Professional Documents

Culture Documents

2.125 DST Packer Test Tool

Uploaded by

Kim MissonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2.125 DST Packer Test Tool

Uploaded by

Kim MissonCopyright:

Available Formats

Perm bility Packer Test Procedure

GEO-Packers T M

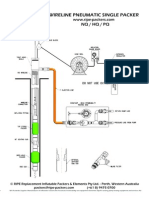

DST PACKER T EST T OOL

GEO-PACKER 2125"

HO DST SINGLE PACKER T EST ING T OOL

.-1

NFLATION / WIRELINE

SEALING TIGHT HEAD

H054LP275E0.5

RIG WIRELINE

1. Pull th inneYT e assembly fromthe core barrel,

leaving the drill string in place.

2. Elevate the drill stria9 off the drill hole bottomand

I expose th permeaBlity zone.

Secure/ st bilise the drill)ktring in place.

Install the sealing tight head.

Lower the packer through the sealing tight head

and drilPtring, positioning into the core barrel.

Install steel washers and rubber shies in the tight

ead and tighten the compression cap.

7. Co ect the nylon inflation tube to the g s/air supply.

8. Slow inflate the permeability packer in i rements

of until e desired pressure is met.

Inject wa r through the tight head asse

packer into he test zone.

10. ermeability est is run in under instruction b

oject engin er.

1 1 Once testing is omplete deflate the packer.

12. M ake suee pack r is fully deflated before movin

fromthe drill ho e.

3. Undo comp si n tight head and remove rubbe

seals and stee shers.

14. Reinstall the co pression cap and remove the pack r.

15. Remove the seal ng tight head and then lower the

inner tube assembl into position.

16. Connect the dr' I rods, lowering the drill string t

the hole botto and restart drilling.

17. OHS procedu es must be followed.

18. Inflation an use of packers and packer equip

is a h rators own risk.

3.78-

Max Working pressure vs hole diameter

Boreholes diameter lin) 2.7' 2.4" 2.6" 2.8" 3" 3.2- 3.4" 3.5" 3.7" 4" 4.1 " 4.3" 4.5"

Percentage inflation diameter 4.8 1 4.3 23.8 33.3 42.9 52.4 61 .9 66.7 76.2 90.5 95.2 1 04.8 1 1 4.3

Inflation pressure (PSI) 2250 2000 1 750 1 450 1 1 50 1 000 850 725 580 500 435 360 290

Non confined Free air Inflation

Diameter (in) 2.2" 2.4" 2.6" 2.8" 3" 3.2"' 3.4" 3.5" 3.7" 4" 4.1 " 4.3- 4.5"

Inflation pressure (PSI) 22 30 36 41 45 52 61 67 80 87 94 1 1 6 1 60

Replacement Inflatable Packers and Elements Pty Ltd

29 Wheeler St Belmont 6104, Perth Western Australia

T el: (+61 (08) 9475 0700 Fax: +61 (08) 9475 0770 packers@ripe-packers.comwww.ripe-packers.com

WA Australia Supplier Manufacturer of Inflatable Packers for DSTWell Packer Testing Permeability single/ double packer testing equipment and Services AU.

Perm bility Packer Test Procedure

rators own risk. h

GEO-Packers T M

DST PACKER T EST T OOL

GEO-PACKER 0 2125"

HO DST DOUBLE PACKER T EST ING T OOL

INFLATION / WIRELINE

SEALING TIGHT HEAD

HQ54LP27SE0.5

RIG WIRELINE

ATER

INJECTION HO

ALL BORE

YLON INFLATI INE

2.

3.

1.

SURFACE

N D U C T O

5.

A

CI RODS DRIL 4

HO CORE HOLE

Pull th inneYT e assembly from the core barrel,

leaving the drill string in place.

Elevate the drill stria9 off the drill hole bottom and

I expose th permeaBlity zone.

Secure/ st bilise the drill)ktring in place.

Install the sealing tight head.

Lower the packer through the sealing tight head

and drilPtring, positioning into the core barrel.

Install steel washers and rubber shies in the tight

ead and tighten the compression cap.

Co ect the nylon inflation tube to the g s/air supply.

Slow inflate the permeability packer in i rements

of until e desired pressure is met.

Inject wa r through the tight head asse

packer into he test zone.

ermeability est is run in under instruction b

oject engin er.

PACKER

UB

WIREL OR1NG DIAMOND BIT

Once testing is

M ake suee pack

from the drill ho

13. Undo comp

seals and stee

14. Reinstall the co

15. Remove the seal

inner tube assembl

16. Connect the dr'

the hole botto

7. OHS procedu

flation an

omplete deflate the packer.

r is fully deflated before movin

e.

n tight head and remove rubbe

shers.

pression cap and remove the packs

ng tight head and then lower the

into position.

I rods, lowering the drill string t

and restart drilling.

es must be followed.

use of packers and packer equip

SI

r.

Bit set OD Bit stot ID HOLE SIZ E

3.7T I Is. 3.78"

KER 2

HO DRILL ROD SPE CATIONS

ID (inch) OD (inch) WEIGHT b) V OL (Gal)

Ni

ithr

31.808 HQ

3.063 3.5

76.896

Max Working pressure vs hole diameter

Boreholes diameter (in) 2.2" 2.4 " 2.6" 2.8" 3" 3.2" 3.4 " 3.5" 3.7" 4 " 4 .1" 4 .3" 4 .5"

Percentage inflation diameter 4 .8 14 .3 23.8 33.3 4 2.9 52.4 61.9 66.7 76.2 90.5 95.2 104 .8 114 .3

Inflation pressure (PSI) 2250 2000 1750 14 50 1150 1000 850 725 580 500 4 35 360 290

Non confined Free air Inflation

Diameter (in) 2.2" 2.4 " 2.6" 2.8" 3" 3.2" 3.4 " 3.5" 3.T 4 " 4 .1" 4 .3" 4 .5"

Inflation pressure (PSI) 22 30 36 4 1 4 5 52 61 67 80 87 94 116 160

Replacement Inflatable Packers and Elements Pty Ltd

29 Wheeler St Belmont 6104 , Perth Western Australia

Tel: (+61 (08) 94 75 0700 Fax: +61 (081 9475 0770 packers@ripe-packers.com www.ripe-packers.com

WA Australia Supplier Manufacturer of Inflatable Packers for DST Well Packer Testing Permeability single/ double packer testing equipment and Services AU.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- C1 (1 - Storey Roof Sheets)Document11 pagesC1 (1 - Storey Roof Sheets)John Michael TalanNo ratings yet

- Mini ProjectsDocument55 pagesMini ProjectsSampath KumarNo ratings yet

- Wireline Pneumatic Single PackerDocument1 pageWireline Pneumatic Single PackerKim MissonNo ratings yet

- K PackersDocument1 pageK PackersKim MissonNo ratings yet

- Wireline Hydraulic Straddle PackerDocument1 pageWireline Hydraulic Straddle PackerKim MissonNo ratings yet

- Replacements and RebuildsDocument1 pageReplacements and RebuildsKim MissonNo ratings yet

- Wireline Hydraulic Single PackerDocument1 pageWireline Hydraulic Single PackerKim MissonNo ratings yet

- Hydraulic Fracturing Inflatable PackersDocument1 pageHydraulic Fracturing Inflatable PackersKim MissonNo ratings yet

- Kpackers MetricDocument1 pageKpackers MetricKim MissonNo ratings yet

- Mini Hydrualic Frac PackersDocument1 pageMini Hydrualic Frac PackersKim MissonNo ratings yet

- RIPE K-Packers: Water Bore Monitoring Well Completion ApplicationsDocument1 pageRIPE K-Packers: Water Bore Monitoring Well Completion ApplicationsKim MissonNo ratings yet

- Grab Packer MetricDocument1 pageGrab Packer MetricKim MissonNo ratings yet

- 42 Standard Wireline Packer System ReplacementsDocument1 page42 Standard Wireline Packer System ReplacementsKim MissonNo ratings yet

- 56 DST Packer Test ToolDocument2 pages56 DST Packer Test ToolKim MissonNo ratings yet

- Grab Packer ImperialDocument1 pageGrab Packer ImperialKim MissonNo ratings yet

- 83 Standard Wireline Packer System ReplacementsDocument1 page83 Standard Wireline Packer System ReplacementsKim MissonNo ratings yet

- 43 DST Packer Test ToolDocument2 pages43 DST Packer Test ToolKim MissonNo ratings yet

- 73 DST Packer Test ToolDocument2 pages73 DST Packer Test ToolKim MissonNo ratings yet

- 42 DST Packer Test ToolDocument2 pages42 DST Packer Test ToolKim MissonNo ratings yet

- 3.27 Standard Wireline Packer System ReplacementsDocument1 page3.27 Standard Wireline Packer System ReplacementsKim MissonNo ratings yet

- An ARN 147V Data SheetDocument2 pagesAn ARN 147V Data SheetStrawichDanielNo ratings yet

- Pacific Earthquake Engineering Researchseismic Safety Commission Tall Building PDFDocument60 pagesPacific Earthquake Engineering Researchseismic Safety Commission Tall Building PDFPatrick CanceranNo ratings yet

- BEL Papers Previous YearsDocument121 pagesBEL Papers Previous YearsjayacharanNo ratings yet

- Deck Machinery PartsDocument3 pagesDeck Machinery Partsmihat jasneyNo ratings yet

- ED 240 Syllabus-Njovu-El-2Document3 pagesED 240 Syllabus-Njovu-El-2Anthony MubangaNo ratings yet

- Namuli Maxine Tamale Research Proposal 2Document38 pagesNamuli Maxine Tamale Research Proposal 2mpairwe cliffortNo ratings yet

- Ocused Ion Beam Microscopy and Micromachining: C.A. Volkert and A.M. Minor, Guest EditorsDocument11 pagesOcused Ion Beam Microscopy and Micromachining: C.A. Volkert and A.M. Minor, Guest EditorsrmehfuzNo ratings yet

- CenturionDocument28 pagesCenturiondan.gonzalez2573No ratings yet

- 2021 Product CatalogueDocument26 pages2021 Product CatalogueJoseNo ratings yet

- DPM Class-NotesDocument38 pagesDPM Class-NotesZephaniah MuneneNo ratings yet

- Installation Instructions USB v1.0.21Document3 pagesInstallation Instructions USB v1.0.21Luis Alvaro MolinaNo ratings yet

- Module 2 - Important Theory Portions: - Friction - Characteristics of FrictionDocument8 pagesModule 2 - Important Theory Portions: - Friction - Characteristics of FrictionHima SNo ratings yet

- AP Lab Assignment 1Document30 pagesAP Lab Assignment 1Ahmad AlsharefNo ratings yet

- SasaDocument20 pagesSasaSpinu AlexandruNo ratings yet

- SurgeTest EPCOSDocument33 pagesSurgeTest EPCOSSabina MaukoNo ratings yet

- Measurement of Small DistancesDocument3 pagesMeasurement of Small DistancesJacie TupasNo ratings yet

- Design of Circular DomesDocument8 pagesDesign of Circular Domesrshyams100% (1)

- Error Running Command Lines CommandDocument2 pagesError Running Command Lines CommandTrần Văn TrườngNo ratings yet

- Akhila ResumeDocument2 pagesAkhila ResumejeelaniNo ratings yet

- Software Engineering I (02161) Lecture Notes: Assoc. Prof. Hubert Baumeister Spring 2012Document16 pagesSoftware Engineering I (02161) Lecture Notes: Assoc. Prof. Hubert Baumeister Spring 2012Karthik KeyanNo ratings yet

- Inventory Managment System Python Mysql CodeDocument13 pagesInventory Managment System Python Mysql CodeLordBoxNo ratings yet

- Effect of Tillage and Crop Roration On Pore Size DistributionDocument12 pagesEffect of Tillage and Crop Roration On Pore Size DistributionWubetie MengistNo ratings yet

- Overall Heat Transfer CoefficientDocument4 pagesOverall Heat Transfer Coefficientvenka07No ratings yet

- EBM Pabst - CPAP - BlowerDocument4 pagesEBM Pabst - CPAP - BlowerlouisNo ratings yet

- Rebar Vs AnchorDocument22 pagesRebar Vs AnchorHenry TuganoNo ratings yet

- APK 20091019 Electrocardiography+CablesDocument18 pagesAPK 20091019 Electrocardiography+Cablesأحمد العريقيNo ratings yet

- Design of Sobel Operator Based Image Edge Detection Algorithm On FPGADocument5 pagesDesign of Sobel Operator Based Image Edge Detection Algorithm On FPGAgoldspiceNo ratings yet

- Principles of Motion EconomyDocument39 pagesPrinciples of Motion EconomyNikhil GargNo ratings yet