.

Expansion & Contraction Control Components

of a Sealed Joint

Principles of Joints and Sealants

Components of a Sealant Joint

The primary purpose of sealing a joint is to prevent water

penetration.

However, control of air leakage, dust penetration, and noise

transmission are additional benefits of sealing a joint.

An unsealed joint may also get filled with incompressible materials

over time, resulting in joint failure.

Although joint sealant is the most important component of a sealed

joint, these other components must also be carefully selected:

Substrate

Primer

Sealant backup

Bond breaker

Un-tooled and Tooled Sealants

Un-tooled and tooled sealants in joints. Note that the depth of the sealant must be at

least half the width of the joint.

Bond Breaker

For the sealant to function effectively, it should be bonded to

only two opposite surfaces of the substrate so that it comes

under axial tension or axial compression when the joint

moves.

A bond breaker is required only if the third surface is hard

and unyielding, such as concrete, metal, masonry, or any other

inflexible backup.

A bond breaker is not required with a flexible backup that

will not significantly restrict the freedom of sealant movement.

A bond breaker is not required in a conventional joint with a

foam backer rod.

10

Use of a Bond Breaker

An ideal sealed joint should only be bonded to two opposite surfaces so that the

sealant is subjected to either tension or compression. A bond between the sealant and

the third (in this case, the rear) surface may cause sealant failure, as shown in (b),

because of the adhesion of sealant to the third surface. Therefore, where a third

surface exists in a sealed joint, a bond breaker should be used, as shown in (c).

Expansion & Contraction Control Types and

Properties of Joint Sealants

Principles of Joints and Sealants

Types and Properties of Joint Sealants

Joint sealants may be divided into three categories:

Preformed tapes

Caulks

Elastomeric sealants

Types of Elastomeric Sealants

Elastomeric sealants are synthetic materials

(polymers) and are the ones most commonly used in

contemporary construction.

The five commonly used synthetic sealants are

1. Polyisobutylene

2. Acrylics

3. Polyurethane

4. Polysulfide

5. Silicone

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Productivity Rate (Labor & Eqpt)Document35 pagesProductivity Rate (Labor & Eqpt)archie_72882% (192)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- NTC 1500 Cuarta ActualizacionDocument237 pagesNTC 1500 Cuarta ActualizacionAndrés FzNo ratings yet

- Ashrae 189.1Document85 pagesAshrae 189.1RyanNo ratings yet

- 2020-Numerical Study and Correlations For Heat and Mass Transfer (Wan)Document17 pages2020-Numerical Study and Correlations For Heat and Mass Transfer (Wan)Mumtaz Ahmad QaisraniNo ratings yet

- Renewable Energy Resources KS4Document37 pagesRenewable Energy Resources KS4Varun Karthikeyan ShettyNo ratings yet

- 2009 - Numerical Simulation of A Semi-Indirect Evaporative Cooler (R. Herrero Martin) PDFDocument10 pages2009 - Numerical Simulation of A Semi-Indirect Evaporative Cooler (R. Herrero Martin) PDFMumtaz Ahmad QaisraniNo ratings yet

- 2009 - Numerical Simulation of A Semi-Indirect Evaporative Cooler (R. Herrero Martin) PDFDocument10 pages2009 - Numerical Simulation of A Semi-Indirect Evaporative Cooler (R. Herrero Martin) PDFMumtaz Ahmad QaisraniNo ratings yet

- BIOL 435 L4 Water MovementDocument10 pagesBIOL 435 L4 Water MovementMumtaz Ahmad QaisraniNo ratings yet

- Energy and Civilization: Patterns of ConsumptionDocument39 pagesEnergy and Civilization: Patterns of ConsumptionMumtaz Ahmad QaisraniNo ratings yet

- Fluid Mechanics and Energy TransportDocument33 pagesFluid Mechanics and Energy TransportMumtaz Ahmad QaisraniNo ratings yet

- Fluid Mechanics: Dimensional Analysis and SimilitudeDocument44 pagesFluid Mechanics: Dimensional Analysis and SimilitudeMumtaz Ahmad QaisraniNo ratings yet

- Flow Over Immersed Bodies: General CharacteristicsDocument19 pagesFlow Over Immersed Bodies: General CharacteristicsMumtaz Ahmad QaisraniNo ratings yet

- Renewable Energy Resources KS4Document37 pagesRenewable Energy Resources KS4Varun Karthikeyan ShettyNo ratings yet

- C Fossil Fuel TrendsDocument28 pagesC Fossil Fuel TrendsMumtaz Ahmad QaisraniNo ratings yet

- Renewable Energy Systems Lecture 1Document47 pagesRenewable Energy Systems Lecture 1Mumtaz Ahmad QaisraniNo ratings yet

- Informe InstrumentacionDocument45 pagesInforme InstrumentacionmaxparionaNo ratings yet

- Flow Over Immersed Bodies: General CharacteristicsDocument16 pagesFlow Over Immersed Bodies: General CharacteristicsMumtaz Ahmad QaisraniNo ratings yet

- Fluid DynamicsDocument44 pagesFluid DynamicsMumtaz Ahmad QaisraniNo ratings yet

- Fluid Mechanics: Dimensional Analysis and SimilitudeDocument44 pagesFluid Mechanics: Dimensional Analysis and SimilitudeMumtaz Ahmad QaisraniNo ratings yet

- ViscousDocument20 pagesViscousMumtaz Ahmad QaisraniNo ratings yet

- S135943111931347XDocument1 pageS135943111931347XMumtaz Ahmad QaisraniNo ratings yet

- Revised: Optimal Design of Horizontal-Axis Wind Turbines Using Blade-Element Theory and Evolutionary ComputationDocument20 pagesRevised: Optimal Design of Horizontal-Axis Wind Turbines Using Blade-Element Theory and Evolutionary ComputationMumtaz Ahmad QaisraniNo ratings yet

- Meshing Tutorial Ans - SysDocument350 pagesMeshing Tutorial Ans - SysCortesar ManuNo ratings yet

- Creating Solid Models From Surface Models Using Solidworks 2015cDocument31 pagesCreating Solid Models From Surface Models Using Solidworks 2015cAnonymous kAlcedIbNo ratings yet

- Fluid Mechanics and Energy TransportDocument33 pagesFluid Mechanics and Energy TransportMumtaz Ahmad QaisraniNo ratings yet

- Final Master Thesis - Waste-To-Energy Recovery Technologies in Pakistan PDFDocument74 pagesFinal Master Thesis - Waste-To-Energy Recovery Technologies in Pakistan PDFMumtaz Ahmad Qaisrani100% (1)

- Intro To RoboticsDocument83 pagesIntro To RoboticsMumtaz Ahmad QaisraniNo ratings yet

- 9 - Ch21 - Lime IbtmDocument16 pages9 - Ch21 - Lime IbtmMumtaz Ahmad QaisraniNo ratings yet

- 08B - Chapter 8, Sec 8.4 - 8.8 BlackDocument18 pages08B - Chapter 8, Sec 8.4 - 8.8 BlackAli HazratNo ratings yet

- 1 Ch03 LoadsDocument10 pages1 Ch03 LoadsMumtaz Ahmad QaisraniNo ratings yet

- Buidling Material and SteelDocument15 pagesBuidling Material and SteelMumtaz Ahmad QaisraniNo ratings yet

- 8 Ch19 SteelDocument13 pages8 Ch19 SteelMumtaz Ahmad QaisraniNo ratings yet

- Buidling Material and SteelDocument15 pagesBuidling Material and SteelMumtaz Ahmad QaisraniNo ratings yet

- Pouring Permit 14k00302 - 6Document4 pagesPouring Permit 14k00302 - 6Abigail Sumatra CalunodNo ratings yet

- Use of Plastics in Different Aspects of The Construction IndustryDocument7 pagesUse of Plastics in Different Aspects of The Construction Industryjanhavi28No ratings yet

- 20EG0075 Widening of ITRDocument1 page20EG0075 Widening of ITRjayson mariNo ratings yet

- BQ - Supporting Building KendalDocument1 pageBQ - Supporting Building KendalKkn TematikNo ratings yet

- Uponor Underfloor Heating Installation GuideDocument56 pagesUponor Underfloor Heating Installation GuidePetre Iosub100% (1)

- BOQ Metal WorkDocument10 pagesBOQ Metal WorkNadeesha WeerasekaraNo ratings yet

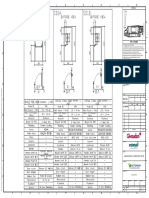

- Corrugated Double Wall Cable Protection PipeDocument8 pagesCorrugated Double Wall Cable Protection PipeAnonymous hi0K1YNo ratings yet

- Vitosolic 200 M1 GBDocument92 pagesVitosolic 200 M1 GBIlarion HoteaNo ratings yet

- BEHAVIOUR AND STRENGTH ASSESSMENT OF Masonry PrismsDocument42 pagesBEHAVIOUR AND STRENGTH ASSESSMENT OF Masonry Prismsmanish_shashikantNo ratings yet

- Fire Barrier Composite Sheet CS-195+Document4 pagesFire Barrier Composite Sheet CS-195+PringetteNo ratings yet

- Floor SystemDocument14 pagesFloor SystemCJ Ong100% (1)

- Specifications: Project: Proposed Two (2) Storey Residential Location: OwnerDocument4 pagesSpecifications: Project: Proposed Two (2) Storey Residential Location: OwnerJ.P.Almera ArDesignNo ratings yet

- M25 DesignDocument4 pagesM25 DesignAmit KumarNo ratings yet

- Vision Built Steel Frame Building System: Systèmes Pour Constructions BausystemDocument36 pagesVision Built Steel Frame Building System: Systèmes Pour Constructions BausystemKyaw Zin HeinNo ratings yet

- Pile Bearing CapacityDocument34 pagesPile Bearing CapacityGema Putra PratamaNo ratings yet

- Fume Hood CatalogDocument42 pagesFume Hood CatalogJasmi Futihal UlaNo ratings yet

- Basic Package Basic Package For Turnkey House Construction Designs & DrawingsDocument3 pagesBasic Package Basic Package For Turnkey House Construction Designs & DrawingsSudheer KmNo ratings yet

- One Way Slab Design: 1. Calculation of LoadDocument6 pagesOne Way Slab Design: 1. Calculation of LoadSaugat ThapaNo ratings yet

- Shop Drawing: Key PlanDocument1 pageShop Drawing: Key PlanEko WiyonoNo ratings yet

- Batch 06,1604 17 732 320Document36 pagesBatch 06,1604 17 732 320syed AffanNo ratings yet

- Recommended Piping Practices For Steam Heating CoilsDocument1 pageRecommended Piping Practices For Steam Heating CoilsJam AvilésNo ratings yet

- Tenants' Repair Manual: Reporting Your RepairsDocument14 pagesTenants' Repair Manual: Reporting Your Repairsmatthilton2005No ratings yet

- ACI 318-14 Chile 2 Slides Per PageDocument36 pagesACI 318-14 Chile 2 Slides Per PageJose Jacobo Alvarez Saint-HilaireNo ratings yet

- Concrete Pier Design Based On ACI 318-05: Input Data & Design SummaryDocument3 pagesConcrete Pier Design Based On ACI 318-05: Input Data & Design SummaryARAVINDNo ratings yet

- Project: Conti'S Bakeshop & Restaurant - SM Bacoor: LOCATION: Unit 134, Upper Ground Floor, SM City Bacoor, CaviteDocument1 pageProject: Conti'S Bakeshop & Restaurant - SM Bacoor: LOCATION: Unit 134, Upper Ground Floor, SM City Bacoor, CaviteAndrew Paul BatacNo ratings yet

- ConstructionCatalog2015Document44 pagesConstructionCatalog2015racing.phreakNo ratings yet