Professional Documents

Culture Documents

75217

Uploaded by

Jose BarreroOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

75217

Uploaded by

Jose BarreroCopyright:

Available Formats

Copyright 2002, Society of Petroleum Engineers Inc.

This paper was prepared for presentation at the SPE/DOE Improved Oil Recovery Symposium

held in Tulsa, Oklahoma, 1317 April 2002.

This paper was selected for presentation by an SPE Program Committee following review of

information contained in an abstract submitted by the author(s). Contents of the paper, as

presented, have not been reviewed by the Society of Petroleum Engineers and are subject to

correction by the author(s). The material, as presented, does not necessarily reflect any

position of the Society of Petroleum Engineers, its officers, or members. Papers presented at

SPE meetings are subject to publication review by Editorial Committees of the Society of

Petroleum Engineers. Electronic reproduction, distribution, or storage of any part of this paper

for commercial purposes without the written consent of the Society of Petroleum Engineers is

prohibited. Permission to reproduce in print is restricted to an abstract of not more than 300

words; illustrations may not be copied. The abstract must contain conspicuous

acknowledgment of where and by whom the paper was presented. Write Librarian, SPE, P.O.

Box 833836, Richardson, TX 75083-3836, U.S.A., fax 01-972-952-9435.

Abstract

Fractures and fractured zones require special reservoir

development plan. They may improve or hider the oil

production. Conductive fracture rocks may provide the

required permeability to drain an oil saturated low

permeability rock matrix. Low sweep efficiency of many oil

reservoirs may be the result of channeling of injected water

through high permeability zones that normally associated with

fracture system in heterogeneous reservoirs. In this case

substantial amount of work focused on improving the

distribution of injected water in the wellbore through different

treatments: using gelling agents, cements, cross-linked

polymer and emulsions. Other alternatives such as microbial

and surfactant based methods have been proposed. This paper

presents the results of research conducted on thermophilic

bacteria that were obtained from UAE local environment.

Coreflooding experiments were conducted on single fractured

cores to show the effectiveness of microbial treatment.

Different fracture angel orientations 45, 90, and 180 of the

axis of the flow were investigated. The effect of matrix

permeability on the treatment was also studied. A comparison

between water flooding and microbial flooding of fractured

systems were investigated. Non-invasive imaging technique

such as Scanning Electron Microscopy (SEM) was employed

to visualize changes on the surface of the fracture as a result of

bacteria flow through the system.

Introduction

The use of microorganism to enhance oil recovery has for

many years been considered as possible by many

investigators. Beckman

1

realized that bacteria are capable of

producing oil as early as 1926.

Zobell

2

performed the first

detailed work of MEOR

in the 1940s. Successful field trials,

in later years, have been reported from the US, Eastern

Europe, and Australia as indicated in Ref. 3 and 4. Based on

the fact that MEOR processes were recognized nearly 70 years

ago, one would think that this technology is in wide use today.

On the contrary, the general perception is quite the opposite.

The negative perception on the use of bacteria for EOR has

been attributed to inadequate methods for transfer of

technology

5

. MEOR processes are potentially cost effective

and particularly well suited for todays economic climate.

Portwood

5

, after review of hundreds of projects, concluded

that the cost of MEOR process ranges from $ 0.25 to $ 0.50

per barrel of oil produced at the time MEOR begins, and does

not go up as oil production increases. The total cost of

incremental oil produced from MEOR is only about $2.00 per

barrel. In addition, MEOR processes are considered

environmentally friendly as verified by tests conducted by

public health laboratories that reported that the mixed culture

of bacteria is safe to handle and poses no threat to plants,

animals, or human beings

5

.

Microorganisms used for MEOR processes rely on

microscopic oil displacement for improving the efficiency of

oil recovery. The most common species are those of Bacillus

and Clostridium. These microorganisms have a greater

potential for survival under petroleum reservoirs harsh

environmental conditions than other species because they

produce in-situ spores, which are dormant, resistant forms of

the cells that can survive under stressful environmental

conditions. Clostridium species produce surfactants, gases,

alcohols, and solvents, whereas some Bacillus species produce

surfactants, acids, and some gases. In the MEOR process, it is

vital that microorganisms can travel through the porous media

and mobilize oil.

Laboratory research has shown that microbial products can

change the chemical and physical properties of oil, and can

selectively plug high permeability zones, which results in

improvement in volumetric sweep efficiency

7

. Once the

bacteria are in place, a designed volume of nutrients may be

injected into the reservoir to support in situ metabolism of the

bacteria. The result of this metabolism is the production of

cellular mass capable of initiating physical plugging. The

physical plugging results in a reduction of the original

permeability and can be expressed as the ratio of impaired to

original permeability. Continuous injection will result in a

diversion of the injected fluid from closed high permeability

zones to upswept zones and significant improvement in

SPE 75217

Microbial and Waterflooding of Fractured Carbonate Rocks: An Experimental Approach

Abdulrazag Y. Zekri, SPE, and Reyadh A. El-Mehaideb, SPE, United Arab Emirates University

2 A. ZEKRI AND R. EL-MEHAIDEB SPE 75217

overall sweep efficiency. Raleigh

8

investigated the nature of

formation plugging with bacteria using dead bacteria (Bacillus

subtillis) and four specific rock types (two sandstone and two

carbonate). Raleigh concluded that pore geometry factor was

a significant petro-physical rock characteristic for correlation

with depth of plugging. Jenneman et al.

9

used indigenous

microbes to the Burbank injection brine to plug off high-

permeability layers through the growth of microbes and to

divert injection fluid to lower-permeability, higher oil

saturation zones. Jenneman

9

observed a 30% drop in the

effective permeability to the injected fluids. Stepp et al.

10

employed polymer-producing bacteria designated as NIPER

11 (Leuconostoc mesenteroides) to improve conformance

control in porous media. They reported a reduction of

effective permeability by as much as 90% due to in situ

polymer production. Bae et al.

11

used a halotolerant, spore-

forming mesophile as microbial near-wellbore profile

modification. They concluded that the spores can effectively

reduce the permeability of sandstone cores and the degrees of

permeability reduction depend on many variables.

Recently more work focused on the improvement of sweep

efficiency using microbial flooding process. Nagase et al.

12

investigated the possibility of using a microorganism named

CJF-002 to plug high permeability zones in Fuyu oilfield.

They injected the polymer-producing microbe into 6

production wells as huff-n-puff test (single cycle). Four wells

indicated oil production increase and water cut decrease.

Based on these results, microbial treatment was conducted at

injection wells for injection profile modification and the effect

of this process has not been confirmed yet. Kadarwati et al.

13

tried to find a cost effective nutrient that will stimulate the

growth of in-situ microbes in Caltex Pacific Indonesia (CPI)

oil fields to create sufficient biological products to plug high-

permeability reservoir thief zones. The primary findings of

their study showed that several nutrients were successful at

creating bioproducts at high temperature and low salinity

conditions, and that molasses may be the most cost effective

nutrient. Han et al.

14

have simulated the effects of fracture

characteristics on the reduction of effective permeability of

fractured rocks due to in-situ bacteria growth. The results

showed that in-situ bacteria growth reduces the permeability

hyperbolically, but the porosity of backbone fracture does not

change significantly.

Material & Apparatus

Bacteria. Mixture strains of bacteria rounded and rod shape

type, both belonging to the Bacillus family, were obtained

from the UAE local hot water streams. These bacteria were

unique in their tolerance of the high temperature and salinity

conditions prevailing in the UAE environment.

Medium. The growth medium was prepared in 10,000 m L

sterilized bioreactor. The bioreactor contained 0.1 liter of

indigenous microbial solution and 3.9 liter of 5% NaCl

solution. In this medium, 10 gram of nutrient (containing

bouillon and yeast-extract) was added. The medium was well

mixed and bacteria count was taken before using the microbial

solution in any experiment. This medium was repeatedly

prepared prior to conducting all of the reported experiments in

this project to insure having fresh and the same bacteria

concentration, which around 10

5

cells/ml, at start of

the experiment.

Rock and Fluids. Limestone cores obtained from outcrops at

Hafeet mountains (Al-Ain, UAE) were cut on average into

2.23.89 cm, 3.817.74, or 3.816.02 cm cylinders using a

core cutting device. The porosity and permeability of these

cores are listed in Table 1. Crude oil was obtained from

United Arab Emirates oil field (AH). The crude oil properties

are presented in Table 2. Cores were cut according to the

required angel, see Figure1, and placed accordingly with a

tissue paper placed along the fracture plane.

Core Flooding Apparatus. The schematic diagram of the

core flooding apparatus is shown in Figure 2. Two fluid

accumulators are connected to a variable rate injection pump.

The core holder is placed in a variable temperature oven.

Pressure and temperature transducers are connected at both

ends of the core inside the core holder. A chart recorder and a

digital pressure recorder are connected to the temperature

transducer and pressure transducer respectively.

Experimental Procedure

Initial tests involved the growth of bacteria in the air curtain

bioreactor under a 22C room temperature. A 10-g/4000 ml of

the Nutrient is added to the microbial solution. The next step

is to observe the bacteria growth as a function of time.

The limestone cores were dried at 80C for 72 h. Each core

was evacuated for 12 h and saturated with 5% (by weight)

brine solution. During this step, we measured the volume of

water required to completely saturate a core in order to

determine its pore volume and porosity. Cores were cut

according to specified fracture angel (45, 90, and 180) of

the axis of the flow and paper napkins were placed along the

fracture plane. Proper zinc coating was applied to each core to

keep the two pieces of the core together and to obtain a tight

fit inside the core holder. The core was placed in the core

holder and put under a confining pressure of 200 psig. Brine

permeability of the cores was measured prior to and after

cutting the cores to establish matrix and fracture permeability.

The displacement processes were studied by two-phase flow

experiments in which injection rates, production volumes, and

pressure drops were measured. Material balance type of

analysis was performed to determine the fluid saturations.

Each core was then flooded at a high rate with the AH crude

until no further brine was produced. The residual brine

saturation for each core was calculated from the recovered

effluent brine volumes. Six runs were conducted; in the first

three runs cores (SZ5, ASD11, OP8) were flooded

individually with a brine solution (5 weight % salt) until oil

production seized (water cut = 100%). The residual oil

saturation from the volume of oil produced for each core and

the initial absolute core permeability to brine were calculated

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Operation Manual: XQ140/12Y Hydraulic Power TongDocument44 pagesOperation Manual: XQ140/12Y Hydraulic Power TongAgustin Roncallo100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Versa Matic 3 Pulg Clamped - ManualDocument19 pagesVersa Matic 3 Pulg Clamped - ManualJose BarreroNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Manual ElevatorDocument124 pagesManual ElevatorJulian Felipe Noguera Cruz100% (3)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- OI-6000 Gen2 USer GudeDocument72 pagesOI-6000 Gen2 USer GudeJose BarreroNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- TI Manual G Series ElevatorDocument12 pagesTI Manual G Series Elevatorvipequi50No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Versa Matic 3 Pulg Clamped - Data SheetDocument1 pageVersa Matic 3 Pulg Clamped - Data SheetJose BarreroNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Valvulas de Aire - ManualDocument16 pagesValvulas de Aire - ManualJose BarreroNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Xyq12a PDFDocument54 pagesXyq12a PDFSebastián ReumannNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- FAQs - Safety NTL Update 7-9-10Document12 pagesFAQs - Safety NTL Update 7-9-10Jose BarreroNo ratings yet

- Motor Lincoln 286 TSCDocument5 pagesMotor Lincoln 286 TSCJose BarreroNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Caterpillar C15 Engine SpecsDocument5 pagesCaterpillar C15 Engine Specsjinxy5779100% (4)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Motor Trifasico Baldor 50 HPDocument1 pageMotor Trifasico Baldor 50 HPJose BarreroNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

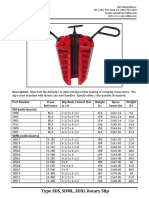

- Type SDS SDML SDXL Rotary Slip Cut SheetDocument2 pagesType SDS SDML SDXL Rotary Slip Cut SheetJose Barrero100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- CAT 3406 C Heavy Duty Truck EngineDocument5 pagesCAT 3406 C Heavy Duty Truck EngineAS_865025438100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Catalogo Varco BJDocument56 pagesCatalogo Varco BJJhon CastRo78% (9)

- Bomba de Lodos BH 800 PDFDocument36 pagesBomba de Lodos BH 800 PDFJose Barrero0% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Hydril GK Annular Blowout Preventers: 18-3/4"-10,000 Psi Ram BOP Automatic Multiple Position Lock (MPL) IllustratedDocument4 pagesHydril GK Annular Blowout Preventers: 18-3/4"-10,000 Psi Ram BOP Automatic Multiple Position Lock (MPL) IllustratedJose BarreroNo ratings yet

- Api 002BDocument13 pagesApi 002BJose BarreroNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- BVM Manual Type "C" Tong 35,000 Ft/lbs TORQUEDocument2 pagesBVM Manual Type "C" Tong 35,000 Ft/lbs TORQUEJose Barrero100% (2)

- Guidelines For Drilling Equipment: ForewordDocument26 pagesGuidelines For Drilling Equipment: ForewordskladvavNo ratings yet

- Lincoln New Code 9935Document22 pagesLincoln New Code 9935Jose Barrero100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Agitador - ManualDocument25 pagesAgitador - ManualJose Barrero100% (2)

- Especificacion de Normas de InspeccionDocument32 pagesEspecificacion de Normas de InspeccionJose BarreroNo ratings yet

- Spe 36630 MSDocument8 pagesSpe 36630 MSJose BarreroNo ratings yet

- 111293Document2 pages111293Jose BarreroNo ratings yet

- Orion Rig Inspection - CheckboxL PDFDocument16 pagesOrion Rig Inspection - CheckboxL PDFdariovivaldiNo ratings yet

- Attachment06 API For Drilling EquipmentDocument4 pagesAttachment06 API For Drilling EquipmentAkang BalaiNo ratings yet

- Final Inspection Report With Codes ExampleDocument23 pagesFinal Inspection Report With Codes Exampleeraswasta100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- 8 - Mantenimiento Preventivo BopDocument19 pages8 - Mantenimiento Preventivo BopJose BarreroNo ratings yet

- 75217Document2 pages75217Jose BarreroNo ratings yet

- A Machine Learning Approach To Waiting Time Prediction in Queueing ScenariosDocument5 pagesA Machine Learning Approach To Waiting Time Prediction in Queueing ScenariosAnoop DixitNo ratings yet

- Data PresentationDocument15 pagesData PresentationAesthethic ArcNo ratings yet

- Swot of Construction Chemical IndustryDocument13 pagesSwot of Construction Chemical IndustryAnant DhingraNo ratings yet

- Worksheet 1 - SolutionDocument4 pagesWorksheet 1 - SolutionKen TangNo ratings yet

- SIH401 - Professional Development - Assessment Brief April 2023Document5 pagesSIH401 - Professional Development - Assessment Brief April 2023Godelieve MakituNo ratings yet

- Innovation Management: Session: LeanDocument29 pagesInnovation Management: Session: LeanAamiTataiNo ratings yet

- Guidelines For Project File, Essay and BibliographyDocument2 pagesGuidelines For Project File, Essay and BibliographyG MukherjeeNo ratings yet

- History of Organizational DevelopmentDocument4 pagesHistory of Organizational DevelopmentAntony OmbogoNo ratings yet

- Finding The Answers To The Research Questions (Qualitative) : Quarter 4 - Module 5Document39 pagesFinding The Answers To The Research Questions (Qualitative) : Quarter 4 - Module 5Jernel Raymundo80% (5)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Mccann 2001Document20 pagesMccann 2001JC BarrientosNo ratings yet

- The Effect of Active Learning Strategy Index Card Match-Typed On Childrens' Ability To CountDocument5 pagesThe Effect of Active Learning Strategy Index Card Match-Typed On Childrens' Ability To CountSintaNo ratings yet

- Investigation Into The Delays of Large Scale Construction Projects in BarbadosDocument7 pagesInvestigation Into The Delays of Large Scale Construction Projects in BarbadosAndre WarnerNo ratings yet

- Liking Versus LovingDocument3 pagesLiking Versus LovingHazie GhazaliNo ratings yet

- Ict Its4 03 0811 Assist With Policy Development For Client SupportDocument21 pagesIct Its4 03 0811 Assist With Policy Development For Client Supportapi-30309557072% (43)

- Miranda, A., Araujo, E. - 2002Document13 pagesMiranda, A., Araujo, E. - 2002HENRY ROMÀN PAUCAR ROMERONo ratings yet

- LIVING IN THE WORLD OF WARCRAFT: Construction of Virtual Identities Among Online GamersDocument81 pagesLIVING IN THE WORLD OF WARCRAFT: Construction of Virtual Identities Among Online GamersVirginia Bautista100% (2)

- When Should You Adjust Standard Errors For Clustering?: Alberto Abadie, Susan Athey, Guido Imbens, & Jeffrey WooldridgeDocument33 pagesWhen Should You Adjust Standard Errors For Clustering?: Alberto Abadie, Susan Athey, Guido Imbens, & Jeffrey WooldridgesreedharbharathNo ratings yet

- Global Competitiveness Report 2004-2005Document48 pagesGlobal Competitiveness Report 2004-2005Gillian Adams50% (2)

- What Is SociolinguisticDocument6 pagesWhat Is SociolinguisticNur Hasina Mohd IbrahimNo ratings yet

- Sop For New Product Devolopment Process ObjectiveDocument18 pagesSop For New Product Devolopment Process ObjectiveYATHISH BABUNo ratings yet

- Lecture 13 NPTEL SAMPLING THEORYDocument8 pagesLecture 13 NPTEL SAMPLING THEORYNARENDRANo ratings yet

- GuideSelectingStatisticalTechniques OCR PDFDocument71 pagesGuideSelectingStatisticalTechniques OCR PDFLourdes DurandNo ratings yet

- Business Research Lecture (2 Sheets)Document8 pagesBusiness Research Lecture (2 Sheets)Gerry BesaNo ratings yet

- Vijaya ConsumerDocument115 pagesVijaya ConsumerVamsi Sakhamuri100% (1)

- The Research On Training Methodologies For AIDS Education and Counselling in Thailand (Phrase II)Document66 pagesThe Research On Training Methodologies For AIDS Education and Counselling in Thailand (Phrase II)adkittipongNo ratings yet

- Analysis of Social Media Data: An Introduction To The Characteristics and Chronological ProcessDocument26 pagesAnalysis of Social Media Data: An Introduction To The Characteristics and Chronological ProcessPriyasu GuinNo ratings yet

- Work Study: Article InformationDocument21 pagesWork Study: Article InformationsuhailNo ratings yet

- Ciocirlan, C. E. (2017) - Environmental Workplace Behaviors, Definition Matter. Organization & Environment, 30 (1) 51-70Document9 pagesCiocirlan, C. E. (2017) - Environmental Workplace Behaviors, Definition Matter. Organization & Environment, 30 (1) 51-70Ikhmatul Rizkya FitrianiNo ratings yet

- CMR Form 2015 VersionDocument5 pagesCMR Form 2015 VersionEllen Glae Daquipil100% (1)

- Development of A Methodology For Road Maintenance Planning of Low Volume Roads Based On Roughness DataDocument8 pagesDevelopment of A Methodology For Road Maintenance Planning of Low Volume Roads Based On Roughness DataSteveNo ratings yet

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseFrom EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseRating: 3.5 out of 5 stars3.5/5 (69)

- Alex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessFrom EverandAlex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessNo ratings yet

- Fire Season: Field Notes from a Wilderness LookoutFrom EverandFire Season: Field Notes from a Wilderness LookoutRating: 4 out of 5 stars4/5 (142)

- The Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionFrom EverandThe Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionRating: 4 out of 5 stars4/5 (812)

- Spoiled Rotten America: Outrages of Everyday LifeFrom EverandSpoiled Rotten America: Outrages of Everyday LifeRating: 3 out of 5 stars3/5 (19)