Professional Documents

Culture Documents

Modeling of Thermal Characteristics For A Furnace of A 500 MW Boiler Fired With High-Ash Coal

Uploaded by

Kroze0 ratings0% found this document useful (0 votes)

17 views1 pageOriginal Title

Modeling of Thermal Characteristics for a Furnace of a 500 MW Boiler Fired With High-Ash Coal

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views1 pageModeling of Thermal Characteristics For A Furnace of A 500 MW Boiler Fired With High-Ash Coal

Uploaded by

KrozeCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

08 St eam r ai si ng ( boi l er operation~design)

mor e compl et el y in t he boiler, due to t he earl i er r el ease of bi omas s

volatiles. The NOx emi ssi on dat a in t he t r ans i ent exper i ment s i ndi cat e

t hat bi omass mor e readi l y r el eases NOx even at lower t emper at ur es .

However, when t he f ur nace r eached hi gher t emper at ur es , t he bl end

r el eased less NOx t han coal despi t e t he hi gher N cont ent of FB; but CO

emi ssi on i ncr eased. The l ong dur at i on exper i ment s in t he modi f i ed

facility conf i r m NOx r educt i on with t he firing of bl end. Lar ge scale

pilot pl ant t est s per f or med at t he DOE Nat i onal Ener gy Technol ogy

Labor at or i es, Pi t t sbur gh conf i r m i mpr oved combus t i on, but NO~

emi ssi on ar e t he s ame for bot h t he coal and bl end.

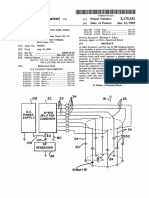

02/ 02108 Desi gn of a 12 MW t r i - cogener at i on syst em of

gas, heat and power

Wang, Q. et al. Proceedings of the International Conference on Fluidized

Bed Combustion, 2001, (16), 439-448.

To meet t he s hor t age of t he gas with me di um cal ori fi c-val ue, heat and

power, a new 12 MW t r i - cogener at i on syst em of gas, heat and power

has been desi gned for a power pl ant in Chi na. In t hi s syst em, one

fl ui di zed bed gasi fi er is combi ned with a 75 t/h ci rcul at i ng fl ui di zed bed

boi l er to real i ze gas and s t eam cogener at i on. Thi s paper i nt r oduces t he

desi gn f eat ur es of t he 12 MW t r i - cogener at i on syst em in detail. A

si mpl i fi ed model devel oped for t he t r i - cogener at i on syst em is us ed to

pr edi ct t he per f or mance pa r a me t e r s of t he 12 MW t r i - cogener at i on

syst em i ncl udi ng t he gas yield, gas composi t i on, cal ori fi c-val ue of gas

and t emper at ur e in t he gasi fi er and t he boiler.

02/ 02109 Enhanced mercury cont rol f or coal - f i r ed ut i l i t y

boi l ers

Kudl ac, G. A. and Amr he i n, G. T. Proceedings - Annual International

Pittsburgh Coal Conference, 2000, (17), 1731-1745.

The Ohi o Coal De ve l opme nt Office wi t hi n t he Ohi o De pa r t me nt of

Devel opment , Babcock & Wilcox Compa ny ( B&W) , and Mc De r mot t

Technol ogy, I ncor por at ed ( MTI ) conduct ed a pr ogr am to opt i mi ze and

commer ci al i ze me t hods to cont r ol Hg in coal -fi red utility boilers. Of

par t i cul ar i nt er est is i mpr ovi ng Hg cont r ol usi ng convent i onal flue gas

cl ean- up e qui pme nt such as el ect rost at i c pr eci pi t at or s (ESP) and wet

scr ubber s. Al so, i nt er est in t he ul t i mat e fat e of t he capt ur ed Hg has

become i ncreasi ngl y i mpor t ant . Pi l ot -scal e t est i ng exami ni ng e nha nc e d

Hg cont r ol t echnol ogi es for wet s cr ubber - equi pped ut i l i t i es was

conduct ed at t he B&W Cl ean Envi r onment Devel opment Facility at

t he MTI Al l i ance Res ear ch Cent er . Res ul t s f r om pi l ot -scal e t est s and

from t he initial st udy of t he fat e of Hg pr es ent in pr ocess bypr oduct

s t r eams are di scussed,

02/ 02110 Exper i ment al research on t wo- st age

desul f ur i zat i on t echnol ogy in t r avel i ng grat e boi l ers

Zhou, J. et al. Energy, 2001, 26, (8), 759-774.

In or der to pr omot e t he desul f ur i zat i on efficiency of cal ci um- based

s or bent s dur i ng coal combus t i on in t ravel l i ng gr at e boilers, t he

i nf l uences on sul f ur r emoval of t he t her mal condi t i ons and t he

s or bent s were di scussed in t hi s paper . It was f ound t hat t he SO_,

concent r at i on first rises, t hen decl i nes al ong t he t ravel l i ng gr at e and

r eaches t he peak near t he mi dpoi nt of t he grat e. The f l uct uat i on of t he

SO2 concent r at i on over t i me in t he flue gas is mai nl y affect ed by t he

fl ame t emper at ur e. Whe n t he part i cl e size of t he s or bent s decr eases

from 75 to 0.1 #m, t he sul f ur r emoval efficiency will i ncr ease slightly. A

r easonabl e Ca/S mol ar rat i o is about 2 when s or bent s are bl ended with

t he coal on t he gr at e and its f ur t her i ncr ease has little benef i t to

desul f ur i zat i on. A new, so-cal l ed t wo-st age desul f ur i zat i on pr ocess -

sul f ur capt ur e firstly in t he coal bed and secondl y in t he combus t i on gas

- is s ugges t ed as it can great l y pr omot e t he sul f ur r emoval efficiency up

to 70~80%. By X-ray powder di ffract i on anal ysi s, s ome t her mal st abl e

phas es were i dent i fi ed in t he sul f ur r et ent i on ci nder obt ai ned f r om t he

on- gr at e process.

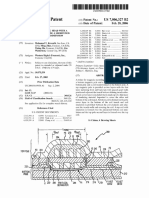

02/ 02111 Heat recovery boi l er f or coal gasi f i cat i on

Yoshi da, K. et al. Jpn. Kokai Tokkyo Koho JP 2000 329,272 (C1.

C10J3/46), 27 Nov 2001, Appl . 2000/150,100, 22 May 2000. 9. (In

Japanese)

The syst em compr i ses me a ns for i nt r oduci ng hi gh- t emper at ur e raw

pr oduct gases f r om a coal gasi fi cat i on f ur nace i nt o t he apex sect i on of a

was t e- heat boi l er havi ng mul t i pl e heat - t r ans f er duct s, me a n s for

di schar gi ng cool ed gases f r om t he boi l er bot t om aft er heat recovery

i nt o a cyclone s epar at or havi ng f unnel - s haped gas flow i nver t er and

dust collecting duct , me a ns for adj ust i ng t he flow of t he pr oduct gases

aft er dus t st r i ppi ng and pas s i ng it t hr ough t he heat - t r ans f er duct s, and

me a ns for f eedi ng t he s epar at ed dus t i nt o t he coal gasi fi cat i on f ur nace.

The syst em pr event s pl uggi ng of dus t deposi t s i nsi de t he heat - t r ans f er

duct s and r educes ener gy cost.

02/ 02112 Model i ng of t her mal char act er i st i cs f or a f ur nace

of a 500 MW boi l er f i red wi t h hi gh- ash coal

Koupr i anov, V. I. Energy, 2001, 26, (9), 839-853.

An advanced zonal comput at i onal me t hod has been used to det er mi ne

t he t e mpe r a t ur e and heat flux profi l es and ot her t her mal char act er -

istics for a f ur nace of t he 500 MW boi l er fi red wi t h hi gh- ash, me di um-

volatile Eki bast uz coal. The pr edi ct ed t e mpe r a t ur e profi l es for a 100%

boi l er l oad and di f f er ent me t hods of fuel di st r i but i on t hr ough t he

bur ner t i ers were compar ed with r espect i ve dat a obt ai ned in

exper i ment al tests. The effect s of t he fuel dus t f i nenes s and excess

air on t he f ur nace t e mpe r a t ur e pat t er n were st udi ed. The case

associ at ed with t he r educed boi l er l oads were consi der ed as well. The

lower limit for t he boi l er l oad has been est abl i shed, based on t he

pr edi ct ed resul t .

02/ 02113 Numer i cal anal ysi s of a pr ot ect i on t echni que f or

t ube erosi on in ut i l i t y boi l ers

Fan, J. R. et al. Chem. Eng. Commun., 2001, (188), 129-142.

Er osi on of heat - exchanger t ubes by coal part i cl es and coal - ash

i mpi ngement has caus ed ser i ous pr obl ems to utility boi l ers. I n t hi s

paper , r esul t s are pr es ent ed of numer i cal i nvest i gat i ons of f i nned- t ube

er osi on pr ot ect i on t echni ques. The s e i ndi cat e t hat fi ns fixed on t he

t ubes provi de a si mpl e and effi ci ent er osi on pr ot ect i on me t hod for

par t i cl e- l aden syst ems, whi ch have er osi on pr obl ems.

02/ 02114 Opt i mi sed NHa- i nj ect i on in CFB- boi l er s

Lj ungdahl , B. and Larfel dt , J. Recents Progres en Genie des Procedes,

2000, 14, (75), 295-302.

A commonl y used me t hod t o r educe t he emi ssi ons of NOx in CFBC

boi l ers is to add NHs ( SNCR) in t he cycl one inlet. However,

exper i ence shows t hat t he conver si on of NOx is s omet i mes ineffective.

In t hi s work it was f ound t hat at condi t i ons when combus t i on occur in

t he cycl one, t he r educt i on of NOx coul d be i mpr oved by at l east 30% by

shi f t i ng t he posi t i on of a mmoni a addi t i on to t he i nner vort ex of t he

cyclone. At condi t i ons when no combus t i on occur s in t he cyclone t he

CO emi ssi on was f ound to decr eas ed 60% at t he s ame meas ur es ,

wi t hout any si gni fi cant changes in NOx r educt i on and NHs-sl i p. The

decr ease in CO is expl ai ned by compet i t i on bet ween NHs decompr es -

si on and CO oxi dat i on for OH radi cal s. The posi t i on for a mmoni a

addi t i on in t he cycl one was f ound f r om l abor at or y exper i ment s of t he

mi xi ng char act er i st i cs of such cycl ones and model l i ng of t he SNCR

r eact i on at wel l -st i rred condi t i ons.

02/ 02115 Per f or mance t est dat a f rom t he f i rst 23 MWt ABFB

boi l er in Tur key

Oymak, O. et al, Proceedings of the International Conference on

Fluidized Bed Combustion, 2001, (16), 994-1001.

Thi s paper looks i nt o t he const r uct i on, commi ssi oni ng, initial s t ar t - up

oper at i on and per f or mance t est dat a of 23 MW t at mos pher i c bubbl i ng

fl ui di zed bed ( ABFB) boi l er pr oj ect at Al ki m Chemi cal s I ncor por at ed,

Dazki ri , Turkey. Thi s boi l er was desi gned by Babcock&Wi l cox ( B&W)

and suppl i ed and i nst al l ed by Babcock Wilcox Ga ma I ncor por at ed, a

j oi nt vent ur e company of B&W and Ga ma Ind. in Tur key. The boiler is

desi gned for s t eam flow of 8.3 kg/s, 4.2 MPa g and 440C with

f eedwat er t e mpe r a t ur e of 125C. The boi l er ut i l i zes lignite with hi gher

heat i ng val ue of 3600-5100 kcal / kg bur ni ng in its own ash. Var i ous

desi gn aspect s of t he boiler such as open bot t om f ur nace and fl ue gas

reci rcul at i on, per f or mance, auxiliary e qui pme nt , and initial st ar t - up

oper at i ng per f or mance are also di scussed.

02102116 Progress t owar d commer ci al i zat i on of wood/ coal

cof i r i ng in st oker boi l ers in Pi t t sbur gh

Cobb, J. T. and Wi l l i am, W. Proceedings - Annual International

Pittsburgh Coal Conference, 2000, (17), 1846-1857.

The Uni ver si t y of Pi t t sbur gh is wor ki ng t owar d t he es t abl i s hment of t he

commer ci al i zat i on of a wood/ coal bl end for us e in st oker boi l ers in

Pi t t sbur gh. The net wor k of compani es and agenci es bei ng devel oped

for t hi s pur pos e i ncl udes a wood pr ocessor , several coal br oker s, t he

oper at or s of several st oker boi l er pl ant s and t he known air pol l ut i on

regul at ors. Pr ogr a mme par t i ci pant s al so i ncl ude t he Uni versi t y, t he

Nat i onal Ener gy Technol ogy Labor at or y, and several f undi ng agenci es.

A t est pr ogr a mme was pl anned for t he Summe r 2000 at t he Pi t t sbur gh

Br ewi ng Compa ny boiler pl ant wi t h work at t he Bellefield Boi l er Pl ant

and t he Br ucet on Res ear ch Cent r e bei ng pl anned for l at er in 2000.

I ssues bei ng addr es s ed are (1) t he pr epar at i on of wood for opt i mal

bl endi ng, (2) t he ma xi mum allowable per cent age of wood in t he bl end,

(3) t he s our ces of wood to provi de t he ne e de d amount s , and (4) t he

bus i nes s a r r a nge me nt s for pr ovi di ng t he bl end. The paper will pr es ent

a s t at us r epor t on t he pr ogr amme.

02/ 02117 Reduct i on of chl or i ne deposi t i on in FB boi l ers

wi t h al umi ni um- cont ai ni ng addi t i ves

Aho, M. Fuel, 2001, 80, (13), 1943-1951.

Chl or i ne- cont ai ni ng fuel s t end to f or m corrosi ve deposi t s on t he heat

t r ansf er sur f aces of boi l er f ur naces. Hi gh risk chl or i ne c ompounds are

of type MCI, wher e M is Na or K. Exper i ment s were per f or med wi t h an

electrically st abi l i zed 20 kW bubbl i ng bed r eact or to det er mi ne t he

concent r at i ons of C1 c ompounds in deposi t s and fine fly ash. The fuel s

F uel and Energy Abs tracts Jul y 2002 273

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Advanced Techniques in Power System Protective Relaying PDFDocument332 pagesAdvanced Techniques in Power System Protective Relaying PDFAngel LalikanNo ratings yet

- Safe Use of Plant EquipmentDocument140 pagesSafe Use of Plant EquipmentFrancisco M. RamosNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- SIMARIS Technical Manual enDocument155 pagesSIMARIS Technical Manual enVictor Rosu100% (1)

- History of Refrigeration - From Ice Boxes to Modern SystemsDocument34 pagesHistory of Refrigeration - From Ice Boxes to Modern SystemsNSS GBPECNo ratings yet

- Asupu Nano BubblesDocument10 pagesAsupu Nano BubblesAgung50% (2)

- Welding Dissimilar MetalsDocument6 pagesWelding Dissimilar MetalsNitintak100% (1)

- United States Patent (19) : (45) Date of Patent: Oct. 12, 1999Document17 pagesUnited States Patent (19) : (45) Date of Patent: Oct. 12, 1999KrozeNo ratings yet

- 2.1 GeneralDocument248 pages2.1 GeneralHugo Alfredo Calderon TapiaNo ratings yet

- Us8608097 PDFDocument10 pagesUs8608097 PDFKrozeNo ratings yet

- Us 6250486Document14 pagesUs 6250486KrozeNo ratings yet

- Variable capacity staged cooling DX geothermal heat pumpDocument44 pagesVariable capacity staged cooling DX geothermal heat pumpKrozeNo ratings yet

- Us 3616264Document4 pagesUs 3616264KrozeNo ratings yet

- Aug. 5, 1969 ?. R. ???.?.?.? 3,459,957: Woltage Regulator CircuitDocument6 pagesAug. 5, 1969 ?. R. ???.?.?.? 3,459,957: Woltage Regulator CircuitKrozeNo ratings yet

- Us 6633161Document21 pagesUs 6633161KrozeNo ratings yet

- Dec. 12, 1967 F. Grossoehme 3,358,210: Filed June 25, 1964Document4 pagesDec. 12, 1967 F. Grossoehme 3,358,210: Filed June 25, 1964KrozeNo ratings yet

- Us 3376803Document26 pagesUs 3376803KrozeNo ratings yet

- Low inductance high energy inductive ignition systemDocument18 pagesLow inductance high energy inductive ignition systemKrozeNo ratings yet

- United States Patent: (21) Appl. N0.: 13/226,109 (Continued)Document17 pagesUnited States Patent: (21) Appl. N0.: 13/226,109 (Continued)KrozeNo ratings yet

- Us 7006327Document11 pagesUs 7006327KrozeNo ratings yet

- Us 3195038Document10 pagesUs 3195038KrozeNo ratings yet

- Low inductance high energy inductive ignition systemDocument18 pagesLow inductance high energy inductive ignition systemKrozeNo ratings yet

- United States Patent (19) (11) Patent Number: 5,179,332Document14 pagesUnited States Patent (19) (11) Patent Number: 5,179,332KrozeNo ratings yet

- Us 5818319Document30 pagesUs 5818319KrozeNo ratings yet

- Us 5379832Document16 pagesUs 5379832KrozeNo ratings yet

- United States Patent (19) (11) Patent Number: 6,130,863: Wang Et Al. (45) Date of Patent: Oct. 10, 2000Document18 pagesUnited States Patent (19) (11) Patent Number: 6,130,863: Wang Et Al. (45) Date of Patent: Oct. 10, 2000KrozeNo ratings yet

- Patent for Moving Coil Linear Actuator with Interleaved Magnetic CircuitsDocument11 pagesPatent for Moving Coil Linear Actuator with Interleaved Magnetic CircuitsKrozeNo ratings yet

- United States PatentDocument14 pagesUnited States PatentKrozeNo ratings yet

- Coil Array Design Enhances Resolution and Depth of Investigation for Induction Logging ToolsDocument21 pagesCoil Array Design Enhances Resolution and Depth of Investigation for Induction Logging ToolsKrozeNo ratings yet

- United States PatentDocument15 pagesUnited States PatentKrozeNo ratings yet

- United States PatentDocument15 pagesUnited States PatentKrozeNo ratings yet

- Patent for Moving Coil Linear Actuator with Interleaved Magnetic CircuitsDocument11 pagesPatent for Moving Coil Linear Actuator with Interleaved Magnetic CircuitsKrozeNo ratings yet

- Us 4774914Document25 pagesUs 4774914KrozeNo ratings yet

- United States PatentDocument25 pagesUnited States PatentKrozeNo ratings yet

- Us 6577888Document12 pagesUs 6577888KrozeNo ratings yet

- United States Patent (19) (11) Patent Number: 5,207,074Document18 pagesUnited States Patent (19) (11) Patent Number: 5,207,074KrozeNo ratings yet

- United States Patent (19) : 16 VoltageDocument12 pagesUnited States Patent (19) : 16 VoltageKrozeNo ratings yet

- Us 4866424Document14 pagesUs 4866424KrozeNo ratings yet

- Causes and Cures of Regulator InstabilityDocument5 pagesCauses and Cures of Regulator Instabilityratninp9368100% (1)

- Lift Truck Gear From DTAUTO - CADocument32 pagesLift Truck Gear From DTAUTO - CAGregGGHNo ratings yet

- Glassy Metals IIIDocument265 pagesGlassy Metals IIICristian HoreaNo ratings yet

- HMT Assignment1Document8 pagesHMT Assignment1Navya IshaNo ratings yet

- Maxxi, Rome's New Museum For The 21st Century Art & Architecture Is A Bold andDocument7 pagesMaxxi, Rome's New Museum For The 21st Century Art & Architecture Is A Bold andIng István-Mátyás Tupper MátéNo ratings yet

- FlywheelDocument8 pagesFlywheelAidil Syawani Kun100% (1)

- Texcan Teck 5KV UnshieldedDocument2 pagesTexcan Teck 5KV UnshieldedJames Ernes Llacza CarmeloNo ratings yet

- Honda's Secret MotoGP Transmission Revealed - Sport Rider Magazine - MobileDocument2 pagesHonda's Secret MotoGP Transmission Revealed - Sport Rider Magazine - Mobilelusso9567No ratings yet

- IC200PBI001Document4 pagesIC200PBI001Humberto BalderasNo ratings yet

- Lean management principles for eliminating wasteDocument2 pagesLean management principles for eliminating wastesimranNo ratings yet

- AccumulatorsDocument9 pagesAccumulatorsBaldo CastilloNo ratings yet

- Kimray T-12 (Temperature Controller)Document6 pagesKimray T-12 (Temperature Controller)CARLOS SARMIENTO100% (1)

- Recent Innovations in Concrete and Foundations Lead to More Sustainable GrowthDocument49 pagesRecent Innovations in Concrete and Foundations Lead to More Sustainable Growthprakash.sharmaNo ratings yet

- Tutorial Pneumatic CircuitDocument5 pagesTutorial Pneumatic CircuitMuhammad Abdullah0% (1)

- Sunsai Pharma Equipments Pvt. ltd-1Document2 pagesSunsai Pharma Equipments Pvt. ltd-1Sunsai VasaiNo ratings yet

- SmagDocument28 pagesSmagcsvasukiNo ratings yet

- Tabela de Corrosão Little GiantDocument12 pagesTabela de Corrosão Little GiantAlex Sandro FerreiraNo ratings yet

- Possibility of Production of Bricks Using Waste Materials and Natural Binding Materials in Sri Lanka.Document5 pagesPossibility of Production of Bricks Using Waste Materials and Natural Binding Materials in Sri Lanka.Rohantha RukshanNo ratings yet

- Pb-Eneos CVT FluidDocument3 pagesPb-Eneos CVT FluidengrsurifNo ratings yet

- 7 Behavior of Rectangular Reinforced Concrete BeamsDocument16 pages7 Behavior of Rectangular Reinforced Concrete Beamsjack21abNo ratings yet

- APMRG1 Series: Packaged Air ConditionersDocument32 pagesAPMRG1 Series: Packaged Air Conditionerszaid jamaluNo ratings yet

- The Foil Specialist's 48 Gauge Polyester FilmDocument1 pageThe Foil Specialist's 48 Gauge Polyester FilmmerrickNo ratings yet