Professional Documents

Culture Documents

Formula

Uploaded by

selisenCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Formula

Uploaded by

selisenCopyright:

Available Formats

Reference Data

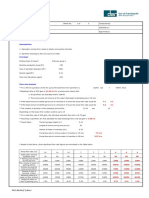

Conversion Factors:

MULTIPLY BY TO OBTAIN MULTIPLY BY TO

OBTAIN

Atmospheres 14.70 Lbs./sq. inch

(Absolute)

Atmospheres 2116.8 Lbs./sq. inch

(Absolute)

B.T.U/min. 0.02356 Horsepower

B.T.U/min. 0.01757 Kilowatts

Feet 30.48 Centimeters

Feet of Water 0.4335 Lbs./sq. inch

(62F)

Gallons 231 Cubic inches

Gallons of Water 8.34 Pounds

Horsepower (Boiler) 33.479 B.T.U./hr.

Horsepower (Boiler) 9.803 Kilowatt-hrs.

Inches 2.54 Centimeters

Inches of Water 0.03613 Lbs./sq. inch

Liters 61.02 Cubic inches

Liters 0.264 Gallons

Tons of Refrigeration 12000 B.T.U./hr

_____________________________________________________________________

Heating and Cooling Calculations:

CFM=Cubic feet of air per minute passing through the coil

Weight per cu ft..=Weight of 1 pound (.075)

Sp ht=BTU required to raise the temperature of 1 lb of air 1 degree F (.24)

T

o

=Temperature of air entering coil in degrees F.

T..=Temperature of air leaving coil in degrees F.

T

1

=Temperature of water leaving coil in degrees F.

T

2

=Temperature of water entering coil in degrees F.

H

1

=Enthalpy of entering air.

H

2

=Enthalpy of leaving air.

Capacity of Hot Water Coil

GPM =CFM X 1.08 X (T T

o

)

(T

2

T

1

) X 500

Capacity of Chilled Water Coil

GPM =(H

1

H

2

) X CFM X .075 X 60

(T

2

T

1

) X 500

Chiller Tonnage

TONS =GPM X (CHWR CHWS)

24

Chiller Coefficient of Performance

COP =(CHWR CHWS) X GPM X

0.0417

0.28433 X KW

DC Current Kilowatts KW ={Amps X Volts}/1000

AC Single Phase Kilowatts KW ={Amps X Volts X Power Factor}/1000

AC Three Phase Kilowatts KW ={Amps X Volts X 1.73 X Power Factor}/1000

VAV Box Air Flow Rate (CFM)

CFM=Cubic feet of air per minute passing through the duct

A..=Duct area in sq. ft.

37

V..=Velocity of the air

Pv.=Pressure in inches of H

2

O from PV3

Equation Q =AV

0.0763 is the density of dry air at 60

o

F

The duct diameter units are in ft.

CFM =1096(Duct Diameter/2)

2

((Pv/.0763))

Linear Reset Schedule Formula

The linear reset schedule is used to reset a particular setpoint based on a particular parameter. Some

examples are:

Boiler hot water supply temperature reset based on the outside air temperature. In this instance, the hot

water bypass valve is modulated to control the temperature of the water flow.

Supply air temperature reset based on the space zone calling for the most cooling or heating.

Chilled water supply temperature reset based on the chilled water return temperature.

Y..=The variable that is reset

m..=The slope of the reset line

x...=The parameter that the reset is based upon

b...=System constant that defines the equation of the line

Y

1

.=Minimum value of the reset variable

Y

2

.=Maximum value of the reset variable

X

1

.=Minimum value of the dependent value

X

2

.=Maximum value of the dependent value

STEP 1: Determine the minimum and maximum values of the system, i.e. Y

1

, Y

2

, X

1

, and X

2

.

Example: Boiler hot water reset schedule. When the outside air temperature is 50 degrees F or below, the

hot water supply temperature should be reset to 140 degrees F. When the outside air temperature is 90

degrees F or above, the hot water supply temperature should be reset to 110 degrees F.

From the sequence of operation above, Y

1

=140, Y

2

=110, X

1

=50, and X

2

=90.

STEP 2: Determine the slope of the line.

m =Y

2

Y

1

=110 140 =-30 =-0.75

X

2

X

1

90 50 40

STEP 3: Determine b. Plug in the known parameters into the equation of the line and solve for b.

Y =mx +b b =Y mx =140 (-0.75)(50) =72.5

b =177.5

38

STEP 4: Plug in the calculated values for m and b into the equation for a line.

Y =mx +b =(-0.75)x +177.5

Here, Y is the HOT WATER SUPPLY TEMPERATURE and x is the OUTSIDE AIR

TEMPERATURE.

Although CBAS 2000 calculates linear reset equations automatically with the RESET

SCHEDULE function, a sample calculation point in another program for this example

would look like:

HOT WATER SUPPLY TEMPERATURE = -0.75 X OUTSIDE AIR TEMPERATURE + 177.5

39

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Sump Pit CalculationDocument4 pagesSump Pit CalculationEng Mahmoud Hamdy33% (3)

- Yama Buggy 400cc Parts List and SchematicsDocument50 pagesYama Buggy 400cc Parts List and Schematicsgeorgemesfin@gmailNo ratings yet

- D20S-7 Sb1159e01 PDFDocument678 pagesD20S-7 Sb1159e01 PDFGORDNo ratings yet

- Insulation Thickness CalculationDocument2 pagesInsulation Thickness Calculationrajpal14667% (6)

- Insulation Thickness CalculationDocument2 pagesInsulation Thickness Calculationrajpal14667% (6)

- Hw3 UpdatedDocument2 pagesHw3 UpdatedGeoffrey Liu0% (1)

- ICEpublishing Complete 2014 Books CatalogueDocument44 pagesICEpublishing Complete 2014 Books CatalogueLamija LamyNo ratings yet

- Snowkey Application HandbookDocument160 pagesSnowkey Application HandbookWalter J Naspirán CastañedaNo ratings yet

- Gantt Chart LDocument8 pagesGantt Chart LAshok PuttaparthyNo ratings yet

- @water & Drainage Equipement DesignDocument46 pages@water & Drainage Equipement DesignDesigner ForeverNo ratings yet

- ABCO Heat Exchanger CalculationsDocument1 pageABCO Heat Exchanger CalculationsselisenNo ratings yet

- Heat Exchanger Calculations: Inside Heat Trasfer CoefficientDocument4 pagesHeat Exchanger Calculations: Inside Heat Trasfer CoefficientBimal DeyNo ratings yet

- Gantt-Chart L2Document7 pagesGantt-Chart L2Elijah JaireNo ratings yet

- HVAC Heater Calculation SheetDocument1 pageHVAC Heater Calculation SheetselisenNo ratings yet

- Cooling Tower. Application - TreybalDocument89 pagesCooling Tower. Application - TreybalPinak ProjectsNo ratings yet

- PW Expansion Tank SizingDocument2 pagesPW Expansion Tank SizingChaosNo ratings yet

- Heat Transfer. Heat Loss From A Buried Oil Pipe. Mills Example 3.3Document34 pagesHeat Transfer. Heat Loss From A Buried Oil Pipe. Mills Example 3.3selisenNo ratings yet

- 02 - Heat ExchangersDocument88 pages02 - Heat ExchangersDana GuerreroNo ratings yet

- Water Properties Calculation ToolDocument2 pagesWater Properties Calculation ToolselisenNo ratings yet

- CdA CalculatorDocument9 pagesCdA CalculatorselisenNo ratings yet

- @water & Drainage Equipement DesignDocument46 pages@water & Drainage Equipement DesignDesigner ForeverNo ratings yet

- Pipe Headloss Calculator: Pipe Selection Fluid Flow InformationDocument1 pagePipe Headloss Calculator: Pipe Selection Fluid Flow InformationselisenNo ratings yet

- Partially Full Pipe Calculation Tool: US UnitsDocument4 pagesPartially Full Pipe Calculation Tool: US UnitsselisenNo ratings yet

- The Theory Behind Heat TransferDocument7 pagesThe Theory Behind Heat TransferselisenNo ratings yet

- 01 Heat Conduction Pipe CalculatorDocument10 pages01 Heat Conduction Pipe CalculatorselisenNo ratings yet

- Chapter 27: Physical Properties Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallDocument23 pagesChapter 27: Physical Properties Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallselisenNo ratings yet

- Viscosity Vs Temperature CalculatorDocument7 pagesViscosity Vs Temperature CalculatorRafael PerraciniNo ratings yet

- Temperature Rise of Centrifugal Pumps at No Flow and Low FlowDocument3 pagesTemperature Rise of Centrifugal Pumps at No Flow and Low FlowselisenNo ratings yet

- Calculation Tool Heat Flux Through A Single Pipe KNOWING Skin TemperaturesDocument5 pagesCalculation Tool Heat Flux Through A Single Pipe KNOWING Skin TemperaturesselisenNo ratings yet

- Processes 09 00939 v2Document19 pagesProcesses 09 00939 v2selisenNo ratings yet

- Heat Loss From PipeDocument11 pagesHeat Loss From Pipemlarakahan100% (1)

- Domestic Water Booster Pump CalculationsDocument25 pagesDomestic Water Booster Pump CalculationsuddinnadeemNo ratings yet

- Duct Elbow Area PDFDocument14 pagesDuct Elbow Area PDFSakthi.pNo ratings yet

- Heat Transfer. Heat Loss From A Pipe in An Indoor LocationDocument29 pagesHeat Transfer. Heat Loss From A Pipe in An Indoor LocationselisenNo ratings yet

- 1082-Adding New Replication From Sybase To OracleDocument4 pages1082-Adding New Replication From Sybase To Oraclegirish10670No ratings yet

- Electric Fan RepairDocument12 pagesElectric Fan RepairYsabelle Tagaruma33% (3)

- CVDocument21 pagesCVAngelica chea NatividadNo ratings yet

- Cu Ext 2015Document4 pagesCu Ext 2015mohammedzuluNo ratings yet

- Chpt6 Taylor Made HONDocument23 pagesChpt6 Taylor Made HONManju MudakaviNo ratings yet

- Manual New AswanDocument18 pagesManual New AswanmohamedmosallamNo ratings yet

- Links Deep WebDocument2 pagesLinks Deep WebArnoldTorresNo ratings yet

- Feedwater Heating SystemsDocument82 pagesFeedwater Heating SystemsJitendra ChaudhariNo ratings yet

- Built in Classes in JavaDocument104 pagesBuilt in Classes in JavaarchanaNo ratings yet

- Characterization and Application of Cerium Fluoride Film in InfraredDocument4 pagesCharacterization and Application of Cerium Fluoride Film in InfrarednguyenthanhhopNo ratings yet

- Ra CocnatsDocument13 pagesRa CocnatsloyioNo ratings yet

- M.Tech. 2nd (Non CBCS) May 2018 - 9 - 5 - 18Document2 pagesM.Tech. 2nd (Non CBCS) May 2018 - 9 - 5 - 18doob marroNo ratings yet

- OpenCV 3.0 Computer Vision With Java - Sample ChapterDocument27 pagesOpenCV 3.0 Computer Vision With Java - Sample ChapterPackt PublishingNo ratings yet

- Casting Fabrication of Carbon Steel Pitman For Crusher Suppliers and Manufacturers China - Professional Factory - Zhengda HDocument1 pageCasting Fabrication of Carbon Steel Pitman For Crusher Suppliers and Manufacturers China - Professional Factory - Zhengda HCarlos Ediver Arias RestrepoNo ratings yet

- 8bit Microprocessor Using VHDLDocument16 pages8bit Microprocessor Using VHDLTanu Newar0% (2)

- Synopsis On Turing MachineDocument4 pagesSynopsis On Turing MachineVivek MishraNo ratings yet

- Lowry Hill East Residential Historic DistrictDocument14 pagesLowry Hill East Residential Historic DistrictWedgeLIVENo ratings yet

- APL APOLLO - Chaukhat - Catalogue A4 English - 04 03 2022 - Low ResDocument48 pagesAPL APOLLO - Chaukhat - Catalogue A4 English - 04 03 2022 - Low ResarrsshaNo ratings yet

- Performance Analysis of Cooperative Communication For Wireless NetworksDocument164 pagesPerformance Analysis of Cooperative Communication For Wireless NetworksIhtesham JadoonNo ratings yet

- Lec 2 - Tall Building Criteria and Loading-2003Document30 pagesLec 2 - Tall Building Criteria and Loading-2003JibonGhoshPritomNo ratings yet

- Power GenerationDocument34 pagesPower GenerationTaufiq AkbarNo ratings yet

- Lewmar Marine Equipment Guide Ed 14Document224 pagesLewmar Marine Equipment Guide Ed 14Renato Fonseca100% (1)

- 6141-Article Text PDF-9899-1-10-20130718 PDFDocument15 pages6141-Article Text PDF-9899-1-10-20130718 PDFGroup-IV ADAM 2019-20No ratings yet

- Datasheet Fuji F5018 F5020Document6 pagesDatasheet Fuji F5018 F5020StaryzgredNo ratings yet

- 651Document26 pages651riskraj1984No ratings yet

- Manual ArchicadDocument67 pagesManual ArchicadkhajaimadNo ratings yet