Professional Documents

Culture Documents

Trapezspindel PDF

Uploaded by

Hanson BlackerOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trapezspindel PDF

Uploaded by

Hanson BlackerCopyright:

Available Formats

Acme Thread Spindles

Acme thread spindles and nuts

We stock the following items in Denmark. Other products and dimensions on request.

Products Materials

Dimensions

12 x 3 12 x 3 L 20 x 4 24 x 5 30 x 6 40 x 7

FFR bronze X X X X

MZP steel X X X X

HBD bronze X X X X

KAM stainless steel

INOX A4 - AISI 316

X X X X X X

KUE carbon steel

EN 10083-2 1C45 1.0503

X X X X

We riserve the right to change sizes and features without notice. 3

PROFILE FOR METRIC TRAPEZOIDAL THREADS TO

ISO STANDARD 2901 2902 2903 2904

H

1

= 0,5 P

h

3

= H

4

= H

1

+ a

c

= 0.5 P + ac

z = 0,25 P = H

1

/2

d

3

= d 2 h

3

d

2

= D

2

= d 2 z = d 0.5 P

D

2

= d + 2 a

c

a

c

= bottom play

es = top deviation for screw

s = 0,26795 es

R

1

max. = 0.5 a

c

R

2

max. = a

c

4 We riserve the right to change sizes and features without notice.

Sizes stocked. Ready reference:

Screws. page 6

Nuts. page 10

Generale features and materials used in Conti precision

Rolled trapezoidal screws and nuts page 16

Screw Lead Accuracy Material

KTS 100 carbon steel EN 10083-2 1C45 1.0503. page 18

KUE 100 carbon steel EN 10083-2 1C45 1.0503. page 19

KKA 50 carbon steel EN 10083-2 1C45 1.0503. page 20

KSR 500 carbon steel EN 10083-2 1C45 1.0503 page 21

KQX 200 carbon steel EN 10084 C15E 1.1141 page 22

KEQ 200 carbon steel EN 10084 C15E 1.1141 page 23

KRP 200 stainless steel INOX A2 - AISI 304 1.4301 page 24

KRE 200 stainless steel INOX A2 - AISI 304 1.4301 page 25

KAM 200 stainless steel INOX A4 - AISI 316 1.4401 page 26

KAF 200 stainless steel INOX A4 - AISI 316 1.4401 page 27

Nut Shape Material

MLF cylindrical steel EN 10277-3 11SMnPb37 1.0737. page 33

MZP cylindrical steel EN 10277-3 11SMnPb37 1.0737. page 33

HSN cylindrical bronze EN 1982 CuSn5Zn5Pb5-C CC491K.. page 34

HBD cylindrical bronze EN 1982 CuSn7Zn4Pb7-C CC493K.. page 34

HDA cylindrical stainless steel INOX A1- AISI 303 1.4305 page 35

HBM cylindrical bronze EN 1982 CuSn12-C CC483K page 35

BIG cylindrical big bronze EN 1982 CuSn12-C CC483K page 36

CQA square steel EN 10277-3 11SMnPb37 1.0737 page 37

QOB square brass EN 12164 CW614N-M (ex OT58) page 37

CQF square holes steel EN 10277-3 11SMnPb37 1.0737 page 38

QBF square holes bronze EN 1982 CuSn12-C CC483K page 39

FTN flanged bronze EN 1982 CuSn5Zn5Pb5-C CC491K. page 40

FXN flanged bronze EN 1982 CuSn12-C CC483K page 41

FMT flanged bronze EN 1982 CuSn12-C CC483K page 42

HDL flanged bronze EN 1982 CuSn12-C CC483K page 43

CBC flanged bronze EN 1982 CuSn12-C CC483K page 44

FFR flanged bronze EN 1982 CuSn5Zn5Pb5-C CC491K page 45

FHD flanged bronze EN 1982 CuSn12-C CC483K page 46

CDF 2-flanged bronze EN 1982 CuSn12-C CC483K page 47

HAL flanged Alu. bronze EN 1982 CuAl11Fe6Ni6-C CC483K page 48

MES exagonal steel EN 10277-3 11SMnPb37 1.0737 page 49

FCS flanged plastic PA 6 + Mo S2 DIN 7728 + self lubrificating. page 50

MPH cylindrical plastic PA 6 + Mo S2 DIN 7728 page 51

We riserve the right to change sizes and features without notice. 5

Specifications:

Screws page 52

Nuts page 54

General choice criteria .... page 56

General sizing criteria . page 57

Use of bronze nuts:

Sizing and example of calculation . page 58

Use of plastic nuts:

Sizing and example of calculation . page 61

Duration and example of calculation . page 65

Critical axial load (peak load). page 67

Critical revolutions per minute .. page 68

Efficiency .. page 69

Torque and Power page 70

Stock numbers for ordering:

Screws . page 71

Nuts . page 73

Comment Card . page 74

6 We riserve the right to change sizes and features without notice.

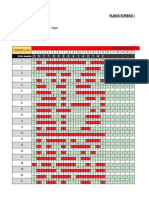

TRAPEZOIDAL SCREWS

Carbon Steel

C45 C15

Single

start

KTS

accuracy 100

page 18

KUE

page 19

KKA

accuracy 50

page 20

KSR

accuracy 500

page 21

KQX

accuracy 200

page 22

KEQ

accuracy 200

page 23

THREAD RH LH RH LH RH LH RH LH RH LH RH LH

Tr 10 x 2

Tr 10 x 3

Tr 12 x 3

Tr 14 x 3

Tr 14 x 4

Tr 16 x 4

Tr 18 x 4

Tr 20 x 4

Tr 22 x 5

Tr 24 x 5

Tr 25 x 3

Tr 25 x 5

Tr 26 x 5

Tr 28 x 5

Tr 30 x 3

Tr 30 x 4

Tr 30 x 5

Tr 30 x 6

Tr 32 x 6

Tr 35 x 3

Tr 35 x 4

Tr 35 x 5

Tr 35 x 6

Tr 35 x 8

Tr 36 x 6

Tr 40 x 3

Tr 40 x 4

Tr 40 x 5

Tr 40 x 6

Tr 40 x 7

Tr 40 x 8

Tr 40 x 10

Tr 44 x 7

Tr 45 x 8

Tr 50 x 3

Tr 50 x 4

Tr 50 x 5

Tr 50 x 6

Tr 50 x 8

Tr 50 x 10

Tr 55 x 9

Tr 60 x 6

Tr 60 x 7

Tr 60 x 9

Tr 70 x 10

Tr 80 x 10

Tr 90 x 12

Tr 95 x 16

Tr 100 x 12

Tr 100 x 16

Tr 120 x 14

Tr 120 x 16

Tr 140 x 14

= Goods in stock. = Goods available upon request only.

We riserve the right to change sizes and features without notice. 7

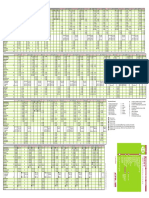

SINGLE START

Stainless Steel

INOX A2 INOX A4

Single

start

KRP

accuracy 200

page 24

KRE

accuracy 200

page 25

KAM

accuracy 200

page 26

KAF

accuracy 200

page 27

THREAD RH LH RH LH RH LH RH LH

Tr 10 x 2

Tr 10 x 3

Tr 12 x 3

Tr 14 x 3

Tr 14 x 4

Tr 16 x 4

Tr 18 x 4

Tr 20 x 4

Tr 22 x 5

Tr 24 x 5

Tr 25 x 3

Tr 25 x 5

Tr 26 x 5

Tr 28 x 5

Tr 30 x 3

Tr 30 x 4

Tr 30 x 5

Tr 30 x 6

Tr 32 x 6

Tr 35 x 3

Tr 35 x 4

Tr 35 x 5

Tr 35 x 6

Tr 35 x 8

Tr 36 x 6

Tr 40 x 3

Tr 40 x 4

Tr 40 x 5

Tr 40 x 6

Tr 40 x 7

Tr 40 x 8

Tr 40 x 10

Tr 44 x 7

Tr 45 x 8

Tr 50 x 3

Tr 50 x 4

Tr 50 x 5

Tr 50 x 6

Tr 50 x 8

Tr 50 x 10

Tr 55 x 9

Tr 60 x 6

Tr 60 x 7

Tr 60 x 9

Tr 70 x 10

Tr 80 x 10

Tr 90 x 12

Tr 95 x 16

Tr 100 x 12

Tr 100 x 16

Tr 120 x 14

Tr 120 x 16

Tr 140 x 14

= Goods in stock. = Goods available upon request only.

8 We riserve the right to change sizes and features without notice.

TRAPEZOIDAL SCREWS

Carbon Steel

C45 C15

Multiple

start

KTS

accuracy 100

page 28

KUE

page 28

KKA

accuracy 50

page 29

KQX

accuracy 200

page 30

KEQ

accuracy 200

page 30

THREAD RH LH RH LH RH LH RH LH RH LH

Tr 10 x 4 (P2)

Tr 12 x 6 (P3)

Tr 14 x 6 (P3)

Tr 16 x 8 (P4)

Tr 18 x 8 (P4)

Tr 20 x 8 (P4)

Tr 20 x 20 (P5)

Tr 22 x 10 (P5)

Tr 24 x 10 (P5)

Tr 25 x 10 (P5)

Tr 25 x 25 (P5)

Tr 26 x 10 (P5)

Tr 28 x 10 (P5)

Tr 30 x 12 (P6)

Tr 30 x 30 (P5)

Tr 32 x 12 (P6)

Tr 36 x 12 (P6)

Tr 40 x 14 (P7)

Tr 40 x 40 (P8)

= Goods in stock. = Goods available upon request only.

We riserve the right to change sizes and features without notice. 9

MULTIPLE START

Stainless Steel

INOX A2 INOX A4

Multiple

start

KRP

accuracy 200

page 31

KRE

accuracy 200

page 31

KAM

accuracy 200

page 32

KAF

accuracy 200

page 32

THREAD RH LH RH LH RH LH RH LH

Tr 10 x 4 (P2)

Tr 12 x 6 (P3)

Tr 14 x 6 (P3)

Tr 16 x 8 (P4)

Tr 18 x 8 (P4)

Tr 20 x 8 (P4)

Tr 20 x 20 (P5)

Tr 22 x 10 (P5)

Tr 24 x 10 (P5)

Tr 25 x 10 (P5)

Tr 25 x 25 (P5)

Tr 26 x 10 (P5)

Tr 28 x 10 (P5)

Tr 30 x 12 (P6)

Tr 30 x 30 (P5)

Tr 32 x 12 (P6)

Tr 36 x 12 (P6)

Tr 40 x 14 (P7)

Tr 40 x 40 (P8)

= Goods in stock. = Goods available upon request only.

10 We riserve the right to change sizes and features without notice.

TRAPEZOIDAL NUTS

MLF page 33

Steel

11SMnPb37

MZP page 33

Steel

11SMnPb37

HDA page 35

Stainless Steel

Aisi 303 1.4305

HSN page 34

Bronze

CuSn5Zn5Pb5-C

HBD page 34

Bronze

CuSn7Zn4Pb7-C

HBM page 35

Bronze

CuSn12-C

Single

start

THREAD RH LH RH LH RH LH RH LH RH LH RH LH

Tr 10 x 2

Tr 10 x 3

Tr 12 x 3

Tr 14 x 3

Tr 14 x 4

Tr 16 x 4

Tr 18 x 4

Tr 20 x 4

Tr 22 x 5

Tr 24 x 5

Tr 25 x 3

Tr 25 x 5

Tr 26 x 5

Tr 28 x 5

Tr 30 x 3

Tr 30 x 4

Tr 30 x 5

Tr 30 x 6

Tr 32 x 6

Tr 35 x 3

Tr 35 x 4

Tr 35 x 5

Tr 35 x 6

Tr 35 x 8

Tr 36 x 6

Tr 40 x 3

Tr 40 x 4

Tr 40 x 5

Tr 40 x 6

Tr 40 x 7

Tr 40 x 8

Tr 40 x 10

Tr 44 x 7

Tr 45 x 8

Tr 50 x 3

Tr 50 x 4

Tr 50 x 5

Tr 50 x 6

Tr 50 x 8

Tr 50 x 10

Tr 55 x 9

Tr 60 x 6

Tr 60 x 7

Tr 60 x 9

Tr 70 x 10

Tr 80 x 10

Tr 90 x 12

Tr 95 x 16

Tr 100 x 12

Tr 100 x 16

Tr 120 x 14

Tr 120 x 16

Tr 140 x 14

= Goods in stock

We riserve the right to change sizes and features without notice. 11

SINGLE START

BIG page 36

Bronze

CuSn12-C

CQA page 37

Steel

11SMnPb37

QOB page 37

Brass

CW614N-M

CQF page 38

Steel

11SMnPb37

QBF page 39

Bronze

CuSn12-C

Single

start

THREAD RH LH RH LH RH LH RH LH RH LH

Tr 10 x 2

Tr 10 x 3

Tr 12 x 3

Tr 14 x 3

Tr 14 x 4

Tr 16 x 4

Tr 18 x 4

Tr 20 x 4

Tr 22 x 5

Tr 24 x 5

Tr 25 x 3

Tr 25 x 5

Tr 26 x 5

Tr 28 x 5

Tr 30 x 3

Tr 30 x 4

Tr 30 x 5

Tr 30 x 6

Tr 32 x 6

Tr 35 x 3

Tr 35 x 4

Tr 35 x 5

Tr 35 x 6

Tr 35 x 8

Tr 36 x 6

Tr 40 x 3

Tr 40 x 4

Tr 40 x 5

Tr 40 x 6

Tr 40 x 7

Tr 40 x 8

Tr 40 x 10

Tr 44 x 7

Tr 45 x 8

Tr 50 x 3

Tr 50 x 4

Tr 50 x 5

Tr 50 x 6

Tr 50 x 8

Tr 50 x 10

Tr 55 x 9

Tr 60 x 6

Tr 60 x 7

Tr 60 x 9

Tr 70 x 10

Tr 80 x 10

Tr 90 x 12

Tr 95 x 16

Tr 100 x 12

Tr 100 x 16

Tr 120 x 14

Tr 120 x 16

Tr 140 x 14

= Goods in stock

12 We riserve the right to change sizes and features without notice.

TRAPEZOIDAL NUTS

FTN page 40

Bronzo

CuSn5Zn5Pb5-C

FXN page 41

Bronzo

CuSn12-C

FMT page 42

Bronzo

CuSn12-C

HDL page 43

Bronzo

CuSn12-C

CBC page 44

Bronzo

CuSn12-C

Single

start

THREAD RH LH RH LH RH LH RH LH RH LH

Tr 10 x 2

Tr 10 x 3

Tr 12 x 3

Tr 14 x 3

Tr 14 x 4

Tr 16 x 4

Tr 18 x 4

Tr 20 x 4

Tr 22 x 5

Tr 24 x 5

Tr 25 x 3

Tr 25 x 5

Tr 26 x 5

Tr 28 x 5

Tr 30 x 3

Tr 30 x 4

Tr 30 x 5

Tr 30 x 6

Tr 32 x 6

Tr 35 x 3

Tr 35 x 4

Tr 35 x 5

Tr 35 x 6

Tr 35 x 8

Tr 36 x 6

Tr 40 x 3

Tr 40 x 4

Tr 40 x 5

Tr 40 x 6

Tr 40 x 7

Tr 40 x 8

Tr 40 x 10

Tr 44 x 7

Tr 45 x 8

Tr 50 x 3

Tr 50 x 4

Tr 50 x 5

Tr 50 x 6

Tr 50 x 8

Tr 50 x 10

Tr 55 x 9

Tr 60 x 6

Tr 60 x 7

Tr 60 x 9

Tr 70 x 10

Tr 80 x 10

Tr 90 x 12

Tr 95 x 16

Tr 100 x 12

Tr 100 x 16

Tr 120 x 14

Tr 120 x 16

Tr 140 x 14

= Goods in stock

We riserve the right to change sizes and features without notice. 13

SINGLE START

FFR page 45

Bronze

CuSn5Zn5Pb5-C

HAL page 48

Alluminium Bronze

CuAl11Fe6Ni6-C

MES page 49

Steel

11SMnPb37

FCS page 50

Plastic PA6 + MoS2 +

self lubricating

MPH page 51

Plastic

PA6 + MoS2

Single

start

THREAD RH LH RH LH RH LH RH LH RH LH

Tr 10 x 2

Tr 10 x 3

Tr 12 x 3

Tr 14 x 3

Tr 14 x 4

Tr 16 x 4

Tr 18 x 4

Tr 20 x 4

Tr 22 x 5

Tr 24 x 5

Tr 25 x 3

Tr 25 x 5

Tr 26 x 5

Tr 28 x 5

Tr 30 x 3

Tr 30 x 4

Tr 30 x 5

Tr 30 x 6

Tr 32 x 6

Tr 35 x 3

Tr 35 x 4

Tr 35 x 5

Tr 35 x 6

Tr 35 x 8

Tr 36 x 6

Tr 40 x 3

Tr 40 x 4

Tr 40 x 5

Tr 40 x 6

Tr 40 x 7

Tr 40 x 8

Tr 40 x 10

Tr 44 x 7

Tr 45 x 8

Tr 50 x 3

Tr 50 x 4

Tr 50 x 5

Tr 50 x 6

Tr 50 x 8

Tr 50 x 10

Tr 55 x 9

Tr 60 x 6

Tr 60 x 7

Tr 60 x 9

Tr 70 x 10

Tr 80 x 10

Tr 90 x 12

Tr 95 x 16

Tr 100 x 12

Tr 100 x 16

Tr 120 x 14

Tr 120 x 16

Tr 140 x 14

= Goods in stock

14 We riserve the right to change sizes and features without notice.

TRAPEZOIDAL NUTS

MLF page 33

Steel

11SMnPb37

MZP page 33

Steel

11SMnPb37

HSN page 34

Bronze

CuSn5Zn5Pb5-C

HBD page 34

Bronze

CuSn7Zn4Pb7-C

FXN page 41

Bronze

CuSn12-C

FMT page 42

Bronze

CuSn12-C

Multiple

start

THREAD RH LH RH LH RH LH RH LH RH LH RH LH

Tr 10 x 4 (P2)

Tr 12 x 6 (P3)

Tr 14 x 6 (P3)

Tr 16 x 8 (P4)

Tr 18 x 8 (P4)

Tr 20 x 8 (P4)

Tr 20 x 20 (P5)

Tr 22 x 10 (P5)

Tr 24 x 10 (P5)

Tr 25 x 10 (P5)

Tr 25 x 25 (P5)

Tr 26 x 10 (P5)

Tr 28 x 10 (P5)

Tr 30 x 12 (P6)

Tr 30 x 30 (P5)

Tr 32 x 12 (P6)

Tr 36 x 12 (P6)

Tr 40 x 14 (P7)

Tr 40 x 40 (P8)

= Goods in stock.

We riserve the right to change sizes and features without notice. 15

MULTIPLE START

HDL page 43

Bronze

CuSn12-C

FFR page 45

Bronze

CuSn5Zn5Pb5-C

FHD page 46

Bronze

CuSn12-C

CDF page 47

Bronze

CuSn12-C

FCS page 50

Plastic PA6 + MoS2+

self lubricating

MPH page 51

Plastic

PA6 + MoS2

Multiple

start

THREAD RH LH RH LH RH LH RH LH RH LH RH LH

Tr 10 x 4 (P2)

Tr 12 x 6 (P3)

Tr 14 x 6 (P3)

Tr 16 x 8 (P4)

Tr 18 x 8 (P4)

Tr 20 x 8 (P4)

Tr 20 x 20 (P5)

Tr 22 x 10 (P5)

Tr 24 x 10 (P5)

Tr 25 x 10 (P5)

Tr 25 x 25 (P5)

Tr 26 x 10 (P5)

Tr 28 x 10 (P5)

Tr 30 x 12 (P6)

Tr 30 x 30 (P5)

Tr 32 x 12 (P6)

Tr 36 x 12 (P6)

Tr 40 x 14 (P7)

Tr 40 x 40 (P8)

= Goods in stock.

16 We riserve the right to change sizes and features without notice.

Features of CONTI Trapezoidal Screws and Nuts

CONTI trapezoidal screws are precision rolled. Continuous search for improvement and many years of CONTI

experience in the development of the cold plastic deformation process which characterizes rolling allow us to offer our

customers trapezoidal screws with excellent features.

Materials

Steel used in trapezoidal screws: Surface hardness after rolling

EN 10084 C15E - 1.1141 carbon steel App. 160/180 HB

EN 10083-2 1C45 - 1.0503 carbon steel App. 250 HB

Inox A2 - AISI 304 -1.4301 stainless steel App. 260 HB

Inox A4 - AISI 316 - 1.4401 stainless steel App. 280 HB

C45 and A2 stainless steel were chosen because in addition to their natural qualities as good construction

materials, after rolling they give very good surface hardness and finish on the thread sides. A4 stainless steel

also has excellent corrosion resistance. C15 is an excellent quality-price compromise.

Roughness is less than 1 m Ra for all.

These two features are decisive factors for qualitative appraisal of trapezoidal screws because they give very

small friction coefficients, much lower than those obtainable with machined screws where other conditions

such as speed, load and lubrication are equal.

Our trapezoidal screws coupled with bronze nuts give the opportunity to realize translation systems whose

efficiency, flowability and quietness are much lower comparing to a coupling with machined screws.

Because of the low friction coefficient the amount of heat generated during movement is limited with resulting

smaller nut heating. Nut life is also increased. We make nuts with 10 kinds of material to better meet the

various requirements.

Steel used in nuts:

EN 10277-3 11SMnPb37 1.0737 steel with sulphur, manganese and lead

EN 10277-3 11SMn30 1.0715 steel with sulphur and manganese

INOX A1- AISI 303 1.4305 stainless steel

Brass used in nuts:

EN 12164 CW614N-M brass

Bronze used in nuts:

EN 1982 CuSn5Zn5Pb5-C CC491K tin bronze with zinc and lead 60-70 HB

EN 1982 CuSn7Zn4Pb7-C CC493K tin bronze with zinc and lead 65-75 HB

EN 1982 CuSn12-C CC483K tin bronze 80-100 HB

EN 1982 CuAl11Fe6Ni6-C CC483K aluminium bronze 160-220 HB

Plastic used in nuts:

PA 6 + Mo S2 DIN 7728 plastic

PA 6 + Mo S2 DIN 7728 + additives self-lubricating plastic

The nuts we make with length 3xTr: HDL, BIG and HAL deserve special attention.

These bronze nuts, thanks to their considerable length, distribute the load over a larger number of holding

threads and thus limit surface contact pressure between screw and nut. This is decisive for long nut life.

By using the 3xTr long nuts compared with bronze nuts with conventional length (approximately 1.5xTr or

2xTr), higher loads can be born for equal traversing speed.

In particular, with HAL aluminium bronze nuts very high loads can be born and it is recommended to apply

continuous steady lubrication. HAL nuts have to be coupled with screws in C45 or in stainless steel A2 or A4;

C15 screws are not recommended.

Where it is not desired to lubricate trapezoidal screws, self-lubricating plastic nuts are recommended.

It is not possible to couple plastic nuts with screws made by machining.

We riserve the right to change sizes and features without notice. 17

Positioning Accuracy

To better meet the requirements of customers using trapezoidal screws as positioning system we produce

screws with lead accuracy according to the following table

Screw type Lead Accuracy Pitch error

KTS 100 (200 *) +/- 0.100 mm every 300 mm of thread

KUE 100 (200 *) +/- 0.100 mm every 300 mm of thread

KKA 50 +/- 0.050 mm every 300 mm of thread

KSR 500 +/- 0.500 mm every 300 mm of thread

KQX 200 +/- 0.200 mm every 300 mm of thread

KEQ 200 +/- 0.200 mm every 300 mm of thread

KRP 200 +/- 0.200 mm every 300 mm of thread

KRE 200 +/- 0.200 mm every 300 mm of thread

KAM 200 +/- 0.200 mm every 300 mm of thread

KAF 200 +/- 0.200 mm every 300 mm of thread

* Class 200 for diameters bigger than 80x10.

Straightness

CONTI screws are produced with controlled straightness.

Screw straightness is appraised by measuring the variation of the deflection when the screw is supported at

the ends on two constraints and slightly rotated.

For example, the screw KKA Tr 30 A (threading Tr 30 x 6 with 1 start) has straightness of 0.3 on 3000 mm.

This means that a screw Tr 30x6 3000 mm long resting on two constraints at the ends and rotated slightly

displays a camber variation less than 0.3 mm at all points of the screw.

= screw weight camber

for screws Tr 30x6 with L = 3000 mm

maximum: 0.3 mm

Good screw straightness gives operation with load always centred on the axis, hence uniform distribution of

surface contact pressure between screw and nut with resulting smooth running, and regular rotation and

translation.

18 We riserve the right to change sizes and features without notice.

Trapezoidal screws type KTS Steel C45 1.0503

Stock no. for screw

RIGHT

Stock no. for screw

LEFT

Diameter

x lead

Thread

starts

Lead

accuracy

m /300 mm

Straightness

mm / mm

Weight

kg/mt

KTS 10 T R KTS 10 T L Tr 10x2 1 100 0,5 / 1000 0,48

KTS 10 A R KTS 10 A L Tr 10x3 1 100 0,5 / 1000 0,42

KTS 12 A R KTS 12 A L Tr 12x3 1 100 0,5 / 1000 0,65

KTS 14 R R KTS 14 R L Tr 14x3 1 100 0,5 / 1000 0,93

KTS 14 A R KTS 14 A L Tr 14x4 1 100 0,5 / 1000 0,86

KTS 16 A R KTS 16 A L Tr 16x4 1 100 0,5 / 1000 1,17

KTS 18 A R KTS 18 A L Tr 18x4 1 100 0,5 / 1000 1,53

KTS 20 A R KTS 20 A L Tr 20x4 1 100 0,4 / 2000 1,94

KTS 22 A R KTS 22 A L Tr 22x5 1 100 0,4 / 2000 2,29

KTS 24 A R KTS 24 A L Tr 24x5 1 100 0,4 / 2000 2,78

KTS 25 R R KTS 25 R L Tr 25x3 1 100 0,3 / 2000 3,30

KTS 25 A R KTS 25 A L Tr 25x5 1 100 0,3 / 2000 3,05

KTS 26 A R KTS 26 A L Tr 26x5 1 100 0,3 / 2000 3,33

KTS 28 A R KTS 28 A L Tr 28x5 1 100 0,3 / 2000 3,92

KTS 30 P R KTS 30 P L Tr 30x5 1 100 0,3 / 3000 4,57

KTS 30 A R KTS 30 A L Tr 30x6 1 100 0,3 / 3000 4,38

KTS 32 A R KTS 32 A L Tr 32x6 1 100 0,3 / 3000 5,06

KTS 35 P R KTS 35 P L Tr 35x5 1 100 0,3 / 3000 6,40

KTS 35 A R KTS 35 A L Tr 35x6 1 100 0,3 / 3000 6,16

KTS 35 M R KTS 35 M L Tr 35x8 1 100 0,3 / 3000 5,85

KTS 36 A R KTS 36 A L Tr 36x6 1 100 0,3 / 3000 6,56

KTS 40 P R KTS 40 P L Tr 40x5 1 100 0,3 / 3000 8,51

KTS 40 O R KTS 40 O L Tr 40x6 1 100 0,3 / 3000 8,26

KTS 40 A R KTS 40 A L Tr 40x7 1 100 0,3 / 3000 8,03

KTS 40 M R KTS 40 M L Tr 40x8 1 100 0,3 / 3000 7,90

KTS 40 I R KTS 40 I L Tr 40x10 1 100 0,3 / 3000 7,49

KTS 44 A R KTS 44 A L Tr 44x7 1 100 0,3 / 3000 9,90

KTS 45 A R KTS 45 A L Tr 45x8 1 100 0,3 / 3000 10,23

KTS 50 P R KTS 50 P L Tr 50x5 1 100 0,3 / 3000 13,70

KTS 50 O R KTS 50 O L Tr 50x6 1 100 0,3 / 3000 13,35

KTS 50 A R KTS 50 A L Tr 50x8 1 100 0,3 / 3000 12,90

KTS 50 I R KTS 50 I L Tr 50x10 1 100 0,3 / 3000 12,37

KTS 55 A R KTS 55 A L Tr 55x9 1 100 0,3 / 3000 15,51

KTS 60 O R KTS 60 O L Tr 60x6 1 100 0,3 / 3000 19,67

KTS 60 N R KTS 60 N L Tr 60x7 1 100 0,3 / 3000 19,36

KTS 60 A R KTS 60 A L Tr 60x9 1 100 0,3 / 3000 18,74

KTS 70 A R KTS 70 A L Tr 70x10 1 100 0,3 / 3000 25,80

KTS 80 A R KTS 80 A L Tr 80x10 1 100 0,3 / 3000 34,39

KTS 90 A R KTS 90 A L Tr 90x12 1 200 0,5 / 300 43,07

KTS 95 W R KTS 95 W L Tr 95x16 1 200 1 / 300 45,90

KTS A0 A R KTS A0 A L Tr 100x12 1 200 1 / 300 53,99

KTS A0 W R KTS A0 W L Tr 100x16 1 200 1 / 300 51,37

KTS C0 A R KTS C0 A L Tr 120x14 1 200 1 / 300 77,72

KTS C0 W R KTS C0 W L Tr 120x16 1 200 1 / 300 76,34

KTS E0 A R KTS E0 A L Tr 140x14 1 200 1 / 300 107,87

= Goods in stock. = Goods available upon request only.

We riserve the right to change sizes and features without notice. 19

Trapezoidal screws type KUE Steel C45 1.0503

Stock no. for screw

RIGHT

Stock no. for screw

LEFT

Diameter

x lead

Thread

starts

Lead

accuracy

m /300 mm

Straightness

mm / mm

Weight

kg/mt

KUE 10 T R KUE 10 T L Tr 10x2 1 100 0,5 / 300 0,48

KUE 10 A R KUE 10 A L Tr 10x3 1 100 0,5 / 300 0,42

KUE 12 A R KUE 12 A L Tr 12x3 1 100 0,5 / 300 0,65

KUE 14 R R KUE 14 R L Tr 14x3 1 100 0,5 / 300 0,93

KUE 14 A R KUE 14 A L Tr 14x4 1 100 0,5 / 300 0,86

KUE 16 A R KUE 16 A L Tr 16x4 1 100 0,5 / 300 1,17

KUE 18 A R KUE 18 A L Tr 18x4 1 100 0,5 / 300 1,53

KUE 20 A R KUE 20 A L Tr 20x4 1 100 0,5 / 300 1,94

KUE 22 A R KUE 22 A L Tr 22x5 1 100 0,2 / 300 2,29

KUE 24 A R KUE 24 A L Tr 24x5 1 100 0,2 / 300 2,78

KUE 25 R R KUE 25 R L Tr 25x3 1 100 0,2 / 300 3,30

KUE 25 A R KUE 25 A L Tr 25x5 1 100 0,2 / 300 3,05

KUE 26 A R KUE 26 A L Tr 26x5 1 100 0,2 / 300 3,33

KUE 28 A R KUE 28 A L Tr 28x5 1 100 0,2 / 300 3,92

KUE 30 P R KUE 30 P L Tr 30x5 1 100 0,2 / 300 4,57

KUE 30 A R KUE 30 A L Tr 30x6 1 100 0,2 / 300 4,38

KUE 32 A R KUE 32 A L Tr 32x6 1 100 0,2 / 300 5,06

KUE 35 P R KUE 35 P L Tr 35x5 1 100 0,2 / 300 6,40

KUE 35 A R KUE 35 A L Tr 35x6 1 100 0,2 / 300 6,16

KUE 35 M R KUE 35 M L Tr 35x8 1 100 0,2 / 300 5,85

KUE 36 A R KUE 36 A L Tr 36x6 1 100 0,2 / 300 6,56

KUE 40 P R KUE 40 P L Tr 40x5 1 100 0,2 / 300 8,51

KUE 40 O R KUE 40 O L Tr 40x6 1 100 0,2 / 300 8,26

KUE 40 A R KUE 40 A L Tr 40x7 1 100 0,2 / 300 8,03

KUE 40 M R KUE 40 M L Tr 40x8 1 100 0,2 / 300 7,90

KUE 40 I R KUE 40 I L Tr 40x10 1 100 0,2 / 300 7,49

KUE 44 A R KUE 44 A L Tr 44x7 1 100 0,2 / 300 9,90

KUE 45 A R KUE 45 A L Tr 45x8 1 100 0,2 / 300 10,23

KUE 50 P R KUE 50 P L Tr 50x5 1 100 0,2 / 300 13,70

KUE 50 O R KUE 50 O L Tr 50x6 1 100 0,2 / 300 13,35

KUE 50 A R KUE 50 A L Tr 50x8 1 100 0,2 / 300 12,90

KUE 50 I R KUE 50 I L Tr 50x10 1 100 0,2 / 300 12,37

KUE 55 A R KUE 55 A L Tr 55x9 1 100 0,2 / 300 15,51

KUE 60 O R KUE 60 O L Tr 60x6 1 100 0,2 / 300 19,67

KUE 60 N R KUE 60 N L Tr 60x7 1 100 0,2 / 300 19,36

KUE 60 A R KUE 60 A L Tr 60x9 1 100 0,2 / 300 18,74

KUE 70 A R KUE 70 A L Tr 70x10 1 100 0,4 / 300 25,80

KUE 80 A R KUE 80 A L Tr 80x10 1 100 0,4 / 300 34,39

KUE 90 A R KUE 90 A L Tr 90x12 1 200 0,5 / 300 43,07

KUE 95 W R KUE 95 W L Tr 95x16 1 200 1 / 300 45,90

KUE A0 A R KUE A0 A L Tr 100x12 1 200 1 / 300 53,99

KUE A0 W R KUE A0 W L Tr 100x16 1 200 1 / 300 51,37

KUE C0 A R KUE C0 A L Tr 120x14 1 200 1 / 300 77,72

KUE C0 W R KUE C0 W L Tr 120x16 1 200 1 / 300 76,34

KUE E0 A R KUE E0 A L Tr 140x14 1 200 1 / 300 107,87

= Goods in stock. = Goods available upon request only.

20 We riserve the right to change sizes and features without notice.

Trapezoidal screws type KKA Steel C45 1.0503

Stock no. for screw

RIGHT

Stock no. for screw

LEFT

Diameter

x lead

Thread

starts

Lead

accuracy

m /300 mm

Straightness

mm / mm

Weight

kg/mt

KKA 10 T R KKA 10 T L Tr 10x2 1 50 0,5 / 1000 0,48

KKA 10 A R KKA 10 A L Tr 10x3 1 50 0,5 / 1000 0,42

KKA 12 A R KKA 12 A L Tr 12x3 1 50 0,5 / 1000 0,65

KKA 14 R R KKA 14 R L Tr 14x3 1 50 0,5 / 1000 0,93

KKA 14 A R KKA 14 A L Tr 14x4 1 50 0,5 / 1000 0,86

KKA 16 A R KKA 16 A L Tr 16x4 1 50 0,5 / 1000 1,17

KKA 18 A R KKA 18 A L Tr 18x4 1 50 0,5 / 1000 1,53

KKA 20 A R KKA 20 A L Tr 20x4 1 50 0,4 / 2000 1,94

KKA 22 A R KKA 22 A L Tr 22x5 1 50 0,4 / 2000 2,29

KKA 24 A R KKA 24 A L Tr 24x5 1 50 0,4 / 2000 2,78

KKA 25 A R KKA 25 A L Tr 25x5 1 50 0,3 / 2000 3,05

KKA 26 A R KKA 26 A L Tr 26x5 1 50 0,3 / 2000 3,33

KKA 28 A R KKA 28 A L Tr 28x5 1 50 0,3 / 2000 3,92

KKA 30 P R KKA 30 P L Tr 30x5 1 50 0,3 / 3000 4,57

KKA 30 A R KKA 30 A L Tr 30x6 1 50 0,3 / 3000 4,38

KKA 32 A R KKA 32 A L Tr 32x6 1 50 0,3 / 3000 5,06

KKA 35 P R KKA 35 P L Tr 35x5 1 50 0,3 / 3000 6,40

KKA 35 A R KKA 35 A L Tr 35x6 1 50 0,3 / 3000 6,16

KKA 35 M R KKA 35 M L Tr 35x8 1 50 0,3 / 3000 5,85

KKA 36 A R KKA 36 A L Tr 36x6 1 50 0,3 / 3000 6,56

KKA 40 P R KKA 40 P L Tr 40x5 1 50 0,3 / 3000 8,51

KKA 40 O R KKA 40 O L Tr 40x6 1 50 0,3 / 3000 8,26

KKA 40 A R KKA 40 A L Tr 40x7 1 50 0,3 / 3000 8,03

KKA 40 M R KKA 40 M L Tr 40x8 1 50 0,3 / 3000 7,90

KKA 40 I R KKA 40 I L Tr 40x10 1 50 0,3 / 3000 7,49

KKA 44 A R KKA 44 A L Tr 44x7 1 50 0,3 / 3000 9,90

KKA 45 A R KKA 45 A L Tr 45x8 1 50 0,3 / 3000 10,23

KKA 50 P R KKA 50 P L Tr 50x5 1 50 0,3 / 3000 13,70

KKA 50 O R KKA 50 O L Tr 50x6 1 50 0,3 / 3000 13,35

KKA 50 A R KKA 50 A L Tr 50x8 1 50 0,3 / 3000 12,90

KKA 50 I R KKA 50 I L Tr 50x10 1 50 0,3 / 3000 12,37

KKA 55 A R KKA 55 A L Tr 55x9 1 50 0,3 / 3000 15,51

KKA 60 O R KKA 60 O L Tr 60x6 1 50 0,3 / 3000 19,67

KKA 60 N R KKA 60 N L Tr 60x7 1 50 0,3 / 3000 19,36

KKA 60 A R KKA 60 A L Tr 60x9 1 50 0,3 / 3000 18,74

KKA 70 A R KKA 70 A L Tr 70x10 1 50 0,3 / 3000 25,80

KKA 80 A R KKA 80 A L Tr 80x10 1 50 0,3 / 3000 34,39

= Goods in stock. = Goods available upon request only.

We riserve the right to change sizes and features without notice. 21

Trapezoidal screws type KSR Steel C45 1.0503

Stock no. for screw

RIGHT

Stock no. for screw

LEFT

Diameter

x lead

Thread

starts

Lead

accuracy

m /300 mm

Straightness

mm / mm

Weight

kg/mt

KSR 10 T R KSR 10 T L Tr 10x2 1 500 -- 0,48

KSR 10 A R KSR 10 A L Tr 10x3 1 500 -- 0,42

KSR 12 A R KSR 12 A L Tr 12x3 1 500 -- 0,65

KSR 14 R R KSR 14 R L Tr 14x3 1 500 -- 0,93

KSR 14 A R KSR 14 A L Tr 14x4 1 500 -- 0,86

KSR 16 A R KSR 16 A L Tr 16x4 1 500 -- 1,17

KSR 18 A R KSR 18 A L Tr 18x4 1 500 -- 1,53

KSR 20 A R KSR 20 A L Tr 20x4 1 500 -- 1,94

KSR 22 A R KSR 22 A L Tr 22x5 1 500 -- 2,29

KSR 24 A R KSR 24 A L Tr 24x5 1 500 -- 2,78

KSR 25 R R KSR 25 R L Tr 25x3 1 500 -- 3,30

KSR 25 A R KSR 25 A L Tr 25x5 1 500 -- 3,05

KSR 26 A R KSR 26 A L Tr 26x5 1 500 -- 3,33

KSR 28 A R KSR 28 A L Tr 28x5 1 500 -- 3,92

KSR 30 R R KSR 30 R L Tr 30x3 1 500 -- 4,57

KSR 30 Q R KSR 30 Q L Tr 30x4 1 500 -- 4,57

KSR 30 P R KSR 30 P L Tr 30x5 1 500 -- 4,57

KSR 30 A R KSR 30 A L Tr 30x6 1 500 -- 4,38

KSR 32 A R KSR 32 A L Tr 32x6 1 500 -- 5,06

KSR 35 R R KSR 35 R L Tr 35x3 1 500 -- 6,77

KSR 35 Q R KSR 35 Q L Tr 35x4 1 500 -- 6,57

KSR 35 P R KSR 35 P L Tr 35x5 1 500 -- 6,40

KSR 35 A R KSR 35 A L Tr 35x6 1 500 -- 6,16

KSR 35 M R KSR 35 M L Tr 35x8 1 500 -- 5,85

KSR 36 A R KSR 36 A L Tr 36x6 1 500 -- 6,56

KSR 40 R R KSR 40 R L Tr 40x3 1 500 -- 8,95

KSR 40 Q R KSR 40 Q L Tr 40x4 1 500 -- 8,71

KSR 40 P R KSR 40 P L Tr 40x5 1 500 -- 8,51

KSR 40 O R KSR 40 O L Tr 40x6 1 500 -- 8,26

KSR 40 A R KSR 40 A L Tr 40x7 1 500 -- 8,03

KSR 40 M R KSR 40 M L Tr 40x8 1 500 -- 7,90

KSR 40 I R KSR 40 I L Tr 40x10 1 500 -- 7,49

KSR 44 A R KSR 44 A L Tr 44x7 1 500 -- 9,90

KSR 45 A R KSR 45 A L Tr 45x8 1 500 -- 10,23

KSR 50 R R KSR 50 R L Tr 50x3 1 500 -- 14,26

KSR 50 Q R KSR 50 Q L Tr 50x4 1 500 -- 13,96

KSR 50 P R KSR 50 P L Tr 50x5 1 500 -- 13,70

KSR 50 O R KSR 50 O L Tr 50x6 1 500 -- 13,35

KSR 50 A R KSR 50 A L Tr 50x8 1 500 -- 12,90

KSR 50 I R KSR 50 I L Tr 50x10 1 500 -- 12,37

KSR 55 A R KSR 55 A L Tr 55x9 1 500 -- 15,51

KSR 60 O R KSR 60 O L Tr 60x6 1 500 -- 19,67

KSR 60 N R KSR 60 N L Tr 60x7 1 500 -- 19,36

KSR 60 A R KSR 60 A L Tr 60x9 1 500 -- 18,74

KSR 70 A R KSR 70 A L Tr 70x10 1 500 -- 25,80

KSR 80 A R KSR 80 A L Tr 80x10 1 500 -- 34,39

= Goods in stock. = Goods available upon request only.

22 We riserve the right to change sizes and features without notice.

Trapezoidal screws type KQX Steel C15 1.1141

Stock no. for screw

RIGHT

Stock no. for screw

LEFT

Diameter

x lead

Thread

starts

Lead

accuracy

m /300 mm

Straightness

mm / mm

Weight

kg/mt

KQX 10 T R KQX 10 T L Tr 10x2 1 200 0,7 / 1000 0,48

KQX 10 A R KQX 10 A L Tr 10x3 1 200 0,7 / 1000 0,42

KQX 12 A R KQX 12 A L Tr 12x3 1 200 0,7 / 1000 0,65

KQX 14 R R KQX 14 R L Tr 14x3 1 200 0,7 / 1000 0,93

KQX 14 A R KQX 14 A L Tr 14x4 1 200 0,7 / 1000 0,86

KQX 16 A R KQX 16 A L Tr 16x4 1 200 0,7 / 1500 1,17

KQX 18 A R KQX 18 A L Tr 18x4 1 200 0,7 / 1500 1,53

KQX 20 A R KQX 20 A L Tr 20x4 1 200 0,6 / 2000 1,94

KQX 22 A R KQX 22 A L Tr 22x5 1 200 0,6 / 2000 2,29

KQX 24 A R KQX 24 A L Tr 24x5 1 200 0,4 / 2000 2,78

KQX 25 R R KQX 25 R L Tr 25x3 1 200 0,4 / 2000 3,30

KQX 25 A R KQX 25 A L Tr 25x5 1 200 0,4 / 2000 3,05

KQX 26 A R KQX 26 A L Tr 26x5 1 200 0,4 / 2000 3,33

KQX 28 A R KQX 28 A L Tr 28x5 1 200 0,4 / 2000 3,92

KQX 30 R R * KQX 30 R L * Tr 30x3 1 200 0,4 / 3000 4,57

KQX 30 Q R * KQX 30 Q L * Tr 30x4 1 200 0,4 / 3000 4,57

KQX 30 P R * KQX 30 P L * Tr 30x5 1 200 0,4 / 3000 4,57

KQX 30 A R KQX 30 A L Tr 30x6 1 200 0,4 / 3000 4,38

KQX 32 A R KQX 32 A L Tr 32x6 1 200 0,4 / 3000 5,06

KQX 35 R R * KQX 35 R L * Tr 35x3 1 200 0,3 / 3000 6,77

KQX 35 Q R * KQX 35 Q L * Tr 35x4 1 200 0,3 / 3000 6,57

KQX 35 P R * KQX 35 P L * Tr 35x5 1 200 0,3 / 3000 6,40

KQX 35 A R KQX 35 A L Tr 35x6 1 200 0,3 / 3000 6,16

KQX 35 M R KQX 35 M L Tr 35x8 1 200 0,3 / 3000 5,85

KQX 36 A R KQX 36 A L Tr 36x6 1 200 0,3 / 3000 6,56

KQX 40 R R * KQX 40 R L * Tr 40x3 1 200 0,3 / 3000 8,95

KQX 40 Q R * KQX 40 Q L * Tr 40x4 1 200 0,3 / 3000 8,71

KQX 40 P R * KQX 40 P L * Tr 40x5 1 200 0,3 / 3000 8,51

KQX 40 O R * KQX 40 O L * Tr 40x6 1 200 0,3 / 3000 8,26

KQX 40 A R KQX 40 A L Tr 40x7 1 200 0,3 / 3000 8,03

KQX 40 M R KQX 40 M L Tr 40x8 1 200 0,3 / 3000 7,90

KQX 40 I R KQX 40 I L Tr 40x10 1 200 0,3 / 3000 7,49

KQX 44 A R KQX 44 A L Tr 44x7 1 200 0,3 / 3000 9,90

KQX 45 A R KQX 45 A L Tr 45x8 1 200 0,3 / 3000 10,23

KQX 50 R R * KQX 50 R L * Tr 50x3 1 200 0,3 / 3000 14,26

KQX 50 Q R * KQX 50 Q L * Tr 50x4 1 200 0,3 / 3000 13,96

KQX 50 P R * KQX 50 P L * Tr 50x5 1 200 0,3 / 3000 13,70

KQX 50 O R * KQX 50 O L * Tr 50x6 1 200 0,3 / 3000 13,35

KQX 50 A R KQX 50 A L Tr 50x8 1 200 0,3 / 3000 12,90

KQX 50 I R KQX 50 I L Tr 50x10 1 200 0,3 / 3000 12,37

KQX 55 A R KQX 55 A L Tr 55x9 1 200 0,3 / 3000 15,51

KQX 60 O R KQX 60 O L Tr 60x6 1 200 0,3 / 3000 19,67

KQX 60 N R KQX 60 N L Tr 60x7 1 200 0,3 / 3000 19,36

KQX 60 A R KQX 60 A L Tr 60x9 1 200 0,3 / 3000 18,74

KQX 70 A R KQX 70 A L Tr 70x10 1 200 0,3 / 3000 25,80

KQX 80 A R KQX 80 A L Tr 80x10 1 200 0,3 / 3000 34,39

* The screw can be supplied as alternative KCC, obtained by thread whirling, at company Contis chioce.

= Goods in stock. = Goods available upon request only.

We riserve the right to change sizes and features without notice. 23

Trapezoidal screws type KEQ Steel C15 1.1141

Stock no. for screw

RIGHT

Stock no. for screw

LEFT

Diameter

x lead

Thread

starts

Lead

accuracy

m /300 mm

Straightness

mm / mm

Weight

kg/mt

KEQ 10 T R KEQ 10 T L Tr 10x2 1 200 -- 0,48

KEQ 10 A R KEQ 10 A L Tr 10x3 1 200 -- 0,42

KEQ 12 A R KEQ 12 A L Tr 12x3 1 200 -- 0,65

KEQ 14 R R KEQ 14 R L Tr 14x3 1 200 -- 0,93

KEQ 14 A R KEQ 14 A L Tr 14x4 1 200 -- 0,86

KEQ 16 A R KEQ 16 A L Tr 16x4 1 200 -- 1,17

KEQ 18 A R KEQ 18 A L Tr 18x4 1 200 -- 1,53

KEQ 20 A R KEQ 20 A L Tr 20x4 1 200 -- 1,94

KEQ 22 A R KEQ 22 A L Tr 22x5 1 200 -- 2,29

KEQ 24 A R KEQ 24 A L Tr 24x5 1 200 -- 2,78

KEQ 25 R R KEQ 25 R L Tr 25x3 1 200 -- 3,30

KEQ 25 A R KEQ 25 A L Tr 25x5 1 200 -- 3,05

KEQ 26 A R KEQ 26 A L Tr 26x5 1 200 -- 3,33

KEQ 28 A R KEQ 28 A L Tr 28x5 1 200 -- 3,92

KEQ 30 R R KEQ 30 R L Tr 30x3 1 200 -- 4,57

KEQ 30 Q R KEQ 30 Q L Tr 30x4 1 200 -- 4,57

KEQ 30 P R KEQ 30 P L Tr 30x5 1 200 -- 4,57

KEQ 30 A R KEQ 30 A L Tr 30x6 1 200 -- 4,38

KEQ 32 A R KEQ 32 A L Tr 32x6 1 200 -- 5,06

KEQ 35 R R KEQ 35 R L Tr 35x3 1 200 -- 6,77

KEQ 35 Q R KEQ 35 Q L Tr 35x4 1 200 -- 6,57

KEQ 35 P R KEQ 35 P L Tr 35x5 1 200 -- 6,40

KEQ 35 A R KEQ 35 A L Tr 35x6 1 200 -- 6,16

KEQ 35 M R KEQ 35 M L Tr 35x8 1 200 -- 5,85

KEQ 36 A R KEQ 36 A L Tr 36x6 1 200 -- 6,56

KEQ 40 R R KEQ 40 R L Tr 40x3 1 200 -- 8,95

KEQ 40 Q R KEQ 40 Q L Tr 40x4 1 200 -- 8,71

KEQ 40 P R KEQ 40 P L Tr 40x5 1 200 -- 8,51

KEQ 40 O R KEQ 40 O L Tr 40x6 1 200 -- 8,26

KEQ 40 A R KEQ 40 A L Tr 40x7 1 200 -- 8,03

KEQ 40 M R KEQ 40 M L Tr 40x8 1 200 -- 7,90

KEQ 40 I R KEQ 40 I L Tr 40x10 1 200 -- 7,49

KEQ 44 A R KEQ 44 A L Tr 44x7 1 200 -- 9,90

KEQ 45 A R KEQ 45 A L Tr 45x8 1 200 -- 10,23

KEQ 50 R R KEQ 50 R L Tr 50x3 1 200 -- 14,26

KEQ 50 Q R KEQ 50 Q L Tr 50x4 1 200 -- 13,96

KEQ 50 P R KEQ 50 P L Tr 50x5 1 200 -- 13,70

KEQ 50 O R KEQ 50 O L Tr 50x6 1 200 -- 13,35

KEQ 50 A R KEQ 50 A L Tr 50x8 1 200 -- 12,90

KEQ 50 I R KEQ 50 I L Tr 50x10 1 200 -- 12,37

KEQ 55 A R KEQ 55 A L Tr 55x9 1 200 -- 15,51

KEQ 60 O R KEQ 60 O L Tr 60x6 1 200 -- 19,67

KEQ 60 N R KEQ 60 N L Tr 60x7 1 200 -- 19,36

KEQ 60 A R KEQ 60 A L Tr 60x9 1 200 -- 18,74

KEQ 70 A R KEQ 70 A L Tr 70x10 1 200 -- 25,80

KEQ 80 A R KEQ 80 A L Tr 80x10 1 200 -- 34,39

= Goods in stock. = Goods available upon request only.

24 We riserve the right to change sizes and features without notice.

Trapezoidal screws type KRP

A2 stainless steel - AISI 304 1.4301

Stock no. for screw

RIGHT

Stock no. for screw

LEFT

Diameter

x lead

Thread

starts

Lead

accuracy

m /300 mm

Straightness

mm / mm

Weight

kg/mt

KRP 10 T R KRP 10 T L Tr 10x2 1 200 0,7 / 1000 0,48

KRP 10 A R KRP 10 A L Tr 10x3 1 200 0,7 / 1000 0,42

KRP 12 A R KRP 12 A L Tr 12x3 1 200 0,7 / 1000 0,65

KRP 14 R R KRP 14 R L Tr 14x3 1 200 0,7 / 1000 0,93

KRP 14 A R KRP 14 A L Tr 14x4 1 200 0,7 / 1000 0,86

KRP 16 A R KRP 16 A L Tr 16x4 1 200 0,7 / 1500 1,17

KRP 18 A R KRP 18 A L Tr 18x4 1 200 0,7 / 1500 1,53

KRP 20 A R KRP 20 A L Tr 20x4 1 200 0,6 / 2000 1,94

KRP 22 A R KRP 22 A L Tr 22x5 1 200 0,6 / 2000 2,29

KRP 24 A R KRP 24 A L Tr 24x5 1 200 0,4 / 2000 2,78

KRP 25 A R KRP 25 A L Tr 25x5 1 200 0,4 / 2000 3,05

KRP 26 A R KRP 26 A L Tr 26x5 1 200 0,4 / 2000 3,33

KRP 28 A R KRP 28 A L Tr 28x5 1 200 0,4 / 2000 3,92

KRP 30 P R KRP 30 P L Tr 30x5 1 200 0,4 / 3000 4,57

KRP 30 A R KRP 30 A L Tr 30x6 1 200 0,4 / 3000 4,38

KRP 32 A R KRP 32 A L Tr 32x6 1 200 0,4 / 3000 5,06

KRP 35 P R KRP 35 P L Tr 35x5 1 200 0,3 / 3000 6,40

KRP 35 A R KRP 35 A L Tr 35x6 1 200 0,3 / 3000 6,16

KRP 36 A R KRP 36 A L Tr 36x6 1 200 0,3 / 3000 6,56

KRP 40 P R KRP 40 P L Tr 40x5 1 200 0,3 / 3000 8,51

KRP 40 O R KRP 40 O L Tr 40x6 1 200 0,3 / 3000 8,26

KRP 40 A R KRP 40 A L Tr 40x7 1 200 0,3 / 3000 8,03

KRP 44 A R KRP 44 A L Tr 44x7 1 200 0,3 / 3000 9,90

KRP 50 P R KRP 50 P L Tr 50x5 1 200 0,3 / 3000 13,70

KRP 50 O R KRP 50 O L Tr 50x6 1 200 0,3 / 3000 13,35

KRP 50 A R KRP 50 A L Tr 50x8 1 200 0,3 / 3000 12,90

KRP 55 A R KRP 55 A L Tr 55x9 1 200 0,3 / 3000 15,51

KRP 60 O R KRP 60 O L Tr 60x6 1 200 0,3 / 3000 19,67

KRP 60 N R KRP 60 N L Tr 60x7 1 200 0,3 / 3000 19,36

KRP 60 A R KRP 60 A L Tr 60x9 1 200 0,3 / 3000 18,74

KRP 70 A R KRP 70 A L Tr 70x10 1 200 0,3 / 3000 25,80

KRP 80 A R KRP 80 A L Tr 80x10 1 200 0,3 / 3000 34,39

KRP 90 A R KRP 90 A L Tr 90x12 1 200 1 / 300 43,07

KRP A0 A R KRP A0 A L Tr 100x12 1 200 1 / 300 53,99

= Goods in stock. = Goods available upon request only.

We riserve the right to change sizes and features without notice. 25

Trapezoidal screws type KRE

A2 stainless steel - AISI 304 1.4301

Stock no. for screw

RIGHT

Stock no. for screw

LEFT

Diameter

x lead

Thread

starts

Lead

accuracy

m /300 mm

Straightness

mm / mm

Weight

kg/mt

KRE 10 T R KRE 10 T L Tr 10x2 1 200 1,5 / 300 0,48

KRE 10 A R KRE 10 A L Tr 10x3 1 200 1,5 / 300 0,42

KRE 12 A R KRE 12 A L Tr 12x3 1 200 1,5 / 300 0,65

KRE 14 R R KRE 14 R L Tr 14x3 1 200 1,5 / 300 0,93

KRE 14 A R KRE 14 A L Tr 14x4 1 200 1,5 / 300 0,86

KRE 16 A R KRE 16 A L Tr 16x4 1 200 1,5 / 300 1,17

KRE 18 A R KRE 18 A L Tr 18x4 1 200 1,5 / 300 1,53

KRE 20 A R KRE 20 A L Tr 20x4 1 200 1,5 / 300 1,94

KRE 22 A R KRE 22 A L Tr 22x5 1 200 1,5 / 300 2,29

KRE 24 A R KRE 24 A L Tr 24x5 1 200 1,5 / 300 2,78

KRE 25 A R KRE 25 A L Tr 25x5 1 200 1,5 / 300 3,05

KRE 26 A R KRE 26 A L Tr 26x5 1 200 1,5 / 300 3,33

KRE 28 A R KRE 28 A L Tr 28x5 1 200 1,5 / 300 3,92

KRE 30 P R KRE 30 P L Tr 30x5 1 200 1,5 / 300 4,57

KRE 30 A R KRE 30 A L Tr 30x6 1 200 1,5 / 300 4,38

KRE 32 A R KRE 32 A L Tr 32x6 1 200 1,5 / 300 5,06

KRE 35 P R KRE 35 P L Tr 35x5 1 200 1,5 / 300 6,40

KRE 35 A R KRE 35 A L Tr 35x6 1 200 1,5 / 300 6,16

KRE 36 A R KRE 36 A L Tr 36x6 1 200 1,5 / 300 6,56

KRE 40 P R KRE 40 P L Tr 40x5 1 200 1,5 / 300 8,51

KRE 40 O R KRE 40 O L Tr 40x6 1 200 1,5 / 300 8,26

KRE 40 A R KRE 40 A L Tr 40x7 1 200 1,5 / 300 8,03

KRE 44 A R KRE 44 A L Tr 44x7 1 200 1,5 / 300 9,90

KRE 50 P R KRE 50 P L Tr 50x5 1 200 1,5 / 300 13,70

KRE 50 O R KRE 50 O L Tr 50x6 1 200 1,5 / 300 13,35

KRE 50 A R KRE 50 A L Tr 50x8 1 200 1,5 / 300 12,90

KRE 55 A R KRE 55 A L Tr 55x9 1 200 1,5 / 300 15,51

KRE 60 O R KRE 60 O L Tr 60x6 1 200 1,5 / 300 19,67

KRE 60 N R KRE 60 N L Tr 60x7 1 200 1,5 / 300 19,36

KRE 60 A R KRE 60 A L Tr 60x9 1 200 1,5 / 300 18,74

KRE 70 A R KRE 70 A L Tr 70x10 1 200 1,5 / 300 25,80

KRE 80 A R KRE 80 A L Tr 80x10 1 200 1,5 / 300 34,39

KRE 90 A R KRE 90 A L Tr 90x12 1 200 1,5 / 300 43,07

KRE A0 A R KRE A0 A L Tr 100x12 1 200 1,5 / 300 53,99

= Goods in stock. = Goods available upon request only.

26 We riserve the right to change sizes and features without notice.

Trapezoidal screws type KAM

A4 stainless steel - AISI 316 1.4401

Stock no. for screw

RIGHT

Stock no. for screw

LEFT

Diameter

x lead

Thread

starts

Lead

accuracy

m /300 mm

Straightness

mm / mm

Weight

kg/mt

KAM 10 T R KAM 10 T L Tr 10x2 1 200 0,7 / 1000 0,48

KAM 10 A R KAM 10 A L Tr 10x3 1 200 0,7 / 1000 0,42

KAM 12 A R KAM 12 A L Tr 12x3 1 200 0,7 / 1000 0,65

KAM 14 R R KAM 14 R L Tr 14x3 1 200 0,7 / 1000 0,93

KAM 14 A R KAM 14 A L Tr 14x4 1 200 0,7 / 1000 0,86

KAM 16 A R KAM 16 A L Tr 16x4 1 200 0,7 / 1500 1,17

KAM 18 A R KAM 18 A L Tr 18x4 1 200 0,7 / 1500 1,53

KAM 20 A R KAM 20 A L Tr 20x4 1 200 0,6 / 2000 1,94

KAM 22 A R KAM 22 A L Tr 22x5 1 200 0,6 / 2000 2,29

KAM 24 A R KAM 24 A L Tr 24x5 1 200 0,4 / 2000 2,78

KAM 25 A R KAM 25 A L Tr 25x5 1 200 0,4 / 2000 3,05

KAM 26 A R KAM 26 A L Tr 26x5 1 200 0,4 / 2000 3,33

KAM 28 A R KAM 28 A L Tr 28x5 1 200 0,4 / 2000 3,92

KAM 30 P R KAM 30 P L Tr 30x5 1 200 0,4 / 3000 4,57

KAM 30 A R KAM 30 A L Tr 30x6 1 200 0,4 / 3000 4,38

KAM 32 A R KAM 32 A L Tr 32x6 1 200 0,4 / 3000 5,06

KAM 35 P R KAM 35 P L Tr 35x5 1 200 0,3 / 3000 6,40

KAM 35 A R KAM 35 A L Tr 35x6 1 200 0,3 / 3000 6,16

KAM 36 A R KAM 36 A L Tr 36x6 1 200 0,3 / 3000 6,56

KAM 40 P R KAM 40 P L Tr 40x5 1 200 0,3 / 3000 8,51

KAM 40 O R KAM 40 O L Tr 40x6 1 200 0,3 / 3000 8,26

KAM 40 A R KAM 40 A L Tr 40x7 1 200 0,3 / 3000 8,03

KAM 44 A R KAM 44 A L Tr 44x7 1 200 0,3 / 3000 9,90

KAM 50 P R KAM 50 P L Tr 50x5 1 200 0,3 / 3000 13,70

KAM 50 O R KAM 50 O L Tr 50x6 1 200 0,3 / 3000 13,35

KAM 50 A R KAM 50 A L Tr 50x8 1 200 0,3 / 3000 12,90

KAM 55 A R KAM 55 A L Tr 55x9 1 200 0,3 / 3000 15,51

KAM 60 O R KAM 60 O L Tr 60x6 1 200 0,3 / 3000 19,67

KAM 60 N R KAM 60 N L Tr 60x7 1 200 0,3 / 3000 19,36

KAM 60 A R KAM 60 A L Tr 60x9 1 200 0,3 / 3000 18,74

KAM 70 A R KAM 70 A L Tr 70x10 1 200 0,3 / 3000 25,80

KAM 80 A R KAM 80 A L Tr 80x10 1 200 0,3 / 3000 34,39

KAM 90 A R KAM 90 A L Tr 90x12 1 200 1 / 300 43,07

KAM A0 A R KAM A0 AL Tr 100x12 1 200 1 / 300 53,99

= Goods in stock. = Goods available upon request only.

We riserve the right to change sizes and features without notice. 27

Trapezoidal screws type KAF

A4 stainless steel - AISI 316 1.4401

Stock no. for screw

RIGHT

Stock no. for screw

LEFT

Diameter

x lead

Thread

starts

Lead

accuracy

m /300 mm

Straightness

mm / mm

Weight

kg/mt

KAF 10 T R KAF 10 T L Tr 10x2 1 200 1,5 / 300 0,48

KAF 10 A R KAF 10 A L Tr 10x3 1 200 1,5 / 300 0,42

KAF 12 A R KAF 12 A L Tr 12x3 1 200 1,5 / 300 0,65

KAF 14 R R KAF 14 R L Tr 14x3 1 200 1,5 / 300 0,93

KAF 14 A R KAF 14 A L Tr 14x4 1 200 1,5 / 300 0,86

KAF 16 A R KAF 16 A L Tr 16x4 1 200 1,5 / 300 1,17

KAF 18 A R KAF 18 A L Tr 18x4 1 200 1,5 / 300 1,53

KAF 20 A R KAF 20 A L Tr 20x4 1 200 1,5 / 300 1,94

KAF 22 A R KAF 22 A L Tr 22x5 1 200 1,5 / 300 2,29

KAF 24 A R KAF 24 A L Tr 24x5 1 200 1,5 / 300 2,78

KAF 25 A R KAF 25 A L Tr 25x5 1 200 1,5 / 300 3,05

KAF 26 A R KAF 26 A L Tr 26x5 1 200 1,5 / 300 3,33

KAF 28 A R KAF 28 A L Tr 28x5 1 200 1,5 / 300 3,92

KAF 30 P R KAF 30 P L Tr 30x5 1 200 1,5 / 300 4,57

KAF 30 A R KAF 30 A L Tr 30x6 1 200 1,5 / 300 4,38

KAF 32 A R KAF 32 A L Tr 32x6 1 200 1,5 / 300 5,06

KAF 35 P R KAF 35 P L Tr 35x5 1 200 1,5 / 300 6,40

KAF 35 A R KAF 35 A L Tr 35x6 1 200 1,5 / 300 6,16

KAF 36 A R KAF 36 A L Tr 36x6 1 200 1,5 / 300 6,56

KAF 40 P R KAF 40 P L Tr 40x5 1 200 1,5 / 300 8,51

KAF 40 O R KAF 40 O L Tr 40x6 1 200 1,5 / 300 8,26

KAF 40 A R KAF 40 A L Tr 40x7 1 200 1,5 / 300 8,03

KAF 44 A R KAF 44 A L Tr 44x7 1 200 1,5 / 300 9,90

KAF 50 P R KAF 50 P L Tr 50x5 1 200 1,5 / 300 13,70

KAF 50 O R KAF 50 O L Tr 50x6 1 200 1,5 / 300 13,35

KAF 50 A R KAF 50 A L Tr 50x8 1 200 1,5 / 300 12,90

KAF 55 A R KAF 55 A L Tr 55x9 1 200 1,5 / 300 15,51

KAF 60 O R KAF 60 O L Tr 60x6 1 200 1,5 / 300 19,67

KAF 60 N R KAF 60 N L Tr 60x7 1 200 1,5 / 300 19,36

KAF 60 A R KAF 60 A L Tr 60x9 1 200 1,5 / 300 18,74

KAF 70 A R KAF 70 A L Tr 70x10 1 200 1,5 / 300 25,80

KAF 80 A R KAF 80 A L Tr 80x10 1 200 1,5 / 300 34,39

KAF 90 A R KAF 90 A L Tr 90x12 1 200 1,5 / 300 43,07

KAF A0 A R KAF A0 AL Tr 100x12 1 200 1,5 / 300 53,99

= Goods in stock. = Goods available upon request only.

28 We riserve the right to change sizes and features without notice.

Trapezoidal screws type KTS Steel C45 1.0503

Stock no. for screw

RIGHT

Stock no. for screw

LEFT

Diameter

x lead

Thread

starts

Lead

accuracy

m /300 mm

Straightness

mm / mm

Weight

kg/mt

KTS 10 J R KTS 10 J L Tr 10x4 (P2) 2 100 0,5 / 1000 0,48

KTS 12 B R KTS 12 B L Tr 12x6 (P3) 2 100 0,5 / 1000 0,65

KTS 14 B R KTS 14 B L Tr 14x6 (P3) 2 100 0,5 / 1000 0,93

KTS 16 B R KTS 16 B L Tr 16x8 (P4) 2 100 0,5 / 1000 1,17

KTS 18 B R KTS 18 B L Tr 18x8 (P4) 2 100 0,5 / 1000 1,53

KTS 20 B R KTS 20 B L Tr 20x8 (P4) 2 100 0,4 / 2000 1,94

KTS 20 D R KTS 20 D L Tr 20x20 (P5) 4 100 0,4 / 2000 1,84

KTS 22 B R KTS 22 B L Tr 22x10 (P5) 2 100 0,4 / 2000 2,29

KTS 24 B R KTS 24 B L Tr 24x10 (P5) 2 100 0,4 / 2000 2,78

KTS 25 B R KTS 25 B L Tr 25x10 (P5) 2 100 0,3 / 2000 3,05

KTS 25 E R KTS 25 E L Tr 25x25 (P5) 5 100 0,3 / 2000 3,05

KTS 26 B R KTS 26 B L Tr 26x10 (P5) 2 100 0,3 / 2000 3,33

KTS 28 B R KTS 28 B L Tr 28x10 (P5) 2 100 0,3 / 2000 3,92

KTS 30 B R KTS 30 B L Tr 30x12 (P6) 2 100 0,3 / 3000 4,38

KTS 30 F R KTS 30 F L Tr 30x30 (P5) 6 100 0,3 / 3000 4,57

KTS 32 B R KTS 32 B L Tr 32x12 (P6) 2 100 0,3 / 3000 5,06

KTS 36 B R KTS 36 B L Tr 36x12 (P6) 2 100 0,3 / 3000 6,56

KTS 40 B R KTS 40 B L Tr 40x14 (P7) 2 100 0,3 / 3000 8,03

KTS 40 E R KTS 40 E L Tr 40x40 (P8) 5 100 0,3 / 3000 7,90

= Goods in stock. = Goods available upon request only.

Trapezoidal screws type KUE Steel C45 1.0503

Stock no. for screw

RIGHT

Stock no. for screw

LEFT

Diameter

x lead

Thread

starts

Lead

accuracy

m /300 mm

Straightness

mm / mm

Weight

kg/mt

KUE 10 J R KUE 10 J L Tr 10x4 (P2) 2 100 0,5 / 300 0,48

KUE 12 B R KUE 12 B L Tr 12x6 (P3) 2 100 0,5 / 300 0,65

KUE 14 B R KUE 14 B L Tr 14x6 (P3) 2 100 0,5 / 300 0,93

KUE 16 B R KUE 16 B L Tr 16x8 (P4) 2 100 0,5 / 300 1,17

KUE 18 B R KUE 18 B L Tr 18x8 (P4) 2 100 0,5 / 300 1,53

KUE 20 B R KUE 20 B L Tr 20x8 (P4) 2 100 0,4 / 300 1,94

KUE 20 D R KUE 20 D L Tr 20x20 (P5) 4 100 0,4 / 300 1,84

KUE 22 B R KUE 22 B L Tr 22x10 (P5) 2 100 0,3 / 300 2,29

KUE 24 B R KUE 24 B L Tr 24x10 (P5) 2 100 0,3 / 300 2,78

KUE 25 B R KUE 25 B L Tr 25x10 (P5) 2 100 0,3 / 300 3,05

KUE 25 E R KUE 25 E L Tr 25x25 (P5) 5 100 0,3 / 300 3,05

KUE 26 B R KUE 26 B L Tr 26x10 (P5) 2 100 0,3 / 300 3,33

KUE 28 B R KUE 28 B L Tr 28x10 (P5) 2 100 0,3 / 300 3,92

KUE 30 B R KUE 30 B L Tr 30x12 (P6) 2 100 0,3 / 300 4,38

KUE 30 F R KUE 30 F L Tr 30x30 (P5) 6 100 0,3 / 300 4,57

KUE 32 B R KUE 32 B L Tr 32x12 (P6) 2 100 0,3 / 300 5,06

KUE 36 B R KUE 36 B L Tr 36x12 (P6) 2 100 0,3 / 300 6,56

KUE 40 B R KUE 40 B L Tr 40x14 (P7) 2 100 0,3 / 300 8,03

KUE 40 E R KUE 40 E L Tr 40x40 (P8) 5 100 0,3 / 300 7,90

= Goods in stock. = Goods available upon request only.

We riserve the right to change sizes and features without notice. 29

Trapezoidal screws type KKA Steel C45 1.0503

Stock no. for screw

RIGHT

Stock no. for screw

LEFT

Diameter

x lead

Thread

starts

Lead

accuracy

m /300 mm

Straightness

mm / mm

Weight

kg/mt

KKA 10 J R KKA 10 J L Tr 10x4 (P2) 2 50 0,5 / 1000 0,48

KKA 12 B R KKA 12 B L Tr 12x6 (P3) 2 50 0,5 / 1000 0,65

KKA 14 B R KKA 14 B L Tr 14x6 (P3) 2 50 0,5 / 1000 0,93

KKA 16 B R KKA 16 B L Tr 16x8 (P4) 2 50 0,5 / 1000 1,17

KKA 18 B R KKA 18 B L Tr 18x8 (P4) 2 50 0,5 / 1000 1,53

KKA 20 B R KKA 20 B L Tr 20x8 (P4) 2 50 0,4 / 2000 1,94

KKA 20 D R KKA 20 D L Tr 20x20 (P5) 4 50 0,4 / 2000 1,84

KKA 22 B R KKA 22 B L Tr 22x10 (P5) 2 50 0,4 / 2000 2,29

KKA 24 B R KKA 24 B L Tr 24x10 (P5) 2 50 0,4 / 2000 2,78

KKA 25 B R KKA 25 B L Tr 25x10 (P5) 2 50 0,3 / 2000 3,05

KKA 25 E R KKA 25 E L Tr 25x25 (P5) 5 50 0,3 / 2000 3,05

KKA 26 B R KKA 26 B L Tr 26x10 (P5) 2 50 0,3 / 2000 3,33

KKA 28 B R KKA 28 B L Tr 28x10 (P5) 2 50 0,3 / 2000 3,92

KKA 30 B R KKA 30 B L Tr 30x12 (P6) 2 50 0,3 / 3000 4,38

KKA 30 F R KKA 30 F L Tr 30x30 (P5) 6 50 0,3 / 3000 4,57

KKA 32 B R KKA 32 B L Tr 32x12 (P6) 2 50 0,3 / 3000 5,06

KKA 36 B R KKA 36 B L Tr 36x12 (P6) 2 50 0,3 / 3000 6,56

KKA 40 B R KKA 40 B L Tr 40x14 (P7) 2 50 0,3 / 3000 8,03

KKA 40 E R KKA 40 E L Tr 40x40 (P8) 5 50 0,3 / 3000 7,90

= Goods in stock. = Goods available upon request only.

30 We riserve the right to change sizes and features without notice.

Trapezoidal screws type KQX Steel C15 1.1141

Stock no. for screw

RIGHT

Stock no. for screw

LEFT

Diameter

x lead

Thread

starts

Lead

accuracy

m /300 mm

Straightness

mm / mm

Weight

kg/mt

KQX 10 J R KQX 10 J L Tr 10x4 (P2) 2 200 0,7 / 1000 0,48

KQX 12 B R KQX 12 B L Tr 12x6 (P3) 2 200 0,7 / 1000 0,65

KQX 14 B R KQX 14 B L Tr 14x6 (P3) 2 200 0,7 / 1000 0,93

KQX 16 B R KQX 16 B L Tr 16x8 (P4) 2 200 0,7 / 1500 1,17

KQX 18 B R KQX 18 B L Tr 18x8 (P4) 2 200 0,7 / 1500 1,53

KQX 20 B R KQX 20 B L Tr 20x8 (P4) 2 200 0,6 / 2000 1,94

KQX 20 D R KQX 20 D L Tr 20x20 (P5) 4 200 0,6 / 2000 1,84

KQX 22 B R KQX 22 B L Tr 22x10 (P5) 2 200 0,6 / 2000 2,29

KQX 24 B R KQX 24 B L Tr 24x10 (P5) 2 200 0,4 / 2000 2,78

KQX 25 B R KQX 25 B L Tr 25x10 (P5) 2 200 0,4 / 2000 3,05

KQX 25 E R KQX 25 E L Tr 25x25 (P5) 5 200 0,4 / 2000 3,05

KQX 26 B R KQX 26 B L Tr 26x10 (P5) 2 200 0,4 / 2000 3,33

KQX 28 B R KQX 28 B L Tr 28x10 (P5) 2 200 0,4 / 2000 3,92

KQX 30 B R KQX 30 B L Tr 30x12 (P6) 2 200 0,4 / 3000 4,38

KQX 30 F R KQX 30 F L Tr 30x30 (P5) 6 200 0,4 / 3000 4,57

KQX 32 B R KQX 32 B L Tr 32x12 (P6) 2 200 0,4 / 3000 5,06

KQX 36 B R KQX 36 B L Tr 36x12 (P6) 2 200 0,3 / 3000 6,56

KQX 40 B R KQX 40 B L Tr 40x14 (P7) 2 200 0,3 / 3000 8,03

KQX 40 E R KQX 40 E L Tr 40x40 (P8) 5 200 0,3 / 3000 7,90

= Goods in stock. = Goods available upon request only.

Trapezoidal screws type KEQ Steel C15 1.1141

Stock no. for screw

RIGHT

Stock no. for screw

LEFT

Diameter

x lead

Thread

starts

Lead

accuracy

m /300 mm

Straightness

mm / mm

Weight

kg/mt

KEQ 10 J R KEQ 10 J L Tr 10x4 (P2) 2 200 -- 0,48

KEQ 12 B R KEQ 12 B L Tr 12x6 (P3) 2 200 -- 0,65

KEQ 14 B R KEQ 14 B L Tr 14x6 (P3) 2 200 -- 0,93

KEQ 16 B R KEQ 16 B L Tr 16x8 (P4) 2 200 -- 1,17

KEQ 18 B R KEQ 18 B L Tr 18x8 (P4) 2 200 -- 1,53

KEQ 20 B R KEQ 20 B L Tr 20x8 (P4) 2 200 -- 1,94

KEQ 20 D R KEQ 20 D L Tr 20x20 (P5) 4 200 -- 1,84

KEQ 22 B R KEQ 22 B L Tr 22x10 (P5) 2 200 -- 2,29

KEQ 24 B R KEQ 24 B L Tr 24x10 (P5) 2 200 -- 2,78

KEQ 25 B R KEQ 25 B L Tr 25x10 (P5) 2 200 -- 3,05

KEQ 25 E R KEQ 25 E L Tr 25x25 (P5) 5 200 -- 3,05

KEQ 26 B R KEQ 26 B L Tr 26x10 (P5) 2 200 -- 3,33

KEQ 28 B R KEQ 28 B L Tr 28x10 (P5) 2 200 -- 3,92

KEQ 30 B R KEQ 30 B L Tr 30x12 (P6) 2 200 -- 4,38

KEQ 30 F R KEQ 30 F L Tr 30x30 (P5) 6 200 -- 4,57

KEQ 32 B R KEQ 32 B L Tr 32x12 (P6) 2 200 -- 5,06

KEQ 36 B R KEQ 36 B L Tr 36x12 (P6) 2 200 -- 6,56

KEQ 40 B R KEQ 40 B L Tr 40x14 (P7) 2 200 -- 8,03

KEQ 40 E R KEQ 40 E L Tr 40x40 (P8) 5 200 -- 7,90

= Goods in stock. = Goods available upon request only.

We riserve the right to change sizes and features without notice. 31

Trapezoidal screws type KRP

A2 stainless steel - AISI 304 1.4301

Stock no. for screw

RIGHT

Stock no. for screw

LEFT

Diameter

x lead

Thread

starts

Lead

accuracy

m /300 mm

Straightness

mm / mm

Weight

kg/mt

KRP 10 J R KRP 10 J L Tr 10x4 (P2) 2 200 0,7 / 1000 0,48

KRP 12 B R KRP 12 B L Tr 12x6 (P3) 2 200 0,7 / 1000 0,65

KRP 14 B R KRP 14 B L Tr 14x6 (P3) 2 200 0,7 / 1000 0,93

KRP 16 B R KRP 16 B L Tr 16x8 (P4) 2 200 0,7 / 1500 1,17

KRP 18 B R KRP 18 B L Tr 18x8 (P4) 2 200 0,7 / 1500 1,53

KRP 20 B R KRP 20 B L Tr 20x8 (P4) 2 200 0,6 / 2000 1,94

KRP 20 D R KRP 20 D L Tr 20x20 (P5) 4 200 0,4 / 2000 1,84

KRP 22 B R KRP 22 B L Tr 22x10 (P5) 2 200 0,4 / 2000 2,29

KRP 24 B R KRP 24 B L Tr 24x10 (P5) 2 200 0,4 / 2000 2,78

KRP 25 B R KRP 25 B L Tr 25x10 (P5) 2 200 0,4 / 2000 3,05

KRP 26 B R KRP 26 B L Tr 26x10 (P5) 2 200 0,4 / 2000 3,33

KRP 28 B R KRP 28 B L Tr 28x10 (P5) 2 200 0,4 / 2000 3,92

KRP 30 B R KRP 30 B L Tr 30x12 (P6) 2 200 0,4 / 3000 4,38

KRP 32 B R KRP 32 B L Tr 32x12 (P6) 2 200 0,4 / 3000 5,06

KRP 36 B R KRP 36 B L Tr 36x12 (P6) 2 200 0,3 / 3000 6,56

KRP 40 B R KRP 40 B L Tr 40x14 (P7) 2 200 0,3 / 3000 8,03

= Goods in stock. = Goods available upon request only.

Trapezoidal screws type KRE

A2 stainless steel - AISI 304 1.4301

Stock no. for screw

RIGHT

Stock no. for screw

LEFT

Diameter

x lead

Thread

starts

Lead

accuracy

m /300 mm

Straightness

mm / mm

Weight

kg/mt

KRE 10 J R KRE 10 J L Tr 10x4 (P2) 2 200 1,5 / 300 0,48

KRE 12 B R KRE 12 B L Tr 12x6 (P3) 2 200 1,5 / 300 0,65

KRE 14 B R KRE 14 B L Tr 14x6 (P3) 2 200 1,5 / 300 0,93

KRE 16 B R KRE 16 B L Tr 16x8 (P4) 2 200 1,5 / 300 1,17

KRE 18 B R KRE 18 B L Tr 18x8 (P4) 2 200 1,5 / 300 1,53

KRE 20 B R KRE 20 B L Tr 20x8 (P4) 2 200 1,5 / 300 1,94

KRE 20 D R KRE 20 D L Tr 20x20 (P5) 4 200 1,5 / 300 1,84

KRE 22 B R KRE 22 B L Tr 22x10 (P5) 2 200 1,5 / 300 2,29

KRE 24 B R KRE 24 B L Tr 24x10 (P5) 2 200 1,5 / 300 2,78

KRE 25 B R KRE 25 B L Tr 25x10 (P5) 2 200 1,5 / 300 3,05

KRE 26 B R KRE 26 B L Tr 26x10 (P5) 2 200 1,5 / 300 3,33

KRE 28 B R KRE 28 B L Tr 28x10 (P5) 2 200 1,5 / 300 3,92

KRE 30 B R KRE 30 B L Tr 30x12 (P6) 2 200 1,5 / 300 4,38

KRE 32 B R KRE 32 B L Tr 32x12 (P6) 2 200 1,5 / 300 5,06

KRE 36 B R KRE 36 B L Tr 36x12 (P6) 2 200 1,5 / 300 6,56

KRE 40 B R KRE 40 B L Tr 40x14 (P7) 2 200 1,5 / 300 8,03

= Goods in stock. = Goods available upon request only.

32 We riserve the right to change sizes and features without notice.

Trapezoidal screws type KAM

A4 stainless steel - AISI 316 1.4401

Stock no. for screw

RIGHT

Stock no. for screw

LEFT

Diameter

x lead

Thread

starts

Lead

accuracy

m /300 mm

Straightness

mm / mm

Weight

kg/mt

KAM 10 J R KAM 10 J L Tr 10x4 (P2) 2 200 0,7 / 1000 0,48

KAM 12 B R KAM 12 B L Tr 12x6 (P3) 2 200 0,7 / 1000 0,65

KAM 14 B R KAM 14 B L Tr 14x6 (P3) 2 200 0,7 / 1000 0,93

KAM 16 B R KAM 16 B L Tr 16x8 (P4) 2 200 0,7 / 1500 1,17

KAM 18 B R KAM 18 B L Tr 18x8 (P4) 2 200 0,7 / 1500 1,53

KAM 20 B R KAM 20 B L Tr 20x8 (P4) 2 200 0,6 / 2000 1,94

KAM 20 D R KAM 20 D L Tr 20x20 (P5) 4 200 0,6 / 2000 1,84

KAM 22 B R KAM 22 B L Tr 22x10 (P5) 2 200 0,6 / 2000 2,29

KAM 24 B R KAM 24 B L Tr 24x10 (P5) 2 200 0,4 / 2000 2,78

KAM 25 B R KAM 25 B L Tr 25x10 (P5) 2 200 0,4 / 2000 3,05

KAM 26 B R KAM 26 B L Tr 26x10 (P5) 2 200 0,4 / 2000 3,33

KAM 28 B R KAM 28 B L Tr 28x10 (P5) 2 200 0,4 / 2000 3,92

KAM 30 B R KAM 30 B L Tr 30x12 (P6) 2 200 0,4 / 3000 4,38

KAM 32 B R KAM 32 B L Tr 32x12 (P6) 2 200 0,4 / 3000 5,06

KAM 36 B R KAM 36 B L Tr 36x12 (P6) 2 200 0,3 / 3000 6,56

KAM 40 B R KAM 40 B L Tr 40x14 (P7) 2 200 0,3 / 3000 8,03

= Goods in stock. = Goods available upon request only.

Trapezoidal screws type KAF

A4 stainless steel - AISI 316 1.4401

Stock no. for screw

RIGHT

Stock no. for screw

LEFT

Diameter

x lead

Thread

starts

Lead

accuracy

m /300 mm

Straightness

mm / mm

Weight

kg/mt

KAF 10 J R KAF 10 J L Tr 10x4 (P2) 2 200 1,5 / 300 0,48

KAF 12 B R KAF 12 B L Tr 12x6 (P3) 2 200 1,5 / 300 0,65

KAF 14 B R KAF 14 B L Tr 14x6 (P3) 2 200 1,5 / 300 0,93

KAF 16 B R KAF 16 B L Tr 16x8 (P4) 2 200 1,5 / 300 1,17

KAF 18 B R KAF 18 B L Tr 18x8 (P4) 2 200 1,5 / 300 1,53

KAF 20 B R KAF 20 B L Tr 20x8 (P4) 2 200 1,5 / 300 1,94

KAF 20 D R KAF 20 D L Tr 20x20 (P5) 4 200 1,5 / 300 1,84

KAF 22 B R KAF 22 B L Tr 22x10 (P5) 2 200 1,5 / 300 2,29

KAF 24 B R KAF 24 B L Tr 24x10 (P5) 2 200 1,5 / 300 2,78

KAF 25 B R KAF 25 B L Tr 25x10 (P5) 2 200 1,5 / 300 3,05

KAF 26 B R KAF 26 B L Tr 26x10 (P5) 2 200 1,5 / 300 3,33

KAF 28 B R KAF 28 B L Tr 28x10 (P5) 2 200 1,5 / 300 3,92

KAF 30 B R KAF 30 B L Tr 30x12 (P6) 2 200 1,5 / 300 4,38

KAF 32 B R KAF 32 B L Tr 32x12 (P6) 2 200 1,5 / 300 5,06

KAF 36 B R KAF 36 B L Tr 36x12 (P6) 2 200 1,5 / 300 6,56

KAF 40 B R KAF 40 B L Tr 40x14 (P7) 2 200 1,5 / 300 8,03

= Goods in stock. = Goods available upon request only.

We riserve the right to change sizes and features without notice. 33

Trapezoidal nut type MLF - Cylindrical steel

Material: EN 10277-3 11 S Mn Pb 37 1.0737

Nut for fastening or manual movement with small load; steel-to-steel coupling tends to seize. Can be MIG welded only.

Electrode welding is not recommended because of the lead.

Trapezoidal nut type MZP - Cylindrical steel

Material: EN 10277-3 11 S Mn Pb 37 1.0737

Nut for fastening or manual movement with

small load; steel-to-steel coupling tends to

seize. Can be MIG welded only. Electrode

welding is not recommended because of the

lead.

(1) Total bearing surface between screw and nut teeth on plane perpendicular to axis.

Nut

Stock no.

RIGHT

Nut

Stock no.

LEFT

Diameter

x

lead

Thread

starts

d

mm

L

mm

Wt.

kg/each

At

mm

2

(1)

MLF 12 A R MLF 12 A L Tr 12x3 1 36 36 0.255 592

MLF 12 B R -- Tr 12x6 (P3) 2 36 36 0.255 592

MLF 14 A R MLF 14 A L Tr 14x4 1 36 36 0.250 677

MLF 16 A R MLF 16 A L Tr 16x4 1 36 36 0.238 792

MLF 16 B R -- Tr 16x8 (P4) 2 36 36 0.238 792

MLF 18 A R MLF 18 A L Tr 18x4 1 36 36 0.224 905

MLF 20 A R MLF 20 A L Tr 20x4 1 40 40 0.306 1130

MLF 20 B R -- Tr 20x8 (P4) 2 40 40 0.306 1130

MLF 22 A R MLF 22 A L Tr 22x5 1 40 40 0.290 1225

MLF 25 A R MLF 25 A L Tr 25x5 1 45 45 0.40 1590

MLF 25 B R -- Tr 25x10 (P5) 2 45 45 0.40 1590

MLF 28 A R MLF 28 A L Tr 28x5 1 45 45 0.36 1800

MLF 28 B R -- Tr 28x10 (P5) 2 45 45 0.36 1800

MLF 30 A R MLF 30 A L Tr 30x6 1 50 50 0.52 2120

MLF 30 B R -- Tr 30x12 (P6) 2 50 50 0.52 2120

MLF 35 A R MLF 35 A L Tr 35x6 1 55 55 0.65 2764

MLF 40 A R MLF 40 A L Tr 40x7 1 60 60 0.79 3440

MLF 40 B R -- Tr 40x14 (P7) 2 60 60 0.79 3440

MLF 45 A R MLF 45 A L Tr 45x8 1 65 65 0.95 4186

MLF 50 A R MLF 50 A L Tr 50x8 1 70 70 1.12 5057

MLF 55 A R -- Tr 55x9 1 80 80 1.78 6345

MLF 60 A R MLF 60 A L Tr 60x9 1 80 80 1.51 6975

Nut

Stock no.

RIGHT

Nut

Stock no.

LEFT

Diameter

x

lead

Thread

starts

d

mm

L

mm

Wt.

kg/each

At

mm

2

(1)

MZP 10 T R MZP 10 T L Tr 10x2 1 22 15 0.038 150

MZP 10 A R MZP 10 A L Tr 10x3 1 22 15 0.037 240

MZP 12 A R MZP 12 A L Tr 12x3 1 26 18 0.061 296

MZP 12 B R -- Tr 12x6 (P3) 2 26 18 0.061 296

MZP 14 R R MZP 14 R L Tr 14x3 1 30 21 0.095 395

MZP 14 A R MZP 14 A L Tr 14x4 1 30 21 0.095 395

MZP 16 A R MZP 16 A L Tr 16x4 1 36 24 0.158 528

MZP 18 A R MZP 18 A L Tr 18x4 1 40 27 0.218 553

MZP 20 A R MZP 20 A L Tr 20x4 1 45 30 0.308 847

MZP 22 A R MZP 22 A L Tr 22x5 1 45 33 0.324 1010

MZP 24 A R MZP 24 A L Tr 24x5 1 50 36 0.440 1215

MZP 26 A R MZP 26 A L Tr 26x5 1 50 39 0.454 1440

MZP 28 A R MZP 28 A L Tr 28x5 1 60 42 0.747 1680

MZP 30 A R MZP 30 A L Tr 30x6 1 60 45 0.773 1908

MZP 32 A R MZP 32 A L Tr 32x6 1 60 48 0.790 2186

MZP 36 A R MZP 36 A L Tr 36x6 1 75 54 1.476 2800

MZP 40 A R MZP 40 A L Tr 40x7 1 80 60 1.826 3440

MZP 44 A R MZP 44 A L Tr 44x7 1 80 66 1.878 4200

MZP 50 A R MZP 50 A L Tr 50x8 1 90 75 2.680 5418

MZP 60 A R MZP 60 A L Tr 60x9 1 100 90 3.698 7847

MZP 70 A R MZP 70 A L Tr 70x10 1 110 105 4.884 10200

MZP 80 A R MZP 80 A L Tr 80x10 1 120 120 6.210 14137

34 We riserve the right to change sizes and features without notice.

Trapezoidal nut type HSN - Cylindrical bronze

Material: EN 1982 Cu Sn5 Zn5 Pb5-C CC491K

Cylindrical bronze nut for movement with modest loads compared with FXN. HDL and HAL.

Good lubrication is recommended.

Trapezoidal nut type HBD - Cylindrical bronze

Material: EN 1982 Cu Sn7 Zn4 Pb7-C CC493K

Cylindrical bronze nut for movement with

modest loads compared with FXN, HDL and

HAL. Good lubrication is recommended.

(1) Total bearing surface between screw and nut teeth on plane perpendicular to axis.

Nut

Stock no.

RIGHT

Nut

Stock no.

LEFT

Diameter

x

lead

Thread

starts

d

mm

L

mm

Wt.

kg/each

At

mm

2

(1)

HSN 12 A R HSN 12 A L Tr 12x3 1 36 36 0.302 594

HSN 14 A R HSN 14 A L Tr 14x4 1 36 36 0.290 677

HSN 16 A R HSN 16 A L Tr 16x4 1 36 36 0.276 792

HSN 16 B R -- Tr 16x8 (P4) 2 36 36 0.276 792

HSN 18 A R HSN 18 A L Tr 18x4 1 36 36 0.259 905

HSN 20 A R HSN 20 A L Tr 20x4 1 40 40 0.354 1130

HSN 20 B R -- Tr 20x8 (P4) 2 40 40 0.354 1130

HSN 22 A R HSN 22 A L Tr 22x5 1 40 40 0.33 1225

HSN 25 A R HSN 25 A L Tr 25x5 1 45 45 0.47 1590

HSN 25 B R -- Tr 25x10 (P5) 2 45 45 0.47 1590

HSN 28 A R HSN 28 A L Tr 28x5 1 45 45 0.42 1800

HSN 28 B R -- Tr 28x10 (P5) 2 45 45 0.42 1800

HSN 30 A R HSN 30 A L Tr 30x6 1 50 50 0.60 2120

HSN 30 B R -- Tr 30x12 (P6) 2 50 50 0.60 2120

HSN 35 A R HSN 35 A L Tr 35x6 1 55 55 0.75 2764

HSN 40 A R HSN 40 A L Tr 40x7 1 60 60 0.92 3440

HSN 40 B R -- Tr 40x14 (P7) 2 60 60 0.92 3440

HSN 45 A R HSN 45 A L Tr 45x8 1 65 65 1.10 4186

HSN 50 A R HSN 50 A L Tr 50x8 1 70 70 1.30 5057

HSN 55 A R -- Tr 55x9 1 80 80 2.07 6345

HSN 60 A R HSN 60 A L Tr 60x9 1 80 80 1.75 6975

Nut

Stock no.

RIGHT

Nut

Stock no.

LEFT

Diameter

x

lead

Thread

starts

d

mm

L

mm

Wt.

kg/each

At

mm

2

(1)

HBD 10 T R HBD 10 T L Tr 10x2 1 22 20 0.058 200

HBD 10 A R HBD 10 A L Tr 10x3 1 22 20 0.057 320

HBD 12 A R HBD 12 A L Tr 12x3 1 26 24 0.094 396

HBD 12 B R -- Tr 12x6 (P3) 2 26 24 0.094 396

HBD 14 R R HBD 14 R L Tr 14x3 1 30 28 0.146 526

HBD 14 A R HBD 14 A L Tr 14x4 1 30 28 0.146 526

HBD 16 A R HBD 16 A L Tr 16x4 1 36 32 0.245 704

HBD 18 A R HBD 18 A L Tr 18x4 1 40 36 0.337 905

HBD 20 A R HBD 20 A L Tr 20x4 1 45 40 0.476 1130

HBD 22 A R HBD 22 A L Tr 22x5 1 45 40 0.456 1225

HBD 24 A R HBD 24 A L Tr 24x5 1 50 48 0.680 1620

HBD 26 A R HBD 26 A L Tr 26x5 1 50 48 0.648 1770

HBD 28 A R HBD 28 A L Tr 28x5 1 60 60 1.237 2400

HBD 30 A R HBD 30 A L Tr 30x6 1 60 60 1.195 2544

HBD 32 A R HBD 32 A L Tr 32x6 1 60 60 1.145 2733

HBD 36 A R HBD 36 A L Tr 36x6 1 75 72 2.232 3732

HBD 40 A R HBD 40 A L Tr 40x7 1 80 80 2.823 4587

HBD 44 A R HBD 44 A L Tr 44x7 1 80 80 2.639 5090

HBD 50 A R HBD 50 A L Tr 50x8 1 90 100 4.142 7224

HBD 60 A R HBD 60 A L Tr 60x9 1 100 120 5.716 10462

HBD 70 A R HBD 70 A L Tr 70x10 1 110 140 7.548 10200

HBD 80 A R HBD 80 A L Tr 80x10 1 120 160 9.60 18850

We riserve the right to change sizes and features without notice. 35

Trapezoidal nut type HDA - Cylindrical stainless steel

Material: INOX A1 - AISI 303 1.4305

Nut of AISI 303 stainless steel especially suitable to withstand corrosive chemical agents

Trapezoidal nut type HBM - Cylindrical bronze

Material: EN 1982 Cu Sn12-C CC483K

Cylindrical bronze nut for movement with modest loads compared with HDL and HAL.

Good lubrication is recommended.

(1) Total bearing surface between screw and nut teeth on plane perpendicular to axis.

Nut

Stock no.

RIGHT

Nut

Stock no.

LEFT

Diameter

x

lead

Thread

starts

d

mm

L

mm

Wt.

kg/each

At

mm

2

(1)

HDA 12 A R HDA 12 A L Tr 12x3 1 26 18 0.060 297

HDA 14 A R HDA 14 A L Tr 14x4 1 30 21 0.095 395

HDA 16 A R HDA 16 A L Tr 16x4 1 36 24 0.157 528

HDA 20 A R HDA 20 A L Tr 20x4 1 45 30 0.305 847

HDA 24 A R HDA 24 A L Tr 24x5 1 50 36 0.436 1215

HDA 30 A R HDA 30 A L Tr 30x6 1 60 45 0.766 1908

HDA 36 A R HDA 36 A L Tr 36x6 1 75 54 1.462 2799

HDA 40 A R HDA 40 A L Tr 40x7 1 80 60 1.808 3440

HDA 50 A R HDA 50 A L Tr 50x8 1 90 75 2.653 5418

Nut

Stock no.

RIGHT

Nut

Stock no.

LEFT

Diameter

x

lead

Thread

starts

d

mm

L

mm

Wt.

kg/each

At

mm

2

(1)

HBM 10 A R HBM 10 A L Tr 10x3 1 20 20 0.044 320

HBM 12 A R HBM 12 A L Tr 12x3 1 24 25 0.078 412

HBM 14 A R HBM 14 A L Tr 14x4 1 24 25 0.071 470

HBM 16 A R HBM 16 A L Tr 16x4 1 28 30 0.118 660

HBM 18 A R HBM 18 A L Tr 18x4 1 34 35 0.214 880

HBM 20 A R HBM 20 A L Tr 20x4 1 38 40 0.304 1130

HBM 25 A R HBM 25 A L Tr 25x5 1 44 45 0.438 1590

HBM 30 A R HBM 30 A L Tr 30x6 1 48 50 0.532 2120

HBM 35 A R HBM 35 A L Tr 35x6 1 58 60 0.959 3015

HBM 36 A R HBM 36 A L Tr 36x6 1 58 60 0.923 3110

HBM 40 A R HBM 40 A L Tr 40x7 1 64 65 1.222 3727

HBM 45 A R HBM 45 A L Tr 45x8 1 68 80 1.579 5152

HBM 50 A R HBM 50 A L Tr 50x8 1 74 80 1.808 5780

HBM 55 A R -- Tr 55x9 1 78 95 2.242 7535

HBM 60 A R HBM 60 A L Tr 60x9 1 84 95 2.536 8282

HBM 70 A R HBM 70 A L Tr 70x10 1 98 120 4.354 8742

HBM 80 A R HBM 80 A L Tr 80x10 1 108 120 4.892 14137

36 We riserve the right to change sizes and features without notice.

Trapezoidal nut type BIG - Cylindrical bronze

Material: EN 1982 Cu Sn12-C CC483K

Large cylindrical nut with nonstandard pitches especially suitable for replacement.

Nut

Stock no.

RIGHT

Nut

Stock no.

LEFT

Diameter

x

lead

Thread

starts

d

mm

L

mm

Wt.

kg/each

At

mm

2

(1)

BIG 20 A R BIG 20 A L Tr 20x4 1 78 60 2.43 1696

BIG 25 A R BIG 25 A L Tr 25x5 1 78 75 2.96 2650

BIG 30 R R BIG 30 R L Tr 30x3 1 78 90 3.30 3600

BIG 30 Q R BIG 30 Q L Tr 30x4 1 78 90 3.31 3560

BIG 30 P R BIG 30 P L Tr 30x5 1 78 90 3.32 3500

BIG 30 A R BIG 30 A L Tr 30x6 1 78 90 3.33 3435

BIG 35 R R BIG 35 R L Tr 35x3 1 88 105 4.85 5000

BIG 35 Q R BIG 35 Q L Tr 35x4 1 88 105 4.86 4900

BIG 35 P R BIG 35 P L Tr 35x5 1 88 105 4.87 4820

BIG 35 A R BIG 35 A L Tr 35x6 1 88 105 4.89 4750

BIG 40 R R BIG 40 R L Tr 40x3 1 98 120 6.80 6530

BIG 40 Q R BIG 40 Q L Tr 40x4 1 98 120 6.82 6447

BIG 40 P R BIG 40 P L Tr 40x5 1 98 120 6.83 6360

BIG 40 O R BIG 40 O L Tr 40x6 1 98 120 6.85 6277

BIG 40 A R BIG 40 A L Tr 40x7 1 98 120 6.87 6200

BIG 40 I R -- Tr 40x10 1 98 120 6.91 6597

BIG 50 R R BIG 50 R L Tr 50x3 1 108 150 9.74 10300

BIG 50 Q R BIG 50 Q L Tr 50x4 1 108 150 9.77 10180

BIG 50 P R BIG 50 P L Tr 50x5 1 108 150 9.79 10070

BIG 50 O R BIG 50 O L Tr 50x6 1 108 150 9.82 9965

BIG 50 A R BIG 50 A L Tr 50x8 1 108 150 9.87 9750

BIG 50 I R -- Tr 50x10 1 108 150 9.92 10600

BIG 60 O R -- Tr 60x6 1 118 180 13.29 14500

BIG 60 N R -- Tr 60x7 1 118 180 13.32 14380

BIG 60 A R -- Tr 60x9 1 118 180 13.36 14130

(1) Total bearing surface between screw and nut teeth on plane perpendicular to axis.

We riserve the right to change sizes and features without notice. 37

Trapezoidal nut type CQA - Square steel

Material: EN 10277-3 11 S Mn Pb 37 1.0737

Used as fastening nut or for manual movement where load is negligible because steel-to-steel coupling used for

movement under load tends to seize. The material used can be MIG welded only. Electrode welding is not recommended

because of the lead.

Trapezoidal nut type QOB - Square brass

Material: EN 12164 CW614N-M

Used as nut for movement of fairly small loads since the brass does not have great load bearing capability nor wear

resistance.

(1) Total bearing surface between screw and nut teeth on plane perpendicular to axis.

Nut

Stock no.

RIGHT

Nut

Stock no.

LEFT

Diameter

x

lead

Thread

starts

S

mm

L

mm

Wt.

kg/each

At

mm

2

(1)

CQA 10 T R CQA 10 T L Tr 10x2 1 17 15 0.027 150

CQA 12 A R CQA 12 A L Tr 12x3 1 25 30 0.123 739

CQA 14 A R CQA 14 A L Tr 14x4 1 30 35 0.211 658

CQA 16 A R CQA 16 A L Tr 16x4 1 30 35 0.199 770

CQA 18 A R CQA 18 A L Tr 18x4 1 35 45 0.353 1131

CQA 20 A R CQA 20 A L Tr 20x4 1 40 50 0.517 1412

CQA 25 A R CQA 25 A L Tr 25x5 1 45 55 0.683 1943

CQA 30 A R CQA 30 A L Tr 30x6 1 50 60 0.877 2544

CQA 35 A R CQA 35 A L Tr 35x6 1 60 70 1.494 3517

CQA 36 A R CQA 36 A L Tr 36x6 1 60 70 1.465 3630

CQA 40 A R CQA 40 A L Tr 40x7 1 60 70 1.347 4013

CQA 50 A R CQA 50 A L Tr 50x8 1 70 90 2.183 6502

CQA 60 A R CQA 60 A L Tr 60x9 1 80 100 2.990 8718

Nut

Stock no.

RIGHT

Nut

Stock no.

LEFT

Diameter

x

lead

Thread

starts

S

mm

L

mm

Wt.

kg/each

At

mm

2

(1)

QOB 10 A R QOB 10 A L Tr 10x3 1 25 20 0.094 320

QOB 12 A R QOB 12 A L Tr 12x3 1 25 25 0.110 411

QOB 14 R R QOB 14 R L Tr 14x3 1 25 20 0.076 658

QOB 14 A R QOB 14 A L Tr 14x4 1 30 35 0.224 658

QOB 16 A R QOB 16 A L Tr 16x4 1 30 35 0.212 770

QOB 18 A R QOB 18 A L Tr 18x4 1 35 45 0.379 1131

QOB 20 A R QOB 20 A L Tr 20x4 1 40 50 0.554 1412

QOB 25 A R QOB 25 A L Tr 25x5 1 45 55 0.735 1943

QOB 30 A R QOB 30 A L Tr 30x6 1 50 60 0.952 2544

QOB 35 A R QOB 35 A L Tr 35x6 1 60 70 1.617 3517

QOB 36 A R QOB 36 A L Tr 36x6 1 60 70 1.563 3630

QOB 40 A R QOB 40 A L Tr 40x7 1 60 70 1.465 4013

38 We riserve the right to change sizes and features without notice.

Trapezoidal nut type CQF Steel square nut with holes

Material: EN 10277-3 11 S Mn Pb 37 1.0737

This nut is used as a fixing nut or for manual movements where the load is not important, because the steel to steel

coupling used for moving under loads tends to seize.

Nut

Stock no.

RIGHT

Nut

Stock no.

LEFT

Diameter

x

lead

Thread

starts

S

mm

L

mm

a

mm

b

mm

c

mm

d

mm

e

mm

Fixing

allen

screws

UNI 5931

Wt.

kg/each

At

mm

2

(1)

CQF 12 A R CQF 12 A L Tr 12x3 1 25 30 20 17 4.2 4 7 M4 0.123 739

CQF 14 A R CQF 14 A L Tr 14x4 1 30 35 24 20 5.2 5 9,5 M5 0.211 658

CQF 16 A R CQF 16 A L Tr 16x4 1 35 40 24 21 5.2 5 9,5 M5 0.199 770

CQF 18 A R CQF 18 A L Tr 18x4 1 35 45 26 24 6.5 6 10 M6 0.353 1131

CQF 20 A R CQF 20 A L Tr 20x4 1 40 50 38 28 6.5 6 10 M6 0.517 1412

CQF 25 A R CQF 25 A L Tr 25x5 1 45 55 40 33 6.5 6 10 M6 0.683 1943

CQF 30 A R CQF 30 A L Tr 30x6 1 50 60 48 38 6.5 6 10 M6 0.877 2544

CQF 35 A R CQF 35 A L Tr 35x6 1 60 70 55 45 8.5 8 13 M8 1.494 3517

CQF 40 A R CQF 40 A L Tr 40x7 1 60 70 55 49 8.5 8 9.9 M8 (3) 1.347 4013

CQF 50 A R CQF 50 A L Tr 50x8 1 70 90 70 60 8.5 8 9.9 M8 (3) 2.183 6502

CQF 60 A R CQF 60 A L Tr 60x9 1 80 100 80 69 8.5 8 9.9 M8 (3) 2.990 8718

(1) Total bearing surface between screw and nut teeth on plane perpendicular to axis.

(3) Special M8 fixing screw with a reduced head screw diameter.

We riserve the right to change sizes and features without notice. 39

Trapezoidal nut type QBF Bronze square nut with holes

Material: EN 1982 Cu Sn12-C CC483K

Tin bronze nut suitable for movements with modest loads. It is recommended for its fixing comfort and for its good wear

resistance.

Nut

Stock no.

RIGHT

Nut

Stock no.

LEFT

Diameter

x

lead

Thread

starts

S

mm

L

mm

a

mm

b

mm

c

mm

d

mm

e

mm

Fixing

allen

screws

UNI 5931

Wt.

kg/each

At

mm

2

(1)

QBF 16 A R QBF 16 A L Tr 16x4 1 35 40 26 24 5.2 5 9,5 M5 0.340 770

QBF 20 A R QBF 20 A L Tr 20x4 1 40 50 38 28 6.5 6 10 M6 0.576 1412

QBF 25 A R QBF 25 A L Tr 25x5 1 45 55 40 33 6.5 6 10 M6 0.725 1943

QBF 30 A R QBF 30 A L Tr 30x6 1 50 60 49 38 6.5 6 10 M6 0.977 2544

QBF 40 A R QBF 40 A L Tr 40x7 1 60 75 55 49 8.5 8 9.9 M8 (3) 1.608 4013

(1) Total bearing surface between screw and nut teeth on plane perpendicular to axis.

(3) Special M8 fixing screw with a reduced head screw diameter.

40 We riserve the right to change sizes and features without notice.

Trapezoidal nut type FTN - Flanged bronze

Material: EN 1982 Cu Sn5 Zn5 Pb5-C CC491K