Professional Documents

Culture Documents

Mini Project

Uploaded by

Syafiq KamilOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mini Project

Uploaded by

Syafiq KamilCopyright:

Available Formats

MEC 4862 - Fatigue and Fracture Mechanics

Mini-Project

Due on Monday May 14, 2014

Organize yourselves in groups of three people. Each group should work independently on

solving the following problems.

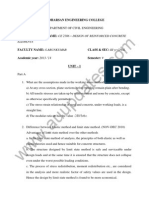

Problem 1. (LO2)

The following information on two steels and two aluminiums has been obtained:

Material

Y

(MPa)

K

Ic

(MPam)

Fabricated cost

($/kg)

Steel A 1240 132 0.95

Steel B 830 176 0.70

Aluminium C 415 55 2.15

Aluminium D 207 88 1.10

You are responsible for the analysis of a 3-m-long section of a pressure vessel (neglect any end

effectsconsider only the 3-m-long section) with the following general conditions:

GENERAL CONDITIONS

(a) Internally pressurized vessel (3-m-long). Cost given is fabricated (cost/kg). Neglect any

other costs of fabrication.

(b) Vessel diameter = 1020 mm (O.D)

(c) Internal pressure, p = 13.8 MPa

(d) Yielding occur when the hoop stress exceeds

Y

.

TWO SPECIFIC CONDITIONS

(I) Flaw-free vesselperfect fabricationfactor of safety of 2 against yielding

(II) Flawed vessel with poor quality control12.7-mm-deep longitudinal crack (a/2c =

0.25)factor of safety of 2 against fracture and yielding

REQUIRED SOLUTION

1. Determine the design stress levels, wall thickness, weight and cost of 3-m section for each

specific condition (I and II) and material (i.e., Steel A, Steel B, Aluminium C and Aluminium

D)

2. Give comments on your answers in (1)

NOTE:

You may use MS Excel spreadsheet, MATLAB, programming in any code or any

Mathematical software to help in your iterative procedure. Sample of calculations,

spreadsheet printout or print of the detailed programming code should be submitted.

DEPARTMENT OF MECHANICAL ENGINEERING

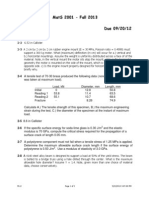

Problem 2. (LO3)

The structural problem to be solved is described in Fig. 1. Use finite element software ANSYS to

find the stress intensity factor.

Run it for different crack length cases and compare your solution with the table provided in the

ASTM standard.

Hints/Assumption:

- Take advantage of symmetry and simplify the geometry a little bit.

- To prevent rigid body translation, fix the x-displacement of the point of application of the load P.

- To facilitate the creation of the focused mesh at the crack tip, place the origin of the axis system at the

crack tip.

- Choose the material properties as those of PMMA (E = 4000 N/mm

2

and = 0.3), although, for this

problem, the material properties do not enter the expression of the stress intensity factor.

- Choose the load P as unity.

- Perform the analysis in plane strain.

Fig. 1

Problem 3. (LO 4)

Use ANSYS to perform the two types of fatigue analysis:

- Strain life

- Stress life

You might also like

- UNIT Dfty57Document8 pagesUNIT Dfty57JPDGLNo ratings yet

- CivE 672 Assignment 1: Flexural design and analysisDocument3 pagesCivE 672 Assignment 1: Flexural design and analysisLennon BaronNo ratings yet

- Machine Design Model PaperDocument2 pagesMachine Design Model PaperVinay Karanam100% (1)

- CE 308-Design of Steel Structures: Analysis of Tension MembersDocument5 pagesCE 308-Design of Steel Structures: Analysis of Tension MembersAli BahuNo ratings yet

- Application of Distributed Loads: 1. Open Preprocessor Menu 2. Give Example A TitleDocument6 pagesApplication of Distributed Loads: 1. Open Preprocessor Menu 2. Give Example A Titlesilverknights007No ratings yet

- CE2306 - Design of RC ElementsDocument22 pagesCE2306 - Design of RC ElementsViswanathan NatesanNo ratings yet

- Department of Mechanical EngineeringDocument4 pagesDepartment of Mechanical EngineeringAshok DaraNo ratings yet

- Give Example A Title: /title, Effects of Self Weight For A Cantilever BeamDocument5 pagesGive Example A Title: /title, Effects of Self Weight For A Cantilever Beamapi-3833671No ratings yet

- EGB485 - Assignment 2a 2020Document2 pagesEGB485 - Assignment 2a 2020fgh fghfghfNo ratings yet

- Finite Element Analysis QuestionsDocument8 pagesFinite Element Analysis QuestionsSatwikMohanty100% (2)

- Finite Element Methods Laboratory Manual: M. Tech in Structural/ Automobile EngineeringDocument12 pagesFinite Element Methods Laboratory Manual: M. Tech in Structural/ Automobile EngineeringDeval DesaiNo ratings yet

- Me309 h05Document15 pagesMe309 h05rksomepalliNo ratings yet

- Materials Selection and Design Design & Selection: Materials IndicesDocument9 pagesMaterials Selection and Design Design & Selection: Materials IndicesTeguh SulistiyonoNo ratings yet

- Explaining Metals Processing and Material PropertiesDocument6 pagesExplaining Metals Processing and Material PropertiesW GangenathNo ratings yet

- FEA of PipeDocument11 pagesFEA of Pipedimos dimouNo ratings yet

- Nottingham Concrete Beam TestingDocument8 pagesNottingham Concrete Beam TestingYaasiin OozeerNo ratings yet

- Cross-Section and Material Optimization of An Automotive Chassis Using FEADocument13 pagesCross-Section and Material Optimization of An Automotive Chassis Using FEABhimsen ShresthaNo ratings yet

- AE682A: Analysis of Composite Structures Assignment 1 Start Date: 11 Aug 2017 Due On: 21 Aug 2017Document1 pageAE682A: Analysis of Composite Structures Assignment 1 Start Date: 11 Aug 2017 Due On: 21 Aug 2017Vishnu A RNo ratings yet

- Structural Mechanics 2015 PaperDocument6 pagesStructural Mechanics 2015 PaperAlexNo ratings yet

- Application of Distributed LoadsDocument7 pagesApplication of Distributed Loadsakroma123No ratings yet

- MDP 2130 Tutorial 2Document4 pagesMDP 2130 Tutorial 2Khaled AbozaidNo ratings yet

- Lab 6-Questions and SolutionsDocument5 pagesLab 6-Questions and Solutionsulageswaran.kishokumarNo ratings yet

- 2-D Bicycle Frame Design: Problem DescriptionDocument2 pages2-D Bicycle Frame Design: Problem DescriptionChristina LopezNo ratings yet

- ES128 Computer Assignment 2Document3 pagesES128 Computer Assignment 2Bassem KhaledNo ratings yet

- Application of Distributed LoadsDocument7 pagesApplication of Distributed LoadsNafees ImitazNo ratings yet

- ENGR380 Assignment 2 Problems Factors Safety TheoriesDocument3 pagesENGR380 Assignment 2 Problems Factors Safety TheoriesTotoGoatsNo ratings yet

- ME3311 Beam FEM Assignment: Truss, Cantilever Beam, Bicycle Frame Analysis in ANSYSDocument3 pagesME3311 Beam FEM Assignment: Truss, Cantilever Beam, Bicycle Frame Analysis in ANSYSMarsha WongNo ratings yet

- ECIV 3452_W2024_A1 (Computer)Document3 pagesECIV 3452_W2024_A1 (Computer)milanchabhadiya288No ratings yet

- MEL311Document281 pagesMEL311Shiri ShaNo ratings yet

- Distributed LoadingDocument6 pagesDistributed LoadingJean David ChanNo ratings yet

- Homework #2: Design Philosophies: Due August 27, 2014 Use E250 Steel (F 250 Mpa and F 410 Mpa)Document1 pageHomework #2: Design Philosophies: Due August 27, 2014 Use E250 Steel (F 250 Mpa and F 410 Mpa)Pranjal SinghNo ratings yet

- UTA016 Engineering Design Project-IDocument6 pagesUTA016 Engineering Design Project-IVishal SinghNo ratings yet

- HW1 MECHancicsDocument2 pagesHW1 MECHancicsJustin NgoNo ratings yet

- Advance Strength of Materials: Topics CoveredDocument22 pagesAdvance Strength of Materials: Topics CoveredhcghgnNo ratings yet

- Prob Set #2Document2 pagesProb Set #2cookiepie21No ratings yet

- Problems Solutions On Fracture MechanicsDocument50 pagesProblems Solutions On Fracture MechanicsRajesh N Priya Gopinathan100% (5)

- Quiz No. 3Document3 pagesQuiz No. 3Mae PaviaNo ratings yet

- Mec613 Lab 1Document1 pageMec613 Lab 1Ahmad FidaudinNo ratings yet

- Exercise 3:: PROBLEM 1: A Welded Built-Up Section Along With Its Support Conditions Is Shown BelowDocument2 pagesExercise 3:: PROBLEM 1: A Welded Built-Up Section Along With Its Support Conditions Is Shown BelowMark Joseph Bandojo VargasNo ratings yet

- Analysis of Fatigue Fracture of Tank Wagon Railway Axles: Cosmin LocoveiDocument5 pagesAnalysis of Fatigue Fracture of Tank Wagon Railway Axles: Cosmin LocoveiZoser KalengayiNo ratings yet

- Mech-V-Design of Machine Elements I (10me52) - SolutionDocument63 pagesMech-V-Design of Machine Elements I (10me52) - SolutionTolbert D'SouzaNo ratings yet

- 5.accidental Car Impact Analysis and CFDDocument6 pages5.accidental Car Impact Analysis and CFDprojectzfourNo ratings yet

- Mechanical Analysis of The R.P.C./M.D.T. Lifting Frame For Transport in AtlasDocument12 pagesMechanical Analysis of The R.P.C./M.D.T. Lifting Frame For Transport in AtlasAzharuddin_kfupmNo ratings yet

- Miet2072 C8Document47 pagesMiet2072 C8vincent02hk_57881301No ratings yet

- Structural Analysis of Automotive Chassis Frame and Design Modification For Weight ReductionDocument7 pagesStructural Analysis of Automotive Chassis Frame and Design Modification For Weight ReductionKapil NandwanaNo ratings yet

- FEA of T-Shaped Flanged PipeDocument16 pagesFEA of T-Shaped Flanged Pipedimos dimouNo ratings yet

- Design Optimization of Power Screw JackDocument7 pagesDesign Optimization of Power Screw JackTd DammikaNo ratings yet

- Assignment 3 PRINTDocument6 pagesAssignment 3 PRINTcricketNo ratings yet

- Factor of Safety Design Codes and StandardsDocument4 pagesFactor of Safety Design Codes and StandardsSujit MishraNo ratings yet

- Effect of Self Weight On A Cantilever BeamDocument5 pagesEffect of Self Weight On A Cantilever Beamakroma123No ratings yet

- Stress Analysis On CrankshaftDocument5 pagesStress Analysis On CrankshaftChanduReddyNo ratings yet

- Special Mid Term Exam CET204Document3 pagesSpecial Mid Term Exam CET204zNo ratings yet

- Project #1 Bicycle Frame DesignDocument8 pagesProject #1 Bicycle Frame DesignWei100% (1)

- AnsysDocument151 pagesAnsyspraveen06apr67% (3)

- Finite Element Analysis of Structures and Heat Transfer ProblemsDocument11 pagesFinite Element Analysis of Structures and Heat Transfer Problemssimalaravi100% (2)

- Golden College of Engineering & Technology: Section A (4x2 8)Document1 pageGolden College of Engineering & Technology: Section A (4x2 8)kulwinder SinghNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Dynamic Damage and FragmentationFrom EverandDynamic Damage and FragmentationDavid Edward LambertNo ratings yet

- Exam TimetableDocument1 pageExam TimetableSyafiq KamilNo ratings yet

- Wind Tunnel Experiments: Calibration, Flow Measurements, and Aerodynamic Force CalculationsDocument9 pagesWind Tunnel Experiments: Calibration, Flow Measurements, and Aerodynamic Force CalculationsSyafiq KamilNo ratings yet

- EIT Acceptance FormDocument1 pageEIT Acceptance FormSyafiq KamilNo ratings yet

- Compressible Flow in A Convergent - Divergent NozzleDocument10 pagesCompressible Flow in A Convergent - Divergent NozzleNeville Lawless75% (8)

- Cruise Flight Equations of Motion and Optimal StrategyDocument3 pagesCruise Flight Equations of Motion and Optimal StrategySyafiq KamilNo ratings yet

- Register Additional Course ApplicationDocument1 pageRegister Additional Course ApplicationSyafiq KamilNo ratings yet

- Open 3rd Party Transfer: SuccessfulDocument1 pageOpen 3rd Party Transfer: SuccessfulSyafiq KamilNo ratings yet

- 1 s2.0 S2215098622001562 MainDocument9 pages1 s2.0 S2215098622001562 MainJUAN DAVID PRADO CORTESNo ratings yet

- Aroso 2015Document7 pagesAroso 2015H Louis AcuñaNo ratings yet

- Fsci Assignment ADocument29 pagesFsci Assignment ARaj PrateekNo ratings yet

- Cleaning Action Soap DetergentDocument5 pagesCleaning Action Soap DetergentMisratul A'la Mahyuddin60% (5)

- CH1104 Chapter 8Document90 pagesCH1104 Chapter 8Chuah Chong YangNo ratings yet

- 4-Settlement of Shallow FoundationsDocument63 pages4-Settlement of Shallow FoundationsENo ratings yet

- 2011 Exam GeotechnicalDocument9 pages2011 Exam GeotechnicalAhmed AwadallaNo ratings yet

- Introduction To GFRCDocument13 pagesIntroduction To GFRCibrahim alshaerNo ratings yet

- Module Outline 2011: Architects Need To Know But Can Never Find. Rockport: MassDocument5 pagesModule Outline 2011: Architects Need To Know But Can Never Find. Rockport: Massapi-115534435No ratings yet

- Forging a SwordDocument3 pagesForging a Swordglen biazonNo ratings yet

- Greene Tweed Energy at A GlanceDocument8 pagesGreene Tweed Energy at A GlanceYang WangNo ratings yet

- Literature Review of Glass FiberDocument7 pagesLiterature Review of Glass Fiberaflsjizaf100% (1)

- Deflection of Simply-Supported Beams: Title of The ExperimentDocument21 pagesDeflection of Simply-Supported Beams: Title of The Experimentopeyemi71No ratings yet

- Viscosity of c5h802 - 19Document1 pageViscosity of c5h802 - 19CharlesNo ratings yet

- Filters ENDocument11 pagesFilters ENChris GavevaNo ratings yet

- Soil Extension and Pavement Thickness - RevisedDocument2 pagesSoil Extension and Pavement Thickness - RevisedSolomon MehariNo ratings yet

- Manganese: Usepa Periodate Oxidation Method Method 8034 0.1 To 20.0 MG/L MN (HR) Powder PillowsDocument6 pagesManganese: Usepa Periodate Oxidation Method Method 8034 0.1 To 20.0 MG/L MN (HR) Powder Pillowslab Kimia PHBNo ratings yet

- IKEA United States (English) - IKEA Kitchen Brochure 2023-5Document12 pagesIKEA United States (English) - IKEA Kitchen Brochure 2023-5lololNo ratings yet

- TCE Babbitt 18391-2Document2 pagesTCE Babbitt 18391-2paulo cesar hernandez mijangosNo ratings yet

- JEE Main 2019 Chemistry April Attempt Shift - 1 (08th April, 2019)Document16 pagesJEE Main 2019 Chemistry April Attempt Shift - 1 (08th April, 2019)Resonance Eduventures83% (24)

- Is 10500 SpecificationDocument10 pagesIs 10500 SpecificationbrahmishtanNo ratings yet

- V0L2 PDFDocument4 pagesV0L2 PDFJohannie Nina ClaridadNo ratings yet

- What Is Punching ShearDocument2 pagesWhat Is Punching Shearmohsina InamdarNo ratings yet

- Wide-Lite Spectra VI Commercial Indoor Bulletin 1989Document4 pagesWide-Lite Spectra VI Commercial Indoor Bulletin 1989Alan MastersNo ratings yet

- Bro-0008.7 Hvofsolutions enDocument16 pagesBro-0008.7 Hvofsolutions enIzziNo ratings yet

- Proposed waiting shed in Lumbia, Cagayan de Oro CityDocument7 pagesProposed waiting shed in Lumbia, Cagayan de Oro CityMac KYNo ratings yet

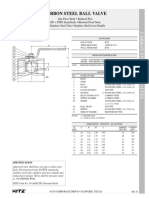

- Carbon Steel Ball Valve: Code # 50 (Aksctk)Document1 pageCarbon Steel Ball Valve: Code # 50 (Aksctk)thilina lakhithaNo ratings yet

- Class 7 Science: Chapter 14 - Elements, Compounds and MixturesDocument6 pagesClass 7 Science: Chapter 14 - Elements, Compounds and MixturesRiddhi RaneNo ratings yet

- Feasibility Study of Hydrogen Chloride ProductionDocument4 pagesFeasibility Study of Hydrogen Chloride ProductionIntratec SolutionsNo ratings yet

- Block B Drawings (As Built & Retrofitted)Document20 pagesBlock B Drawings (As Built & Retrofitted)hamapa4070No ratings yet