Professional Documents

Culture Documents

Noria Article Reprint 2009

Uploaded by

Paul RuckCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Noria Article Reprint 2009

Uploaded by

Paul RuckCopyright:

Available Formats

I

f you regularly read this column, you have likely seen my articles

on grease application and selection. In the past, I have focused

on manual grease application. For this issue, I decided to offer

opinions on the topic of automatic grease application specifically,

single-point automatic grease applicators.

There are two primary reasons to select automatic application:

improved quality of lubrication and/or reducing man-hour require-

ments for grease application. Like most other lubrication methods,

the successful use of single-point grease applicators requires some

knowledge of lubrication fundamentals; many common mistakes are

made. In order to get positive results from such devices, you must

select the right type of applicator for a given application, install the

device correctly and determine the optimum application rate.

Comparing Methods

There are certainly advantages to automatic application when

compared to manual application. Theoretically, it is preferable to

apply small amounts of grease at short intervals rather than large

amounts of grease at long intervals.

With manual application, the trick is to apply as much grease as

possible without causing harm due to over-greasing, thereby maxi-

mizing the relubrication interval. While this is fine for most

grease-lubricated components, there are many applications that may

benefit from more frequent application or could be harmed by large

application volumes. Of course, you could choose to simply lubricate

these components very frequently, but the associated labor cost would

likely make the option of automatic lubricators attractive.

To accurately determine which lubricated components would be

good candidates for automatic applicators, you must understand

the factors that cause a need for frequent relubrication, such as

excessive temperature, high speeds and contamination.

Temperature is a perfect example. In high-temperature applica-

tions, such as those commonly found in steel mills, some bearings

may need to be lubricated every day or even every few hours. While

this is an extreme example, its easy to see that it would require a

veritable army of technicians to perform manual relubrication on

hundreds of bearings every day, thus making automatic application

the preferred method. Some high-speed applications not only

require frequent application, but they also may be damaged by the

addition of large volumes of grease, causing overheating or skid-

ding of bearing elements. In many cases, the largest contributing

factor to grease reapplication requirements is contamination. Any

application can require very frequent application when contamina-

tion is severe, regardless of other factors. These are just some of the

primary factors to consider; there may be others such as inaccessi-

bility and limited manpower for lubrication activities.

Advantages of Single-Point

For systems with many lubrication points, such as the steel mill

example, centralized automatic systems are often ideal. But for

many others, including systems with just a few lube points or with

long distances separating the lube points, single-point lubricators

offer many of the same benefits at a small fraction of the cost.

Consider an incline conveyor with bearings that require frequent

lubrication due to contamination ingression. In such an applica-

tion, a centralized system would require extensive plumbing to

lubricate only a few points, making single-point applicators a great

f it. Grease-lubricated pump bearings, fan bearings and grease-

lubricated packing seals are all good examples where such devices

would likely provide significant value.

Typical Issues with Single-Point

There are several issues to keep in mind when using single-point

lubricators that may lead to improper grease application. These

issues include insufficient pressure to deliver the grease, improper

dispense rates and probably the biggest issue of all a failure to

properly inspect the device for proper operation.

FROM THE FIELD

When to Use Automatic

Grease Applicators

1 July - August 2009 www.machinerylubrication.com Machinery Lubrication

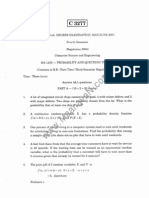

Too Much: Product Contamination and Breached Seals

Too Little: Friction and Wear

Optimal

Manual Lubrication

Automated Lubrication

Figure 1. A Simple Comparison Between Manual

and Automated Lubrication

BY JARROD POTTEIGER, NORIA CORPORATION

REPRINT FROM MACHINERY LUBRICATION

JULY - AUGUST 2009

FROM THE FIELD

2 July - August 2009 www.machinerylubrication.com Machinery Lubrication

The issue of insufficient pressure isnt a problem

with the applicator, but rather a problem with

selection. Depending on the delivery method, some

of these devices only generate approximately 50 to

75 psi. It is important to ensure that the system

pressure will be sufficient for a given application

and installation method. This can be determined by

first manually applying grease to the component

using a grease gun fitted with a pressure gauge. This

issue also should be considered when installing the

unit. Take steps to minimize the amount of back

pressure on the device by using as few fittings as

possible and keeping the length of any tubing or

piping to a minimum. Whatever the requirements

are, you should be able to select a device that

provides ample pressure.

While there are factors that can affect dispen-

sation rates, such as temperature and grease

consistency, the most common problem is simply

selecting the wrong setting. Before installing the

unit, determine the appropriate application rate

by using valid lubrication engineering methods.

Many problems can arise from over- or under-

lubricating a component, including overheating,

excessive wear or simply wasting grease and

making an unnecessary mess.

Of course, the biggest pitfall is a failure to

routinely inspect single-point lubricators for

proper function. Installing an automatic lubri-

cator doesnt ensure that you will have a properly

lubricated component. They must be inspected

just like anything else. In fact, a proper inspection

process should identify and allow for correction of

the previously mentioned issues. Determine the

frequency of inspection based on the units appli-

cation rate and the components sensitivity of

over- or under-lubrication. A good idea for such

inspections is to record the installation date on

the unit and make marks at each inspection

denoting the date and reservoir level. Based on the

desired application rate and reservoir size, you

should be able to determine if the unit is operating

normally. Inspect the lubricated component as

well to check for an indication that the grease

application rate is optimum. You may want to

include condition monitoring such as acoustic

energy measurements or high-frequency vibration

to monitor the condition of lubrication.

Education Before Selection

Most industrial facilities have at least some

applications that may benef it from automatic

grease application; and for many of those, single-

point lubricators may be the best option. Those

considering the addition of single-point lubrica-

tors to their lubrication program should educate

themselves on the different types of systems avail-

able, as well as the pros and cons of each.

About the Author

Jarrod Potteiger has vast experience in industrial and

marine lubricant sales, where he designed lubrication

and oil analysis programs and implemented contamina-

tion control strategies. He has performed machinery

failure analysis for numerous clients. As technical serv-

ices director for Noria, his primary responsibilities

include lubrication program design, benchmark surveys,

on-site training and Noria Field Services support.

Contact Jarrod at jpotteiger@noria.com.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Light Guage Silo Hopper Design PDFDocument27 pagesLight Guage Silo Hopper Design PDFPaul RuckNo ratings yet

- Hopper DesigningDocument34 pagesHopper DesigningZaeem Uddin Ali100% (2)

- NUGROUT HI SPEC cementitious groutDocument2 pagesNUGROUT HI SPEC cementitious groutPaul RuckNo ratings yet

- MM1080 Ie 3Document3 pagesMM1080 Ie 3Paul RuckNo ratings yet

- MDC Material Data SheetDocument8 pagesMDC Material Data SheetPaul RuckNo ratings yet

- Powerteam RD Double Acting CylindersDocument2 pagesPowerteam RD Double Acting CylindersPaul RuckNo ratings yet

- Best Practice - Damaged HosesDocument1 pageBest Practice - Damaged HosesPaul RuckNo ratings yet

- GBT 702-2008Document14 pagesGBT 702-2008Paul Ruck100% (1)

- DIN 22101 - 2011 - Belt ConveyorsDocument56 pagesDIN 22101 - 2011 - Belt ConveyorsDiego Figueroa Mercado96% (25)

- ArcelorMittal DOMSpecsDocument12 pagesArcelorMittal DOMSpecsAnurag DixitNo ratings yet

- Porlock MarshDocument3 pagesPorlock MarshPaul RuckNo ratings yet

- Recommended Guidelines For Safe Use of Tools at Height April 2011Document11 pagesRecommended Guidelines For Safe Use of Tools at Height April 2011Paul RuckNo ratings yet

- Masterflow668BChockGrout IngDocument6 pagesMasterflow668BChockGrout IngPaul RuckNo ratings yet

- Recommended Guidelines For Safe Use of Tools at Height April 2011Document11 pagesRecommended Guidelines For Safe Use of Tools at Height April 2011Paul RuckNo ratings yet

- Mma - Welding Procedure For Clip Bases.: ScopeDocument2 pagesMma - Welding Procedure For Clip Bases.: ScopePaul RuckNo ratings yet

- Hydraulic BumpersDocument17 pagesHydraulic BumpersRich DuganNo ratings yet

- Chapter 9 - Welding DefectsDocument18 pagesChapter 9 - Welding Defectsbibin2010100% (1)

- G Rapid PlusDocument2 pagesG Rapid PlusPaul RuckNo ratings yet

- G Rapid PlusDocument2 pagesG Rapid PlusPaul RuckNo ratings yet

- Sintap British Steel Bs-17Document65 pagesSintap British Steel Bs-17Paul RuckNo ratings yet

- Ship Classification: Torbjörn Rydbergh Account Manager Sweden Chalmers 6 May 2010Document65 pagesShip Classification: Torbjörn Rydbergh Account Manager Sweden Chalmers 6 May 2010Stefano CozziNo ratings yet

- Wind ForceDocument1 pageWind ForcePaul RuckNo ratings yet

- Sparrows Instruction SI01Document53 pagesSparrows Instruction SI01Glen AshwellNo ratings yet

- Surface Preparation Standards Comparison ChartDocument2 pagesSurface Preparation Standards Comparison ChartajuhaseenNo ratings yet

- A9547C 0913 Man RiderDocument68 pagesA9547C 0913 Man RiderPaul RuckNo ratings yet

- EN353-1 2002 WithhdrawnDocument1 pageEN353-1 2002 WithhdrawnPaul RuckNo ratings yet

- AWS D1.1 GuidesDocument6 pagesAWS D1.1 GuidesBiju_Pottayil100% (6)

- Master LinkDocument1 pageMaster LinkPaul RuckNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Poynting OMNI A0098 BrochureDocument2 pagesPoynting OMNI A0098 BrochurekaminareNo ratings yet

- Effects of Osteoarthritis and Fatigue On Proprioception of The Knee JointDocument5 pagesEffects of Osteoarthritis and Fatigue On Proprioception of The Knee JointRosaneLacerdaNo ratings yet

- Valuation and Risk ModelsDocument226 pagesValuation and Risk Models1690295017qq.comNo ratings yet

- Valve Selection Guide For WWTPDocument11 pagesValve Selection Guide For WWTPsf wNo ratings yet

- TIMO Mock 2019 卷P3fDocument9 pagesTIMO Mock 2019 卷P3fDo Yun100% (1)

- Tendenze Attuali Nei Metodi Di Calcolo Per Progettare GearboxDocument40 pagesTendenze Attuali Nei Metodi Di Calcolo Per Progettare GearboxLuis TestaNo ratings yet

- Unisonic Technologies Co., LTD: 8-Channel Analog Multiplexers/DemultiplexersDocument7 pagesUnisonic Technologies Co., LTD: 8-Channel Analog Multiplexers/DemultiplexersNaresh KsNo ratings yet

- Vesda Arrange Fire Alarm SystemDocument1 pageVesda Arrange Fire Alarm SystemGaurav Kumar SharmaNo ratings yet

- Laminar Flow Reactor ProblemDocument6 pagesLaminar Flow Reactor ProblemAileen Banua Añonuevo100% (1)

- Abstract Load Balancing 1Document3 pagesAbstract Load Balancing 1Naveen AbhiNo ratings yet

- Operating Instruction Precision Balance: Kern EwDocument15 pagesOperating Instruction Precision Balance: Kern EwjohnNo ratings yet

- Installation and Setup Guide For The Cisco Active Directory Agent, Release 1.0Document62 pagesInstallation and Setup Guide For The Cisco Active Directory Agent, Release 1.0Madelaine Velasquez Blacutt100% (1)

- MSCS) (V4.12.10) MSC Server Hardware DescriptionDocument148 pagesMSCS) (V4.12.10) MSC Server Hardware DescriptionDeepak JoshiNo ratings yet

- Product Guide (English 140702)Document11 pagesProduct Guide (English 140702)Dineshkumar MahedranNo ratings yet

- Pritchett Clock Repair Shop Breakeven Analysis ExcelDocument138 pagesPritchett Clock Repair Shop Breakeven Analysis ExcelMohd Yousuf MasoodNo ratings yet

- Data MiningDocument48 pagesData MiningJAYASREE K.KNo ratings yet

- Answer All The Questions. No Negative Marks For Wrong Answers. Please Do Not Mark Anything On The Question PaperDocument13 pagesAnswer All The Questions. No Negative Marks For Wrong Answers. Please Do Not Mark Anything On The Question PaperMainak DeNo ratings yet

- TG SkripsiDocument138 pagesTG SkripsiYudanto SetyoNo ratings yet

- Microsoft Office Tips and TricksDocument12 pagesMicrosoft Office Tips and TricksJayr BVNo ratings yet

- Class - 8 PT3 - Portion 2023 24 - 1Document5 pagesClass - 8 PT3 - Portion 2023 24 - 1gurdeepbeniwal97No ratings yet

- Aimo 2019 Trial g6Document6 pagesAimo 2019 Trial g6Jomar EjedioNo ratings yet

- NCERT Solutions For Class 8 Maths Chapter 14 - FactorizationDocument25 pagesNCERT Solutions For Class 8 Maths Chapter 14 - FactorizationSATAMANYU BHOLNo ratings yet

- HE Drilling JarsDocument32 pagesHE Drilling Jarsmr_heeraNo ratings yet

- PQT MJ07Document6 pagesPQT MJ07Raguraman BalajiNo ratings yet

- Johannes KeplerDocument25 pagesJohannes KeplersigitNo ratings yet

- Shape and angle detective game for kidsDocument21 pagesShape and angle detective game for kidsbemusaNo ratings yet

- NeurophysiologyDocument364 pagesNeurophysiologyTaimoor Ul HassanNo ratings yet

- Physico-Chemical Properties of DrugsDocument64 pagesPhysico-Chemical Properties of DrugsYap Jacky33% (6)

- Hysys For Aspen Plus Users PDFDocument11 pagesHysys For Aspen Plus Users PDFKarim KholeifNo ratings yet

- Periodic TableDocument1 pagePeriodic TableChemist MookaNo ratings yet