Professional Documents

Culture Documents

Pile Load Test

Uploaded by

utoy032367Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pile Load Test

Uploaded by

utoy032367Copyright:

Available Formats

AL-fath,Jornal,No22,2005 Nesreen Kurdy Thabbah Al-Obaidy

Evaluate the Efficiency of Plate Load Test of ASTM

Standard Procedure of Stone Piles

Nesreen Kurdy Thabbah Al-Obaidy University of Diala

College of Engineering,

Abstract

The last studies has been studied a general behavior of stone

piles and found that behavior is be very complicated if compare with

that of other types of piles. Since the field studies are regarded to be

the better way to describe such behavior, by using the ASTM standard

procedure.

The present paper discusses the efficiency of ASTM standard

procedure in case of full-scale tests on stone piles. The field study

here included installing observation points on soil surface neighboring

pile face.

The results of study establish that ,the procedure is need to a

perform a some moderation in dimensions of loading system.

! "#%&#'(! ")*!+-(! /0&)2 4##'6 ) ASTM ( 79&2: ;<= >&#'-(! "<.&2 ?+@B ;<=

"$CDA

!"#%&

!"#%')* +-./0#2) 3.45)* 6#79:)* <>$? @:)* AB.C)* =.>*$D)* EG stone piles

*D& DA5G H;D&I @:)*I " +-.0#)* EG J#LM* N*OPM.B F$OQ .G *RS .

TM* @U V5QOW)* =.>*$D)* <P.0 .W)I 6#7X:)* Y[)R \]8O) ^#_`)* EVbB EcG df

'Vh7ij)* dklVW'; mop'T 3Dq:rs>* DtuAT plate load test mvw'T =*Oxy`L z{|V}`:B Y~)RI

@>.VA)* dVW':)* ) ASTM . (

V!">.VA)* =.h$%8*OW)* &()Q.*G Y),./0I ASTM 12V5QOW)* d45VW':)* nO78'T :;).( @=>T

@AV5QOW)* CDE(GW)* a.IJAP ELMG ?DOPQ N$, eGRSL EUVG W YZ"#%')* +-.\]0#2) observation

points ^+V0#)* H&O) ^$I.%W)* B#:)* _`> `2Q .

dVW':2) V>.VA)* h8*OW)* HPS <:}bS GDAW)* >*$D)* c-.:P ) ASTM ( `d)* e.:';

.8O7ghijklmL d"Dopqrstu5:)* Ewxyz{|}G d!"#$%&V2Q " d()*+,-.VW':)* 3.0123456EP ?.89:;<=>5B?B zABCDEFG25:W)* H+JKLMNOP%)* @RSTUVWXT .

1-Introduction

A semi-direct method to estimate the bearing capacity of a soil

in the field is to apply a load to a model footing and measure the

amount of load necessary to induce a given amount of settlement A

plate load testing is available (see Bowels,1988) .

The method of performing this test is outlined in some details as

ASTM standard procedure as shown in Fig.1.

In case of piles , the test should continue until a total settlement

of 25 mm is obtained, or the capacity of the testing apparatus is

reached.

Since both the rate and amount of settlement of stone piles are

the greatest if compare with other type of piles as it come in all last

studies, it expected that the plate load test is not proper in such type of

piles during loading and unloading process. That may be back to the

settlement of soil neighboring pile body which effected by settlement

of pile body that extended in most times to tenths of centimeters

during loading test.

However, most of last studies were depended ASTM standard

procedure where it was employed in their field tests ,see (Hughes et

al,1975; Goughnour and Bayuk,1979;Engelhardt and Golding,1975;

Dayte and Nagaraju,1981; Ahmed,1998; Al-Recabi,1999;and Al-

obaidy,2000).

In this paper, six observation points were installed during

loading and unloading process. Installing these points to study the

behavior of soil neighboring pile body in area between pile face and

reference beam (loading system support).

The aim of present study to perform a some moderation on

ASTM standard in case of field load test on stone piles.

2-Site Condition and Soil Properties

The test program was carried out at the old Al-Muthanna airport

area in Baghdad governorate.

In position of testing area a bore hole was made, at the

laboratory of NNCL[national center for construction laboratories ] ,

the porogram was set to test the obtained disturbed and undisturbed

sample in order to revealsoil properties.

Plate

Reference

beam

D 1.5

D

Several dial gages attached to an

independent suspension system to record

plate settlements

Dead weight

Jack

Short

block

Fig.(1) Performing plate-load testing as ASTM

standard procedure

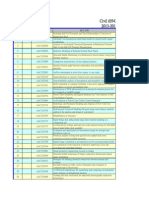

Chemical Tests Consolidation Tests Drained

Shear

Samples

Cl

%

pH So

3

%

Pc

(k

N/

m

2

)

C

r

C

c

E

0

0

C

(kN/

m

2

)

U.C.

Test

KN/m

2

Type No.

D 1

.0

6

7.73 0.35 SS 2

D 3

.13

15

5

0.0

23

0.12

0.7

5

30 27 U 4

19 SS 5

SS 6

.0

5

7.79 .12 SS 7

SS 8

D 9

SS 10

D 11

SS 12

D 13

0.1 32 0 SS 14

D 15

7.73 0.23 SS 16

3-Stone Pile Properties

Table (1) A Complete Summary of Laboratory Test Results

A graduated Cino stone added by a boulder represent a main backfilling

of a pile that decided to be in test .

Dimensions of this pile body are (6*1.5)m [see Fig.2]

4- Equipment

The

equipment are

included the

following:

1- All equipment of dead load Kentledge system

[loads,supports(references beam),hydraulic jucks,steel plates ,dial

gauges,etc] .

2- Six dial gauges of 0.01 mm accuracy.

3- Six steel bars .

4- Six circular block of concrete.

5-I nstallation Technique

The stone pile was constructed and the load was placed centrally

and vertically by means of dead load Kentledge system.

Six observation points were fixed in two orthogonal directions,

each point consists of the following:

-A dial gauge for monitoring the readings of settlement,

-Steel bar for establish the gauge,

D=1.5 m

h=6 m

Cino

stone

Soil

Fig.(2) Dimensions of stone pile body

-Concrete block fixed on soil surface and conducted with the steel

bar,Fig.3 shows the main sketch of one observation point.

In addition, that six points arranged at distances equal to

(0.5,1,and1.75m) respectively far from pile face, see figures 4 &5

where the first figure represents a top view of points from pile

perimeter and the second shows the cross section of loading system

gives positions of points.

0.5 m

Bar of steel

0.3 m

0.1 m

Dial gage of

0.01 mm

Circular block

of concrete

Fig.(3) observation point

Observation

D=1.5m 0.7

0.5

0.5

0.3

Observation

Stone

Dir.2

Dir.1

Fig.(4) Top view to position of observation

Plate

Referenc

e

beam of

1.5m

2.25

Dead weight

Jack

Short

Fig.(5) Cross section in loading system shows

positions of observation points

0.5m 0.5m 0.75m

soil

Stone

Observatio

n points in

6-Testing Program

To study the influence area around pile body, it has been chosen

the observation points in a distances far from pile face as seen in last

section, then tend to monitor readings of settlement under loading and

unloading process.

Points1, 2,and3 placed in direction (1)which is perpendicular with

reference beam of 6 m long (see plate-1-) whereas the other points

4,5,and6 placed in direction (2) which is perpendicular with reference

beam of 18 m long (see plate "2-)

The specification ASTM No.D1143-87 was employed. During

testing process, the load was placed centrally and vertically on a circular

plate above stone pile body. The axial load was applied on the piles by

means of hydraulic jacks and two type of reference beams 6 and 18 m

long were used as above illustration.

The piles were loaded to 200% of design load with (8) increments,

each one is equal to 25% of design load maintained for one hour, the final

load increment maintained more than 12 hr Then the unloading process

was performed by four equal decrements, each one is 50% of design load.

The readings of dial gauges of observation points were taken.

Plate (1) Positions of Points of dir.1 (1,2,and3) orthogonal to reference

beam of 6 m long

Plate (2) Positions of Points of dir.2 (4,5,and6) orthogonal to

reference beam of 18m long

7-Presentation and discussion the results

Fig.(6) shows the load-settlement relationships and Fig.(7) shows

the corresponding time "settlement curves for chosen observation points

during the first cycle of loading and unloading of stone pile.

From previous figure and after application the load increment on

pile body, it can be observed that the settlement of a certain point in one

direction gradually increases with time interval in amount proportional

with a distance far away pile face.

If we take direction-1, we found that the nearest point (1) suffer

from high settlement if it compare with two other points in same

direction. In such away point (2) settles with amount greater than that of

point (3).

In the same manner, it can be found all three points in direction-2-

but with a little amount of settlement.

If we traced the behavior of these points in the two direction during

unloading process, we almost found that it continued in settle, that may

be go back to voids which are formed in pile body during it unloading

such that soil particles push toward pile body to fill the forming spaces.

In addition to re "arrangement for pile material causes a sudden

movement for soil neighboring pile body.

Therefore, the settlement of observation points in area between pile

body and reference beam increases during loading and unloading. so the

chosen distance 2.25 m between pile body and a reference beam of 6 m

long according ASTM specification is consider to be so near and

improper ,so it must to adopt anew specification is different from

available specification take in consideration the high sum and rate of

settlement for stone pile or at least select anew dimension for the

distance between pile face and reference beam, see plate-3- which

describe the soil surrounding pile body effected by loading system in

moment of finishing testing program .

Here, it is benefit to suggest the dimension between pile body and

reference beam as 2.5D instead of 1.5D dependent on the laboratory study

of Al- Mosawe et al in 1985.

*

o

+

Point1

Point2

Point3

Point4

Point5

Point6

S

e

t

t

l

e

m

e

n

t

i

n

c

m

Load in kN

Fig.(6) load- settlement curves of observation points

during loading and unloading

unloading

loading

*

o

+

Point1

Point2

Point3

Point4

Point5

Point6

Time in hr.

Fig(7). Time-settlement curves of observation

points during loading and unloading

S

e

t

t

l

e

m

e

n

t

i

n

c

m

unloadin

loadin

loadin

Recommendations

1- Study the efficiency of standard specification in case of group

stone piles.

2- Perform axial loading test on stone pile according ASTM

specification with make a moderation by take the distance between

pile body and reference beam equal to 2.5D.

3- Install a large number of observation points in different

directions and it can monitor the dissipation of pore water pressure

of surrounding soil to pile body.

Plate-3-. Soil neighboring pile body effected by loading system after

finishing the test

References

1. Ahmed, A.A. (1998), Performance of Stone Columns in Soft

Soils , Ph. D. Thesis, University of Baghdad.

2. Al-Mosawe,M. J.,Abbas, A. J., and Majeed, A. H.,

(1985),!Prediction of ultimate capacity of a single amd groups of

stone columns! , Iraqi Conference of Engineering ICE 85,Vol. I,

Baghdad.

3. Al-Obaidy, N.K. (2000), Full Scale Tests on Stone Piles!,

M.Sc. Thesis, University of Baghdad.

4. Al-Recabi, M.K. (1999), Stabilized Stone Pile in Soft Clay

with New Reinforcement Patterns , M.Sc. Thesis, University of

Baghdad.

5. ASTM,!American Society for Testing and Materials!, Part 14

&19,Annual book of ASTM standards.

6. Bowles, J. E., (1988),!Foundation Analysis and Design!,

McGraw-Hill, NewYork.

7. Dayte, K. R., and Nagaraju, S. S. (1981), Design Approach

and field Control for Stone Columns!, Proceedings 10

th

International Conference in Soil Mechanics and Foundation

Engineering Stockholm,Sweden,Vol.4,pp. 634-640.

8. Engelhardt, K. and Golding, H.C. (1975), Field Testing to

Evaluate Stone Column Performance in a seismic Area!,

Geot.,Vol.XXV, No.1, PP. 61-69.

9. Goughnour, R. R.,and Bayuk, A. A.,(1979),!A Field Study of

Long Term Settlement of Loads Supported by Stone Columns in

Soft Ground!,R.C. coll. Int. Reinf., No.1,pp. 279-285.

10. Hughes, J. M. O., Withers, N. J., and Greenwood, D. A., (1975),!A

Field Trail of Reinforcing Effects of Stone Columns in Soil!,

Geotechnique,Vol.25,No.1,March 1975,pp. 31-44.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- PMT Product Manager Technical Role GuidelineDocument14 pagesPMT Product Manager Technical Role GuidelineKishore Kumar100% (2)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- SPP SummarizedDocument9 pagesSPP SummarizedLanz Castro67% (3)

- Wind Loads SBC Pt1Document29 pagesWind Loads SBC Pt1insane88No ratings yet

- Piled Raft Design Process For A Tall Building in AustraliaDocument9 pagesPiled Raft Design Process For A Tall Building in AustraliaJosé ChávezNo ratings yet

- SP 34 1987handbookonreinforcementanddetailing 140310080531 Phpapp01 PDFDocument286 pagesSP 34 1987handbookonreinforcementanddetailing 140310080531 Phpapp01 PDFutoy032367No ratings yet

- ACI Example Problem - Buried Concrete Basement Wall DesignDocument9 pagesACI Example Problem - Buried Concrete Basement Wall DesignleodegarioporralNo ratings yet

- Computer Modeling of Structure To Earthquake Load PDFDocument26 pagesComputer Modeling of Structure To Earthquake Load PDFvjacintNo ratings yet

- NCSPA Installation ManualDocument51 pagesNCSPA Installation ManualKyle ForemanNo ratings yet

- Point Loads Applied in Beam (B3)Document1 pagePoint Loads Applied in Beam (B3)utoy032367No ratings yet

- Seismic Design of Reinforced Concrete Special Moment FramesDocument31 pagesSeismic Design of Reinforced Concrete Special Moment FrameswilfredNo ratings yet

- Bonded Vs UnbondedDocument10 pagesBonded Vs Unbondedarun0001100% (1)

- Earth and EarthquakesDocument32 pagesEarth and Earthquakesnymufti100% (4)

- Kelken US Metric Chart ASTM A615 Grade 60 RebarDocument1 pageKelken US Metric Chart ASTM A615 Grade 60 RebarAvsin CevaNo ratings yet

- TrusSteel Design Manual 08Document75 pagesTrusSteel Design Manual 08utoy032367100% (1)

- IBC 2006 SEISMIC PARAMETER For StaadDocument22 pagesIBC 2006 SEISMIC PARAMETER For Staadutoy032367No ratings yet

- Etabs Design of Tall Building Reinforcement DetailingDocument54 pagesEtabs Design of Tall Building Reinforcement Detailingutoy032367100% (8)

- Asce 7 Wind ExampleDocument27 pagesAsce 7 Wind ExampleJose Guillermo MonarrezNo ratings yet

- Resume For Broadcasting InternshipDocument7 pagesResume For Broadcasting Internshipbcrqs9hr100% (2)

- CCN144 Studio 5000 Logix Designer Level 4 Kinetix 6500 (CIP) ProgrammingDocument2 pagesCCN144 Studio 5000 Logix Designer Level 4 Kinetix 6500 (CIP) Programmingبلال حسينيNo ratings yet

- Abs Catalogo 2021 ENGDocument26 pagesAbs Catalogo 2021 ENGMo ZeidNo ratings yet

- Enclosed Ground Flare RGBDocument4 pagesEnclosed Ground Flare RGBbabuyuvarajNo ratings yet

- Methods Tools Design Methodology and Design PractiDocument9 pagesMethods Tools Design Methodology and Design PractiAde SurNo ratings yet

- CMF 300Document2 pagesCMF 300AGA30No ratings yet

- Engineering-Civil (0543)Document48 pagesEngineering-Civil (0543)myusuf_engineerNo ratings yet

- Artificial Intelligence For Robotics: Sai Ram Engineering CollegeDocument2 pagesArtificial Intelligence For Robotics: Sai Ram Engineering CollegehoddceNo ratings yet

- Ies CollegeDocument5 pagesIes Collegeravi maheshwari100% (1)

- The Solution Design Optimization of Breaker Plate in Extrusion MachinesDocument3 pagesThe Solution Design Optimization of Breaker Plate in Extrusion MachinesMehul PatelNo ratings yet

- Ec 02Document77 pagesEc 02Alberto Hanna Suárez100% (1)

- Bob Katovich - Awesome Robotics Projects For Kids - 20 Original Steam Robots and Circuits To Design and Build-Rockridge Press (2020)Document182 pagesBob Katovich - Awesome Robotics Projects For Kids - 20 Original Steam Robots and Circuits To Design and Build-Rockridge Press (2020)eknath100% (3)

- CE 537 SPRSVDocument5 pagesCE 537 SPRSVCarl Justin AzucenaNo ratings yet

- SWD NZS 3101 2006 PDFDocument74 pagesSWD NZS 3101 2006 PDFsamir_ssh7151No ratings yet

- Ibrahim Alquraishi's CVDocument1 pageIbrahim Alquraishi's CVAnonymous Mz5S9Mn6bNo ratings yet

- 19 Dimova - Skoplje - 2014 - 351Document35 pages19 Dimova - Skoplje - 2014 - 351nebojsadj6411No ratings yet

- MechanicalDocument609 pagesMechanicalMohammed100% (1)

- Vlsi Lab Wo VM PDFDocument68 pagesVlsi Lab Wo VM PDFanon_680775278No ratings yet

- FINALDocument11 pagesFINALSourav JenaNo ratings yet

- 1971 - Seismic Resistance of Prestressed Concrete Beam-Column AssembliesDocument16 pages1971 - Seismic Resistance of Prestressed Concrete Beam-Column AssembliesshuangyaksaNo ratings yet

- FINAL - Evaluation of Protective Relay Performance - REEES-2010 ITMDocument21 pagesFINAL - Evaluation of Protective Relay Performance - REEES-2010 ITMjaythakar8887No ratings yet

- Highway Engineering Notes - Chapter 5Document33 pagesHighway Engineering Notes - Chapter 5Muhammad Farhan GulNo ratings yet

- Using Equotip Hardness Test BlocksDocument5 pagesUsing Equotip Hardness Test Blocksanilbabu4No ratings yet

- E-Learning - Design-ThinkingDocument17 pagesE-Learning - Design-ThinkingMarsha AuliaNo ratings yet

- Engineering Article - Intelligent Systems For Hazop Analysis of Complex Process PlantsDocument12 pagesEngineering Article - Intelligent Systems For Hazop Analysis of Complex Process PlantsAlNo ratings yet

- Kathmandu District Rate 2080 - 81Document268 pagesKathmandu District Rate 2080 - 81Dibya100% (1)

- Different Approaches in Modeling of RC Shear Wall: A ReviewDocument15 pagesDifferent Approaches in Modeling of RC Shear Wall: A Reviewrahimmulla100% (2)

- Dhruv Patidar: Product Design Engineer - MechanicalDocument1 pageDhruv Patidar: Product Design Engineer - MechanicalChetan HinganeNo ratings yet