Professional Documents

Culture Documents

Reciprocating Pump

Uploaded by

muna222Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reciprocating Pump

Uploaded by

muna222Copyright:

Available Formats

AIM OF THE EXPPERIMENT :Study of reciprocating pump.

REQUIRMENTS:

1.Model of reciprocating pump.

2.Map of reciprocating pump.

THEORY:Reciprocating pump is a positive displacement pump in which the liquid is sucked and

then it is pushed due to the thrust exerted on it by a moving member,which results in lifting the liquid tp

the required height. The reciprocating pumps can be classified according to the liquid being in pumps

can be classified according to the liquid being in contact with one side or bpth sides of the piston and

according to the number of cylinders provided.According to former the reciprocating pumps may be

classified as (1)single acting pump (2)double acting pump.In single acting pump the liquid is in contact

with one side of piston.But in double acting pump the same is in contact with both the sides of the

piston.According to the number of cylinders, the reciprocating pumps may be classified as (1)Single

cylinder pump (2)double cylinder pump (3)triple cylinder pump (4)duplex double acting pump and

(5)quintuplex pump.

CONSTRUCTION: A reciprocating pump in its simplest form consits of a cylinder in which a piston

works.The movement of the piston is obtained by a connecting rod,which connects the piston and the

rotating crank.A suction pipe connects the source of water and cylinder.A deliver pipe is fitted to an air

vessel into which the water is discharged from the cylinder .A suction valve on the suction pipe admits

the flow from the suction pipe to the cylinder .A delivery valve on the delivery pipe admits the fluid to

flow to measuring tank.An air vessel filled with compressed air keeps the flow uniform.A spring loaded

safety valve releases extra pressure from the delivery pipe.

WORKING PRINCIPLE : During the suction stroke, the piston moves towards the right, thus creating

vacuum in the cylinder . This vacuum causes the suction valve to open and water enters the cylinder.

During the delivery stroke the piston moves towards left, thus increasing pressure in the cylinder .This

increase in pressure causes the suction valve to close and delivery valve to open and the water is forced

into the air vessel. Air vessel maintains the uniform flow and discharges the liquid to the delivery pipe.

If in a single acting reciprocating pump

L=length of the stroke in meters

A=cross sectional area of the piston in m

N=r.p.m.of crank

Q=LAN/60 m/sec

PRACTICAL APPLICATION :Reciprocating pumps are used for high head and small discharge .

PROCEDURE: Draw the constructional details of a reciprocating pump. Locate the different parts .Rotate

the handle of reciprocating pump model .Observe the motion of the piston and valve position of it.Give

five numbers of important manufacture of reciprocating pump.

You might also like

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Chapter 6 - PumpDocument50 pagesChapter 6 - Pumpa9157272235No ratings yet

- Net Positive Suction Head for Rotodynamic Pumps: A Reference GuideFrom EverandNet Positive Suction Head for Rotodynamic Pumps: A Reference GuideRating: 5 out of 5 stars5/5 (1)

- Reciprocating PumpDocument2 pagesReciprocating PumpMd. Masudur RahmanNo ratings yet

- Chapter 2:-Reciprocating Pump 2.1: IntroducationDocument7 pagesChapter 2:-Reciprocating Pump 2.1: IntroducationParth VyasNo ratings yet

- Chapter 3Document17 pagesChapter 3mohamedbadawyNo ratings yet

- Reciprocating Pump With Air VesselDocument19 pagesReciprocating Pump With Air VesselKrunal Patil93% (15)

- Pumps 220308 155039Document23 pagesPumps 220308 155039Dhruvi PadmaniNo ratings yet

- Lab ReportDocument8 pagesLab ReportNurMd NabilNo ratings yet

- Assignment Pump and Its PartsDocument19 pagesAssignment Pump and Its PartsSabyasachi PradhanNo ratings yet

- Pumps: Pumps and Its TypesDocument34 pagesPumps: Pumps and Its TypesAmir Hamza100% (1)

- CF Pump Study 1stageDocument7 pagesCF Pump Study 1stageHa M ZaNo ratings yet

- Chapter 4 2Document39 pagesChapter 4 2Subarna RegmiNo ratings yet

- I. History: II. Typical Design / Parts / ComponentsDocument16 pagesI. History: II. Typical Design / Parts / ComponentsAriel GamboaNo ratings yet

- Pump & Types of PumpsDocument33 pagesPump & Types of PumpsAhmad JuttNo ratings yet

- Reciprocating Pump: Presented ByDocument10 pagesReciprocating Pump: Presented ByNikhil ChauhanNo ratings yet

- Pumps 01Document15 pagesPumps 01Pyae Sone KyawNo ratings yet

- Reciprocating PumpDocument6 pagesReciprocating PumpManish SoniNo ratings yet

- Lec-8 Fm-IiDocument18 pagesLec-8 Fm-IiAzhar AliNo ratings yet

- ReciprocatingDocument15 pagesReciprocatingRohit soniNo ratings yet

- CHC303 Report (Pumps) - 20CH8067 - Sabyasachi PradhanDocument19 pagesCHC303 Report (Pumps) - 20CH8067 - Sabyasachi PradhanSabyasachi PradhanNo ratings yet

- Design of Radial Flow Pump UPDATEDDocument74 pagesDesign of Radial Flow Pump UPDATEDrahuldbajaj2011100% (1)

- Design, Installation and Fabrication of Reciprocating PumpDocument40 pagesDesign, Installation and Fabrication of Reciprocating PumpMehdi Baghaie78% (9)

- Activity No. 3 Study of Pump Units - Positive and Non-Positive Displacement IDocument19 pagesActivity No. 3 Study of Pump Units - Positive and Non-Positive Displacement ILeonito Ypon FulgadoNo ratings yet

- Classification of PumpsDocument23 pagesClassification of PumpsRam Krishna SinghNo ratings yet

- Hydrauli C Pumps: Sebastian Rivera Lina Soto Jose Roa Introduced To: Felipe LealDocument32 pagesHydrauli C Pumps: Sebastian Rivera Lina Soto Jose Roa Introduced To: Felipe LealSebastian RiveraNo ratings yet

- Name of The Expt: Performance Test On Reciprocating PumpDocument6 pagesName of The Expt: Performance Test On Reciprocating PumpIndra Chandra RazbongshiNo ratings yet

- Lecture 12 - ME 101 - May 2018 - Pump Fan Blower - FinalDocument19 pagesLecture 12 - ME 101 - May 2018 - Pump Fan Blower - FinalAbeer Hossain AneekNo ratings yet

- Chapter:3 Tyep of Reciprocating Pump 3.1: Classification of Reciprocating PumpDocument10 pagesChapter:3 Tyep of Reciprocating Pump 3.1: Classification of Reciprocating PumpParth VyasNo ratings yet

- Faculty of Engineering Technology and Research: Centrifugal PumpDocument16 pagesFaculty of Engineering Technology and Research: Centrifugal PumpsushantNo ratings yet

- Hydraulic PumpsDocument40 pagesHydraulic PumpsRanjith KNo ratings yet

- A Course On Reciprocating PumpDocument11 pagesA Course On Reciprocating PumpSwami VedatitanandaNo ratings yet

- Pumps: Principle of A Hydraulic PumpDocument20 pagesPumps: Principle of A Hydraulic PumpMaureen KamauNo ratings yet

- PumpsDocument11 pagesPumpsamk3745No ratings yet

- Reciprocating PumpsDocument11 pagesReciprocating PumpsOwais EngrNo ratings yet

- 5.resiprocating PumpsDocument15 pages5.resiprocating PumpsRonak patelNo ratings yet

- Fluid Mechanics PumpsDocument63 pagesFluid Mechanics PumpsKaushik SreenivasNo ratings yet

- Lesson 6 PumpsDocument9 pagesLesson 6 PumpsBon Adrian IsabedraNo ratings yet

- Ivan-Mac Ivan MagbatocDocument16 pagesIvan-Mac Ivan MagbatocJayjay MonterdeNo ratings yet

- 20-ME-9 Uzair Akram FM Lab 7Document8 pages20-ME-9 Uzair Akram FM Lab 7uzair akramNo ratings yet

- (Pumps) : Report AboutDocument10 pages(Pumps) : Report AboutCutie PieNo ratings yet

- Positive Displacement Pump Pressure or Head: Activity No. 3 Physical Study of Pump UnitDocument9 pagesPositive Displacement Pump Pressure or Head: Activity No. 3 Physical Study of Pump UnitMerie Ann Aumentado CallejaNo ratings yet

- Intro To Positive Displacement PumpsDocument8 pagesIntro To Positive Displacement PumpsMuhammad RidhwanNo ratings yet

- Types of Pumps and Centrifugal PumpDocument23 pagesTypes of Pumps and Centrifugal PumpRatul HasanNo ratings yet

- By: Ricky S. Alegre Gabrel C ArsenioDocument19 pagesBy: Ricky S. Alegre Gabrel C ArsenioVictor GuijoNo ratings yet

- PumpdesignDocument45 pagesPumpdesignFredric PaulNo ratings yet

- Pumps Notes: H Q PowerDocument12 pagesPumps Notes: H Q PowerahmedaboshadyNo ratings yet

- Fluids Week 10: Types of Reciprocating PumpsDocument9 pagesFluids Week 10: Types of Reciprocating PumpsRecla DynmerNo ratings yet

- For Other Uses of "Pump" or "Pumps", SeeDocument26 pagesFor Other Uses of "Pump" or "Pumps", Seekhalil zahaniNo ratings yet

- Pumps: Displacement Pumps Reciprocating Pump Rotary PumpDocument9 pagesPumps: Displacement Pumps Reciprocating Pump Rotary PumpHassan technologistNo ratings yet

- PumpsDocument5 pagesPumpsBRIGHT TETTEHNo ratings yet

- Pump Pump Piping Presentation PDFDocument55 pagesPump Pump Piping Presentation PDFPoonam Ashwin100% (1)

- Chapter 1Document140 pagesChapter 1Syed YousufuddinNo ratings yet

- Chapter 2Document32 pagesChapter 2Uzair MaswanNo ratings yet

- By The End of The Lecture, The Students Will Be Able To: - Be Familiarized With Reciprocating Type of PumpsDocument28 pagesBy The End of The Lecture, The Students Will Be Able To: - Be Familiarized With Reciprocating Type of PumpsKim TanNo ratings yet

- Figure: Centrifugal PumpDocument5 pagesFigure: Centrifugal PumpDhruv BagadeNo ratings yet

- Torsion Testing MachineDocument2 pagesTorsion Testing Machinemuna222No ratings yet

- Study of Reaction TurbineDocument2 pagesStudy of Reaction Turbinemuna222No ratings yet

- Pulse Tube RefrigeratorDocument6 pagesPulse Tube Refrigeratormuna222No ratings yet

- Experiment No - 3.10: Aim of The ExperimentDocument2 pagesExperiment No - 3.10: Aim of The Experimentmuna222No ratings yet

- Impact Testing MachineDocument4 pagesImpact Testing Machinemuna222No ratings yet

- Aim of The ExperimentDocument2 pagesAim of The Experimentmuna222No ratings yet

- Francis TurbineDocument3 pagesFrancis Turbinemuna222No ratings yet

- Degree (Angle) - Wikipedia, The Free EncyclopediaDocument4 pagesDegree (Angle) - Wikipedia, The Free Encyclopediamuna222No ratings yet

- Aim of The Experiment: Max w1 1Document3 pagesAim of The Experiment: Max w1 1muna222No ratings yet

- Brinell Hardness TestingDocument4 pagesBrinell Hardness Testingmuna222No ratings yet

- Ultrasonic Sensor - Wikipedia, The Free EncyclopediaDocument3 pagesUltrasonic Sensor - Wikipedia, The Free Encyclopediamuna222No ratings yet

- 4 Traction and StressDocument16 pages4 Traction and Stressmuna222No ratings yet

- Metallurgical Changes in Steels Due To Cryogenic Processing Its Applications Full ReportDocument14 pagesMetallurgical Changes in Steels Due To Cryogenic Processing Its Applications Full Reportmuna222No ratings yet

- Springs: Definition For SpringDocument20 pagesSprings: Definition For Springmuna222No ratings yet

- Mechanical Engineering LaboratoryDocument3 pagesMechanical Engineering Laboratorymuna222No ratings yet

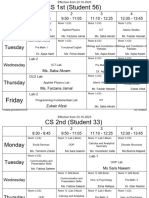

- 3b - Classwise Time Table - 2Document15 pages3b - Classwise Time Table - 2Hamza khalidNo ratings yet

- Mobile Crane Inspector & CertificationDocument3 pagesMobile Crane Inspector & CertificationgptothNo ratings yet

- Flight Training Instruction: Naval Air Training CommandDocument174 pagesFlight Training Instruction: Naval Air Training CommandITLHAPN100% (1)

- Cembrit Patina Design Line - LowresDocument11 pagesCembrit Patina Design Line - LowresRaul AntonieNo ratings yet

- Vacuum Gauges 45Document20 pagesVacuum Gauges 45Sameeksha AnandNo ratings yet

- Lab 1: Basic Cisco Device Configuration: Topology DiagramDocument17 pagesLab 1: Basic Cisco Device Configuration: Topology DiagramnhiNo ratings yet

- Na Edifact Desadv SpecificationsDocument17 pagesNa Edifact Desadv Specificationsrajendra2505No ratings yet

- TPCN Monthly List of Subcontractors 06-2017Document3 pagesTPCN Monthly List of Subcontractors 06-2017Teddy WilsonNo ratings yet

- FTJ Series Product Guide PDFDocument12 pagesFTJ Series Product Guide PDFJhon SendokNo ratings yet

- 1 1 6 Blood Splatter Analysis Experimental DesignDocument4 pages1 1 6 Blood Splatter Analysis Experimental Designapi-343751193100% (1)

- Surface Roughness TesterDocument1 pageSurface Roughness TesterRenju NairNo ratings yet

- Active Suspension System of Quarter CarDocument70 pagesActive Suspension System of Quarter CarMarcu SorinNo ratings yet

- Copyright Green PaperDocument122 pagesCopyright Green Papertorrentfreak100% (1)

- Automotive Engg. & TechnologyDocument15 pagesAutomotive Engg. & TechnologysayuuishotNo ratings yet

- Physics 2Document2 pagesPhysics 2MarcusKlahnTokoeJr.No ratings yet

- Faqs: Instant Credit Card Approval and IssuanceDocument1 pageFaqs: Instant Credit Card Approval and Issuancedaong_84No ratings yet

- A5 MSMD 400WDocument1 pageA5 MSMD 400WInfo PLSNo ratings yet

- Wwii Aircraft Vol 2Document50 pagesWwii Aircraft Vol 2Virág Árpád100% (5)

- On The Job Winter 2013Document3 pagesOn The Job Winter 2013alanhynesNo ratings yet

- Mass Flow SensorDocument0 pagesMass Flow Sensorwong_arifNo ratings yet

- Technical Proposal: Genale Dawa-6 Hydroelectric Power ProjectDocument336 pagesTechnical Proposal: Genale Dawa-6 Hydroelectric Power ProjectEyob AdNo ratings yet

- PTX PRM PGL T5 750929eDocument382 pagesPTX PRM PGL T5 750929eListiyo Imam SantosoNo ratings yet

- My CVDocument2 pagesMy CVKourosh AhadiNo ratings yet

- Udhe 2.standardsDocument1 pageUdhe 2.standardsom dhamnikarNo ratings yet

- Mail Scanner - Community Ubuntu DocumentationDocument4 pagesMail Scanner - Community Ubuntu DocumentationAjith PathiranaNo ratings yet

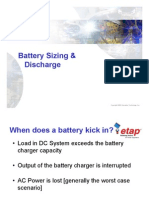

- 23 - Battery Sizing DischargeDocument19 pages23 - Battery Sizing Dischargechanchai T100% (4)

- Course Add Drop Form For Ug Course 1718T2 PDFDocument1 pageCourse Add Drop Form For Ug Course 1718T2 PDFArtyomNo ratings yet

- AcknowledgementDocument4 pagesAcknowledgementPurna GuptaNo ratings yet

- ASME VIII Unfired Vessel Relief ValvesDocument53 pagesASME VIII Unfired Vessel Relief Valvessaid530No ratings yet

- PDF CatalogEngDocument24 pagesPDF CatalogEngReal Gee MNo ratings yet