Professional Documents

Culture Documents

European Patent Specification: Optimizing Guidance of Railway Vehicles

Uploaded by

Alejandro Copete MorilloOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

European Patent Specification: Optimizing Guidance of Railway Vehicles

Uploaded by

Alejandro Copete MorilloCopyright:

Available Formats

Note: Within nine months of the publication of the mention of the grant of the European patent in the European

Patent

Bulletin, any person may give notice to the European Patent Office of opposition to that patent, in accordance with the

Implementing Regulations. Notice of opposition shall not be deemed to have been filed until the opposition fee has been

paid. (Art. 99(1) European Patent Convention).

Printed by Jouve, 75001 PARIS (FR)

(19)

E

P

1

8

2

6

0

9

1

B

1

111111|111111

(11) EP 1 826 091 B1

(12) EUROPEAN PATENT SPECIFICATION

(45) Date of publication and mention

of the grant of the patent:

07.04.2010 Bulletin 2010/14

(21) Application number: 07102904.5

(22) Date of filing: 22.02.2007

(51) Int Cl.:

B61F 5/38

(2006.01)

(54) Method for optimizing guidance of railway vehicles

Verfahren zum Optimieren der Fhrung von Schienenfahrzeugen

Procd doptimisation de guidage des vhicules ferroviaires

(84) Designated Contracting States:

AT BE BG CH CY CZ DE DK EE ES FI FR GB GR

HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI

SK TR

Designated Extension States:

AL BA HR MK

(30) Priority: 24.02.2006 ES 200600440

(43) Date of publication of application:

29.08.2007 Bulletin 2007/35

(73) Proprietor: Patentes Talgo, S.L.

28290 Las Matas (Madrid) (ES)

(72) Inventor: Lpez Gmez, Jos Luis

Patentes Talgo, S.A.

28230 Madrid (ES)

(74) Representative: Elzaburu Marquez, Alberto et al

Elzaburu S.L.P.

Miguel Angel 21, 2

28010 Madrid (ES)

(56) References cited:

EP-A- 1 063 143 EP-A1- 0 765 791

US-A- 4 693 185 US-A- 5 463 963

EP 1 826 091 B1

2

5

10

15

20

25

30

35

40

45

50

55

Description

Field of the Invention

[0001] The invention relates to a method for optimizing

guidance of railway vehicles that can be applied to free-

wheel railway vehicles, such as vehicles with TALGO-

type one-axle running gear with independent wheels, and

to railway vehicles with wheels coupled bogies.

Background of the Invention

[0002] Spanish patents 2.133.229 and 2.084.551,

which belong to the same applicant filing this invention,

describe guidance systems that can be respectively ap-

plied to freewheel and coupled wheel railway vehicles.

[0003] Those guidance systems have the purpose of

achieving that the angle formed by each wheel flange

with the line tangent to a curve in the track at the point

of contact with the latter be null, and they respond to the

principle that the rail should not guide the train, but rather

that the train must move on the rail. To that end such

systems are based on the interaction of the chasses on

the running gear through guiding bars such that the rel-

ative movement of said chasses suitably orients the run-

ning gear so that the wheels remain parallel to the rail

even in curves so as to increase the running safety and

to reduce the wear of the wheels and the track.

[0004] Nevertheless, these guidance systems are not

as accurate as they should be, especially for high-speed

trains; they therefore need to be optimized.

[0005] In response to this need, Spanish patent

2.195.756 belonging to the same applicant filing this in-

vention discloses a system and a method for optimizing

free-wheel guidance of railway vehicles.

[0006] EP 0765791 A1 describes a single-axle bogie

for a rail vehicle in which a single wheel assembly is guid-

ed in a bogie frame; there is provided a resilient device

for producing a return force against the steering deflec-

tion of the bogie frame which occurs when negociating

a curve in the track. It has a yoke that is displaceable

with respect to the railway car body in a vertical direction

and in a transverse direction and to which the bogie frame

is vertically steerably connected. A power-regulated ac-

tuator may be provided for producing a counteracting

force which acts against the return force. A sensor may

be provided for detecting the actual value of steering de-

flection and a regulating circuit for re-adjusting the mag-

nitude of the power at the power-regulated actuator in

the event of deviation of the reference value of steering

deflection from the actual value.

[0007] The present invention is also aimed at meeting

the need of optimizing free-wheel guidance of railway

vehicles.

Summary of the Invention

[0008] The first object of the present invention is an

optimized method for guidance of railway vehicles of the

free-wheel or coupled wheel type comprising adjustable

suspension means for suspending the wagons on the

chassis or bogie housing the wheels, comprising the fol-

lowing steps:

- detecting for each vehicle axle an off-centering of its

wheels in relation to the rails;

- modifying the height of the supports for the suspen-

sion means for the wagons placed on each chassis

by the magnitude required to center the wheels on

the rails.

[0009] The second object of the present invention is

an optimized method for guidance of railway vehicles of

the free-wheel or coupled wheel type comprising adjust-

able suspension means for suspending the boxes on the

chassis or bogie housing the wheels including asymmet-

rical dampers, with two electrovalves that can be actuat-

ed, comprising the following steps:

- detecting for each vehicle axle an off-centering of its

wheels in relation to the rails;

- modifying the position of the center of the chassis or

bogie by the magnitude required to center the wheels

on the rails acting on the asymmetrical dampers.

[0010] The methods object of the present invention will

preferably be used as a supplement to the aforemen-

tioned guidance systems, but it is necessary to point out

that they can be used separately from them.

[0011] Other features and advantages of the present

invention will be understood from the following detailed

description of an embodiment illustrating its object in re-

lation to the attached figures.

Brief Description of the Drawings

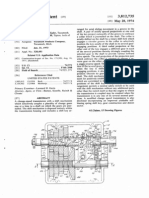

[0012]

Figure 1 shows a schematic view of an axle of a

railway vehicle, the wheels of which are off-centered

with respect to the rails.

Figure 2 schematically shows the influence of the

position of the wagons in the guidance.

Figure 3 shows a chassis of a railway vehicle with

pneumatic suspension means adjusted by level

valves.

Detailed Description of the Invention

[0013] According to Figure 1, it can be seen that the

axle integrating the wheels 11, 13 is off-centered in re-

lation to the rails 15, 17, and this translates into the fact

that the diameter D2 of the section of the wheel 13 in

contact with the rail 17 is not diameter Dm that would

correspond to it if the wheel 13 were centered, rather it

is smaller.

1 2

EP 1 826 091 B1

3

5

10

15

20

25

30

35

40

45

50

55

[0014] For its part, diameter D1 of the section of the

wheel 11 in contact with the rail 15 is not diameter Dm

that would correspond if the wheel 11 were centered,

rather it is larger.

[0015] Accordingly, the angular velocities of the

wheels 11 and 13 are not the same- which would occur

if they were centered- but rather they are different.

[0016] The magnitude and direction of the different an-

gular velocity of the wheels of one axle are parameters

that define their being off-centered, and their values can

be obtained using known means such as sensors for the

antilock brake system (ABS) incorporated in many trains

today. In fact, the system and method disclosed in patent

document 2.195.756, which optimizes the guidance by

acting on the guidance bars, the off-centering of the

wheels is detected from the measurement of their angular

velocities.

[0017] The present invention has come about from the

observation of the effects of the operation of the suspen-

sion means used, which are briefly described below, on

guidance of railway vehicles.

[0018] In the first embodiment of the invention and ac-

cording to Figure 2, three perfectly centered free-wheel

type chasses 41, 43, 45 can be seen. The main elements

have been referenced in chassis 45 for the purpose of

the present invention: the wheels 11, 13, suspension

means 21, 23, the supports 25, 27 of the suspension

means 21, 23 and the guidance bars 19 corresponding

with those described in patent documents 2.133.229 and

2.195.756.

[0019] The off-centering that occurs in the chassis 41

when its left suspension 21 is under the right suspension

23 can be seen in the central right part of Figure 2: the

running gear axle 53 separates from the axis of the track

55 and subsequent the angle between the axle 51 of the

chassis 41 and the axis of the track 55 is not 90.

[0020] This proves that there is a direct relation be-

tween the angle with the horizontal of a supposed axis

57 that joined suspensions 21, 23 and the magnitude of

the off-centering, and therefore the method proposed by

the present invention consists of correcting the off-

centering of the wheels by acting on the suspension

means. So if an off-centering of the chassis 41 such as

that shown in Figure 2 is detected when the angular ve-

locities of its wheels are compared, according to the

method, the left suspension 21 must be lifted by the mag-

nitude that is necessary to correct the off-centering.

[0021] The following is necessary to implement the

method:

- Means of detecting the speed of the wheels of each

axle.

- Adjustable suspension means on each axle.

- Management and control means that allow comput-

ing the modification of the height of the suspension

means required to correct the off-centering accord-

ing to its magnitude.

[0022] Trains today generally incorporate these

means, so they are not a specific object of the present

invention.

[0023] In the case of the pneumatic suspension means

such as those shown in Figure 3 regulated by level valves

61, their heights would be adjusted by acting on the con-

trol means of said valves 61.

[0024] In a second embodiment of the invention, which

can be applied to trains provided with asymmetrical

dampers, the method would be applied by acting on the

asymmetrical dampers so that they displace the centers

of the bogie and wagon towards the appropriate side to

optimize rolling.

[0025] The asymmetrical damper is similar to the

standard damper, with the particularity that it has two

electrovalves, such that when the two electrovalves are

deactivated, it performs like a normal damper. The same

force is required for traction as for compression. If an

electrovalve is actuated, the compression one for exam-

ple, the compression strength is reduced to "0" or is pro-

gressively reduced, achieving displacement of the wag-

on when the vehicle is running due to the tendency of

said vehicle to move to the side.

[0026] In the embodiments described above those

modifications comprised within the scope of the following

claims can be introduced.

Claims

1. Optimized method for guidance of railway vehicles

of the free-wheel or coupled wheel type comprising

adjustable suspension means for suspending the

wagons on the chassis or bogie (41,43,45) housing

the wheels, characterized in that it comprises the

following steps:

- detecting for each vehicle axle an off-centering

of its wheels (11, 13) in relation to the rails (15,

17);

- modifying the height of the supports (25, 27)

for the suspension means (21, 23) for the wag-

ons placed on each chassis (41, 43, 45) by the

magnitude required to center the wheels (11,

13) on the rails (15, 17).

2. Optimized method for guidance of railway vehicles

according to claim 1, characterized in that the sus-

pension means (21,23) are pneumatic and their

height is adjusted by means of level valves (61).

3. Optimized method for guidance of railway vehicles

of the free-wheel or coupled wheel type comprising

adjustable suspension means for suspending the

wagons on the chassis or bogie (41, 43, 45) housing

the wheels including asymmetrical dampers, with

two electrovalves that can be activated, character-

ized in that it comprises the following steps:

3 4

EP 1 826 091 B1

4

5

10

15

20

25

30

35

40

45

50

55

- detecting for each vehicle axle an off-centering

of its wheels (11, 13) in relation to the rails (15,

17);

- modifying the position of the center of the chas-

sis or bogie (41,43,45) by the magnitude re-

quired to center the wheels (11, 13) on the rails

(15, 17) acting on the asymmetrical dampers.

Patentansprche

1. Optimiertes Verfahren zur Fhrung von Schienen-

fahrzeugen der Freilauf- oder Kuppelrad-Bauart, die

einstellbare Aufhngungseinrichtungen zur Aufhn-

gung der Wagen an dem Fahrwerk oder Drehgestell

(41, 43, 45), das die Rder aufnimmt, aufweisen,

dadurch gekennzeichnet, dass es die folgenden

Schritte aufweist:

- Erfassen einer Dezentrierung ihrer Rder (11,

13) in Bezug auf die Schienen (15, 17) fr jede

Fahrzeugachse;

- Modifizieren der Hhe der Trger (25, 27) fr

die Aufhngungseinrichtungen (21, 23) fr die

auf jedem Fahrwerk (41, 43, 45) platzierten Wa-

gen um die Gre, die erforderlich ist, um die

Rder (11, 13) auf den Schienen (15, 17) zu

zentrieren.

2. Optimiertes Verfahren zum Fhren von Schienen-

fahrzeugen nach Anspruch 1, dadurch gekenn-

zeichnet, dass die Aufhngungseinrichtungen (21,

23) pneumatisch sind und ihre Hhe mittels Niveau-

ventile (61) eingestellt wird.

3. Optimiertes Verfahren zum Fhren von Schienen-

fahrzeugen der Freilauf- oder Kuppelrad-Bauart, die

einstellbare Aufhngungseinrichtungen zur Aufhn-

gung der Wagen an dem Fahrwerk oder Drehgestell

(41, 43, 45), das die Rder aufnimmt, einschlielich

asymmetrischer Dmpfungseinrichtungen mit zwei

Elektroventilen, die bettigt werden knnen, aufwei-

sen, dadurch gekennzeichnet, dass es die folgen-

den Schritte aufweist:

- Erfassen einer Dezentrierung ihrer Rder (11,

13) in Bezug auf die Schienen (15, 17) fr jede

Fahrzeugachse;

- Modifizieren der Position des Zentrums des

Fahrwerks oder Drehgestells (41, 43, 45) um die

Gre, die erforderlich ist, um die Rder (11,

13) auf den Schienen (15, 17) zu zentrieren, un-

ter Einwirkung auf die asymmetrischen Dmp-

fungseinrichtungen.

Revendications

1. Procd optimis pour le guidage de vhicules fer-

roviaires du type roue libre ou roue couple com-

prenant des moyens de suspension ajustables pour

la suspension des wagons sur le chssis ou la bogie

(41, 43, 45) recevant les roues, caractris en ce

quil comprend les tapes suivantes :

dtection pour chaque axe de vhicule dun ex-

centrage de ses roues (11, 13) par rapport aux

rails (15, 17) ;

modification de la hauteur des supports (25, 27)

des moyens de suspension (21, 23) pour les wa-

gons placs sur chaque chssis (41, 43, 45) par

lamplitude ncessaire pour centrer les roues

(11, 13) sur les rails (15, 17).

2. Procd optimis pour le guidage de vhicules fer-

roviaires selon la revendication 1, caractris en

ce que les moyens de suspension (21, 23) sont

pneumatiques et leur hauteur est ajuste au moyen

de vannes de mise niveau (61).

3. Procd optimis pour le guidage de vhicules fer-

roviaires du type roue libre ou roue couple com-

prenant des moyens de suspension ajustables pour

la suspension des wagons sur le chssis ou la bogie

(41, 43, 45) recevant les roues comprenant des

amortisseurs asymtriques avec deux lectrovan-

nes qui peuvent tre actives, caractris en ce

quil comprend les tapes suivantes :

dtection pour chaque axe de vhicule dun ex-

centrage de ses roues (11, 13) par rapport aux

rails (15, 17) ;

modification de la position du centre du chssis

ou de la bogie (41, 43, 45) par lamplitude n-

cessaire pour centrer les roues (11, 13) sur les

rails (15, 17) en agissant sur les amortisseurs

asymtriques.

5 6

EP 1 826 091 B1

5

EP 1 826 091 B1

6

EP 1 826 091 B1

7

REFERENCES CITED IN THE DESCRIPTION

This list of references cited by the applicant is for the readers convenience only. It does not form part of the European

patent document. Even though great care has been taken in compiling the references, errors or omissions cannot be

excluded and the EPO disclaims all liability in this regard.

Patent documents cited in the description

ES 2133229 [0002] [0018]

ES 2084551 [0002]

ES 2195756 [0005] [0016] [0018]

EP 0765791 A1 [0006]

You might also like

- EP09166154NWA1Document10 pagesEP09166154NWA1maes.daan1No ratings yet

- Monorail - US4996928Document8 pagesMonorail - US4996928Rob ZelNo ratings yet

- European Patent Specification: Neutral Position Setting Apparatus of Wireless Remote-Control ModelDocument18 pagesEuropean Patent Specification: Neutral Position Setting Apparatus of Wireless Remote-Control Modeltrtry34No ratings yet

- SR662Document38 pagesSR662BabulalSahuNo ratings yet

- April 2, 1940.: P. Ravigneaux - 2,195,783Document9 pagesApril 2, 1940.: P. Ravigneaux - 2,195,783Stefan IlicNo ratings yet

- Four-Speed Transmission Shift MechanismDocument18 pagesFour-Speed Transmission Shift MechanismJoão Paulo Canto RibeiroNo ratings yet

- Chapter 8. Other MechanismsDocument8 pagesChapter 8. Other MechanismsAshish SinglaNo ratings yet

- Aligning Overhead Crane Rails - HOIST MagazineDocument3 pagesAligning Overhead Crane Rails - HOIST MagazineDaniel ConwayNo ratings yet

- Variable Speed Transmission for VehiclesDocument10 pagesVariable Speed Transmission for VehiclesFernandoNo ratings yet

- Chapter No 2 Methodology: Antireverse DifferentialDocument32 pagesChapter No 2 Methodology: Antireverse DifferentialDEEPAK CNo ratings yet

- Other Mechanisms: Looking For GATE Preparation Material? Join & Get Here Now!Document7 pagesOther Mechanisms: Looking For GATE Preparation Material? Join & Get Here Now!Akash SoniNo ratings yet

- European Patent Specification F16H 61/00: Printed by Jouve, 75001 PARIS (FR)Document10 pagesEuropean Patent Specification F16H 61/00: Printed by Jouve, 75001 PARIS (FR)Aja YlNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2011/0192672 A1Document14 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2011/0192672 A1Sahaya GrinspanNo ratings yet

- Locomotive Wheel Speed Measurement Under Wheel Slip ConditionsDocument6 pagesLocomotive Wheel Speed Measurement Under Wheel Slip Conditionsbinhtb14No ratings yet

- ME 2213 (Gear Train)Document36 pagesME 2213 (Gear Train)tanvir2013004No ratings yet

- transmission-inertia-brake-ball-ramp-actuationDocument15 pagestransmission-inertia-brake-ball-ramp-actuationolduren53No ratings yet

- Analysis of Piston-Crank System Balancing in V-VR Engines: Sławomir WierzbickiDocument8 pagesAnalysis of Piston-Crank System Balancing in V-VR Engines: Sławomir WierzbickiNourTarekHassenNo ratings yet

- Inflation PressureDocument17 pagesInflation PressurecherrymanojNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2015/0051052 A1Document8 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2015/0051052 A1Adarsh Avaneesh KamillaNo ratings yet

- Project ZDocument31 pagesProject ZADITYANo ratings yet

- 059 062 PDFDocument4 pages059 062 PDFMario MereniNo ratings yet

- BY (Zém $7406: C. A. FranklinDocument5 pagesBY (Zém $7406: C. A. FranklinHasitha AmarasekaraNo ratings yet

- EP2065596A1Document10 pagesEP2065596A1duffy5555No ratings yet

- Bellcrank Mechanisms For Stirling EnginesDocument6 pagesBellcrank Mechanisms For Stirling Engineshmwong76No ratings yet

- Hutchinson Mfg. Co. v. Mayrath, 192 F.2d 110, 10th Cir. (1951)Document6 pagesHutchinson Mfg. Co. v. Mayrath, 192 F.2d 110, 10th Cir. (1951)Scribd Government Docs100% (1)

- Differentials and Final DrivesDocument2 pagesDifferentials and Final Drivesmburuiann180No ratings yet

- Drives Couplings.: Conveyor Belt Installations and Related ComponentsDocument3 pagesDrives Couplings.: Conveyor Belt Installations and Related ComponentsEric ToroNo ratings yet

- Steer-By-Wire For Vehicle State Estimation and ControlDocument6 pagesSteer-By-Wire For Vehicle State Estimation and ControlvincemugnaioNo ratings yet

- US2631476Document17 pagesUS2631476Stefan IlicNo ratings yet

- Nguyen1992 Article TrajectoryPlanningAndControlOfDocument19 pagesNguyen1992 Article TrajectoryPlanningAndControlOfAshish MeenaNo ratings yet

- Shaft Mounting Device Measures and Controls Thrust LoadsDocument7 pagesShaft Mounting Device Measures and Controls Thrust LoadsNicandroGonzalesNo ratings yet

- R.M. Van Druten, P.G. Van Tilborg, P.C.J.N. Rosielle, M.J.W. SchoutenDocument6 pagesR.M. Van Druten, P.G. Van Tilborg, P.C.J.N. Rosielle, M.J.W. SchoutenAjay ChandranNo ratings yet

- Damping device for limiting trailer yaw motionsDocument12 pagesDamping device for limiting trailer yaw motionsErkanAksoyluNo ratings yet

- Mass College ProjectDocument68 pagesMass College ProjectGLOBAL INFO-TECH KUMBAKONAMNo ratings yet

- Modeling and Optimal Shift Control of A Planetary Two-Speed TransmissionDocument16 pagesModeling and Optimal Shift Control of A Planetary Two-Speed TransmissionEduardo DelfinoNo ratings yet

- CAR 20051050 - PaperDocument6 pagesCAR 20051050 - Paperg_popa96No ratings yet

- Mechanical ActuatorsDocument39 pagesMechanical ActuatorsKashif UsmanNo ratings yet

- Wheel Steering SystemDocument28 pagesWheel Steering SystemKshitij SharmaNo ratings yet

- April 2, 1946-C. F. Voytech - 2,397,634: Filed Oc'C. 19, 1945 2 Sheets-Sheet 1Document8 pagesApril 2, 1946-C. F. Voytech - 2,397,634: Filed Oc'C. 19, 1945 2 Sheets-Sheet 1belchior alvaroNo ratings yet

- Automatic wheel alignment for vehiclesDocument4 pagesAutomatic wheel alignment for vehiclesMahatma GandhiNo ratings yet

- Design Developmentand AnalysisofvariablepumpDocument7 pagesDesign Developmentand AnalysisofvariablepumpMINA MiladNo ratings yet

- Controller Design of A New Active Front Steering SystemDocument11 pagesController Design of A New Active Front Steering SystemENIC-AITCGNo ratings yet

- TEPZZ 7Z - A T: European Patent ApplicationDocument39 pagesTEPZZ 7Z - A T: European Patent ApplicationseehariNo ratings yet

- Annals 2013 4 01Document10 pagesAnnals 2013 4 01Febrian anggaNo ratings yet

- Kinematics of MachineryDocument20 pagesKinematics of Machineryvenkatkavin0% (1)

- United States Patent 1191Document13 pagesUnited States Patent 1191ddeeff715No ratings yet

- Electric Rear Wheel Steering ActuatorDocument10 pagesElectric Rear Wheel Steering ActuatorPCezzzNo ratings yet

- Antilock Braking System With Abs (Automatic Braking System) Using ArduinoDocument55 pagesAntilock Braking System With Abs (Automatic Braking System) Using ArduinoRaj kumar SenNo ratings yet

- Design of A 3R Cobot Using Continuously Variable TransmissionsDocument6 pagesDesign of A 3R Cobot Using Continuously Variable TransmissionsPedro PrachedesNo ratings yet

- European Patent Specification: Printed by Jouve, 75001 PARIS (FR)Document22 pagesEuropean Patent Specification: Printed by Jouve, 75001 PARIS (FR)avalosheNo ratings yet

- Wheel/Rail Contact Analysis of Tramways and Lrvs Against DerailmentDocument5 pagesWheel/Rail Contact Analysis of Tramways and Lrvs Against DerailmentKamel BelloutiNo ratings yet

- 2.kinematics of MachineryDocument14 pages2.kinematics of MachineryJegan ParamasivamNo ratings yet

- Design, Development and Analysis of Variable Displacement Pump by Application of Linkage Motion AdjusterDocument6 pagesDesign, Development and Analysis of Variable Displacement Pump by Application of Linkage Motion AdjusterDorry PrayogaNo ratings yet

- Sect 08 Rail Freight Vehicle Underframe and Body Structures Incl New As Id1Document9 pagesSect 08 Rail Freight Vehicle Underframe and Body Structures Incl New As Id1serzo75No ratings yet

- Running Gearing Engine AnalysisDocument16 pagesRunning Gearing Engine Analysisabcde0% (1)

- EP1070663A2Document4 pagesEP1070663A2atabNo ratings yet

- What-When-How: The Ackermann Principle As Applied To Steering (Automobile)Document9 pagesWhat-When-How: The Ackermann Principle As Applied To Steering (Automobile)Pradyumn MangalNo ratings yet

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsFrom EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsNo ratings yet

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- Traffic and Highway Engineering Si Edition 5th Edition Garber Solutions ManualDocument27 pagesTraffic and Highway Engineering Si Edition 5th Edition Garber Solutions ManualalicegalvingrdknNo ratings yet

- DHL Logistics Report AnalysisDocument57 pagesDHL Logistics Report AnalysisSamraizTejaniNo ratings yet

- Zheng He's VoyagesDocument17 pagesZheng He's Voyagesapi-351804626No ratings yet

- Nissan Pathfinder D21 Repair Manual 91 DownloadDocument5 pagesNissan Pathfinder D21 Repair Manual 91 DownloadAlejandro0% (3)

- Procedure For Compliance With Regulations and Safety Requirements For MAN ProductsDocument6 pagesProcedure For Compliance With Regulations and Safety Requirements For MAN ProductsAkmal NizametdinovNo ratings yet

- Maintaining Square PlansiftersDocument16 pagesMaintaining Square PlansiftersEdwar André PgalNo ratings yet

- Hyundai I30 Sedan SpecificationsDocument5 pagesHyundai I30 Sedan SpecificationsFendy SutrisnoNo ratings yet

- Rear Wiper and WasherDocument3 pagesRear Wiper and WasherNam TèoNo ratings yet

- Oic Grasp BrochureDocument8 pagesOic Grasp BrochureAbid HassaanNo ratings yet

- Copy For Kind Perusal To:: SMEC International Pty. LTDDocument3 pagesCopy For Kind Perusal To:: SMEC International Pty. LTDMohd UmarNo ratings yet

- Different Types of Fire Extinguishers Used On ShipsDocument13 pagesDifferent Types of Fire Extinguishers Used On Shipsstamatis100% (1)

- IJFE Forensic Investigation Crane AccidentsDocument24 pagesIJFE Forensic Investigation Crane Accidentsaderaysiahaan 19No ratings yet

- Position Paper About Cebu PacificDocument1 pagePosition Paper About Cebu PacificPeter Paul ParasNo ratings yet

- Service Publication ListDocument177 pagesService Publication ListCristian m VizcainoNo ratings yet

- Training and Certification of VTS PersonnelDocument4 pagesTraining and Certification of VTS PersonnelsarvannnNo ratings yet

- Admiralty Digital Publications ADP FactsheetDocument6 pagesAdmiralty Digital Publications ADP FactsheetVisveswaran Inbasekaran100% (1)

- SACHS TengelykapcsoloDocument36 pagesSACHS TengelykapcsoloniloblueNo ratings yet

- Quattro The Evolution of Audi AWDDocument50 pagesQuattro The Evolution of Audi AWDAntónio FernandesNo ratings yet

- Conditional Sentences PaperDocument16 pagesConditional Sentences PaperNursalamah putriNo ratings yet

- Search and Rescue PatternsDocument6 pagesSearch and Rescue Patternsrockmoredave67% (3)

- 6 ASEGH - Marshalling AircraftDocument38 pages6 ASEGH - Marshalling AircraftRon McintyreNo ratings yet

- As 4876.1-2002 Motor Vehicle Frontal Protection Systems Road User ProtectionDocument7 pagesAs 4876.1-2002 Motor Vehicle Frontal Protection Systems Road User ProtectionSAI Global - APACNo ratings yet

- Traffic Collision Investigation Manual For Patrol OfficersDocument119 pagesTraffic Collision Investigation Manual For Patrol Officerssithlord_shag8697100% (1)

- Strategic Renewal and Action Plan For: Kilcona ParkDocument62 pagesStrategic Renewal and Action Plan For: Kilcona ParkTessa VanderhartNo ratings yet

- BMW Inspection II Guide for E36 E46 E39 E38 E52Document3 pagesBMW Inspection II Guide for E36 E46 E39 E38 E52Douglas fabian PeñaililloNo ratings yet

- Form Laporan Insiden ReportDocument3 pagesForm Laporan Insiden Reporthasbi13No ratings yet

- Andaman Trip ItineraryDocument16 pagesAndaman Trip ItinerarySwapnil KhandezodNo ratings yet

- Reinforced Cement Concrete (CT-312) Stair DesignDocument43 pagesReinforced Cement Concrete (CT-312) Stair Designmuhammad irfanNo ratings yet

- A Study On The Application of Operations Research in The Airline IndustryDocument14 pagesA Study On The Application of Operations Research in The Airline IndustryInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Sop For Hemm MaintenanceDocument11 pagesSop For Hemm MaintenanceHitesh Gulabani100% (3)