Professional Documents

Culture Documents

(Ebook) Multivariable Control, An Introduction PDF

Uploaded by

Caterine Feria RamirezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(Ebook) Multivariable Control, An Introduction PDF

Uploaded by

Caterine Feria RamirezCopyright:

Available Formats

1

Multivariable Control: An introduction

Dr M.J. Willis

Department of Chemical and Process Engineering

University of Newcastle upon Tyne

email: mark.willis@ncl.ac.uk

Written: 4

th

November, 1998

Modified: 8

th

November, 1999

Aims and Objectives

To introduce the basic concepts of multivariable control (a continuous stirred tank

reactor will be used as the motivating example). To highlight the phenomenon of

loop interactions. To learn how to model multivariable systems using input-output

descriptions. To introduce the relative gain array (RGA) - a tool for the selection of

input-output pairings.

At the end of this section of the course you should be able to select appropriate

manipulated variable - controlled variable pairings to minimise the effect of loop

interactions in multivariable systems. You should know how to formulate and

interpret the RGA.

Plan

Define the terms SISO and MIMO.

Introduce MIMO control and loop interaction using a CSTR as the motivating

example.

discuss systems modelling for MIMO systems (the transfer function approach).

clarify discussions using a worked example (modelling and control of a mixing

process).

introduce the RGA and discuss how it may be used to select input-output

pairings.

2

Introduction

Processes with only one output being controlled by a single manipulated variable are

classified as single-input single output (SISO) systems. It should be noted however,

that most unit operations in chemical engineering have more than one control loop.

In fact, each unit typically requires the control of at least two variables, e.g. product

rate and product quality. There are therefore usually at least two control loops.

Systems with more than one control loop are known as multi-input multi-output

(MIMO) or multivariable systems.

A Continuous Stirred Tank Reactor (CSTR)

A continuous stirred tank reactor (CSTR) is used to convert a reactant (A) to a

product (B). The reaction is liquid phase, first order and exothermic. Perfect mixing is

assumed. A cooling jacket surrounds the reactor to remove the heat of reaction.

Effluent

Coolant

C

Ao

, F

o

, T

o

F, C

A

, T

T

j

A B

Exothermic, first order

Constant Volume

TC

CC

Fig 1 A basic control scheme for a CSTR

In this system variables of interest (from a control engineers perspective) could be,

for example, product composition and temperature of the reacting mass. There will

therefore be a composition control loop as well as a temperature control loop. Feed

to the reactor is often used to manipulate product composition while temperature is

controlled by adding (removing) energy via heating (cooling) coils or jackets. This

basic control configuration is demonstrated in Fig (1). 'TC' represents a temperature

controller, the mv for this loop being coolant flowrate to the jacket. 'CC' represents

the composition controller, the mv being reactant feedrate.

Assuming that the control system has been configured in this manner, lets consider

a change in feed flowrate. Perhaps this is necessary to bring composition back to its

desired level. This manipulation of feedflow will also change the temperature of the

reaction mass. Heat removal or addition, on the other-hand, would influence the

rate of reaction and hence composition. This phenomenon, known as loop

interaction, occurs in many processes and must be considered when developing a

3

control strategy. If it is not, it may be difficult to run the unit under closed loop

control, creating many operational problems.

Thus, for two loops to work successfully together each loop must know what the

other is doing. Otherwise, in trying to achieve their respective objectives each loop

may act against the interests of the other.

Developing Process Models for Multivariable Systems Analysis

When designing a multivariable control strategy, the process must first be modelled.

This can be achieved either analytically using sets of differential equations to

describe a systems behaviour or empirically, using data obtained from an open loop

step test fitted to an assumed model structure. For the purposes of the control

system design we often use the latter, parameterising the model using 1

st

order plus

time-delay transfer functions.

Input-Output Multivariable System Models

1

For systems with more than one output, input-output models may assume a number

of structural forms. However, discussions will be restricted to the model structure

shown in the diagram below,

G

11

(s)

Loop 1

Loop 2

G

21

(s)

G

12

(s)

G

22

(s)

+

+

mv

1

mv

2

cv

1

cv

2

Fig 2 (2 x 2) Multivariable model structure

Here G

11

(s) is a symbol used to represent the forward path dynamics between mv

1

and cv

1

, while G

22

(s) describes how cv

2

responds after a change in mv

2

. The

interaction effects are modelled using transfer functions G

21

(s) and G

12

(s). G

21

(s)

describes how cv

2

changes with respect to a change in mv

1

while G

12

(s) describes

how cv

1

changes with respect to a change in mv

2

.

1

For sake of simplicity during these, and subsequent discussions only (2 x 2) processes will be considered.

4

For the CSTR shown in figure (1) mv

1

could be the coolant flowrate, while mv

2

could

be the flowrate of the reactant. The output cv

1

may be the reactor temperature while

the output cv

2

would be the effluent concentration.

The mathematical model written in matrix-vector notation

The elements within the blocks of Figure (2) are transfer functions, defining the

relationship between the respective input output pairs. As usual, the following

general transfer function description will be used,

G s

k e

s

p

p

s

p

( )

+

1

(1)

where k

p

is a process gain,

p

the process time constant and the process time

delay. Note that each of the 4 blocks in Figure (2) will have different parameters that

must be determined.

Referring to fig. 2., on a loop by loop basis, the outputs of the system model are

related to the inputs as follows,

Loop 1: cv

1

= G

11

mv

1

+ G

12

mv

2

(2)

Loop 2: cv

2

= G

21

mv

1

+ G

22

mv

2

(3)

Equations (2) and (3) may be expressed more compactly in matrix-vector notation

as:

cv = G mv (4)

where cv = [cv

1

, cv

2

]

T

; mv = [mv

1

mv

2

]

T

and, G

G G

G G

,

]

]

]

11 12

21 22

Note that this is a matrix of transfer function elements.

Incorporation of load disturbance terms into the systems model

Thus far, only the major part of the process has been considered. In many

situations, processes are influenced by external factors such as changes in ambient

conditions, changes in the quality of raw materials; changes in the operating

environment and so on. To cater for these effects, load disturbance terms may also

5

be incorporated within the model. Incorporation of load disturbance terms in the

model representation leads to the following expression:

cv = Gmv + G

d

dv (5)

where [ ] G

G

G

and dv ,dv

d

d

d

,

]

]

]

1

2

1 2

0

0

dv

The block diagram representation of this system model is given by,

G

11

(s)

Loop 1

Loop 2

G

21

(s)

G

12

(s)

G

22

(s)

+

+

u

1

u

2

y

1

y

2 +

G

d1

(s)

G

d2

(s)

d

1

d

2

Fig. 3. Incorporating load disturbances into the system model

In other words, disturbances are added to the process output in exactly the same

fashion as considered for single loop systems in process control 1.

Worked Example

Consider the following mixing process,

f

1

f

2

f

o

c

#

Control objective: regulate f

o

and c

#

to desired levels

6

Manipulated variables: f

1

and f

2

Assume that the system is a two component system. Let f

1

be the flowrate (kg/hr) of

stream 1, f

2

be the flowrate of stream 2 (kg/hr) while f

o

is the total flowrate. Also, if c

1

and c

2

are the mass fractions of component A in each stream and c

#

the mass

fraction of component A in the mixed stream:

1. What are the material balance equations for this system ?

2. Develop a linear (2 x 2) model representation by linearisation of the material

balance equations around the following steady-state operating point, f

o

= 100

kg/hr, c

#

= 60% with c

1

=80% and c

2

=20%.

3. If the dynamics of the mixed streams concentration and measurement sensors

and are characterised by the following expressions,

G s

f

f

m

o

m

o

( ) 1

and

G s

e

c

c

m

s

m

( )

#

2

1

(6)

i.e measurement of flow is assumed instantaneous, while the measurement of mass

fraction is assumed to be affected by an analyser delay (which is modelled as a pure

time delay process). Develop the overall linearised dynamic model of the system.

Draw the block diagram representation of the system.

Solution

1) The overall mass balance is given by,

f

o

= f

1

+ f

2

(7)

The component balance is given by,

f

o

c

#

=f

1

c

1

+ f

2

c

2

(8)

2) We require the mathematical relationship between the two outputs and the two

manipulated variables. Equation (7) provides one expression. Rewriting the material

balance equations (7) and (8) gives the other as,

c

f c f c

f f

#

+

+

1 1 2 2

1 2

(9)

Equation (1) is linear however, equation (3) is not a linear function. To linearise the

relationship between c

#

and the manipulated variables, f

o

and f

1

it is necessary to

use a 1

st

order Taylor series expansion of equation (9) around the steady-state

7

operating point (see the Appendix for an explanation about linearisation via the

Taylor series). The basic structure of the linear equation is:

c

dc

df

f

dc

df

f

ss ss

#

#

'

#

'

'

j

(

,

\

,

( +

j

(

,

\

,

(

1

1

2

2

The following partial differentials are required

2

dc

df

f c c

f f

#

( )

( )

1

2 1 2

1 2

2

+

and

dc

df

f c c

f f

#

( )

( )

2

1 1 2

1 2

2

+

(10)

This gives the linearised model,

c

f c c

f f

f

f c c

f f

f

ss ss

# ' '

'

[

( )

( )

] [

( )

( )

]

+

+

+

2 1 2

1 2

2 1

1 1 2

1 2

2 2

(11)

where c

#

= c

#

- c

#

ss

, f

1

= f

1

- f

1ss

and f

2

= f

2

- f

2ss

are deviation variables.

To calculate the steady-state conditions required by equation (12), solve the material

balance. We have two algebraic expressions,

100 = f

1

+ f

2

0.6*100 = 0.8*f

1

+ 0.2*f

2

(13)

Solving for f

1

and f

2

gives,

f

1

= 66

2

/

3

kg/hr and f

2

= 33

1

/

3

kg/hr

Therefore,

c# = 2x10

-3

f

1

+ (-4x10

-3

)f

2

(14)

where c

#

= c

#

-0.6, f

1

= f

1

- 66

2

/

3

and f

2

= f

2

- 33

1

/

3

Using a block diagram to visualise this system model we have,

2

To do this differentiation I have used the quotient rule, i.e

d u v

dx

v

du

dx

u

dv

dx

v

( / )

2

8

f

1

f

2

f

o

c

#

2

+

+

1

1

2 x 10

-3

-4 x 10

-3

1

c

m

f

o

m

e

s

and this may be written as,

f s

c s x e x e

f s

f s

o

m

m

s s

( )

( )

( )

( )

,

,

]

]

]

,

]

]

]

,

,

]

]

]

1 1

2 10 4 10

3 3

1

2

(15)

Summary

So far, these notes have introduced multivariable systems modelling by

consideration of a 2 x 2 (2 input - 2 output) representation. The block diagram

representation is used to clearly illustrate system dynamics and interactions. Once a

mathematical model of the system has been developed, and the presence of

process interactions identified, the next stage of the control design procedure is to

synthesise the control law.

With multivariable systems, where loop interactions exist, configuration of two single

loop PI(D) controllers could cause system instability, or at the very least result in

poor control performance. This can be overcome by,

choosing a manipulated variable - controlled variable pairing so that system

interactions are minimised. The basic question for a 2 x 2 system is do we want

mv

1

-cv

1

, mv

2

-cv

2

(i.e. mv

1

to control cv

1

and mv

2

to control cv

2

) or the other way

round ?

the design a multivariable controller that achieves non interacting control.

Design of multivariable controllers will be considered later in the course. The next

section of the notes concentrates on a systematic technique for choosing a

manipulated variable - controlled variable pairing so that system interactions are

minimised.

9

The Relative Gain Array (RGA)

One of the most important factors, common to all process control applications, is the

correct (best) pairing of the manipulated and controlled variables. A number of

quantitative techniques are available to assist in the selection process. One of the

earliest methods proposed was the Relative Gain Array (RGA), Bristol (1966). The

original technique is based upon the open loop steady state gains of the process

and is relatively simple to interpret

2

.

Determining relative gains from process experiments

Consider the 2x2 system shown in Figure 2. Suppose mv

2

remains constant, then a

step change in mv

1

of magnitude mv

1

will produce a change cv

1

in output cv

1

.

Thus, the gain between mv

1

and cv

1

when mv

2

is kept constant is given by:

g

11

|mv

2

=

cv

mv

mv

1

1

2

(16)

If instead of keeping mv

2

constant, cv

2

is now kept constant by closing the loop

between cv

2

and mv

2

. A step change in mv

1

of magnitude mv

1

will result in another

change in cv

1

. The gain in this case is denoted by:

g

11

|y

2

=

cv

mv

cv

1

1

2

(17)

The gain relationships, equations (16) and (17) may have different values. If

interaction exists, then the change in cv

1

due to a change in mv

1

for the two cases

when mv

2

and cv

2

are kept constant, will be different.

The ratio:

11

=

g

g

mv

cv

11

11

2

2

|

|

(18)

is a dimensionless value and it defines the relative gain between the output cv

1

and

the input mv

1

.

Interpretation of the relative gain

1.

ij

= 1. There is no interaction with other control loops.

2.

ij

= 0. Manipulated input, i, has no affect on output, j.

2

As no information about the process dynamics is used a "health-warning" should be attached to the results

although in practice the interpretation is normally valid.

10

3.

ij

= 0.5. There is a high degree of interaction. The other control loops have the

same effect on the output, j, as the manipulated input, i.

4. 0.5 <

ij

< 1. There is interaction between the control loops. However, this would

be the preferable pairing as it would minimise interactions.

5.

ij

> 1. The interaction reduces the effect gain of the control loop. Higher

controller gains are required.

6.

ij

> 10. The pairing of variables with large RGA elements is undesirable. It can

indicate a system sensitive to small variations in gain and possible problems

applying model based control techniques.

7.

ij

< 0. Care must be taken with negative RGA elements. Negative off-diagonal

elements indicate that closing the loop will change the sign of the effective gain.

More importantly, negative diagonal elements can indicate integral instability i.e.

the control loop is unstable for any feedback controller.

Elements of the RGA

For the 2 x 2 process, three other relative gain elements can be defined yielding the

matrix,

3

=

11 12

21 22

11 11

11 11

1

1

,

,

]

]

]

,

]

]

]

Determining relative gains from process models

A computational method is possible if a steady-state model of the system is

available. If this model is given by:

cv

1

= g

11

mv

1

+ g

12

mv

2

cv

2

= g

21

mv

1

+ g

22

mv

2

(19)

then g

11|mv2

= (cv

1

/mv

1

)|

mv2

= g

11

(20)

Eliminating mv

2

from the steady-state relationships, Eqs. (19) and (20), results in:

cv

1

= g

11

mv

1

+ g

12

(cv

2

-g

21

mv

1

)/g

22

(21)

from which:

g

11

|

cv2

= (cv

1

/mv

1

)|

cv2

= g

11

-g

12

g

21

/g

22

3

A property of the RGA is that the rows and columns sum to 1.

11

The relative gain

11

is therefore given by:

11

=

g

g

g

g

g g

g

u

y

11

11

11

11

12 21

22

2

2

|

|

Therefore:

11

=

1

1

12 21 11 22

( ) / ( ) g g g g

(22)

A general calculation procedure for the RGA

Skogestad (1987) demonstrated that the RGA calculation can be expressed in

matrix notation, facilitating computation for systems larger than 2x2.

( ) RGA G G

T

.*

1

(23)

where, G is the process gain matrix, '.* ' represents Schur (element by element)

matrix multiplication, [.]

-1

denotes a matrix inverse and [.]

T

is the transpose operator.

The mixing example revisited: calculation of the RGA

For the mixing process the following two control schemes are possible:

Mixer

FT

FC

CT

CC

F

1

, x

1

F

2

, x

2

F , x

Mixer

CT

CC

FT

FC

F

1

, x

1

F

2

, x

2

F , x

Now that the steady-state gain matrix has been calculated, it is possible to use the

RGA to determine the "best" manipulated variable control variable pairings.

12

Calculating the RGA in Matlab

To illustrate how the RGA is calculated in Matlab, consider the steady-state gain

matrix of the mixer,

G

x x

,

]

]

]

1 1

2 10 4 10

3 3

Enter the MATLAB environment and enter the commands preceeded by the

MATLAB prompt >>. The text after the % is intended to tell you what you are doing

(and should not be typed).

% enter the steady-state gain matrix

>>g = [1 1 ; 2e-3 -4e-3]

% calculate the RGA

4

>> rga = g.*inv(g)

This should give the result,

rga =

0.6667 0.3333

0.3333 0.6667

In other words, the RGA analysis suggests f

1

should be used to control f

o

, while f

2

should be used to control c

#

Exercises

1. Simulate the following transfer function representation of a 2 x 2 process using

simulink

4

In Matlab, inv calculates the inverse of a matrix while calculates the transpose of the matrix

13

mv

1

mv

2

cv

1

cv

2

+

+

1

10 1 s +

1

20 1 s +

+

0 2

5 1

.

s

08

10 1

.

s +

a) discuss the dynamic response characteristics of cv

1

and cv

2

with respect to

changes in mv

1

and mv

2

.

b) Tune two PI(D) controllers the first to control cv

1

using mv

1

and the second to

control cv

2

using mv

2

. (use the simulink simulation environment). Make critical

comments on the functionality of the system.

Summary

Using a simple process example these notes have:

introduced the concept of systems interaction.

demonstrated how multivariable systems can be represented (modelled).

introduced the relative gain array (RGA).

shown how the RGA may be used to select loop pairings.

If the RGA indicates little interaction within the system then it may be possible to use

single loop controllers. In some situations this may not be possible in which case it

will be necessary to develop a multivariable control law. The design of multivariable

controllers will be covered in detail in later lectures.

14

Appendix: Linearisation

Given a function,

dx

dt

f x ( )

Expand f(x) using a Taylor series around x

o

,

f x f x

df

dx

x x

o x o

o

( ) ( ) ( ) ( ) + (Ignoring higher order terms)

Control system models are always expressed in terms of deviation variables. That

deviation (or difference) being the difference between the actual value and a steady-

state value. If x

ss

is the steady-state value of x, then,

dx

dt

f x

ss

ss

( ) 0

and so,

d x x

dt

df

dx

x x

ss

x ss

ss

( )

( ) ( )

or, if the deviation variable is defined as x=x-x

ss,

d x

dt

df

dx

x

x

ss

( )

( )

'

'

This concept generalises if there is more than one variable. For instance if there are

two variables we have,

f x x

df

dx

x

df

dx

x

x x x x

ss ss ss ss

( , ) ( ) ( )

, , , ,

,

'

,

'

1 2

1

1

2

2

1 2 1 2

+

You might also like

- WEEK 6 MODULE 6 - Multivariable Control - NEWDocument106 pagesWEEK 6 MODULE 6 - Multivariable Control - NEWmutencoNo ratings yet

- New Microsoft Word Document 4.1Document19 pagesNew Microsoft Word Document 4.1prashantmaukaNo ratings yet

- Thermodynamics - Lectures b4 MidsemDocument545 pagesThermodynamics - Lectures b4 MidsemVismit Parihar100% (1)

- Modern Aspects of Electrochemistry No. 34 - B. E. ConwayDocument296 pagesModern Aspects of Electrochemistry No. 34 - B. E. ConwaycyberdjoxNo ratings yet

- Froth Recovery Measurement in Plant Scale Flotation CellsDocument7 pagesFroth Recovery Measurement in Plant Scale Flotation Cellsjsotofmet4918No ratings yet

- Viva Question For PDCDocument1 pageViva Question For PDCJunaid ParkerNo ratings yet

- Energy Balance and Metal ExtractionDocument4 pagesEnergy Balance and Metal ExtractionikamelyaastutiNo ratings yet

- Process Dynamic ModellingDocument30 pagesProcess Dynamic ModellingthenmolhiNo ratings yet

- CHAPTER 4 Chemical Kinetic PDFDocument138 pagesCHAPTER 4 Chemical Kinetic PDFSiti Wajihah Mohd NazriNo ratings yet

- EPSRC Thermal Management Sheffield Drying Tech Feb 2010Document50 pagesEPSRC Thermal Management Sheffield Drying Tech Feb 2010Anonymous VlKfgxLNo ratings yet

- Calculation Cover Sheet Date: Author: Project: Calc No: TitleDocument5 pagesCalculation Cover Sheet Date: Author: Project: Calc No: TitleNicolas Yoel Molina TapiaNo ratings yet

- Internship ReportDocument24 pagesInternship ReportSumaiya AltafNo ratings yet

- Peristaltic Pump ManualDocument27 pagesPeristaltic Pump Manualdaniel adamNo ratings yet

- Ee421: Introduction To Scientific Computing With MatlabDocument53 pagesEe421: Introduction To Scientific Computing With MatlabHadjer zit100% (1)

- Multivariable Control SystemDocument39 pagesMultivariable Control SystemAmeerRashidNo ratings yet

- Belt Weigher ArticleDocument4 pagesBelt Weigher Articlevivekbharti83No ratings yet

- 4 11Document189 pages4 11Sree Krishna DasNo ratings yet

- Mass Transfer Operations II: Humidification and Air ConditioningDocument14 pagesMass Transfer Operations II: Humidification and Air ConditioningYELUVU KARTHIEKNo ratings yet

- Calculus Problem Solution and Simulation Using Gui of Matlab PDFDocument5 pagesCalculus Problem Solution and Simulation Using Gui of Matlab PDFMohd Iqbal MuttaqinNo ratings yet

- Intro - Matlab - and - Numerical - Method Lab Full DocumentDocument75 pagesIntro - Matlab - and - Numerical - Method Lab Full DocumentEyu KalebNo ratings yet

- Model Predictive ControlDocument49 pagesModel Predictive ControlchethanNo ratings yet

- Computer Integrated ManufacturerDocument2 pagesComputer Integrated ManufacturerHafiezul HassanNo ratings yet

- Rossin Ramler AnalisisDocument5 pagesRossin Ramler AnalisisNicolas Yoel Molina TapiaNo ratings yet

- Floatability ComponentsDocument26 pagesFloatability ComponentsJlreyNo ratings yet

- 6 - Turbomachinery-Pumps Performance 2Document31 pages6 - Turbomachinery-Pumps Performance 2medo ElrefaeyNo ratings yet

- Process Control LessonDocument1 pageProcess Control LessonAnonymous JDXbBDBNo ratings yet

- Funda of Multivariable ControlDocument69 pagesFunda of Multivariable Controlኪዳንኪ ማርያም ዘኢየሀልቅNo ratings yet

- Psychrometric ReviewDocument27 pagesPsychrometric ReviewfarinNo ratings yet

- Tuning of PID Controllers Using SimulinkDocument9 pagesTuning of PID Controllers Using SimulinkVarun MishraNo ratings yet

- Automatic Control ExerciseDocument140 pagesAutomatic Control Exercisetaile1995No ratings yet

- Can Spreadsheet Solvers Solve Demanding Optimization Problems PDFDocument8 pagesCan Spreadsheet Solvers Solve Demanding Optimization Problems PDFDayang Radiah Awang BiakNo ratings yet

- Lecture Note Drying May19Document50 pagesLecture Note Drying May19ara_1909No ratings yet

- Chapter 7 A GrooverDocument10 pagesChapter 7 A GrooverSyma ShaheenNo ratings yet

- MATLAB AssignmentsDocument12 pagesMATLAB AssignmentsnilimaNo ratings yet

- D 4607 - 94 R99 - RDQ2MDC - 1 PDFDocument5 pagesD 4607 - 94 R99 - RDQ2MDC - 1 PDFWynona BasilioNo ratings yet

- A Major Project ON Biodiesel Production From Waste Cooking Oil (Literature and Planning)Document20 pagesA Major Project ON Biodiesel Production From Waste Cooking Oil (Literature and Planning)Ankur SemleNo ratings yet

- CUSUM ChartDocument23 pagesCUSUM ChartSaurabh Jain0% (1)

- MATLAB - Modelling in Time Domain - Norman NiseDocument3 pagesMATLAB - Modelling in Time Domain - Norman Niseichigo325No ratings yet

- DryingDocument24 pagesDryingramnareshretneniNo ratings yet

- Odes: Initial-Value ProblemsDocument88 pagesOdes: Initial-Value ProblemsAndres S LutzNo ratings yet

- Concentration Changes in A CSTR (Continuous Stirred Tank Reactor)Document10 pagesConcentration Changes in A CSTR (Continuous Stirred Tank Reactor)pekanselandarNo ratings yet

- CHE3162.Lecture11 CascadeDocument33 pagesCHE3162.Lecture11 Cascadexhche7No ratings yet

- Tutorial 4 - Inheritance, Abstract Classes and InterfacesDocument1 pageTutorial 4 - Inheritance, Abstract Classes and InterfacesKhoi Phan FofNo ratings yet

- CS Lecture Notes Units 1 2 3Document88 pagesCS Lecture Notes Units 1 2 3sushinkNo ratings yet

- Chemical Engineering Screening and Size Reduction RefresherDocument171 pagesChemical Engineering Screening and Size Reduction RefresherDean Joyce AlborotoNo ratings yet

- Bio OxidationDocument21 pagesBio OxidationManu Jain100% (2)

- Mathematical Modeling of Fluid SystemsDocument10 pagesMathematical Modeling of Fluid Systemsabdullah HRB100% (1)

- Process ModelingDocument38 pagesProcess ModelingAdilaAnbreenNo ratings yet

- Intro To Finite Element Modeling and COMSOLDocument18 pagesIntro To Finite Element Modeling and COMSOLSCR_010101No ratings yet

- Ce206 OdeDocument23 pagesCe206 OdeBorhan ShaikatNo ratings yet

- Temperature Distributions in Solids and in Laminar FlowDocument4 pagesTemperature Distributions in Solids and in Laminar FlowSambasiva Rao KaturiNo ratings yet

- FiltrationDocument30 pagesFiltrationMurong MedinaNo ratings yet

- WPL Lamella Separator Technical DatasheetDocument1 pageWPL Lamella Separator Technical Datasheettallef001No ratings yet

- Lab Report GROUP3Document70 pagesLab Report GROUP3Maheshree GohilNo ratings yet

- 04 - First Order SystemDocument16 pages04 - First Order SystemNayyar RazaNo ratings yet

- Laminar Flow and Convective Transport Processes: Scaling Principles and Asymptotic AnalysisFrom EverandLaminar Flow and Convective Transport Processes: Scaling Principles and Asymptotic AnalysisNo ratings yet

- Multivariable Predictive Control: Applications in IndustryFrom EverandMultivariable Predictive Control: Applications in IndustryNo ratings yet

- CX Lite Opc en Int01Document8 pagesCX Lite Opc en Int01fdfdfdfrtmNo ratings yet

- 1 s2.0 0005109896855579 Main PDFDocument6 pages1 s2.0 0005109896855579 Main PDFCaterine Feria RamirezNo ratings yet

- (Ebook) DSL Advances - Prentice Hall PDFDocument586 pages(Ebook) DSL Advances - Prentice Hall PDFCaterine Feria RamirezNo ratings yet

- 2N2646Document1 page2N2646Anonymous XM3KoTUTgNo ratings yet

- Nunez2007 PDFDocument6 pagesNunez2007 PDFCaterine Feria RamirezNo ratings yet

- 3G3MX2 User Manual I570-E1-01Document446 pages3G3MX2 User Manual I570-E1-01Caterine Feria RamirezNo ratings yet

- BS en 10297 2Document36 pagesBS en 10297 2Sharma ShailenNo ratings yet

- Product Note PD30 en RevA 2011 Anti-Sway Control ProgramDocument2 pagesProduct Note PD30 en RevA 2011 Anti-Sway Control ProgramkumarNo ratings yet

- Computer Numerical Control CNC: Ken Youssefi Mechanical Engineering DepartmentDocument43 pagesComputer Numerical Control CNC: Ken Youssefi Mechanical Engineering DepartmentSreedhar PugalendhiNo ratings yet

- Lect 4Document28 pagesLect 4george samyNo ratings yet

- A Level Chemistry Data Booklet 2009Document11 pagesA Level Chemistry Data Booklet 2009Alan YapNo ratings yet

- Electronic Ballast Tester - UI5000Document1 pageElectronic Ballast Tester - UI5000Jimmy ClavelNo ratings yet

- Me VR10 PDFDocument153 pagesMe VR10 PDFeng ameer alburihyNo ratings yet

- Suntech STP225-20 WD 225Wp ENDocument2 pagesSuntech STP225-20 WD 225Wp ENmax2503No ratings yet

- Synthesis and Characterization of Manganese (II), Cobalt (II) and Nickel (II) Complexes of Phenyl Glycine - O-Carboxylic AcidDocument4 pagesSynthesis and Characterization of Manganese (II), Cobalt (II) and Nickel (II) Complexes of Phenyl Glycine - O-Carboxylic AcidJASH MATHEWNo ratings yet

- Toshiba Just Vision 200Document2 pagesToshiba Just Vision 200kazugawa100% (4)

- Part Number 26-84: Illustrated Parts BreakdownDocument90 pagesPart Number 26-84: Illustrated Parts BreakdownJesus OliverosNo ratings yet

- Weather ElementsDocument6 pagesWeather ElementsFrenzie Mae Vasquez RiveraNo ratings yet

- 1 Rack and PinionDocument6 pages1 Rack and PinionMectrosoft Creative technologyNo ratings yet

- Teaching Quantum Mechanics On An Introductory Level PDFDocument10 pagesTeaching Quantum Mechanics On An Introductory Level PDF24263537No ratings yet

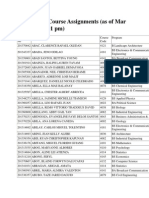

- UP Diliman Course AssignmentsDocument82 pagesUP Diliman Course Assignmentsgamingonly_accountNo ratings yet

- Eco Brick Paper 140314 - Full Paperr2Document30 pagesEco Brick Paper 140314 - Full Paperr2zero kakumaruNo ratings yet

- 01 - The Freerider Free Energy Inverter Rev 00DDocument18 pages01 - The Freerider Free Energy Inverter Rev 00Dpeterfoss791665No ratings yet

- Homework 1Document6 pagesHomework 1Ahmet Kemal ÇetinNo ratings yet

- Quantum Mechanics Module NotesDocument12 pagesQuantum Mechanics Module NotesdtrhNo ratings yet

- 5200 Shelves and Components, Part 1 of 2 PDFDocument266 pages5200 Shelves and Components, Part 1 of 2 PDFalek nowalNo ratings yet

- Semiconductor: 1 PropertiesDocument9 pagesSemiconductor: 1 PropertiesGilberto ManhattanNo ratings yet

- Summary A PDFDocument3 pagesSummary A PDFAhmad TouqirNo ratings yet

- Qa TableDocument9 pagesQa Tableapi-299403846No ratings yet

- Chap 3 DieterDocument25 pagesChap 3 DieterTumelo InnocentNo ratings yet

- Analysis of Buckling of Piles Fully Embedded in Ground According To Finite Element MethodDocument5 pagesAnalysis of Buckling of Piles Fully Embedded in Ground According To Finite Element Methodctlim88No ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.2.1 License # 14VSTSP6QKXWAC6Document2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.2.1 License # 14VSTSP6QKXWAC6Luis Miguel GaviñoNo ratings yet

- 6 +ok+MEASURE+MENT+OF+SEQUENCE+REACTANCES+OF+SALIENT+POLE+SYNCHRONOUS+MACHINEDocument3 pages6 +ok+MEASURE+MENT+OF+SEQUENCE+REACTANCES+OF+SALIENT+POLE+SYNCHRONOUS+MACHINEaissmsNo ratings yet

- Astm E448-82 R02 E02 PDFDocument5 pagesAstm E448-82 R02 E02 PDFJORGE ARTURO TORIBIO HUERTANo ratings yet

- TankDocument24 pagesTankUDayNo ratings yet

- Physics Ia FinalDocument11 pagesPhysics Ia FinalscarletNo ratings yet