Professional Documents

Culture Documents

Product Range Folder Gas Updated 130123

Uploaded by

sbtbrkcbcOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product Range Folder Gas Updated 130123

Uploaded by

sbtbrkcbcCopyright:

Available Formats

MICROPUMPS

www.xavitech.com

>

CONCEPT

Principle of operation The micro-

pumps from Xavitech are based

on the principle of the oscillating

displacement pump. The motor

causes an internal axle to move back

and forth. This action is transferred

to the elastic diaphragm which, in

cooperation with the non-return

valve, produces the pumping effect.

>

X-LIFE MOTOR

The patented pump technology

from Xavitech is unique in several

aspects. Thanks to the X-life motor

design, problems associated with

other electro-magnetic pumps are

simply eliminated. The axle motion

is friction-less and it avoids striking

into the magnet. As a consequence,

the lifetime is long, the operation

is safe, free of sparks, and reliable.

In addition, the pump is oil-less and

free of maintenance.

>

INTELLIGENT

The Xavitech pumps are also char-

acterized by the built-in intelligence,

offered by the internal microproces-

sor and the patented positioning

system that displays the location

and motion of the axle. This opens

up vast new possibilities. For exam-

ple, the axle motion reveals informa-

tion of the working conditions (e.g.

stroke frequency, flow, and pres-

sure). By processing this information,

the pump can automatically take

necessary measures in real-time

to adjust its performance according

to any condition changes.

GAS PUMPS

Long Life-Time

Calibrated ow

Customized functions

System savings

KEY BENEFITS

Serial control

Pressure measuring capabilities

Flow and pressure regulating capa-

bilities

Constant flow regardless of battery

voltage

LCD control capabilities

Programmable frequency

Contol capabilities of external

components

APPLICATIONS

Gas analysis

Pressure / vacuum holding

Picking machines

Blood pressure

NPWT pump

Aneastetic delivery

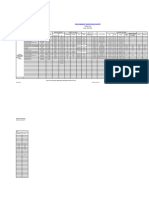

V1500-GAS-12V V1500-GAS-24V P1500-GAS-12V P1500-GAS-24V

Voltage* 5-12V 12-24V 5-12V 12-24V

Max ow 800 ml/min 1000 ml/min 1000 ml/min 1000 ml/min

Max vacuum 350 mbar 350 mbar 110 mbar 110 mbar

Max pressure 110 mbar 110 mbar 350 mbar 350 mbar

Wetted parts PPS & EPDM PPS & EPDM PPS & EPDM PPS & EPDM

Minimum supply 470F, 10V @ 1000F, 25V @ 470F, 10V @ 1000F, 25V @

Capacitator 5V supply 12V supply 5V supply 12V supply

470F, 25V @ 1000uF, 35V @ 470F, 25V @ 1000F, 35V @

12V supply 24V supply 12V supply 24V supply

*) Each pump can be run at a lower voltage than the specified maximum, but this will then reduce the performance.

STANDARD

GAS PUMPS

>

GENERAL DATA V1500/P1500

Motor type: X-Life motor

Permissible amb. temp.: 0C to 55C

Medium temp.: 0C to 55C

Weight: 105 grams

Dimensions (L*H*W): 57*31*31 mm

Tube connectors: 4 mm in diameter

V200-GAS-5V V200-GAS-12V P200-GAS-5V P200-GAS-12V

Voltage* 3.2-5V 5-12V 3.2-5V 5-12V

Max ow 300 ml/min 350 ml/min 300 ml/min 350 ml/min

Max vacuum 300 mbar 350 mbar 70 mbar 150 mbar

Max pressure 70 mbar 150 mbar 350 mbar 350 mbar

Wetted parts PPS & EPDM PPS & EPDM PPS & EPDM PPS & EPDM

Minimum supply 47F, 6.3V @ 100F, 10V @ 47F, 6.3V @ 100F, 10V @

Capacitator 3.3V supply 5V supply 3.3V supply 5V supply

47F, 10V @ 100uF, 16V @ 47F, 10V @ 100F, 16V @

5V supply 12V supply 5V supply 12V supply

*) Each pump can be run at a lower voltage than the specified maximum, but this will then reduce the performance.

STANDARD

GAS PUMPS

>

GENERAL DATA V200/P200

Motor type: X-Life motor

Permissible amb. temp.: 0C to 55C

Medium temp.: 0C to 55C

Weight: 39 grams

Dimensions (L*H*W): 37*21*21 mm

Tube connectors: 3 mm in diameter

>

TECHNICAL NOTE

INSTALLATION/OPERATION

Power supply

All pumps are of diaphragm type and require

a regulated DC voltage. This DC voltage is

internally applied to a built-in intelligent

motor controller which regulates the pump

motion.

The motor in the pump causes a ripple on

the supplied DC voltage. Therefore it is

required to use an external capacitor. The

minimum required capacitor is specified for

each pump in this document and the con-

nection scheme is shown below. The ripple

can be further decreased by an increase of

the capacitance. Keep in mind that specified

voltage over capacitor must be higher than

the peak of the voltage ripple.

Please note that

Missing external capacitor can damage the pump.

Incorrect lead connection can damage the pump.

To insure lifetime, air filters should be used in order to

prevent contaminations like dust to enter the pump.

The connector is 70.1 mm wide and 0.30.05 mm

thick. 70-75 mm long.

Recommended connector: Molex 0526100672 FFC/

FPC.

Connection scheme:

Vacuum and pressure control The volt-

age range specified for each pump in this

document can be used to control vacuum

or pressure. Using V-pumps you can control

vacuum with voltage and for P-pumps

you can control the pressure. In general,

the higher voltage, the higher maximum

vacuum/pressure is possible. In addition, a

higher voltage results in a higher flow due to

a slightly increased stroke frequency.

Frequency adjustment via analog input The

stroke frequency, and thus the flow, can be

changed independently of the applied volt-

age. This is an important feature that enables

flow control independently of supply volt-

age and thus a lower flow can be achieved

without reducing maximum vacuum/pres-

sure. In addition, this enables the users to

minimize the current consumption and it

suppresses the need of flow restrictors. Con-

sequently, this allows the users to be both

cost-effective and power efficient.

TECHNICAL NOTES

PIN DESCRIPTION VOLTAGE RANGE

VCC Supply voltage See each pump

GND Ground Ground

I/O X Default frequency (max) =0-0.05

Voltage controlled freq. range =0.05-2.75

Pump stop =2.8-3,3

I/O R Serial receive connector with Logic Hi=1,71-3,3

10k internal pull-up Logic Lo=0-0,85

I/O T Serial transmit connector Logic Hi=2,85

with 10k internal pull-up Logic Lo=0

PRINCIPLE OF

OPERATION

Flow in

Open Valve

Membrane

Moving disc,

PCB

Photo transistor

Flat spring

Electromagnet

Closed Valve

IR emitter

Xavitech pump pulling gas

Flow out

Xavitech pump pushing gas

Mote light hits photo

transistor

Airgap/strokelength

Closed Valve

Open valve

>

PUMPING MOTION

The microcontroller directs cur-

rent through the electromagnet.

This make the moving disc to move

towards the electromagnet thus the

membrane get pulled by the disc.

Then the inlet valves opens and the

outlet valve closes, and the pump-

chamber is filled with gas. Mean-

while the microcontroller samples

(in 10kHz) the analog voltage gener-

ated by phototransistor to deter-

mine the disc position. When the

position of the disc are cose to the

elctromagnet, the microcontroller

stops directing current through the

electromagnet.

Then the tension in the flat spring

generates a force to push the mov-

ing disc back to its default position

thus the pumpchamber is emptied.

Depending on what flow the pump

is calibrated for the microcontroller

have a delay before it direct current

through the electromagnet again. A

standard pump works with a fre-

quency of about 100Hz.

The great lifetime of the V200 is

achived by not having any bearings

and brusches.

SERIAL FLOW

CONTROL

>

DESCRIPTION

The pump frequency, and thus the

flow, can be changed indepen-

dently of the applied voltage. This

is an important feature that enables

flow control independently of sup-

ply voltage and thus a lower flow

can be achieved without reducing

maximum vacuum/pressure. This

also reduces current consumption

and the need of flow restrictors.

It is both costeffective and power

efficient.

>

ASYNCHRONOUS COMMUNI-

CATION

The standard pump has 9600 baud

asynchronous communication at

8bit using one start bit no stop bit

and no parity. Serial communication

with SPI or I2C can be implemented

on special requests, but the purpose

of this document is to describe

standard pump.

>

SERIAL PROTOCOL

By default pump frequency is

controlled by analog input pin

I/O X. This is further described in

installation and operation notes in

the datasheets of standard pumps.

Analog frequency control will

be automatically turned off and

switched to serial control when

first serial package is sent. After that

I/O X only works as a pump on/off

switch. The command package is 10

bytes long:

<0> <0> <0> <0> <1> <126>

<129> <Lo Byte> <Hi Byte> <CHKSM>

Maximum allowed time between

the bytes in the package is 10mS.

The frequency is defined as a 16-bit

number and is actually a delay time

between each new pump stroke.

Therefore the highest frequency

is achieved by the lowest number.

The lowest allowed delay time on

the standard pump is 80 delay units

and the maximum allowed delay

time is 65535. That represents about

160Hz to 0,5Hz at free flow. If it

is liquid being umped the maxi-

mum flow is not at the maximum

frequency. Depending on viscosity

the maximum flow can be found

by gradually decrease frequency

from maximum until a maximum is

observed. This 16-bit number is sent

to the pump as two bytes. The Hi

Byte and the Lo Byte.

>

CHECKSUM

To ensure that the package is com-

plete and correct

a checksum has to be sent to the

pump as the last byte in the pack-

age. The checksum is a sum of all

first nine bytes in the command

package sent to the pump. This

number usually becomes larger than

one byte. By only using the lower 8

bits of the checksum, the checksum

can fit into a byte. Example:

Delay = 1000

<0> <0> <0> <0> <1> <126> <129> <232>

<3> <235>

>

COMMAND CONFIRMATION

Within 100mS the pump should

return the byte <165> as a confirma-

tion that command was executed. If

the pump return <90> then com-

mand checksum was incorrect. If

no confirmation is received within

100mS the pump has not detected

a complete command.

ELECTRICAL

INTERFACE

PIN

VCC

GND

I/O X

I/O R

I/O T

Description

Supply

Ground

Max freq.

Freq. Control

Pump stop

Serial receive

10k Ohm internal

pull-up

Serial transmit

10k Ohm internal

pull-up

Voltage range

See each pump

0 V

= 0-0.05V

= 0.05 - 2.75V

= 2.8 - 3.3V

Logic hi=1.71 - 3.3V

Logic lo=0-0.85V

Frequency adjustment

16-bit resolution

>

INTRODUCTION

Customers have been asking for a

low cost mounting solution which

can be used on PCBs or drilled holes

in steel sheets or plastic housings.

Xavitech can now offer a ready to

use solution for this to meet cus-

tomer demands.

>

THE SOLUTION

The solution is based on moulded

parts in soft TPE material for pull

through quick mount. It is resistant

to ageing and has a broad tem-

perature range of -20 to 70 degrees

celcius. By press fitting two soft

holders, one from each side of the

pump, you get 4 soft arrow like pins

underneath the pump. Theese pins

you can pull through holes and they

will expand on the other side of a

PCB and thus create a lock. There

are two arrows on each pin so you

can mount the pump at two diffrent

levels. At level 1 the pump will be

elevated 2.75mm and enables you to

have electrical components un-

derneath the pump. When pump is

mounted on PCB, excessive parts of

the pin underneath the PCB can be

cut away.

MOUNTING FOR

200 & 250 PUMP

TPE material

Absorbs vibration

Mounts on PCB or sheet drill holes

Optional mounting height

>

INTRODUCTION

Customers have been asking for a

low cost mounting solution which

can be used on PCBs or drilled holes

in steel sheets or plastic housings.

Xavitech can now offer a ready to

use solution for this to meet cus-

tomer demands.

>

THE SOLUTION

The solution is based on moulded

parts in soft TPE material for pull

through quick mount. It is resistant

to ageing and has a broad tem-

perature range of -20 to 70 degrees

celcius. By press fitting two soft

holders, one from each side of the

pump, you get 4 soft arrow like pins

underneath the pump. Theese pins

you can pull through holes and they

will expand on the other side of a

PCB and thus create a lock. There

are two arrows on each pin so you

can mount the pump at two diffrent

levels. At level 1 the pump will be

elevated 2.75mm and enables you to

have electrical components un-

derneath the pump. When pump is

mounted on PCB, excessive parts of

the pin underneath the PCB can be

cut away.

MOUNTING FOR

1500 & 2500

TPE material

Absorbs vibration

Mounts on PCB or sheet drill holes

Optional mounting height

>

CONCEPT

Xavitech can supply calibrated

pumps according to customer

needs. Just as important, the cus-

tomers can also adjust the pump

performance themselves. This is

really valuable during the design

phase of a system since the user will

be able to compensate for condition

changes simply by reprogramming

the pumps. Once the system layout

is fixed the customer can inform

Xavitech on which pump setting

was the best. Hereafter, Xavitech

can easily supply calibrated pumps

according to the new requirements.

Such a procedure implies a quick

production transfer which saves

time and costs for the user.

>

FLOW CALIBRATION UNIT

The flow calibration unit will enable

the user to adjust the flow through

altering the pump frequency and

store setting permanently into the

pump memory.

FLOW

CALIBRATION UNIT

Calibrate ow

Reduce power use

Shorten R&D process

Save money & time

KEY BENEFITS

Simple to use

Reduce power consumption

Minimize pump noise

Flexibility

Settings stored in pump

Speed up system tuning

APPLICATIONS

R&D for new product development

LAB

PUMP FOR

GAS ANALYSIS

>

GAS ANALYSIS

The Xavitech pumps V200 and

V1500 are excellent choices for gas

analysis. First of all, the invented

X-life motor implies a longer lifetime

than brushless pumps, yet Xavitech

pumps have about the same price as

brushed ones. In addition, Xavitech

pumps offer important features such

as constant flow and small pressure

oscillations.

>

REFERENCE & EXPERIENCE

Xavitech has supplied thousands

of pumps every year since 2007 to

medical capnography devices and

other gas analysis instrument to

happy customers.

Customers have measured up to ten

times smaller pressure oscillations

using Xavitech pumps compared to

available diaphragm pumps on the

market for air sampling. The pumps

can also synchronise with gas sen-

sors such that they always make a

pump stroke after a gas measure. This

further removes the usual artefact of

pressure oscillations. It is easy to

integrate a Xavitech pump in a sys-

tem. Either the pump configuration

is done by Xavitech engineers or

the customers use the flow calibra-

tion unit to set-up flow rate, vacuum

power and input voltage themselves.

The information from such a cus-

tomer evaluation is then forwarded

back to Xavitech, thus providing a

quick production transfer. Finally, it is

important to notice that the allowed

input voltage ranges from 3.2 to 26

volts without the use of voltage

regulators. Thus, all the power loss in

such a device is avoided.

>

RECOMMENDED MODELS

V200-GAS

V1500-GAS

IF YOU ARE INTERESTED IN MORE

INFORMATION ABOUT XAVITECH

PUMPS OR NEED ASSISTANCE WITH

THE DESIGN OF THE ELECTRONIC

SYSTEM PLEASE FEEL FREE TO CON-

TACT US.

Small size

Market leading lifetime-cost performance

Excellent ow stability over time

Minimizes pressure oscillations

Syncronised strokes reduce sensor artifacts

Very long lifetime

PUMP FOR

NPWT

>

OEM PUMP FOR NPWT

The Xavitech pumps, P200 and

P1500, are excellent choices for

NPWT products. By merging NPWT

product functionality into the mi-

croprocessor inside the pump and

utilizing all the abilities of the pump,

Xavitech has a truly integrated and

miniaturized solution for the NPWT

market.

>

REFERENCE & EXPERIENCE

Xavitech has supplied thousands

of pumps every year since 2007 to

medical devices. The two pump

models suitable for NPWT, P200 and

P1500, are in production and used in

many different applications.

>

TECHNOLOGY

The pump technology is based on the

patented X-life motor, which has very

few moving parts. It does impress by

being unique and simple. It is com-

bined with a patented motion sensing

and analysis system, which is inte-

grated inside the pump. The system

enables the pump to precisely sense

vacuum without the use of any

regular pressure sensor. The method

it uses to sense vacuum is covered

by patent. Moreover, the the pump

has the ability to generate alarm

sound using the pump membrane. At

frequencies above frequencies that

generate flow, the pump generates

alarm tones. This allows the pump to

give alarms such as low battery,

canister full or leak. The pump

also has the ability to estimate the

amount of liquid inside a canister and

thus give warning. Using the built-in

microprocessor Xavitech can pro-

gram the pump to control external

LED indicators or displays. The pump

regulates its own power and can

therefore be connected directly to

almost any battery on the market.

Since the pump is programmable

it can be adjusted to the specifica-

tion and interface requested by the

market.

Small size 21*21*37mm or 31*31*57mm

Programmable NPWT control system inside

Built-in alarm speaker & LED alarm control

Built-in vacuum sensing & control

Cost-eective longevity

Patented technology

Illustrated design presents a belt NPWT system containing a separate canister and a housing

with user interface. The housing contains the P1500 pump from Xavitech and a battery.

PUMP FOR

NPWT

>

DESIGN CONCEPT

Presented here is an illustrated design

based on the idea of a low-cost high-

volume system to be sold for smaller

wounds. The design is a wearble

homecare device that has a separate

disposable canister. The separate

canister can also be of different sizes

depending on the needs. The device

illustrated would be the smallest one

on the market but still housing our

largest pump P1500 with one liter of

flow.

>

OUR OFFER

These pumps have the ability to

become the next revolutionary min-

iaturized NPWT product. Xavitech is

now looking for a partner that is will-

ing to CE-mark and make the pump

technology available to the market.

Xavitech have developed concepts

of housings and have the pump that

would be used in them in full produc-

tion. Functional pumps with NPWT

software have been developed and

are ready for demonstration. The

partner should have good under-

standing of the wound care market.

>

LEGAL DISCLAIMER

The pump P200 and V1500 or the

design concepts presented are not

finished CE marked medical devices.

They are potential components for

future medical devices and ideas.

>

INTELLIGENT PUMPS INSIDE:

>

P200-GAS

Motor type: X-life motor

Supply voltage: 3.2 to 12 VDC

Wetted parts: PPS and EPDM

Weight: 39 grams

Size: 21*21*37 mm

Flow: 450 ml/min

Vacuum: 125 mmHg

Direct battery operation

>

P1500-GAS

Motor type: X-life motor

Supply voltage: 3.2 to 12 VDC

Wetted parts: PPS and EPDM

Weight: 105 grams

Size: 31*31*57 mm

Flow: 1 L/min

Vacuum: 150 mmHg

Direct battery operation

Information furnished is believed to be accurate and reliable. However, Xavitech assumes no responsibility for the consequences of use of such information nor for any infringement of patents or

other rights of third parties which may result from its use. No license is granted by implication or otherwise under any patent or patent rights of Xavitech. Specifications mentioned in this publication

are subject to change without notice. This publication supersedes and replaces all information previously supplied. Xavitech products are not authorized for use as critical components in life support

devices or systems without express written approval of Xavitech.

2010 Xavitech - All Rights Reserved

Product range folder gas updated 130123

XAVITECHAB. INDUSTRIGATAN17. 87153. HRNSAND. SWEDEN

Xavitech Europe

Phone: +46(0)611-556100

Fax: +46(0)611-782510

Hours:8am to 5pm GMT-1

Xavitech USA

Phone: 860-381-6060

Hours: 6am to 4pm EST

CONTACT INFORMATION

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- LW SeriesDocument8 pagesLW SeriesAbraham AutomationNo ratings yet

- Cantidad Codigo Descripcion Precio UnitDocument2 pagesCantidad Codigo Descripcion Precio UnitJOEL ESCALANTENo ratings yet

- Bipolar Stepper Motor Driver 74194Document12 pagesBipolar Stepper Motor Driver 74194mekuannintmesfin100% (2)

- Nguyenvanthinh BKC13107 N01Document35 pagesNguyenvanthinh BKC13107 N01Văn thinh NguyenNo ratings yet

- Innovation and TechnologyDocument8 pagesInnovation and TechnologyMuthomi DenisNo ratings yet

- HT-S5600 EnglishDocument100 pagesHT-S5600 EnglishAnand PaulNo ratings yet

- Procurement Monitoring Report JuneDocument2 pagesProcurement Monitoring Report JuneKaJong JaclaNo ratings yet

- HR Works EssDocument50 pagesHR Works EssSijesh ThiruthiyilNo ratings yet

- Zepto Product Teardown - Likhita ParasuDocument6 pagesZepto Product Teardown - Likhita ParasuVikas DeshmaneNo ratings yet

- Activity 6 - Two Station Motor Control With Emergency Stop (Non-Reversing)Document15 pagesActivity 6 - Two Station Motor Control With Emergency Stop (Non-Reversing)AJ LunaNo ratings yet

- Proteza Oticon More Minirite R Instructions For UseDocument49 pagesProteza Oticon More Minirite R Instructions For UseOvidiu PascuNo ratings yet

- Boiler PPTDocument27 pagesBoiler PPTDev DixitNo ratings yet

- XYZ: PFD and P&ID Diagrams - PDF - Instrumentation - Control TheoryDocument15 pagesXYZ: PFD and P&ID Diagrams - PDF - Instrumentation - Control TheoryAhmed Essam El-DinNo ratings yet

- BIO PROJECT MOBILE RADIATION 2 (Official Release)Document28 pagesBIO PROJECT MOBILE RADIATION 2 (Official Release)Sarosij Sen Sarma67% (3)

- Cain and Banks Utility Scale Wind Presentation 2015 SEAOC ConventionDocument24 pagesCain and Banks Utility Scale Wind Presentation 2015 SEAOC ConventionTrầmLãngNo ratings yet

- UZZ32 Suspension Codes PDFDocument32 pagesUZZ32 Suspension Codes PDFAdel Sta MariaNo ratings yet

- 7) Progress PaymentDocument5 pages7) Progress Paymentkerwin jayNo ratings yet

- Security Specialization Sample Exam - ENDocument8 pagesSecurity Specialization Sample Exam - ENbloodscreamNo ratings yet

- Lesson 6 ExercisesDocument2 pagesLesson 6 ExercisesLoyaltyNo ratings yet

- Category ID Product Quantity Unit Price TotalDocument2 pagesCategory ID Product Quantity Unit Price TotalMohammad RumanNo ratings yet

- BIM Applications of Rule-Based Checking in ConstruDocument9 pagesBIM Applications of Rule-Based Checking in ConstrumounirNo ratings yet

- T & C Fastener Co, LTD.: Certified Material Test ReportDocument1 pageT & C Fastener Co, LTD.: Certified Material Test Reportlady romeroNo ratings yet

- Resonance Electrical CircuitsDocument3 pagesResonance Electrical CircuitsdllabarreNo ratings yet

- HENRY, ET AL (2017) QR CodeDocument6 pagesHENRY, ET AL (2017) QR CodeMiki AntonNo ratings yet

- GNC Rfid PDFDocument66 pagesGNC Rfid PDFFederico Manuel Pujol100% (1)

- Huawei AR1200 Series Enterprise Routers Data SheetDocument8 pagesHuawei AR1200 Series Enterprise Routers Data SheetMuharrem ÖzerNo ratings yet

- HTML FormDocument5 pagesHTML Formshivam ashishNo ratings yet

- Vin PlusDocument20 pagesVin PlusNamrata ShettiNo ratings yet

- Bts3900 v100r010c10spc255 Enodeb FDD UpgDocument38 pagesBts3900 v100r010c10spc255 Enodeb FDD UpgJennis Sherano FernandoNo ratings yet

- Wireless Communication Networks and Systems 1st Edition Beard Solutions ManualDocument11 pagesWireless Communication Networks and Systems 1st Edition Beard Solutions ManualHasnin shah0% (1)