Professional Documents

Culture Documents

Centrifugal Pump Set Failure Modes

Uploaded by

John Tan0 ratings0% found this document useful (0 votes)

199 views59 pagesFluid Mechanics

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFluid Mechanics

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

199 views59 pagesCentrifugal Pump Set Failure Modes

Uploaded by

John TanFluid Mechanics

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 59

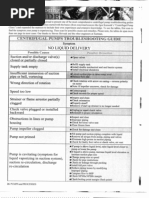

Centrifugal Pump Set Failure Modes and Causes

Pump Set Pump Set

failure modes failure mechanism

No Liquid Delivered Pump not primed

Liquid returned backward

Suction valve shut

Discharge valve shut

Suction piping blocked

Discharge piping blocked

Insufficient NPSH available

Motor failure

Impeller jammed by foreign body

Impeller seized

Supply tank / vessel empty

No liquid supply in pipe

Motor wired wrongly

Specific gravity higher than specified

Viscosity higher than specified

Volute shattered

Drive coupling broken

Drive shaft broken

Bearings in housing seized

Bearings in motor seized

Motor power supply loss

Insufficient Flow Speed tuned down

Discharge valve partially closed

Cavitation

Gas / vapour entrainment (poor suction piping design)

Turbulence (fittings / valves too close to pump suction)

Turbulence (restriction in line prior pump suction)

Broken impeller

Bent vanes

Incorrect impeller

Incorrect impeller diameter

System head too high

Instrumentation error

Suction valve blocked

Suction valve partially closed

Discharge valve blocked

Discharge valve partially closed

Suction piping blocked

Discharge piping blocked

Motor wired wrongly

Motor rotating backwards

Rotational speed too low

Excessive air / vapour trapped in liquid

Insufficient NPSH available

Impeller clogged

Specific gravity higher than specified

Viscosity higher than specified

Intermittent Flow Air leak in suction line

Excessive air / vapour trapped in liquid

Loss of prime e.g. liquid rans back through check / foot valve

Insufficient Pressure Instrumentation error

Broken impeller

Bent vanes

Incorrect impeller

Incorrect impeller diameter

Cavitation

Rotating backwards

Rotational speed too low

Insufficient NPSH available

Assembled incorrectly

Pump Leaking Mechanical seal passes

Stuffing box packing excessively worn (for packed gland)

Stuffing box bore damaged (for packed gland)

Pump shaft surface damaged (for packed gland)

Packing installed incorrectly (for packed gland)

Flange leaks (flange not sealing)

Flange leaks (gasket not sealing)

Assembled incorrectly

Volute cracked

Volute corroded

Volute eroded

Inadequate foundation size and design

5 72

Sources of Information:

http://www.vibanalysis.co.uk/technical

http://www.elongo.com/pdfs/BearingFailures990519.pdf

The McNally Institute CD

http://www.delzer.com/Rexnord/falk/108010.pdf

Impeller Impeller

failure modes failure mechanism

Chamber / Vane Wear Erosion (high flow rate)

Erosion (internal flow recirculation)

Erosion (suspended material on fluid)

Pump-out vanes worn (if part of impeller design)

Blocked balance holes between inlet and back of impeller (if part of impeller design)

Cavitation

Corrosion Chemical corrosion

Galvanic corrosion

Cavitation Damage Long suction pipe

Small diameter suction pipe

Blocked suction pipe

Partially closed valve in suction line

NPSH available is to little

Liquid temperature rise

Loose on Shaft Assembled incorrectly

Taper seat damaged

Nut corroded

Nut under torqued

Incorrect impeller bore

Wear Ring Damage Recirculation

Solids suspended in product

Erosion (high flow rate)

Cavitation (pressure falls across cut water, like in a labyrinth)

Incorrect impeller bore alignment

5 24

Blocked balance holes between inlet and back of impeller (if part of impeller design)

Volute Volute

failure modes failure mechanism

Wear Ring Damage Recirculation

Solids suspended in product

Erosion (high flow rate)

Cavitation

Cut Water Wear Erosion (high flow rate)

Erosion (internal flow recirculation)

Cavitation

Corrosion Chemical corrosion

Galvanic corrosion

Cracked Pipe stress

Soft foot dsitortion

3 11

Shaft Shaft

failure modes failure mechanism

Snapped Shaft Bending fatigue (surface crack initiated)

Bending fatigue (surface corrosion initiated)

Bending fatigue (surface damage initiated)

Tortional fatigue (surface crack initiated)

Tortional fatigue (surface corrosion initiated)

Tortional fatigue (surface damage initiated)

Shaft diameter too small for application

Shaft material tensile strength too low for application

Shaft rotating while bent by service load

Equipment jammed by product

Equipment bearing seized

Overloaded during operation

Chemical attack

Galvanic corrosion

Temperature changes metallurgical properties

Stress raiser, scratches, mechanical damage (e.g. Pipe wrench used to turn seized shaft)

Stress raiser, excessive interference fit with mating component

Stress raiser, welding heat affected zone

Fillet radius too small

Fretting and pitting corrosion

Surface defects such as welding inclusions

Deep machining marks or scratches

Poor blending of fillet radius into journal

Wear grooves at or close to fillet radius

Keyway Broken Keyway fatigue

Improper keyway design

Inadequate shoulder fillet radius

Machining defects (residual stresses induced)

Machining dimension /tolerance error

Overloaded during operation

2 30

Stress raiser, scratches, mechanical damage (e.g. Pipe wrench used to turn seized shaft)

Shaft Seal (Mechanical)

failure modes

Accelerated Seal Face Wear

Edge Chipping

Seal Face Cracked / Fractured

Open Seal Face - Axial

Open Seal Face - Radial

Static O-Ring Seal Failure

Dynamic O-Ring Seal Failure

Product Leakage

Seal Embrittlement

Fractured Spring

Clogged Spring

Axial Shear

Torsional Shear

Seal Face Distortion

Slow Mechanical Response

Bellows Cracked

16

Shaft Seal (Mechanical)

failure mechanism

Abrasives suspended in the process fluid

Abrasives in solution in the process fluid (crystallisation)

Abrasives from the environment such as sand and dirt

Abrasives from the environment such as product

Adhesive wear at start-up (faces contacting)

Carbonisation on faces (high temperature, high contact load)

Stuck faces (film transfer of seal face material-of-construction)

Scale build-up (filming)

Vaporisation between faces (high temperature, high contact load)

Vaporisation between faces (loss of lubrication film)

Dirt dragged or blown across the faces when they separate

Blistered carbon face from air trapped in carbon expanding and blowing out

Surface finish deterioration

Pump shaft out-of-roundness

Blistering (seal face sub-surface vaporisation)

Excessive start-up torque

Excessive shaft end play

Seal installation misalignment

Pump shaft misalignment to driver

Pump shaft bent

Shaft bent due to overhang because impeller is located too far away from the bearing

Selective leaching is picking up elements from the piping system and depositing them on the seal face

One or both of the seal faces is not lapped flat to within three helium light bands (0,000033" or 1 micron)

Mishandling damage to a lapped face

Damaged faces during delivery

Uneven clamping not 'equal and opposite' across the stationary face

One or both of the faces is being distorted by a temperature differential

Water hammer pressure surge

Carbon in metal holder under residual stress and not stress relieved remove residual stress in the lapped face

Oxidizing agents and halogens attack all forms and grades of carbon-graphite

De-ionized water can attack carbon seal

Chemicals attack carbon seal

Silicon carbide seal attacked by acidic liquid

Solvent flushed through pipes for cleaning attacked seal material

Poor / wrong carbon grade selected

Corrosion rate increased by temperature rise (10 degree Centigrade rise doubles corrosion rate in many fluids)

The plating or hard coating is coming off from the hard face

Rotating face is not centered in the stationary face and is running off the edge of the stationary face

Dirt or solids are clogging the movable components

Foreign object has passed into the seal chamber and is interfering with the free movement of the seal

Solids have packed up in front of the inner seal in a "back to back" dual seal design

Seal face rocks due to installation misalignment

Vaporisation on seal faces

Pump shaft excess whip

Pump shaft excess deflection

Vibration transferred to seal (pipe harmonics)

Vibration transferred to seal (out-of-balance)

Vibration transferred to seal (loose mounting)

Vibration transferred to seal (running at critical speed)

Vibration transferred to seal (Cavitation)

Vibration transferred to seal (Running well off BEP (for single volute))

Water hammer pressure surge

Run dry (no product)

Run dry (no barrier / quench fluid)

Run dry (cavitation)

Run dry (pump-out vanes create low pressure / vacuum)

Thermal shock (distortion from sudden high temperature rise)

High temperature differential across the ceramic

Excessive fluid pressure on seal

Water hammer pressure surge

Excessive pressure velocity (high pressure at slow rotational speed)

Stress corrosion cracking

Barrier / quench fluid failure

The elastomer is swelling up under a carbon face.

The shaft is hitting the stationary face or the rotating seal face is hitting a stationary object

Product is solidifying between the faces and they are breaking at start up

Excessive vibration is causing the drive or anti-rotation pins to crack the face

Cracked during assembly / disassembly. Inspect crack for tell-tale signs of discolouration deep inside seal indicating breakage prior installation

Shaft / sleeve is oversize

Fretting corrosion between seal and shaft

A gasket or fitting is protruding into the stuffing box and touching seal component

Pump shaft end play

Trust movement

Water hammer pressure surge

Thermal growth differential

Impeller adjustment towards wet end of pump opens seal faces

Product is vaporizing and separating the faces allowing solid material to blow across the lapped face

Dynamic elastomer not free to move due to oversize shaft

Dynamic elastomer not free to move due rough surface finish

Dynamic elastomer not free to move due to sticking to shaft from high surface temperature

Dynamic elastomer not free to move due to contaminants locking it in place

Chipper edges causing face separation

Spiral failure where seal component stick and cause internal twist

Springs stick and prevent dynamic movement

Seal as mishandled during installation

Elastomer seals on a porous carbon surface rather than a hard metal surface. When the shaft rotation stops the elastomer relaxes and flows into the carbon surface irregularities

Set screws have come loose

Set screws corroded

Initial setting of seal incorrect and once experiencing a little wear the spring load has gone

Axial temperature growth of the shaft has altered the original setting

Shaft sleeve moved when the impeller was tightened to the shaft

Seal was set-screwed to a hardened shaft or sleeve and has slipped due to vibration

Spring has been painted and cannot compress fully

Cartridge seal static seal has jammed and preventing proper location of faces

Inner seal of a dual seal application was not balanced in both directions and is opening up with reversing pressure

Single spring found in some seal designs was wound in the wrong direction for the shaft rotation

Rotating bellows seal has lost cooling and the anti-vibration lugs are engaging the shaft. Normal shaft movement or vibration will cause the faces to open

Pump shaft bent (excess run-out)

Pump shaft excess whip

Pump shaft excess deflection

Out-of-balance impeller

Fretting corrosion under seal (by axial movement transmitted to the seal)

Excessive elastomer temperature

Excessive fluid pressure

Installation error (elastomer damage)

Corrosive attack (incompatible chemical)

Water hammer

Compression set (extreme temperature operation causes elastomer elasticity memory loss)

Compression set (product is too hot)

Elastomer swollen by incompatible chemical product

Elastomer has extruded because of high pressure or excessive clearance.

Elastomer is cracked from too long on the shelf (particularly Buna-N (nitrile rubber))

Elastomer is cracked (High heat hardens elastomer and cracks)

Elastomer is cracked (cryogenic temperatures)

The elastomer is twisted, cut or damaged on installation

Shaft is corroded, damaged, or fretted under the elastomer

Seal body O-ring groove is damaged or coated with a solid material

Wrong lubricant was used at installation to aid fitting the elesomer on the shaft

Oxidizers can attack the carbon black in O-rings and other elastomers

Distorted sleeve or shaft

Fretting corrosion (axial movement transmitted to the seal)

Excessive elastomer temperature

Excessive fluid pressure

Installation error (elastomer damage)

Corrosive attack (incompatible chemical)

Water hammer pressure surge

Compression set (extreme temperature operation causes elastomer elasticity memory loss)

Compression set (product is too hot)

Elastomer swollen by incompatible chemical product

Solids attached at dynamic elastomerand preventing it from moving

Elastomer has extruded because of high pressure or excessive clearance.

Elastomer is cracked from too long on the shelf (particularly Buna-N (nitrile rubber))

Elastomer is cracked (High heat hardens elastomer and cracks)

Elastomer is cracked (cryogenic temperatures)

The elastomer is cut or damaged on installation

Oxidizers can attack the carbon black in O-rings and other elastomers

Insufficient seal face compression

Installation error (wrongly located on shaft)

Installation error (mounting screws loosen)

Loss of spring tension

Foreign material contamination on faces

Uinbalanced seals in dual seal applications

Application changes from vacuum to a positive pressure. O-rings are the only common elastomers that seal in both directions. Wedges, U cups, and chevrons do not have this ability

The glue between the carbon and its metal holder is not compatible with the product

Differential expansion between 'pressed-in' carbon and its metal holder

Out-of-roundness of 'shrunk-in' carbon caused by the tolerace on the carbon outside diameter and the metal holder inside diameter

Gland gasket has failed

Cracked bellows

Barrier / quench leck misdiagnosed as product leak

Contaminants in pumped fluid

Contaminants in barrier / flush fluid

Pumped fluid / seal material-of-construction chemical incompatibility

Thermal degradation of material-of-construction

Idle periods between use

Material flaw

Manufacturing flaw

Stress corrosion due to tooling marks

Corrosive attack

Seal installation misalignment

Pumped fluid contaminated with solids

Barrier / flush fluid contaminated with solids

Excessive pressure loading

Improper lubrication causes excessive torque

Excessive fluid pressure surges

Excessive fluid pressure on seal

Foreign material trapped between faces

Excessive pressure velocity (high pressure at slow rotational speed)

Insufficient seal face lubrication film thickness

Excessive squeeze on seal faces

Excessive seal swell

Seal extrusion

Metal-to-metal contact due to out of alignment

Seal rub (shaft deflection causes the mechanical seal to contact the bore of the stuffing box)

Internal erosion (barrier / flush fluid contaminated with solids)

The product interfers with the free movement of the components. The fluid is crystallising, solidifying, viscous

A gasket or fitting is protruding into the stuffing box and touching seal component

Foreign object has passed into the seal chamber and is interfering with the free movement of the seal

Stress corrosion cracking

178

This illustration describes a mechanical seal that can be classified into several different categories:

Cracked during assembly / disassembly. Inspect crack for tell-tale signs of discolouration deep inside seal indicating breakage prior installation

Elastomer seals on a porous carbon surface rather than a hard metal surface. When the shaft rotation stops the elastomer relaxes and flows into the carbon surface irregularities

Inner seal of a dual seal application was not balanced in both directions and is opening up with reversing pressure

Rotating bellows seal has lost cooling and the anti-vibration lugs are engaging the shaft. Normal shaft movement or vibration will cause the faces to open

Application changes from vacuum to a positive pressure. O-rings are the only common elastomers that seal in both directions. Wedges, U cups, and chevrons do not have this ability

Out-of-roundness of 'shrunk-in' carbon caused by the tolerace on the carbon outside diameter and the metal holder inside diameter

This illustration describes a mechanical seal that can be classified into several different categories:

Roller Bearings Roller Bearings

failure modes failure mechanism

Bearing Wear Abrasive particles, such as grit or swarf that have entered the bearing

Lack of cleanliness before and during mounting operation

Ineffective seals

Lubricant contaminated by worn particles from brass cage

Lubrication contamination (wear particles)

Lubricant additives gradually been used up

Lubricant has lost its chemical lubricating properties

Lubricant loss through seal

Lubricant has leaked away

Lubrication contamination (external liquid ingress)

Lubrication contamination (liquid product ingress)

Lubrication contamination (dust and dirt ingress)

Lubrication contamination (solid product ingress)

Lubrication contamination (sand and material from within castings, flaking protective coatings, rust from inside castings, etc)

Bent shafts

Skewed ring from burrs or dirt on bearing mounting surfaces and bearing abutment surfaces

Shaft shoulders which are not perpendicular to the bearing abutment surface

Locking nut faces which are not perpendicular to the bearing seating face

Non-concentric bores on which the bearings are mounted leading to an angular axis of rotation of the shaft and thus misaligning the rotating axis of the bearings

Reverse Loading Failure is one such failure which occurs due to the bearing getting loaded in the opposite direction in which it is intended to bear the load. This type of failure is quite common in angular contact and thrust bearings

Bad bearing supplied (especially cheap bearings made of inferior material)

Solids were introduced into the system during the assembly process because of a lack of cleanliness

Shaft coupling bore machined off-center / skewed

Bearing Overheated Clearance looseness (shaft shrinkage)

Clearance looseness (housing expansion)

Clearance looseness (loose fit shaft)

Clearance looseness (loose fit housing)

Spalling of race ways

Inadequate or improper lubrication

Excessive preload on account of fits being too tight

Insufficient heat transmission from housing due to build-up of material and product over casing

Rapid cooling of housing causes shrinkage and reduction in clearance

Incorrect viscosity of the lubricant

Incorrect lubricant chemistry

Form 'varnish' residue and 'coke' at elevated temperature that destroys the ability of the grease or oil to lubricate the bearing

Oil level too low

Oil level too high

Plugged oil return holes

Over greased bearing

Under greasing bearing

Suction pressure too high and causing axial thrust

Out-of-balance rotating element

Hydrogen embrittlement or blistering by water within microscopic cracks on raceways and rolling elements

Insufficient clearance in labyrinth seals

Base frame distorted

Process temperature conducted along shaft

Normal aspiration as the pump cooled down, and the moisture laden atmosphere entered the bearing case

Axially mislocated shaft coupling

Grease or lip seals too tight

Brinell and False Brinell Hit during mounting / installation

Dented by self-weight load when standing-still

Dented by vibration impact loads when standing-still e.g. machinery transported on rough roads

Situated close to machinery producing vibrations

Mounting pressure applied to the wrong ring during installation

Excessively hard drive-up on tapered seating during installation

Overloading while not running

Excessive preload on account of fits being too tight

Smearing on installation produces microscopic surface cracks

Stuffing box packing overtightened

Creeping Slippage Ring fit is oversize

Ring fit is worn

Fretting corrosion

Smearing rollers and raceways Smeared roller ends from sliding under heavy axial loading and with inadequate lubrication

Roller acceleration on entry into the loaded zone due to too much clearance

Load is too light for the speed

As bearings are being mounted, the ring with the roller and cage assembly is entered askew, without being rotated during insertion

Blows applied to the wrong ring or heavy preloading without rotating the bearing

External surfaces of heavily loaded bearings from movement of the bearing ring relative to its shaft or housing

Slip fit is too loose on sliding ring

Smearing Thrust Ball Bearings due to rotational speed is too high in relation to the loading. The centrifugal force then impels the balls to the outer part of the shallow raceways. There the balls do not roll satisfactorily and a great deal of sliding occurs at the ball-to-raceway contacts

Surface Distress Cracks Inadequate lubrication

Improper lubrication

Corrosion - Deep seated rust Presence of water, moisture over a long period of time

Presence of corrosive substances

Corrosion - Fretting Fit too loose

Shaft seating with errors of form

Housing seating with errors of form

Electrical Erosion Electrical fluting due to passage of electric current through rotating ring

Electrical fluting due to passage of electric current through non-rotating ring

Earthing problem in equipment

Raceway Spalling Excessive preload on account of fits being too tight

Excessive drive-up on a tapered seating

Excessive preload adjustment e.g. Single row angular contact ball bearings or taper roller bearings

Temperature differential between inner and outer rings too great

Foreign particles in the lubricant, metal particles from within the system, etc allow wear particles to be jammed between roller and race causing impact stress

Cavitation induced stress overload

Vibration induced stress from running off BEP

Clearance tightness (shaft expansion)

Clearance tightness (housing shrinkage)

Clearance tightness (tight shaft fit)

Clearance tightness (tight housing fit)

Pinched bearing (shaft ovality excessive)

Pinched bearing (housing ovality excessive)

Pinched bearing (pipe stress distortion)

Pinched bearing (Soft foot causing frame distortion)

Distorted bore of Plummer blocks from mounting on an uneven base becoming oval when the base bolts are tightened

Incorrect mounting, which results in axial loading, e.g. excessive preloading of angular contact ball bearings and taper roller bearings.

The non-locating bearing has jammed.

Axial freedom of movement has not been sufficient to accommodate the thermal expansion.

Cracked Rings Blows, with a hammer or hardened chisel, have been directed against the ring when the bearing was being mounted

Fatigue cracks (installation misalignment cyclic overloading)

Fatigue cracks (differential frame growth misalignment cyclic overloading)

Fatigue cracks (bent shaft cyclic overloading)

Fatigue cracks (shaft deflection from running off BEP)

Fatigue cracks (Smearing during installation causes surface crack initiation)

Fatigue cracks (Fretting corrosion caused crack initiation)

Clearance tightness (shaft expansion)

Clearance tightness (housing shrinkage)

Clearance tightness (tight shaft fit)

Clearance tightness (tight housing fit)

Sliding under heavy axial loading and with inadequate lubrication

Cage Damage Fatigue cracks (vibration forces of inertia are so great as to cause fatigue cracks to form in the cage material, after a time leading to cage fracture)

Fatigue cracks (run at speeds in excess of cage design subjecting it to heavy forces of inertia that may lead to fractures)

Fatigue cracks (bearing rings are fitted out of alignment with each other, the path of the rollers take an oval configuration. If the cage is centred on the rollers, it has to change shape for every revolution it performs)

Severe acceleration and retardation, in conjunction with fluctuations in speed cause forces of inertia. These give rise to considerable pressure on cage contacting surfaces, with consequent heavy wear

Inadequate lubrication

Abrasive particles

Fragments of flaked material or other hard particles may become wedged between the cage and a rolling element, preventing the latter from rotating round its own axis

Bearing is severely misaligned

Seized Bearing Metal to metal contact cause micro-welding

Clearance tightness causes lack of rolling element rotation

Inadequate lubrication (viscosity too low)

Inadequate lubrication (moisture in lubricant)

Excessive mechanical overload (bearing too small in surface area)

Excessive mechanical overload (high operating load)

Rolling element jammed and not rolling due to solid contaminant

Rolling element jammed and not rolling due mechanical stress

Grease or lip seal contact on the shaft, right next to the bearings. These seals can add as much as 38C (100F) to the shaft temperature

Lock nut came loose

13 129

Category

Lube contamination by inclusion

Lube contamination by inclusion

Lube contamination by ingress

Lube contamination by ingress

Lube contamination by ingress

Lube chemical degradation

Lube chemical degradation

Lubricant loss

Lubricant loss

Lube contamination by ingress

Lube contamination by ingress

Lube contamination by ingress

Lube contamination by ingress

Lubrication contamination (sand and material from within castings, flaking protective coatings, rust from inside castings, etc) Lube contamination by ingress

Installation error

Skewed ring from burrs or dirt on bearing mounting surfaces and bearing abutment surfaces Installation error

Shaft shoulders which are not perpendicular to the bearing abutment surface Installation error

Installation error

Non-concentric bores on which the bearings are mounted leading to an angular axis of rotation of the shaft and thus misaligning the rotating axis of the bearings Installation error

Reverse Loading Failure is one such failure which occurs due to the bearing getting loaded in the opposite direction in which it is intended to bear the load. This type of failure is quite common in angular contact and thrust bearings Installation error

Material strength failure

Solids were introduced into the system during the assembly process because of a lack of cleanliness Lube contamination by inclusion

Installation error

Incorrect fits and tolerance

Incorrect fits and tolerance

Incorrect fits and tolerance

Incorrect fits and tolerance

Lube contamination by inclusion

Lube contamination by inclusion

Lube chemical degradation

Insufficient heat transmission from housing due to build-up of material and product over casing Temperature change

Temperature change

Lube chemical degradation

Lube chemical degradation

Form 'varnish' residue and 'coke' at elevated temperature that destroys the ability of the grease or oil to lubricate the bearing Lube chemical degradation

Lubricant loss

Lubricant excessive

Lubricant excessive

Lubricant excessive

Lubricant insufficient

Operational induced stress

Unbalance

Hydrogen embrittlement or blistering by water within microscopic cracks on raceways and rolling elements Lube contamination by ingress

Incorrect fits and tolerance

Incorrect fits and tolerance

Temperature change

Normal aspiration as the pump cooled down, and the moisture laden atmosphere entered the bearing case Lube contamination by ingress

Installation error

Installation error

Installation error

Operational induced stress

Dented by vibration impact loads when standing-still e.g. machinery transported on rough roads Operational induced stress

Operational induced stress

Installation error

Installation error

Operational induced stress

Incorrect fits and tolerance

Installation error

Installation error

Incorrect fits and tolerance

Incorrect fits and tolerance

Incorrect fits and tolerance

Smeared roller ends from sliding under heavy axial loading and with inadequate lubrication Incorrect fits and tolerance

Roller acceleration on entry into the loaded zone due to too much clearance Incorrect fits and tolerance

Incorrect fits and tolerance

As bearings are being mounted, the ring with the roller and cage assembly is entered askew, without being rotated during insertion Installation error

Blows applied to the wrong ring or heavy preloading without rotating the bearing Installation error

External surfaces of heavily loaded bearings from movement of the bearing ring relative to its shaft or housing Incorrect fits and tolerance

Incorrect fits and tolerance

Smearing Thrust Ball Bearings due to rotational speed is too high in relation to the loading. The centrifugal force then impels the balls to the outer part of the shallow raceways. There the balls do not roll satisfactorily and a great deal of sliding occurs at the ball-to-raceway contacts Operational induced stress

Lubricant insufficient

Lube chemical degradation

Lube contamination by ingress

Lube contamination by ingress

Incorrect fits and tolerance

Incorrect fits and tolerance

Incorrect fits and tolerance

Electrical induced damage

Electrical induced damage

Electrical induced damage

Incorrect fits and tolerance

Incorrect fits and tolerance

Excessive preload adjustment e.g. Single row angular contact ball bearings or taper roller bearings Incorrect fits and tolerance

Incorrect fits and tolerance

Foreign particles in the lubricant, metal particles from within the system, etc allow wear particles to be jammed between roller and race causing impact stress Lube contamination by ingress

Operational induced stress

Operational induced stress

Incorrect fits and tolerance

Incorrect fits and tolerance

Incorrect fits and tolerance

Incorrect fits and tolerance

Incorrect fits and tolerance

Incorrect fits and tolerance

Incorrect fits and tolerance

Incorrect fits and tolerance

Distorted bore of Plummer blocks from mounting on an uneven base becoming oval when the base bolts are tightened Installation error

Incorrect mounting, which results in axial loading, e.g. excessive preloading of angular contact ball bearings and taper roller bearings. Installation error

Incorrect fits and tolerance

Axial freedom of movement has not been sufficient to accommodate the thermal expansion. Installation error

Blows, with a hammer or hardened chisel, have been directed against the ring when the bearing was being mountedInstallation error

Installation error

Incorrect fits and tolerance

Installation error

Operational induced stress

Fatigue cracks (Smearing during installation causes surface crack initiation) Installation error

Incorrect fits and tolerance

Incorrect fits and tolerance

Incorrect fits and tolerance

Incorrect fits and tolerance

Incorrect fits and tolerance

Installation error

Fatigue cracks (vibration forces of inertia are so great as to cause fatigue cracks to form in the cage material, after a time leading to cage fracture) Unbalance

Fatigue cracks (run at speeds in excess of cage design subjecting it to heavy forces of inertia that may lead to fractures) Operational induced stress

Fatigue cracks (bearing rings are fitted out of alignment with each other, the path of the rollers take an oval configuration. If the cage is centred on the rollers, it has to change shape for every revolution it performs) Installation error

Severe acceleration and retardation, in conjunction with fluctuations in speed cause forces of inertia. These give rise to considerable pressure on cage contacting surfaces, with consequent heavy wear Operational induced stress

Lubricant insufficient

Lube contamination by inclusion

Fragments of flaked material or other hard particles may become wedged between the cage and a rolling element, preventing the latter from rotating round its own axis Lube contamination by ingress

Installation error

Lube chemical degradation

Incorrect fits and tolerance

Lube chemical degradation

Lube chemical degradation

Design error

Operational induced stress

Lube contamination by ingress

Incorrect fits and tolerance

Grease or lip seal contact on the shaft, right next to the bearings. These seals can add as much as 38C (100F) to the shaft temperature Design error

Installation error

SKF List of bearing failure causes - Bearing failures and their causes - Product information 401

Wear

Wear caused by abrasive particles

Wear caused by inadequate lubrication

Wear caused by vibration

Indentations

Indentations caused by faulty mounting or overloading

Indentations caused by foreign particles

Smearing

Smearing of roller ends and guide flanges

Smearing of rollers and raceways

Raceway smearing at intervals corresponding to the roller spacing

Smearing of external surfaces

Smearing in thrust ball bearings

Surface distress

Corrosion

Deep seated rust

Fretting corrosion

Damage caused by the passage of electric current

Flaking (spalling)

Flaking caused by preloading

Flaking caused by oval compression

Flaking caused by axial compression

Flaking caused by misalignment

Flaking caused by indentations

Flaking caused by smearing

Flaking caused by deep seated rust

Flaking caused by fretting corrosion

Flaking caused by fluting or craters

Cracks

Cracks caused by rough treatment

Cracks caused by excessive drive-up

Cracks caused by smearing

Cracks caused by fretting corrison

Cage damage

Vibration

Excessive speed

Wear

Blockage

Other causes of cage damage

SKF List of bearing failure causes - Bearing failures and their causes - Product information 401

Wear caused by abrasive particles

Wear caused by inadequate lubrication

Indentations caused by faulty mounting or overloading

Indentations caused by foreign particles

Smearing of roller ends and guide flanges

Smearing of rollers and raceways

Raceway smearing at intervals corresponding to the roller spacing

Damage caused by the passage of electric current

Flaking caused by oval compression

Flaking caused by axial compression

Flaking caused by deep seated rust

Flaking caused by fretting corrosion

Flaking caused by fluting or craters

Cracks caused by rough treatment

Cracks caused by excessive drive-up

Cracks caused by fretting corrison

Flexible Drive Coupling Flexible Drive Coupling

failure modes failure mechanism (Tyre Coupling)

Premature Component Wear Shaft misalignment axial

Shaft misalignment parallel

Shaft misalignment angular

Shaft thermal expansion

Severe distortion under maximum instantaneous torque (wind-up)

Erratic/pulsating/high-inertia loads

Excessive back-lash within coupling for shock loads

Rotational speed is beyond design RPM

Loosening of the coupling's fastener to the shaft

Changed assembly gap between hubs of the coupling

Damaged or broken components

Bore machined askew

Bore machined non-concentric

Excessive shaft end float

Bent shafts, excessive run-out

Excess back-lash between coupling parts / components

Material-of-Construction incorrect for duty loads / torque

Hub Damage Shaft out-of-round or incorrect form

Split / cracked due to improper interference fit

Movement of the hub on the shaft

Shaft surface finish too rough and offers insufficient surface area for support

Shaft not straight

Shaft under bore nicked, hammer-rash or damaged

Axial misalignment

Concentrated heat on the hubs cause distortion

Keyway Failure Excessive shaft interference fit

High torque load transmitted through the key

Excessively loose fitting key allows high impact on start / reverse

Key Failure Excessively loose fitting key allows high impact on start / reverse

Improper key material selected

Corrosion

Chemical attack

High torque load transmitted through the key

Elastometric Element Failure Excessive torque loading

Atmospheric contamination / deterioration

Chemical attack

Overload

Torsional vibrations (look for liquefaction of the material internal of the insert)

Coupling out-of-balance

Cracked due to rubber hardening from chemical contamination

Elastomer material has limited service life

Excessive high temperature

Flange Fastener Failure High starting or impact loads occur in combination with reversing service or severe load fluctuations exist, fasteners have failed in reverse bending fatigue

Bending fatigue loading may also be characterized by: fretting corrosion on the bolt body diameter, imbedding of the bolt washer face diameter into the sleeve, wallowing out of the sleeve flange holes and/or offset of the bolt body diameter.

Insufficient fastener tightening torque

System torsional vibration

Reversing loads which exceed the flange joint capacity

System was subjected to unexpected overloads

Elongated bolt holes due to fastener impact (fastener loosened off)

Elongated bolt holes due to fastener impact (fastened insufficiently tight)

Cyclic fatigue life exceeded

Shaft passes through natural frequncy and large vibrations / movements cause micro-motion of coupling flanges

6 52

Sources of Information:

http://pt.rexnord.com/products/e-catalog/catalog/CachedImages/0000001/t004_r00171_v0.pdf

http://motionsystemdesign.com/mag/couplings_shafts/

Flexible Drive Coupling

failure mechanism (Gear Coupling)

Gear couplings, frictional movment on teeth due to misalignment

Gear couplings, loss of lubricant film

Gear couplings, not relubricated as maintenance

Gear couplings, contaminated lubricant

Severe distortion under maximum instantaneous torque (wind-up) Gear couplings, sleeve seal cage end ring failures may result from high misalignment, improper gap setting and/or hub axial float

Gear couplings, teeth lock-up due to excessive misalignment

Gear couplings, teeth lock-up due to excessive misalignment

Shaft surface finish too rough and offers insufficient surface area for support

Excessively loose fitting key allows high impact on start / reverse

Excessively loose fitting key allows high impact on start / reverse

Torsional vibrations (look for liquefaction of the material internal of the insert)

Cracked due to rubber hardening from chemical contamination

High starting or impact loads occur in combination with reversing service or severe load fluctuations exist, fasteners have failed in reverse bending fatigue

Bending fatigue loading may also be characterized by: fretting corrosion on the bolt body diameter, imbedding of the bolt washer face diameter into the sleeve, wallowing out of the sleeve flange holes and/or offset of the bolt body diameter.

Elongated bolt holes due to fastener impact (fastener loosened off)

Elongated bolt holes due to fastener impact (fastened insufficiently tight)

Shaft passes through natural frequncy and large vibrations / movements cause micro-motion of coupling flanges

Flexible Drive Coupling

failure mechanism (Jaw Coupling)

Jaw Coupling, elastomer compression set from over-torque

Jaw Coupling, elastomer compression set from normal use

Jaw Coupling, excessive hub spider leg wear

Jaw Coupling, shaft radial misalignment

Jaw Coupling, shaft angular misalignment

Jaw Coupling, shaft axial misalignment

Jaw Coupling, hub spider jaws sheared

High starting or impact loads occur in combination with reversing service or severe load fluctuations exist, fasteners have failed in reverse bending fatigue

Bending fatigue loading may also be characterized by: fretting corrosion on the bolt body diameter, imbedding of the bolt washer face diameter into the sleeve, wallowing out of the sleeve flange holes and/or offset of the bolt body diameter.

Flexible Drive Coupling

failure mechanism (Disc Coupling)

Disk couplings, cracking or breaks in the individual disk packs or bolts

Disk couplings, check for loose disk pack bolts and/or nuts

Disk couplings, disk cyclic fatigue due to excessive misalignment

Bending fatigue loading may also be characterized by: fretting corrosion on the bolt body diameter, imbedding of the bolt washer face diameter into the sleeve, wallowing out of the sleeve flange holes and/or offset of the bolt body diameter.

Electric Motor Electric Motor

failure modes failure mechanism

Over-Current Draw Mechanical overload

Poor power conditioning

Excessive effective service factor

Over-voltage

Voltage unbalance

Brushes fail open

Voltage surges

Drop a phase due to winding failure

Fail to Start Power provider interruption

Under-voltage

Cable mechanically damaged

Cable burnt-out from overload

Cable connection overheated

Motor starter failure

Rotor Damage Winding is saturated with water (ingress of water)

Aspirated moisture (ingress of humidity)

High operating temperature

High ambient temperature

Variable frequency drives are employed, insulation life expectancy will be reduced

Chemical ingress degrades internals

Dirt build-up on cooling fins

Frequent stops and starts

Starting method cause high starting loads

Rotor faults, casting voids

Rotor faults, broken rotor bars

Insulation-to-ground faults

Air gap faults, including eccentric rotors

Overloading (load demands exceeding the rating of the motor)

Improper matching of motor to load (inertia matching)

Loose internal wiring connections

Vibration / mechanical looseness

Excessive starts and reversals

Unequal voltage between phases

Voltage surges, switching power circuits ,lightning strikes, capacitor discharges and solid-state power devices

Nuisance tripping

Transient voltage peaks

Stator Damage Very high currents in the stator winding due to a locked rotor condition

Dirt build-up on cooling fins

Balance weight came loose and struck the winding

Winding is saturated with water (ingress of water)

Aspirated moisture (ingress of humidity)

Moisture over motor allows short-circuit current to earth

Terminal bolting to wrong connection

Terminal bolting loose connection

Loose internal wiring connections

Insulation-to-ground faults

Overloading (load demands exceeding the rating of the motor)

Excessive starts and reversals

Voltage surges, switching power circuits ,lightning strikes, capacitor discharges and solid-state power devices

Nuisance tripping

Transient voltage peaks

Shorts between conductors or coils

Rotor Bar Failure Poor welded connection

Vibration due to misalignment

Vibration transmitted by nearby equipment

Vibration due to loose mountings

Vibration from out-of-balance

Frame distortion from softfoot

Bearing Failure Excessive radial or axial loading

Electric current flowing through bearings from inverters (Variable Frequency Drive waveforms)

Insufficient bearing lubrication

Excess bearing lubrication

Lubricant is contaminated

Incorrect lubricant

Out-of-balance, rotor unbalanced

Out-of-balance, balance weight lost

Induced vibration

Shaft misalignment

Wrong coupling type or installation

Belt misalignment

Incorrect belt tension

Defective bearing housings

Defective shaft mounting

Bad mechanical fits

High static loading when stopped

Frame warpage

Broken mounts

Base plate distortion

Missing or deteriorated grouting

Foundation deterioration

Inadequate foundation size and design

Bad or worn shaft

Shaft, bent and run-out excessive

Shaft, axial float excessive

induced mechanical vibration

Overhung loads

Mechanical resonance

Rotor deflection

Shaft Broken Stress raiser, corrosion

Stress raiser, chemical attack

Stress raiser, scratches, mechanical damage (e.g. Pipe wrench used to turn seized shaft)

Locked rotor

Bending/ torsional fatigue from misalignment

Massive imposed overload

Keyway fatigue

Improper keyway design

Inadequate shoulder fillet radius

Manufacturing defects (residual stresses induced)

Overloaded during operation

Fretting and pitting corrosion

7 100

5

Variable frequency drives are employed, insulation life expectancy will be reduced

Overloading (load demands exceeding the rating of the motor)

Voltage surges, switching power circuits ,lightning strikes, capacitor discharges and solid-state power devices

Very high currents in the stator winding due to a locked rotor condition

Overloading (load demands exceeding the rating of the motor)

Voltage surges, switching power circuits ,lightning strikes, capacitor discharges and solid-state power devices

Electric current flowing through bearings from inverters (Variable Frequency Drive waveforms)

Stress raiser, scratches, mechanical damage (e.g. Pipe wrench used to turn seized shaft)

Pump Set Base Frame Pump Set Base Frame

failure modes failure mechanism

Loose on Foundation Hold-down bolt nuts loose

Hold-down bolts corroded

Hold-down bolts pulled out of concrete

Excessive machine vibration

Warped Frame Foundation not level

Pulled-down unequally on hold-down bolts

Impact by object

Corroded Frame Chemical attack

Water sitting in contact with frame

3 9

1 2

Pump Set Foundation

failure modes

Broken Foundation

Corroded Foundation

Foundation Moves

3

1

Pump Set Foundation

failure mechanism

Impact by object

Concrete shrink cracks

Foundation support flexs

Ground conditions unsuitable

Chemical attack

Ground strength weak

Undersize foundation

7

You might also like

- Centrifugal Pump Set Failure ModesDocument59 pagesCentrifugal Pump Set Failure Modesyozetb80% (5)

- Seal Reliability and Failure AnalysisDocument41 pagesSeal Reliability and Failure Analysiskarioke mohaNo ratings yet

- Asset Integrity Management A Complete Guide - 2020 EditionFrom EverandAsset Integrity Management A Complete Guide - 2020 EditionNo ratings yet

- The Relatioship of Vibration To Problems in Centrifugal Pumps - CheDocument7 pagesThe Relatioship of Vibration To Problems in Centrifugal Pumps - Chehtaboada2008100% (1)

- Troubleshooting Rotating Machinery: Including Centrifugal Pumps and Compressors, Reciprocating Pumps and Compressors, Fans, Steam Turbines, Electric Motors, and MoreFrom EverandTroubleshooting Rotating Machinery: Including Centrifugal Pumps and Compressors, Reciprocating Pumps and Compressors, Fans, Steam Turbines, Electric Motors, and MoreNo ratings yet

- Forsthoffer’s Component Condition MonitoringFrom EverandForsthoffer’s Component Condition MonitoringRating: 4 out of 5 stars4/5 (2)

- Reliability Centered Maintenance Rcm A Complete Guide - 2019 EditionFrom EverandReliability Centered Maintenance Rcm A Complete Guide - 2019 EditionNo ratings yet

- Why Industrial Bearings Fail: Analysis, Maintenance, and PreventionFrom EverandWhy Industrial Bearings Fail: Analysis, Maintenance, and PreventionNo ratings yet

- Case Studies #4: Professional Services For Proactive MaintenanceDocument13 pagesCase Studies #4: Professional Services For Proactive MaintenanceMiguel VillegasNo ratings yet

- Understanding Journal BearingsDocument26 pagesUnderstanding Journal BearingsΡαφαηλ Καμ.100% (1)

- Failure Analysis of Centrifugal Pump ShaftDocument11 pagesFailure Analysis of Centrifugal Pump Shaftyhy_ahmed534450% (2)

- Shaft Fits and TolerancesDocument16 pagesShaft Fits and TolerancesKUNKRINo ratings yet

- Manual AMARILLO Drive Pump Repair Man 250 350 v0215Document23 pagesManual AMARILLO Drive Pump Repair Man 250 350 v0215Widi PrasetyoNo ratings yet

- 3-Day Gen Open 112003 1a (Compatibility Mode)Document84 pages3-Day Gen Open 112003 1a (Compatibility Mode)api-3703348100% (1)

- ARP E Reliability Engineer CourseDocument4 pagesARP E Reliability Engineer CourseLyonelNo ratings yet

- Mode Shapes of Centrifugal Pump Impeller PDFDocument4 pagesMode Shapes of Centrifugal Pump Impeller PDFhachanNo ratings yet

- Troubleshooting VTP Vertical Turbine PumpDocument20 pagesTroubleshooting VTP Vertical Turbine PumpKrrish100% (1)

- Pumps and SystemsDocument5 pagesPumps and SystemsYashwant Kumar Saini100% (2)

- Failure Code 2FEB2019Document30 pagesFailure Code 2FEB2019Rylai CrestfallNo ratings yet

- Diagnostic Reference ChartDocument4 pagesDiagnostic Reference ChartRao ShahbazNo ratings yet

- 10 Steps To Pump Reliability Part 1Document5 pages10 Steps To Pump Reliability Part 1Anonymous ua66zYwrpNo ratings yet

- 07-Sundyne Presentation Fs OringsDocument26 pages07-Sundyne Presentation Fs Oringsjoseellargo0% (1)

- 08-Sundyne Presentation - Fs Installation1Document15 pages08-Sundyne Presentation - Fs Installation1joseellargo100% (1)

- Sunflo Pumps SundyneDocument30 pagesSunflo Pumps Sundynemasoud67aNo ratings yet

- A Study On Failure of Mechanical PumpDocument34 pagesA Study On Failure of Mechanical PumpAzif Ali MoothantevileyilNo ratings yet

- Plant Air CompressorDocument20 pagesPlant Air CompressorAndrei SavvaNo ratings yet

- Condition Monitoring and Assessment For Rotating MachineryDocument22 pagesCondition Monitoring and Assessment For Rotating MachineryMohamed KhaledNo ratings yet

- BearingDocument41 pagesBearingM.IBRAHEEMNo ratings yet

- Steam Trapping Overview GB GST 33 enDocument22 pagesSteam Trapping Overview GB GST 33 enJerges Gerardo Mamani SilvaNo ratings yet

- Shaft Alignment: Oleh: Parno Raharjo Politeknik Negeri Bandung (Politeknik ITB)Document47 pagesShaft Alignment: Oleh: Parno Raharjo Politeknik Negeri Bandung (Politeknik ITB)hanifni2173No ratings yet

- Anti Friction Bearings For PumpsDocument165 pagesAnti Friction Bearings For PumpsJaime BerryNo ratings yet

- Aladon Reliability-Mgmt E-Brochure 062116Document4 pagesAladon Reliability-Mgmt E-Brochure 062116HugoCabanillasNo ratings yet

- Start Up and Operation: Presented by Fs Engineer SundyneDocument36 pagesStart Up and Operation: Presented by Fs Engineer SundyneNaveedullah AwanNo ratings yet

- Condition Monitoring For Steam Turbines Part IIDocument31 pagesCondition Monitoring For Steam Turbines Part IIempswookNo ratings yet

- RCA - 05-P521A Shaft FailureDocument40 pagesRCA - 05-P521A Shaft FailureAnkit SharmaNo ratings yet

- Vibration Diagnostics ChartDocument49 pagesVibration Diagnostics ChartHaitham MohammadNo ratings yet

- SDT Lubrication ULTRASONIDO INGLES PDFDocument14 pagesSDT Lubrication ULTRASONIDO INGLES PDFALONSO SOLÍSNo ratings yet

- Causes of Rotor Distortions and Applicable Common Straightening Methods For Turbine Rotors and ShaftsDocument6 pagesCauses of Rotor Distortions and Applicable Common Straightening Methods For Turbine Rotors and Shaftsbigsteve9088No ratings yet

- Vibration SeverityDocument19 pagesVibration Severityanon_900141394No ratings yet

- Gearbox Vibration - Fact or FictionDocument9 pagesGearbox Vibration - Fact or Fictioneko bagus sunaryoNo ratings yet

- Gearbox Improved Oil Pump Sundyne 40-20-27 Field Engineering BulletinDocument1 pageGearbox Improved Oil Pump Sundyne 40-20-27 Field Engineering BulletinSuresh Kumar MittapalliNo ratings yet

- Bearing Life TimeDocument83 pagesBearing Life TimeFadoooll100% (1)

- Plate Heat Exchangers ManualDocument15 pagesPlate Heat Exchangers ManualMichał KisielewskiNo ratings yet

- Troubleshooting Guide For Fan BearingsDocument11 pagesTroubleshooting Guide For Fan BearingsSanjeevi Kumar SpNo ratings yet

- Tilting Pad TroubleshootingDocument7 pagesTilting Pad Troubleshootinghamedia83No ratings yet

- EngineersGuide2012 UnlockedDocument192 pagesEngineersGuide2012 UnlockedSanan JalilNo ratings yet

- Shaft Alignment & CouplingsDocument30 pagesShaft Alignment & CouplingsInaam Ur RehmanNo ratings yet

- Spirax Marshall Ball Float Steam TrapDocument2 pagesSpirax Marshall Ball Float Steam TrapNikhil RajanNo ratings yet

- Torsional Vibration Analysis of Synchronous Motor Driven TCDocument16 pagesTorsional Vibration Analysis of Synchronous Motor Driven TCBharath Chandra ReddyNo ratings yet

- Centrifugal Pump Troubleshooting GuideDocument10 pagesCentrifugal Pump Troubleshooting GuideSteve Sund100% (1)

- Phase AnalysisDocument3 pagesPhase Analysisk_shah_777No ratings yet

- Grease Refill QtyDocument3 pagesGrease Refill QtyParmasamy SubramaniNo ratings yet

- Turbo Machinery Operation and MaintenanceDocument2 pagesTurbo Machinery Operation and MaintenanceNirmal SubudhiNo ratings yet

- 12 1989 Shaft StressDocument4 pages12 1989 Shaft StressRonald GeorgeNo ratings yet

- MisalignmentDocument13 pagesMisalignmentZeeshan Sajid100% (1)

- 1 - Overview Rev-20170225Document11 pages1 - Overview Rev-20170225AhmadNo ratings yet

- Optimizing Equipment Maintenance PDFDocument244 pagesOptimizing Equipment Maintenance PDFAgung MhzNo ratings yet

- Vibraition For Non-Vibraiton EngineersDocument35 pagesVibraition For Non-Vibraiton EngineersMuralitcl100% (1)

- Whitepaper Reciprocating MachineryDocument19 pagesWhitepaper Reciprocating MachinerySofiane HalimiNo ratings yet

- Disiglent Power Factory ModellingDocument1 pageDisiglent Power Factory ModellingJohn TanNo ratings yet

- Tension Insulator SwingDocument1 pageTension Insulator SwingJohn TanNo ratings yet

- Plscadd UploadDocument1 pagePlscadd UploadJohn TanNo ratings yet

- Existin G: New M69 Drain ValveDocument1 pageExistin G: New M69 Drain ValveJohn TanNo ratings yet

- It All Comes Tumbling DownDocument1 pageIt All Comes Tumbling DownJohn TanNo ratings yet

- Dislighent Modelling Done by Athe Bond OsDocument1 pageDislighent Modelling Done by Athe Bond OsJohn TanNo ratings yet

- I Am The Bone of My SWRRD FGDocument1 pageI Am The Bone of My SWRRD FGJohn TanNo ratings yet

- How ToDocument1 pageHow ToJohn TanNo ratings yet

- Young Engineers Chartered Survey ResultsDocument1 pageYoung Engineers Chartered Survey ResultsJohn TanNo ratings yet

- This Is The EndDocument1 pageThis Is The EndJohn TanNo ratings yet

- SdasDocument1 pageSdasJohn TanNo ratings yet

- DOCument AsdcDocument1 pageDOCument AsdcJohn TanNo ratings yet

- DfsdsDocument1 pageDfsdsJohn TanNo ratings yet

- PlescdDocument1 pagePlescdJohn TanNo ratings yet

- How ToDocument1 pageHow ToJohn TanNo ratings yet

- UBW - DSMDocument1 pageUBW - DSMJohn TanNo ratings yet

- Admednatns S D Sad As Das D As D As D AsDocument1 pageAdmednatns S D Sad As Das D As D As D AsJohn TanNo ratings yet

- Modal VerifyDocument1 pageModal VerifyJohn TanNo ratings yet

- Corrosion of Car BodyDocument1 pageCorrosion of Car BodyJohn TanNo ratings yet

- PIPE, PUMPS and Valves. This Is A Coument Etc Sdsad SD Sad As D Sad Sad Sa Dsa D SaDocument1 pagePIPE, PUMPS and Valves. This Is A Coument Etc Sdsad SD Sad As D Sad Sad Sa Dsa D SaJohn TanNo ratings yet

- EndNote X7 Installation-InstructionDocument1 pageEndNote X7 Installation-InstructionJohn TanNo ratings yet

- Truss-FEM AnalysisDocument3 pagesTruss-FEM AnalysisJohn TanNo ratings yet

- Mental Health Legal IssuesDocument4 pagesMental Health Legal IssuesJohn TanNo ratings yet

- Structural Analysis and Design Tcm4-118204Document141 pagesStructural Analysis and Design Tcm4-118204nataliepoison8917No ratings yet

- Gear ForcesDocument7 pagesGear ForcesSahil Kumar100% (1)

- FatigueDocument5 pagesFatigueJohn TanNo ratings yet

- Part K: Corresponding To The End Tip of The RampDocument2 pagesPart K: Corresponding To The End Tip of The RampJohn TanNo ratings yet

- Eng ChartDocument12 pagesEng ChartJohn TanNo ratings yet

- CodeDocument1 pageCodeJohn TanNo ratings yet

- Typical Initial Cathodic Protection Current Densities in Chloride Contaminated Stucutres Are in The Range of 1 To 20 Ma/m2 of Steel SurfaceDocument1 pageTypical Initial Cathodic Protection Current Densities in Chloride Contaminated Stucutres Are in The Range of 1 To 20 Ma/m2 of Steel SurfaceJohn TanNo ratings yet

- Pump - Model Hurlcon CTX SeriesDocument2 pagesPump - Model Hurlcon CTX SeriesMechanicalLatestNo ratings yet

- UTP CementDocument56 pagesUTP CementbrayanNo ratings yet

- Experimental Evaluation of A Solid Desiccant System Integrated With Cross Flow Maisotsenko Cycle Evaporative CoolerDocument12 pagesExperimental Evaluation of A Solid Desiccant System Integrated With Cross Flow Maisotsenko Cycle Evaporative CoolerkashifNo ratings yet

- Plastic Laser Welding Design Guidelines PDFDocument14 pagesPlastic Laser Welding Design Guidelines PDFAbhishek MohiteNo ratings yet

- Bohler-Welding-Germany 207Document1 pageBohler-Welding-Germany 207Anghelache RazvanNo ratings yet

- Tarifa Repagas 2015 PDFDocument284 pagesTarifa Repagas 2015 PDFAntonio Alvarez DominguezNo ratings yet

- Kennedy GVDocument4 pagesKennedy GVoscarninanNo ratings yet

- Chapter8 Vapor Cycles ProblemsDocument77 pagesChapter8 Vapor Cycles ProblemsAldren ArnaizNo ratings yet

- WDE - Anganwadi Building - PasthalaDocument52 pagesWDE - Anganwadi Building - PasthalaGurram Lakshmi NavakanthNo ratings yet

- 4 - SPC-FD-Part 4 of 5-Division 26Document1 page4 - SPC-FD-Part 4 of 5-Division 26Fathy RamadanNo ratings yet

- Traditional and Innovative Joints in Bamboo ConstructionDocument3 pagesTraditional and Innovative Joints in Bamboo ConstructionAulia Rahman FahmiliNo ratings yet

- RYfnnd 7 LQ 1180612121529Document206 pagesRYfnnd 7 LQ 1180612121529Bickey LakhaNo ratings yet

- Padstones Bearing Lengths MM) Max Fac Reaction F Under BearingDocument19 pagesPadstones Bearing Lengths MM) Max Fac Reaction F Under BearingFaraz HussainNo ratings yet

- Bulkhead Connector: 1" PM25 EntireDocument3 pagesBulkhead Connector: 1" PM25 EntireJ Gabriel GomezNo ratings yet

- Fire Door Assembly Classifications: DecodedDocument3 pagesFire Door Assembly Classifications: DecodedTty SmithNo ratings yet

- Sika Concrete Hand BookDocument151 pagesSika Concrete Hand BookIwan TirtaNo ratings yet

- IBR - 1950 - Reg. 391 A - 1Document3 pagesIBR - 1950 - Reg. 391 A - 1Balakrishna G Setty0% (1)

- Manolea H Modern Approaches in Choosing Materials For Implant Supported ProsthesisDocument7 pagesManolea H Modern Approaches in Choosing Materials For Implant Supported ProsthesisHoriaManNo ratings yet

- Gajjar Industries ADocument15 pagesGajjar Industries AMPNo ratings yet

- R600a R1150Document4 pagesR600a R1150elpancasero77No ratings yet

- Valve - Check - Globe - StopDocument288 pagesValve - Check - Globe - StopveneethgeoNo ratings yet

- 2022 11 - TMS402 602 22 ArcCastStoneDocument2 pages2022 11 - TMS402 602 22 ArcCastStonejomargatemarceloNo ratings yet

- CSC Portal FrameDocument11 pagesCSC Portal FramePhilip AmankwahNo ratings yet

- Nickel and Other Super Alloys: TSUF 06 Materiales AeronauticosDocument28 pagesNickel and Other Super Alloys: TSUF 06 Materiales AeronauticosFam HandmNo ratings yet

- Samsing Washing Machine ManualDocument44 pagesSamsing Washing Machine ManualSoyoko U.0% (1)

- Furnace Replace Carrier 302075 304 Board Ig LIAF044 1Document2 pagesFurnace Replace Carrier 302075 304 Board Ig LIAF044 1topogigio240No ratings yet

- MESC SPE 74-014 - 2010 - Duplex-Superduplex Ss Pipe To Astm A790Document12 pagesMESC SPE 74-014 - 2010 - Duplex-Superduplex Ss Pipe To Astm A790sathi11189No ratings yet

- Eaton FAZ Miniature Circuit Breakers (MCBS)Document91 pagesEaton FAZ Miniature Circuit Breakers (MCBS)kn65238859No ratings yet

- Thermodynamic HWDocument9 pagesThermodynamic HWMuzamil ShahNo ratings yet

- Awtz14lbc Aotz14lbc 9315236036 OperationDocument28 pagesAwtz14lbc Aotz14lbc 9315236036 OperationjovanangelssNo ratings yet