Professional Documents

Culture Documents

Hea DB (Ni) 9904supplement1

Uploaded by

Ver Bautista0 ratings0% found this document useful (0 votes)

56 views28 pagesThe Medical Devices Agency helps safeguard public health by working with users, manufacturers and lawmakers. The key aim of the Northern Ireland adverse incident Centre (NIAIC) is to record and investigate reported adverse incidents. NIAIC also disseminates safety information in northern ireland, including information provided by MDA.

Original Description:

Original Title

Hea Db(Ni)9904supplement1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe Medical Devices Agency helps safeguard public health by working with users, manufacturers and lawmakers. The key aim of the Northern Ireland adverse incident Centre (NIAIC) is to record and investigate reported adverse incidents. NIAIC also disseminates safety information in northern ireland, including information provided by MDA.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

56 views28 pagesHea DB (Ni) 9904supplement1

Uploaded by

Ver BautistaThe Medical Devices Agency helps safeguard public health by working with users, manufacturers and lawmakers. The key aim of the Northern Ireland adverse incident Centre (NIAIC) is to record and investigate reported adverse incidents. NIAIC also disseminates safety information in northern ireland, including information provided by MDA.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 28

Checks and

tests for newly

delivered medical

devices.

DB 9904 (NI) SUPPLEMENT 1

MARCH 2001

D

E

V

I

C

E

Supplement to Medical device and equipment management

for hospital and community-based organisations DB 9904 (NI)

BULLETIN

(Northern Ireland Version)

An Executive Agency of the Department of

Health, Social Services and Public Safety

isneacht Feidhmeannach don Roinn Slinte,

Serbhs Sisialta agus Sbhilteacht Phoibl

The Medical Devices Agency helps safeguard public health by working with users, manufacturers and

lawmakers to ensure that medical devices meet appropriate standards of safety, quality and performance

and that they comply with the relevant Directives of the European Union.

Our primary responsibility is to ensure that medical devices achieve their fullest potential to help

healthcare professionals give patients and other users the high standard of care they have a right to

expect.

The Medical Devices Agency is an Executive Agency of the Department of Health

The key aim of the Northern Ireland Adverse Incident Centre (NIAIC), part of Health Estates, is to

record and investigate reported adverse incidents involving Medical Devices and equipment used in

Health and Personal Social Services in Northern Ireland and to issue warning notices and guidance to

help prevent recurrence and avert patient or user injury. NIAIC has direct links with MDA who co-

ordinate across the adverse incident centres in England, Scotland, Wales and Northern Ireland. NIAIC

also disseminates safety information in Northern Ireland, including information provided by MDA.

Health Estates is an Executive Agency of the Department of Health, Social Services and Public Safety.

1

CONTENTS

EXECUTIVE SUMMARY..............................................................................3

1 OBJECTIVES.............................................................................................4

1.1 Scope...............................................................................................4

1.2 Introduction.....................................................................................4

2 CHOOSING SUITABLE CHECKS AND TESTS FOR A

PARTICULAR PRODUCT ........................................................................5

2.1 Broad guidelines .............................................................................5

2.2 Building up suitable tests from modules ........................................6

2.3 Training and knowledge which testers need...................................8

2.4 Efficient and record keeping...........................................................8

3 LEGAL REQUIREMENTS FOR ELETRICAL

SAFETY TESTING..................................................................................10

4 SPECIAL CASES.....................................................................................10

4.1 Devices which require commissioning.........................................10

4.2 Devices which might need a local certificate of safety................11

4.3 Devices loaned by manufacturers.................................................13

5 FORMS ....................................................................................................14

5.1 Draft form for bulk-packed products............................................14

5.2 Draft modules for mechanical/electrical devices..........................14

Module A Paperwork....................................................................14

Module B Visual Inspection .........................................................15

Module C Functional check..........................................................15

Module D Electrical safety (basic) ...............................................15

Module E Electrical safety for patient connected devices ...........16

Module F Calibration and measurement ......................................16

ANNEX 1 BACKGROUND - delivery checks .............................................18

ANNEX 2 BACKGROUND - pre-use tests ..................................................19

Acknowledgments

We are grateful to Charing Cross Hospital Department of Clinical Engineering

for their contribution to Section 4.2.

2

3

EXECUTIVE SUMMARY

This guidance document:

replaces HEI 95 Code of practice for acceptance testing of medical

electrical equipment, which is now withdrawn, and extends the

scope of pre-first-use checks and tests to non-electrical medical

devices;

replaces HEI 140 part II Code of practice for acceptance testing of

electrically operated hospital laboratory equipment for in vitro

diagnostic medical devices, pending further guidance in this area;

is designed to minimise the risks associated with using a product

for the first time;

is a supplement to DB9904 (NI) Medical device and equipment

management for hospital and community-based organisations.

User organisations whose procedures require implementation of document

updates should insert it in their DB9904 (NI) folder. However the guidance

is designed to be self-contained, and this supplement can be used as a

stand-alone document.

1. OBJECTIVES

We present a straightforward approach to choosing appropriate pre-first use

checks and tests for most newly-delivered products (see Section 2).

However two exceptional product groups need special treatment:

large, complex products which need installation and commissioning

(see Section 4.1).

products which may need a local certificate of safety - for example

products not manufactured under the Medical Devices Regulations or

supplied second-hand (see Section 4.2).

A risk assessment is needed to ensure that tests and checks are appropriate

for a particular product. Section 2 provides a simple rule-based risk

assessment which leads directly to appropriate lists of checks and tests for

the majority of products. The two exceptional groups involve user

organisations in a local risk assessment to determine an appropriate

procedure.

Chapter 5 of DB9904 (NI): When a new device is delivered is also

relevant. This supplement replaces and extends HEI 95 (Code of practice

for acceptance testing of medical electrical equipment), which is now

withdrawn.

User organisations should check the safety and functionality of newly-

delivered medical devices.

Aims for all devices include:

checking that the correct product, complete with manuals and

accessories, has been supplied;

providing assurance that product items have been delivered in good

condition and (where relevant) in working order;

ensuring that risks associated with using a particular model for the

first time have been minimised.

Additionally, for re-usable devices:

recording the device on a database, so that appropriate maintenance can

be initiated and, in the event of an adverse incident when a new device

is first used, evidence of good practice can be produced.

complying with safety legislation.

These aims are relevant to all medical devices - not just electrically

powered devices. As well as pre-use checks and tests, a procedure for

managing new devices should identify:

any training needs;

appropriate planned preventative maintenance;

technical support needs of users

1

Medical Devices Regulations 1994-SI 1994/3017, see DB9904 (NI) Appendix A1 p. vi. All products covered here are

medical devices under the definition in Article 1 of the regulations intended for the diagnosis, prevention, monitoring,

treatment or alleviation of disease...injury or handicap. Most but not all are therefore subject to the MDR.

4

1.1 Scope

1.2 Introduction

Quality, suitability and conformity to standards must be addressed before

purchase (DB9904 (NI) Chapter 3). There is no sense in buying something and

then deciding that it is not acceptable. The pre-use checks suggested here are the

intended to minimise risks associated with using a newly delivered device, and

not to provide a belated critique of purchasing decisions.

Many of the tests specified in standards are type tests which pose a challenge to

the device, and should only be carried out by the manufacturer or a test house.

Product items subjected to types tests are never put into service, in case the test

has caused some damage. Type tests must never be used as pre-use tests.

2. CHOOSING SUITABLE CHECKS AND

TESTS FOR A PARTICULAR PRODUCT

This section applies to products which are:

brand new;

CE-marked under the MDR (see DB9904 (NI) Section A1.4

CE-marking for purchasers).

Table 1 distinguishes between bulk-pack products, for which there is a single list

of checks (5.1), and products delivered as single items, for which a risk matrix

(Table 2) gives guidance on which of the six modules in section 5.2 are needed.

Every protocol should include checks that:

the delivery is complete;

the product is exactly what was ordered;

there has been no damage in transit.

Category Examples Key issues Draft form

Sterile and non-sterile medical gloves, stock rotation/use Section 5.1

bulk products - checks tongue, by dates

must focus on bulk pack. depressors, tracing lots if there

catheters, is a recall

syringes, circulating instructions

dressings, and safety information

when necessary

faulty packaging

Individual non-active walking frame device is safe to use Assemble from

items modules (see

active infusion pump device functions as sections 2.2

intended and 5.2)

5

2.1 Broad

guidelines

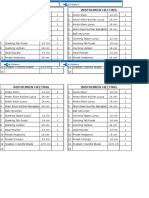

Modules A, B and C are delivery checks. Modules D, E ad F are safety and

calibration test and checks (Table 2).

The appropriate checks and tests for individual product items are chosen

from a set of modules, according to Table 3.

DELIVERY A Paperwork device checks against order and PPQ

CHECKS manuals, compliance and calibration

certificates, test results all included

see Annex 1 for where relevant

background is same model already represented on

database? (if not training/

documentation needed)

is device included in maintenance

system?

B Visual inspection outer packaging intact and undamaged

no damage apparent on inspection

case markings where relevant - CE

marking, notified body number,

electrical class, applied part type

(B/BF/CF)

does the device (or any component

part or accessory) need sterilizing

before the first use?

C Functional check are accessories/parts compatible?

do indicators and displays function

correctly when powered up?*

does it start when you press go?*

action of knobs and switches as

intended*

(see Example 1)

SAFETY AND D Electric - mains leads, plugs, and other

CALIBRATION basic safety connectors undamaged

CHECKS electrical safety test with Portable

Appliance Tester (PAT)

see Annex 2 for E Electric - patient acceptable leakage currents (see p 12)

background connected

F Calibration and Use test device to check

measurement accuracy of physiological measurements

dose delivery*

energy delivery*

accuracy of other outputs*

*only for active devices

6

2.2 Building up

suitable tests

from modules

Lower Risk devices

(typically CE class 1) A.B A,B,C,D

Moderate (typically A,B,C,F A,B,C,D,E,F

classes 2a and 2b) and

High Risk (class 3)

devices

See pp x and xi (DB9904 (NI) Appendix A 1.4) for CE-marking class definitions.

7

Active devices

(Electrical, electronic, gas

pressure powered and

complex mechanical)

Non-active (simple

mechanical devices -

no power source)

Example 1 - Functional test from a dialysis

machine manual

Installation test

The device must not be connected to a patient

during the installation test. Be sure that the test

is conducted using a container of water to

substitute for the patient.

If a malfuncture alarm occurs during the

installation test, the Control Unit has failed the

test. Do not use the control unit.

Call a trained and qualified technician

for service.

Procedure

To perform the installation test, follow the steps

below:

1. Turn on the control unit as described under

start-up in the Operation chapter. The control

unit performs an initialisation test during the

Startup procedure. Verify that the red, yellow,

and green lights are illuminated.

.......

.......

.......

10. Press the STOP softkey, then press the

END TREATMENT softkey and follow

the instructions to unload the set.

Functional tests

Example 1 gives an extract from a

typical manual.

In general such tests check that:

controls operate as expected;

motors and actuators move

freely - device functions

properly;

displays show appropriate

information.

They do not aim to show that

performance conform to any standard,

or exhaustively check every possible

error state. The operations included are

ones normally carried out by a user - the

device is not, for example, placed in

engineering mode, or connected to test

equipment.

For simple electrical devices it will

generally be adequate to simply plug the

device in and switch on. A light source,

for example, ought to light up.

Checks and testers can only be effective if everyone carrying them out has

appropriate training. Table 4 indicates the skills required for the various

modules:

Module Skills Required

(see sections

2.2 and 5.2)

A Familiarity with:

ordering system

inventory system

names and appearances of common medical devices

medical device documentation (manuals, certificates)

serial numbers and model identification codes.

B Knowledge of areas to check for damage.

Familiarity with:

the appearance of product in good condition

common defects.

C Basic electrical safety training - actions to take in cases

where fuse blows or circuit breaker trips. In cases where

manufacturers instructions specify assembly or

manipulation (eg loading a set), familiarity with necessary

components and accessories sufficient to follow

instructions.

D Training in visual electrical safety inspection techniques.

Training in use of simple (go/no go) PAT tester.

E,F Tests which should be carried out by a full-trained technician

Everyone carrying out checks and tests needs to be provided with appropriate

information:

which test modules to apply in a particular case;

where compliance and calibration certificates are necessary;

where to send the device after checking

what to do with manuals and certificates;

what records are needed.

This system is based on a thorough paperwork check and visual

examination carried out by well-trained, but not necessarily technically

qualified staff. Annex 1 gives the background to this policy. Bench tests

need technically qualified staff have been reduced to the minimum

needed to assure safety, on order to increase the time available for work

with users. Annex 2 gives background.

Eliminating duplication

In many cases tests and checks are carried out in stages, by different people.

It is easy to duplicate effort inadvertently, to introduce delays, and to fail to

produce coherent records. Table 5 shows the possible sources of relevant

information, including the data acquired by the manufacturer before

despatch. In many organisations, however, some or all of the functions in this

8

2.3 Training and

knowledge

which testers

need

2.4 Efficient

organisation

and record

keeping

table will be carried out by single department. If clinical staff need to do

checks or tests before first use, they should be alerted - probably best by

attaching a label to the device before it is released for use.

Stage User organisation action Test modules

possibly involved

(see sections 2.2 and

5.2)

Before dispatch - Acquire and assess data C

manufacturer from manufacturer (not for sterile product)

(function, calibration and D,E,F

safety checks which they

have carried out).

Stores/goods inwards Check damage in transit, A,B

order details.

Engineering Perform technical tests, eg D,E,F

departments electrical safety.

Medical physics Check radiation safety, F

calibration of monitoring

equipment.

Before use - Check integrity of pack Bulk pack form (5.1)

clinical staff for sterile devices. C

Perform functional tests (not for sterile product)

where appropriate.

Data from manufacturers

Some user organisations may wish to use data generated by the

manufacturer rather than carry out tests themselves. They must receive

adequate documentation of the tests and their results. It is important to

establish that any tests were carried out on the actual product item in

question, and are not just sample data. Users need to be confident that:

manufacturers are using appropriate test methods;

there has been no damage in transit.

Record Keeping

User organisations should keep records of any safety or functional safety or

functional test. It should always be possible to find out the test result - who

carried it out, when and how:

Health and Safety Inspectors will expect records to be available;

a defence in a negligence if documentation is available for the

particular devices involved.

It is important that all reusable devices are entered onto a device database,

to facilitate efficient equipment management.

9

3. LEGAL REQUIREMENT FOR

ELECTRICAL SAFETY TESTING

The Electricity at Work Regulations Northern Ireland (EWR) 1991 (a

statutory rule SR1991/13, under the Health and Safety at Work Order

(Northern Ireland) 1998 (HASAWO) have regulated electrical safety in the

workplace since March 1991, and form the basis of the programmes used

by hospital estates department for the regular electrical testing of portable

electrical equipment.

HASAWO imposes a duty on employers to provide:

plant and systems of work that are, so far as is reasonably possible,

safe and without risks to health?

such information, instruction, training and supervision as is necessary.

EWR states that no electrical equipment shall be put into use when its

strength and capability may be exceeded... and that all systems shall be

maintained so as to prevent, so far as is reasonably practicable, danger.

Complying with this legislation has led organisations to implement

electrical safety testing programmes, involving pre-use testing of new

devices and periodic subsequent tests. The legislation itself does not spell

out what tests should be done at which intervals. There is no specific legal

obligation - or even guidance - requiring user organisations to do any

particular test, but here is a general duty to take necessary steps to protect

employees from danger.

4. SPECIAL CASES

When a new device model is introduced, or when pre-first-use functional

checks are complicated, technical and clinical staff should work together to

ensure that:

checks are successfully carried out and documented;

users have all the technical information and manuals that they need;

training needs have been identified and acted on;

technical staff are familiar with how the device performs in a clinical

context.

It should be recognised that some single-use products, such as balloon

catheters, are complex (and expensive), and staff training needs should be

taken into account. In most cases a manufacturers representative ought to

be present when a novel product of this type is first used.

Installed devices

When a device needs to be installed, there should be a procedure for

commissioning, worked out in collaboration with the supplier and the

10

4.1 Devices

which require

commissioning

Under the MDR, suppliers must provide instructions for installing a device

and bringing it into use. Where appropriate these instructions will include

specifications for safety and performance checks. A designated member of

staff should have oversight of the commissioning process, and

responsibility of deciding that it has been completed satisfactorily.

The purpose of a local safety certificate is to:

provide assurance that a device is safe and effective;

put appropriate limits on use.

Categories of products which should be subjected to risk assessment are

shown in Table 6.

Some devices fall into more than one category.

Category Examples

Medical devices manufactured outside Manufactured before the regulations

the scope of the MDR came into force.

Purchased by an individual outside EU.

In-house manufacture.

Devices which have (or may have) Bought second-hand.

been previously used. Property of patients or staff.

Lent by another user organisation.

Devices within cope of MDR, but not Custom-made for a named patient.

CE-marked. Under clinical investigation.

Table 7 gives possible outcomes for the risk assessment.

Category Evidence (examples) Outcome

Risk not significantly Custom-made and

greater than for a new clinical investigation Use modular

CE-marked product products with satisfactory tests from

MDR statements. Section 5.2

Previously used devices with

full maintenance history.

Risks significantly Devices of unknown Testing for

greater previous ownership. local safety

Devices manufactured certificate

in house.

In the second case (Risks significantly greater) risk assessment will lead

to a programme of local testing, and the issue of a local safety certificate if

this is successfully completed. If not, risks will outweigh possible benefits,

and the correct decision will be not to use the device in question. Past

history should be taken into account: devices on loan from organisations

with a quality assurance system in place for device maintenance are likely

to be safe and reliable. Example 2 shows a local safety certificate used by

one trust for equipment which needs a comprehensive safety assurance.

11

4.2 Devices

which might

need a local

certificate of

safety

organisation doing the installation. This usually occurs when there is a need

for any of the following:

substantial assembly work on site;

permanent plumbing, electrical and gas pipeline connections;

permanent fixing in place.

Example 2 - Local Certificate of Safety for devices subject to additional investigation.

CERTIFICATE OF ELECTRICAL AND MECHNICAL SAFETY

Applicable only to equipment that has not been commissioned from new

Item No..................... Model/Serial No.....................

VISUAL INSPECTION SECTION

Suitable 13 Amp plug fitted and correctly wired, fitted with a fuse rated at ............. Amp

Mains cable, outer sheath inspected

Mains cable entry / IEC connector, strain relief adequate

Instrument case provides adequate protection from the mains and all fixings are in place

Are the device mountings suitable and properly fitted? If none put na

ELECTRICAL MEASUREMENT SECTION

Earth Leakage Enclosure leakage A Patient Earth leakage A Patient auxiliary

A Only where if protective current A

earth

6 7 8 9 10 11 12 13 14 15 16

Normal supply Normal earth supply Normal earth supply normal earth supply

o/c o/c o/c o/c o/c o/c o/c

QUALITY CONTROL MUST BE COMPLETED BY TEAM LEADER

It was necessary to certificate the equipment because no proof of previous quality checks were available.

either - The equipment has no CE mark, and is not known to conform to BS5724

or - Other, give reason

Indicate what the future planned maintenance will be:

either - On a planned maintenance programme (PM interval..........months)

or - Equipment on fixed term loan. Indicate loan expiry date on licence licence until

Comments

12

Electrical Safety Class:

1B, 1BF, 1CF, 2B, 2BF, 2CF

Ring which is applicable

(3) Insulation resistance ...........MOhms

(4) BF & CF only ...........MOhms

(5) Earth bonding resistance 0...........Ohms

Products being evaluated

Users should check that all devices on loan from manufacturers are subject to

the Regional Supplies Service loan indemnity. This means that the

manufacturer has made suitable arrangements, and that the users exposure to

liability is no different than it would be if they had purchased the device under

normal conditions of sale. Thus pre-use procedures for loan equipment should

be the same as those for purchased equipment.

Products for patients to use at home

Enteral feeding pumps provide a typical example (see DB9904 (NI), page E4).

In cases where ownership and device management remain with the supplier, it

may be satisfactory to accept that manufacturers pre-dispatch tests combined

with simple pre-use checks by those responsible for the care of the patient in

the community (e.g. community nurse of carer) provide an adequate assurance

of safety.

13

4.3 Devices

loaned by

manufacturers

5. FORMS

1. Date/supplier/device type

2. Delivery note checks with order? yes no

3. Outer packaging undamaged? yes no

4. Goods checks with delivery note? yes no

Model/type identification

5. Goods clean, inner packaging intact? yes no

6. Lots or batch number

7. Use by date

8. Stock rotation procedures followed yes no

9. Instructions included yes no

Instructions circulated yes no

Module A Paperwork

1. Date/supplier/device type

2. Delivery note checks with order? yes no

3. Goods checks with delivery note? yes no

Model/type identification

Serial Number

Mains voltage

(where relevant)

Leads supplied yes no

Accessories supplied yes no

User manual supplied yes no

Instructions supplied yes no

Maintenance manual supplied yes no

Warranty document included yes no

Final test certificate supplied yes no

4. Local serial/inventory

5. Device type new to healthcare facility yes no

if yes, instructions circulated appropriately yes no

6. New Device sticker attached yes no

14

5.1 Draft form for

bulk-pack

products

5.2 Draft modules

for mechanical/

electrical devices

Module B Visual Inspection

1. Outer packaging undamaged? yes no

2. Case not dented/broken yes no

3. Panels etc. secure yes no

4. No rattles yes no

Module C Functional check

Plug in, turn on (following instruction manual)

1. Indicator lamps light up yes no

2. Display as described in manual yes no

3. Passes self test routine yes no

4. Moving parts operate properly yes no

5. Knobs and switches act properly yes no

Module D Electrical safety (basic)

1. (Moulded IEC mains connector and mains plug)

Connectors firmly attached yes no

No cores or bare wires visible yes no

Outer insulation intact yes no

Appropriate fuse fitted (see manual) yes no

Fuseholder secure yes no

2. Mains lead permanently attached).

Cord grips satisfactory yes no

3. Fuse value

4. Plugs and sockets mate yes no

5. Clamps and doors hatch yes no

6. Passes PAT test yes no

15

16

Module E Electrical safety for patient connected devices

This set of tests is designed:

to test equipment in normal working order;

not subject to equipment to currents or voltages exceeding those

experienced in normal operating conditions.

Thus no tests involve shorting electrodes together, or applying high voltages

to electrodes.

1. Electrical safety class: 1 2

type: B BF CF

2. Insulation resistance (class 1 only) between mains plug earth and other

two pins (line and neutral) connected together.

Measures at 350 V DC

2

Greater than 20 Megohms

3

yes no

3. Earth continuity (class 1 only) between mains plug earth pin and

accessible conductive parts. Current not more than 1 amp.

Less than 0.2 Ohms. yes no

4. Leakage currents

Setup Mains Mains must be Yes No

normal reversed

Earth (class 1 only) <500 A

Enclosure (tester

connected to <100 A

exposed conductive

part on device case)

Patient (tester 1. <100 A (B and BF)

connected to each 2. <10 A (CF)

electrode in turn 3.

4.

5.

6.

7.

...

2

It is very unlikely that electrical safety analysers operating at 500 V DC will cause any

harm.

3

A measured value less than 20 MQ should be investigated, but does not necessarily mean

that the equipment is unsafe. In some cases what is being measured is not the resistance of

the insulation but the value of an electronic component (a bleed resistor in a mains filter, for

instance), whose inclusion may be desirable and is entirely permissible provided it does not

cause excessive leakage current. If in doubt consult the manufacturer.

Megohms

Ohms

17

Device passes tests in manual Yes

Date

Data

(Insert mearsurements needed from manual, or locally generated

procedure).

No

Module F Calibration and measurement.

18

ANNEX 1 BACKGROUND -

DELIVERY CHECKS

Simple checks on delivery can save time

and avoid trouble - if a device is

discovered to be broken or inappropriate

only when someone tries to use it for the

first time, it can lead to:

delayed or interrupted

treatment;

waste of clinical staff time;

difficulties in returning the

device and establishing

when and where the

problem arose;

invalidation of warranties;

injury to patients and staff.

Other countries have issued similar

guidance (see Example 3)

Delivery checks are plainly cost effective

- they are a necessary part of any device

management system, and also eliminate

unnecessary risks (see Example 4).

These checks are uncontroversial - all

the manufacturers and user organisations

we have consulted agree that they should

be applied to all medical devices,

including single-use and consumable

items.

Example 3 AS/NZS 3551: 1996 Technical

management programs for medical devices

(An Australian/New Zealand standard)

Initial inspection Persons accepting

delivery (e.g. inwards goods staff) shall

check the packaging is undamaged. Any

damage shall be noted.

General acceptance inspection The medical

device shall be inspected as soon as possible

after delivery to establish that it is complete

with specified accessories and that it has not

been damaged in transit.

Example 4 Wrong trolley delivered

A firm supplying a trolley for a transport

incubator supplied a unit slightly modified

from the sample which the hospital had

judged to be satisfactory before purchase.

The model supplied did not have the correct

clamps, and broke loose when mounted in an

ambulance. The error was only discovered

after the adverse incident had occurred, but

could have become apparent during pre-use

testing.

19

ANNEX 2 BACKGROUND -

PRE-USE TESTS

Evidence about risk-levels

MDA/NIAIC receives very few adverse incident reports relating to newly

delivered products. Table 8, for example, gives details of incidents

involving damage in transit.

Category Number of incidents recorded

Wheelchairs and walking aids 54

Single-use devices 10

Nebulisers/oxygen supply 7

Beds and tables 5

Portable electro-medical devices 4

Safety tests.

The over-riding principle here is that pre-use tests should not be outside the

bounds of normal use:

Disassembly should be restricted to what is necessary for normal

use and cleaning;

Currents or voltages applied during tests should not exceed those

occurring in normal use.

Any test which involves an abnormal stress - for example loading a hoist

above its stated maximum working load - carries an unacceptable risk of

causing permanent damage, and may invalidate any warranty.

Failure to follow this advice may lead to dangerous devices being put into

service.

Damage in transit

Although faults can arise during transportation:

adequate packaging should provide any necessary protection;

delivery checks will detect damage to packaging - a good indicator

of possible problems during transport.

Table 8 shows the tiny incidence of damage in transit problems on the

MDA/NIAIC adverse incident data base.

Manufacturers guidance

Maintenance instructions may specify tests on a new device (for example,

in order to generate baseline data for later comparisons). A pragmatic

approach is to avoid duplication - these tests may serve as a functional

check and/or a calibration check.

20

Fig. 1 Incidents involving electric shock as a percentage of all reports

received by MDA.

% of incidents involving electric shock

Year

90 92 94 96 98

0.1

0.15

0.2

0.05

0.25

0

%

Performing extra tests not required by the manufacturer should be avoided.

If a manufacturers instructions seem to be inadequate to ensure continued

safety and adequate performance, this fact should be reported to, MDA and

we will take the appropriate action.

Electrical safety testing

Fig 1 shows all the incidents involving electric shock reported to the MDA

over the last 9 years (a total of 43). These do not exceed 0.25 % of reports

received in any year, and in 40 of these 43 cases injuries are categorised as

none or minor. No deaths by electrocution in the UK are recorded on

the MDA database. reports cover all medical devices in service, so risks for

new devices are very much lower.

21

Example 5 Quotes from speakers at Acceptance

testing for medical devices - the way forward?

meeting, organised by IPEM, ABHI and MDA.

1) John Conely (John Radcliffe Hospital,

Oxford)

The old HEI 95 ... goes into great detail as to what

we should check for electrical safety. Whats the

supreme importance of electrical safety over all

other safety considerations? In my own department

in the last seven years, I can recall two items of

equipment which failed electrical safety tests. One

took out the fuse when plugged in, and the other

had a heater element which caused some high

readings. For over seven years its an awful lot of

effort and not a lot of electrical safety problems.

2) Richard Mellish, (MDA)

I think there are two reasons why we have tended

to concentrated on electrical safety.

Because we know how to do it, and thats

a bad reason.

There is a legal obligation to do safety

testing on electrical equipment in use in

places of work from time to time to make

sure it hasnt become dangerous.

3) Nicholas Abraham (Charing Cross

Hospital)

Electrical safety tests have even less value

(than planned preventative maintenance tests).

Fire risks apart, this is the least of our worries.

Functional failure of equipment is far more

serious, especially for infusion pumps,

defibrillators, anaesthetic machines, etc.

Electrical safety has a place and shouldnt be

ignored but it really isnt the be all and end of

all safety. Weve seen a few cases IEC leads

with failed earth continuity - just enough to

support the testing rule. Weve seen even fewer

failures on patient leakage current - just

enough to support testing. We appreciate that if

youre going to rest either of those things, once

youve got the machine out, the marginal cost

of making all the tests is small enough to make

it really not worth arguing about. So we might

as well do the tests. But remember, its quite

easy for something quite dangerous to pass

electrical safety tests*. I certainly would not be

advocating setting up a whole service from

scratch just to do electrical safety testing.

* eg an intense light source with a faulty fan

will pass an electrical safety test, but overheat

dangerously if operated for any length of time.

Many user organisations have traditionally carried out extensive electrical

safety testing programmes, but evidence that these programmes are

important for maintaining device safety is weak - one hospital clinical

engineering department has told us that it has conducted 13000 electrical

safety tests on new equipment without finding a single electricity unsafe

device. Published data also shows low rates of electrical safety faults.

(Amoore, J.N., Stay, D.G., and Mather, J. Scheduled inspection of

electromedical equipment. Planning and assessment Journal of Medical

Engineering and Technology 19 211-218).

There is thus little evidence that electrically-powered medical devices are a

special hazard and no justification for a disproportionate allocation of

resources to test them - as compared to non-electrical products with similar

risks levels. This document presents a compromise position, recognising

that some electrical testing is legally necessary (see Section 3), and that the

decision to eliminate some of the tests currently in use is a difficult one to

take.

Example 5 has quotes from papers given by senior biomedical engineers

at a meeting organised by IPEM, ABHI and MDA in March 1998.

22

Methods for electrical testing

Role of visual examination

Structured visual inspections involve checks of integrity, compatibility,

correct fusing, and correct labelling. In general, for double-insulated

devices with no accessible metal parts, electrical safety can only be

assessed by a structured visual examination.

Purpose-built appliance testers

A portable tester (PAT) gives a simple pass/fail reading. It requires some

training in its use, though no specialist electronic skills. PAT tests normally

include earth bonding and insulation resistance.

More sophisticated electrical testers such as the Bioteck electrical safety

analyzer print out a list of resistance and current values, and require a

higher competency to operate safely, and not to interpret the findings. Some

of the tests involve operating the device with its safety earth disconnected

and must only be conducted in a suitably equipped workshop. In some

circumstances the testing may constitute live working.

Reducing electrical testing without compromising safety

Table 9 summarises three approaches we considered:

Strategy For all devices Additional tests Additional tests

or devices with for patient

exposed metal connected

parts devices

1 No electrical Structured visual Accept Accept

testing exam + functional manufacturers manufacturers

test assurance assurance

2 Typical estates Structured visual PAT tester Accept

protocol exam + functional manufacturers

test assurance

3 Risk-related Structured visual PAT tester Electrical safety

testing effort exam + functional analyzer

test

Strategy 1 employs a structured visual inspection and simple functional test

for all devices. The functional test will detect electrical faults which cause a

fuse to blow, or the device to fail to operate. Otherwise this strategy relies

on the manufacturers inspection before dispatch for electrical safety. See

Section 3 for legal requirements in this area.

23

Strategy 2 adds a PAT test for any device which is not double-insulated.

This will align medical device practice with procedures used for other

electrical equipment within the same organisation, for example hospital

estates departments testing non-medical devices,

It would seem reasonable for healthcare organisations to adopt a common

safety standard for medical devices:

for use by staff;

supplied to patients to use themselves (or for their carers to use).

Strategy 3. As 2, but with an electrical safety analyser for patient-

connected devices. This reduces a very slight risk of electrocution via leads,

due to an out-of-box failure. Many biomedical engineers have argued

strongly for this option, even if they are persuaded that a full set of

electrical tests on every single device is a waste of time.

The modular approach in section 2 is based on strategy 3, but healthcare

organisations may find that strategy 2 or even strategy 1 proves acceptable

in their particular circumstances, following a risk assessment.

DISTRIBUTION

This Device Bulletin should be brought to the attention of managers and staff in all HPSS

Organisations.

This device bulletin should also be brought to the attention of medical device coordinators, medical

engineering and medical physics staff, IT staff, medical and nursing directorate managers, general

practitioners, dental practitioners, pathology laboratory managers and staff responsible for medical

equipment used in the community.

TECHNICAL ENQUIRIES

General enquiries concerning this Device Bulletin should be addressed to:-

Mr Brian Godfrey

Northern Ireland Adverse Incident Centre

Health Estates

Estate Policy Directorate

Stoney Road

Dundonald

BT16 1US

Tel: 028 9052 3714

Fax: 028 9052 3900

email: brian.godfrey@dhsspsni.gov.uk

FURTHER COPIES

Further copies of this Device Bulletin are free to Health and Social Care providers and may be obtained

on written request from:

Northern Ireland Adverse Incident Centre

Room A7

Health Estates

Estate Policy Directorate

Stoney Road

Dundonald

Belfast

BT16 1US

Tel: 028 9052 3704

Fax: 028 9052 3900

Health Estates

An Executive Agency of the Department of Health, Social Services and Public Safety

isneacht Feidhmeannacdh don Roinn Slinte, Serbhs Sisialta agus Sbhilteacht Phoibl

You might also like

- Guide To Classify of Medical DevicesDocument11 pagesGuide To Classify of Medical DevicesPranav UpadhyayaNo ratings yet

- List Recognized Standards Medical Devices Guidance CanadaDocument35 pagesList Recognized Standards Medical Devices Guidance CanadaRobert SplinterNo ratings yet

- Iba't Ibang Ahensiyang PamahalaanDocument4 pagesIba't Ibang Ahensiyang PamahalaanVer Bautista0% (1)

- Blood Pressure ChartDocument9 pagesBlood Pressure ChartVer BautistaNo ratings yet

- Medical EquipmentDocument48 pagesMedical EquipmentKhalid Khassawneh100% (2)

- EU Guide Medical Device DirectiveDocument112 pagesEU Guide Medical Device DirectiveJoherNo ratings yet

- Managing Medical Devices within a Regulatory FrameworkFrom EverandManaging Medical Devices within a Regulatory FrameworkBeth Ann FiedlerRating: 5 out of 5 stars5/5 (1)

- OGP Standards For Local Medical SupportDocument36 pagesOGP Standards For Local Medical Supportihwan100% (1)

- Unit 2 - Medical Device SafetyDocument27 pagesUnit 2 - Medical Device SafetyBetty MollaNo ratings yet

- How To Design Solar PV SystemDocument53 pagesHow To Design Solar PV SystemVer Bautista100% (2)

- Complaint Handling 60.60 23JUN2020Document11 pagesComplaint Handling 60.60 23JUN2020Abdul RahmanNo ratings yet

- Medical Device GuidanceDocument34 pagesMedical Device GuidanceVanessaNo ratings yet

- Medication Safety PDFDocument95 pagesMedication Safety PDFMangayarkarasi ChandrakasanNo ratings yet

- MED EquDocument9 pagesMED EquAmir100% (1)

- CSDT GMDDocument40 pagesCSDT GMDSyafiqNo ratings yet

- History of Nursing in The Philippines Group 2Document10 pagesHistory of Nursing in The Philippines Group 2Karen Joyce Costales MagtanongNo ratings yet

- International Standard (Iso 11014-1)Document10 pagesInternational Standard (Iso 11014-1)Kanupriya100% (1)

- Electrical & Electronic Testing of EquipmentsDocument52 pagesElectrical & Electronic Testing of EquipmentsPriti BhardwajNo ratings yet

- A Sample of The Completed Essential Principles Conformity Checklist MD CCLDocument12 pagesA Sample of The Completed Essential Principles Conformity Checklist MD CCLAyman Ali100% (1)

- Interview Skills: An RCN Guide For Health Care Assistants and Assistant PractitionersDocument9 pagesInterview Skills: An RCN Guide For Health Care Assistants and Assistant PractitionersWalter AlexandruNo ratings yet

- National Guideline For Patient Safety Incident Reporting and Learning in South Africa Version 2 - Web LayoutDocument82 pagesNational Guideline For Patient Safety Incident Reporting and Learning in South Africa Version 2 - Web LayoutSheena Mabaquiao-PadernalNo ratings yet

- Er Admission PolicyDocument9 pagesEr Admission PolicyIrish Martinez100% (2)

- CSSDDocument43 pagesCSSDMohd SalahuddinNo ratings yet

- IVD GuideDocument23 pagesIVD GuidevolkandemirNo ratings yet

- CE Guidelines Classification Medical DeviceDocument17 pagesCE Guidelines Classification Medical DeviceMehdi100% (4)

- Kitchen LayoutDocument47 pagesKitchen LayoutVer Bautista100% (5)

- Guidelines On Medical Equipment Management in NigeriaDocument8 pagesGuidelines On Medical Equipment Management in NigeriaBALANo ratings yet

- Medical DeviceDocument8 pagesMedical DeviceHarshvardhan ChoudharyNo ratings yet

- Clinical Evaluation Report SampleDocument12 pagesClinical Evaluation Report Sampleibrahim kademogluNo ratings yet

- WHTM 01-01 Part BDocument37 pagesWHTM 01-01 Part BMorcosNo ratings yet

- Manual Fetal Doppler SonolineDocument29 pagesManual Fetal Doppler SonolineOmar del CastilloNo ratings yet

- Define What Is PhysicsDocument6 pagesDefine What Is PhysicsVer BautistaNo ratings yet

- Night NightDocument21 pagesNight Nightapi-402315475No ratings yet

- Medical Devices StandardsDocument135 pagesMedical Devices StandardsGnanasaravanan 2508100% (1)

- Human Factors Medical Devices v2.0Document35 pagesHuman Factors Medical Devices v2.0EKNo ratings yet

- Silay City Watersports and Recreation Park (Chapter VI)Document30 pagesSilay City Watersports and Recreation Park (Chapter VI)Aisa Castro Arguelles100% (1)

- Guide To IEC 62353Document36 pagesGuide To IEC 62353Marco Todde100% (2)

- HIS ADHOC BillStatement STD Rev1Document2 pagesHIS ADHOC BillStatement STD Rev1Quinio ReyNo ratings yet

- Topic 1 Quality Standard Regulations 22Document48 pagesTopic 1 Quality Standard Regulations 22Aiman SyakirinNo ratings yet

- Medical Devices and IVDs: Fit for the new EU-Regulations: Your complete seminar for projekt, study and jobFrom EverandMedical Devices and IVDs: Fit for the new EU-Regulations: Your complete seminar for projekt, study and jobNo ratings yet

- M20 - Chapter 1 - Medical Device Safety Standard PDFDocument80 pagesM20 - Chapter 1 - Medical Device Safety Standard PDFTakIe AdnanNo ratings yet

- Bulletin Healthcare Organisations 03142023Document46 pagesBulletin Healthcare Organisations 03142023dodyNo ratings yet

- SafetyDocument15 pagesSafetyBetty MollaNo ratings yet

- Leitfaden Fuer App Entwickler Def ENDocument53 pagesLeitfaden Fuer App Entwickler Def ENYousra El MeriniNo ratings yet

- GHTF Imdrf Clasificacion de DMDocument30 pagesGHTF Imdrf Clasificacion de DMPieroNo ratings yet

- USA PMS RegulationsDocument42 pagesUSA PMS RegulationsDayaNo ratings yet

- 2010 CLinical Investigations - 2 - 7 - 4 - en PDFDocument10 pages2010 CLinical Investigations - 2 - 7 - 4 - en PDFWillem MuetstegeNo ratings yet

- WHO 2019 NCoV PPE Specifications 2020.1 EngDocument40 pagesWHO 2019 NCoV PPE Specifications 2020.1 EngHervian LanangNo ratings yet

- Clinical Investigations: Serious Adverse Event Reporting Under Directives 90/385/eec and 93/42/eec.Document12 pagesClinical Investigations: Serious Adverse Event Reporting Under Directives 90/385/eec and 93/42/eec.FranciscoNo ratings yet

- GHTF-sg1-n41r9-safety& PerformanceDocument16 pagesGHTF-sg1-n41r9-safety& PerformanceLoganathan SellappanNo ratings yet

- GN 07 r2 2 Guidance On Complaint Handling (2022 Nov) - PubDocument8 pagesGN 07 r2 2 Guidance On Complaint Handling (2022 Nov) - PubJEYA KUMARANNo ratings yet

- Designing Medical Electrical Equipment To Meet Safety Certification and Regulatory RequirementsDocument6 pagesDesigning Medical Electrical Equipment To Meet Safety Certification and Regulatory RequirementsMohamed Abdel FatahNo ratings yet

- Australia Post Market Activity GuidelinesDocument31 pagesAustralia Post Market Activity Guidelinesspenceblack7999No ratings yet

- Final ThesisDocument69 pagesFinal ThesisAswin WSNo ratings yet

- Standard No. CEA/Wellness Centre-018Document21 pagesStandard No. CEA/Wellness Centre-018Gladys MatiraNo ratings yet

- H3 Standares para El Soporte MedicoDocument36 pagesH3 Standares para El Soporte Medicoleo limpiasNo ratings yet

- Benchtop Steam Sterilizers - Guidance On Purchase, Operation and MaintenanceDocument48 pagesBenchtop Steam Sterilizers - Guidance On Purchase, Operation and MaintenanceSigrid MiNo ratings yet

- Medical Device Act 2012Document53 pagesMedical Device Act 2012ram010No ratings yet

- Meddev 2.7 4Document10 pagesMeddev 2.7 4Jug_HustlerNo ratings yet

- ADV-G0004 Guide To The Classification of A Medical Device v2Document11 pagesADV-G0004 Guide To The Classification of A Medical Device v2Putu Gede GandharaNo ratings yet

- Asean MDPWG CSDT - Final - 21 Oct 2010Document12 pagesAsean MDPWG CSDT - Final - 21 Oct 2010Brian WilliamsNo ratings yet

- Spain Product SafetyDocument5 pagesSpain Product SafetySebastian VanderlindenNo ratings yet

- Standard For Equipment in Critical Care: The Intensive Care SocietyDocument15 pagesStandard For Equipment in Critical Care: The Intensive Care SocietyAhmed Sabaa ayounNo ratings yet

- GHTF sg1 n70 2011 Label Instruction Use Medical Devices 110916Document17 pagesGHTF sg1 n70 2011 Label Instruction Use Medical Devices 110916Use EreNo ratings yet

- Bao Duong May Tiet TrungDocument51 pagesBao Duong May Tiet TrungĐức CườngNo ratings yet

- GHTF sg5 n2r8 2007 Clin EvalDocument28 pagesGHTF sg5 n2r8 2007 Clin EvalLoganathan SellappanNo ratings yet

- Planned Preventive MaintenanceDocument4 pagesPlanned Preventive MaintenanceMOHAMMAD AHMADNo ratings yet

- Unistor User and Installation ManualDocument56 pagesUnistor User and Installation ManualIan RamageNo ratings yet

- Medical Devices Handling, Environmental SafetyDocument37 pagesMedical Devices Handling, Environmental SafetyGnanasaravanan 2508No ratings yet

- ProcedureDocument62 pagesProcedureAshok KumarNo ratings yet

- Healthsmart Design Authority: Ihi Pre-Implementation ProjectDocument31 pagesHealthsmart Design Authority: Ihi Pre-Implementation Projectwidayat81No ratings yet

- Emc Emi SystemsDocument2 pagesEmc Emi SystemsVer BautistaNo ratings yet

- UNFPA Technical Requirements For Medical DevicesDocument7 pagesUNFPA Technical Requirements For Medical DevicesVer BautistaNo ratings yet

- Transformation of Energy 8 UnitDocument25 pagesTransformation of Energy 8 UnitVer BautistaNo ratings yet

- Biomed Poster IIDocument1 pageBiomed Poster IIVer BautistaNo ratings yet

- Energy EfficiencyDocument2 pagesEnergy EfficiencyVer BautistaNo ratings yet

- Bachelor of Technical Teacher Education in The PhilippinesDocument14 pagesBachelor of Technical Teacher Education in The PhilippinesVer Bautista0% (1)

- Term Paper 1 Eco Health (Qingwen Kawaji)Document12 pagesTerm Paper 1 Eco Health (Qingwen Kawaji)Ver BautistaNo ratings yet

- Capacitor and Voltage RatingDocument2 pagesCapacitor and Voltage RatingVer BautistaNo ratings yet

- Current Members of SenateDocument3 pagesCurrent Members of SenateVer BautistaNo ratings yet

- Comparison Chart LED CFL ILDocument5 pagesComparison Chart LED CFL ILVer BautistaNo ratings yet

- Mortuary FreezerDocument4 pagesMortuary FreezerVer BautistaNo ratings yet

- ChlorineDocument1 pageChlorineVer BautistaNo ratings yet

- BP Cuff Sizes For Manual SphygmomanometerDocument1 pageBP Cuff Sizes For Manual SphygmomanometerVer BautistaNo ratings yet

- BP Cuff Sizes For Manual SphygmomanometerDocument1 pageBP Cuff Sizes For Manual SphygmomanometerVer BautistaNo ratings yet

- CalibrationDocument25 pagesCalibrationWaqarAhmedButtNo ratings yet

- S.W.G. ChartDocument1 pageS.W.G. ChartVer BautistaNo ratings yet

- Definitions of Acids and Bases0Document15 pagesDefinitions of Acids and Bases0Ver BautistaNo ratings yet

- Etymology of LiteratureDocument28 pagesEtymology of LiteratureVer Bautista50% (2)

- QuotesDocument2 pagesQuotesVer BautistaNo ratings yet

- Biological Safety Cabinet GermfreeDocument3 pagesBiological Safety Cabinet GermfreeVer BautistaNo ratings yet

- Shortcut Keys ReferenceDocument4 pagesShortcut Keys ReferenceVer BautistaNo ratings yet

- An Innovative DesignDocument5 pagesAn Innovative DesignVer BautistaNo ratings yet

- Autodesk Autocad BasicsDocument80 pagesAutodesk Autocad BasicsVer BautistaNo ratings yet

- Temporary Override Keys ReferenceDocument2 pagesTemporary Override Keys ReferenceVer BautistaNo ratings yet

- Alat HectingDocument4 pagesAlat HectingjuliperNo ratings yet

- Case StudiesDocument4 pagesCase StudiesL KennedyNo ratings yet

- Benefits of Preoperative Education For Adult Elective Surgery PatientsDocument6 pagesBenefits of Preoperative Education For Adult Elective Surgery PatientschayankkuNo ratings yet

- SusiDocument32 pagesSusiWebItKpiNo ratings yet

- SIMULATION of EMERGENCY ROOMS USING FLEXSIMDocument10 pagesSIMULATION of EMERGENCY ROOMS USING FLEXSIMBrandon VarnadoreNo ratings yet

- What Service Do You Need? Read The Statements, Look at The Pictures, and Complete The CrosswordDocument2 pagesWhat Service Do You Need? Read The Statements, Look at The Pictures, and Complete The CrosswordOmar GutiérrezNo ratings yet

- Updated CVDocument4 pagesUpdated CVcrazylucarioNo ratings yet

- Nice PrelimDocument2 pagesNice PrelimKaren Mae Santiago AlcantaraNo ratings yet

- Umibilical Cord - ProlapsDocument22 pagesUmibilical Cord - ProlapsAtikah PurnamasariNo ratings yet

- RCPsych Final Forensic Programme 2018at26febDocument8 pagesRCPsych Final Forensic Programme 2018at26febbrunotrancasNo ratings yet

- E-R Diagram Examples Questions PrintDocument9 pagesE-R Diagram Examples Questions PrintGetachew ShambelNo ratings yet

- Assignment Building SystemDocument5 pagesAssignment Building SystemMohd MezlanNo ratings yet

- 1 s2.0 S1879406821000631 MainDocument1 page1 s2.0 S1879406821000631 MainmiNo ratings yet

- ACUTE ABDOMEN Systemic SonographicDocument6 pagesACUTE ABDOMEN Systemic SonographiciwanNo ratings yet

- The Best of Charlie Munger 1994 2011Document12 pagesThe Best of Charlie Munger 1994 2011Vishnu PradeepNo ratings yet

- Hospital ManagementDocument20 pagesHospital ManagementGokulNo ratings yet

- Chap 15Document32 pagesChap 15IngenieroHenryNo ratings yet

- Windshield Survey Nurs340Document10 pagesWindshield Survey Nurs340api-247143627No ratings yet

- Claim Form - IPDDocument2 pagesClaim Form - IPDEswar Kiran ReddyNo ratings yet

- Assessment Diagnosis Goals and Objectives Planning Intervention Rationale EvaluationDocument3 pagesAssessment Diagnosis Goals and Objectives Planning Intervention Rationale EvaluationCrissa AngelNo ratings yet

- Daftar Pustaka Refrat Bedah PlastikDocument3 pagesDaftar Pustaka Refrat Bedah PlastikAnggita DewiNo ratings yet

- Finaltest Listen SuperGoal11f2Document8 pagesFinaltest Listen SuperGoal11f2yahia222000No ratings yet