Professional Documents

Culture Documents

07 Software Design PDF

Uploaded by

Prasad TlnsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

07 Software Design PDF

Uploaded by

Prasad TlnsCopyright:

Available Formats

1

Ladder sequence design specification.

Sequence classifies roughly in Main, process and others. (diagram-1)

Explain it in (Fx,A) series Mitsubishi PLC & OMRON.

Step 0

END

Main program

Process 1 program

Process 2 program

Process 3 program

Process x program

Other program

Diagram-1

2

11. Main program

Such as follows is constituted.

Setting of dummy coil

PLC preparation circuit

Mode choice(auto,mamu)

Gathered original position

in each process

State gathered of each process

Setting of start condition

Step 0

Diagram-2

Gathered of abnormal detection

Auto stop circuit

Auto start circuit

ORG position return circuit

3

. Process program

Such as follows is constituted.

. Other programs

Interface to system. Lamp. Buzzer. Counter.

Interface program

Actuator drive program

ORG position condition of process

Start condition detect circuit

Start stop circuit of process

Automatic driving program

Origin return program

Diagram-3

Reset program of process

Trouble detection program

4

Main program.

Use a usually OFF relay at the time of adjustment, a trial run.3-2-1.

Use a flicker relay for indicate lamp.3-2-1.

Initial timer, Initial ON pulse are aimed for protection of calculation circuit.

Cf. Chart below.

Must write this circuit in the beginning of programe.

ComplementOMRON CJ series special relay.

No CF113 (P_On)Name always ON

No CF114 (P_Off)Name always OFF

No CF002 (P_EQ)Name = Flag

No CF005 (P_GT)Name > Flag

No CF102 (P_1s)Name 1 sec clock

0.5sec

|0.5sec ||

( M0 always OFF

( TO flicker ON time

0.5sec

M0

T1

T0

M0

T2

( M1 flicker

Step 0

K5

( T1 flicker OFF time

0.3sec

K3

( T2 initial timer

0.2sec

K2

( M2 initial ON pls

PLS

5

Example use of dummy contact.

Example 1: Shortening of start condition. Always OFF relay.

Start condition pass (M90,M91,M92) Start I condition of (X0,X1,)

Example 2 : Automatic sequence

M101 Sequence start

Head down

IL

Interlock condition

M10

Interlock

Start condition

M100

M101

M101

Head lower

M102

M102 Escape forwad

Escape front

M0

M102

M103 Head up

M103

M0

M102

M103 Head up

M103

ILC Interlock clear

M90 M91 M92 M119 X0 X1

M0

(

M100) Start condition

6

. Flicker relay

Example : Start & Stop lamp blinking.

Flicker

M1

Cycle stop

M69

Y010 Drive lamp

Y011 Stop lamp

Cycle stop

M69

Driving

M70

Cycle stop

M69

Driving

M70

Flicker relay

Cycle stop relay Become OFF after Stop.

Drive relay

Driving lamp will blinking until it completely stop.

An than Turn on when it stop.

7

Preparation circuit

Input air pressure sensor,PLC run signal,E-stop signal and constitute circuit.

I/O unit

W10.00

( M7 PLC normal

(

M9 Air pressure

Lower

(

M10 Driving

Preparation

M10

M7

A20011 T2

CPU

error

1 Scan ON

After CPU run

( M8 E-STOP

E-Stop contact

M8

Reset

10.00

Air pressure

sensor

M9

Reset

10.00

Driving

Preparation

E-STOP

M8 M9

PC normal

Air press

Lower

Alarm

W10.00

00.00

8

Example : Indicate trouble at touch panel.

CPU

error

W10.00

I/O Unit

alarm

W 10.01

Reset

10.00

1 scan ON

after CPU run

A20011

= K1 D0

RSET

M 8

E-STOP

E-STOP

SET

M 8

E-STOP

Reset

10.00

= K2 D0

RSET

M 9

Air pressure

Air

pressure SET

M 9

Air pressure

Indication screen No.

Indication No 1(K=1) E-STOP Indication.

Indication No2 (K=2) Air pressure lower.

9

Mode choice. (Auto---Manual)

Use timer for change circuit.

Condition of the drive preparation is necessary for auto,manu,inching mode.

T1

M2

M1

T2

Auto assist

Auto

Manu assist

Manual

Auto SS Manu SS

T1

M2

Auto SS Manu SS

T2

M1

M10 M1

( M11 AUTO MODE

preparation

( M12MANU MODE

M2 M1

AUTO Manu

M2

10

Model change.

Gathered original position in each process

M13

( M14 Model A

M13

Model B

Model C

M14

Model A

( M13 Model change READY

All ORG Drive

Process 1

ORG

( M20 All ORG

Process 2

ORG

Process 3

ORG

11

Gathered trouble.

Divide it into 3 kinds.

Trouble 1 The trouble that must stop immediately.

*) E-STOP Cycle time over Robot error etc.

Trouble 2 Cycle stop trouble.

*)Full(c/v,tray,etc ) Inspection NG etc.

Trouble 3 Auto driving continua.

*)Lack of work etc.

All trouble Compile trouble 1-3.

*)Use signal tower & buzzer etc.

(

M40 Trouble 1

(

M41 Trouble 2

(

M42 Trouble 3

(

M43 All trouble

(

M60 signal tower

RED

(

M70 Buzzer

(

M44 Buzzer stop

Trouble A

M44 M42

M41

M40

Buzzer stop SW M43

M44

12

Gather state of each process.

Setting of auto start condition.

Make memory of auto start condition.

Stop circuit.

Make memory of cycle stop & running interruption.

This circuit being step in front of driving circuit.

* Foregoing paragraph,trouble1&2 turn on main stop memory to stop auto driving.

Auto driving stop timing.

Turn off driving memory of each process by trouble 1.

Circuit example is the following page

No1 process start memory

( M50 process

operating

No2 process start memory

No3 process start memory

All ORG

(M50)

(

M60 Auto start

Condition OK

All trouble Process

operating

13

Auto start circuit.

Start button can use start condition OK.

Stop circuit

(

M71 Stop OK

START OFF

Trouble 2

Trouble 1

STOP PB

M70

START

All process

driving

M50

Auto

Mode

(M80)

(

M70 STOP

Auto start

Circuit

( Y start lamp

M60 START PB

Stop OK

M71

M80

( M80 START

(driving

Auto

mode

Condition

M70

( Y STOPlamp

14

All origin position return circuit.

Each process make original position return when the memory is activation.

(

M60 All ORG position

Return direction

All unit

Stop

All ORG

Return reset

M60

Driving

OK

Auto

mode

All ORG

Return SW

preparation

15

Process program.

Explanation about index table and supply takeout P&P.

Details of system constitution are attached sheet.

Setting of ORG position condition.

Gather up PLC input.(sensor)

Original position is movement start/endpoint of machine. Cycle stop position.

When machine inertia is big, prior stop signal is necessary.

Start condition of process.Supply PP

Setting start condition and prohibited condition.

(

M100 Supply P&P

ORG position

Chuck open

LS

Upper

LS

Backward

LS

( M101 Supply P&P

Start condition

Turn table

Supply pos

work LS

work

Arrival LS

P&P ORG

M100

Turn table

Turn complet

STOP

M200

P.P

Start

M103

Start condition Prohibit condition

16

Condition setting of start reset.

Make forced stop memory.

Start stop of process

We have start circuit of 2 ways.

ORG position start. It can start subject to original position.

Anywhere start. It is three ways of circuits.

Example)

Use ORG position memory and movement end memory.

Also make OR circuit.

Example) 2

Use master control instructions and jump instruction. (Mitsubishi)

(

M102 SupplyP&P

Start reset

Supply unit

Trable

Auto

mode

17

4-4-1

(1) Auto start circuit

Anywhere start

CRB Auto mode

CRO ORG memory

CRW Completion memorycompleted welding. etc

CRE E-STOP (normal ON)

ORG position start.

CRB Auto mode

CRO ORG memory

CRW Completion memorycompleted welding. etc

CRE E-STOP (normal ON)

CRW

CRO CRE

CRA

Start PB

CR

A

CRB

Auto run

CRW

CRO CRE

CRA

Start PB

CR

A

CRB

Auto run

CRO

ORG position

18

Cycle stop circuit

The circuit which stop at origin position.

CRB Auto mode

CRO ORG memory

CRW Completion memorycompleted welding. etc

CRE E-STOP (normal ON)

CRW

CRO CRE

CRA

Start PB

CR

A

CRB

Auto run

CRS

Cycle stop PB

CRS

CRA

CR

S

Cycle stop

19

Restart prevention circuit.

CRB Auto mode

CRO ORG memory

CRW Completion memorycompleted welding. etc

CRE E-STOP (normal ON)

Use edge-triggered differential output

Use M0 in substitution for start PB by above circuit.

CRW

CRO CRE

CRA

Start PB1

CR

A

CRB

Auto run

CRC

CRO

CR

C

Restart

prevention

Start PB1

CRC

PLS MO

(Mitsubishi PLC)

Start PB

1 scan ON

ON

start PB

out M0

20

2Actuator drive circuit

Actuator drive circuit control the same coil with auto & manual operation

circuit as parallel.

PLC output

M2

M1

PB

Y

Y2

Work clamp

Auto circuit

Manual circuit

21

Example

2 position double solenoid & motor control output puts each others

interlock of contact.

M 2 0 M 1 L S Y 1 0

Y

Wo r k c l a m p

P B

M 2 0 M 1 L S Y 1 w o r k

u n c l a m p

P B

Y

1 0

We l d i n g

c o m p l e t i o n

M

2 0

M 1 M 3

M 2 0

c o m p l e t i o n

M e m o r y b c o n t a c t

A u t o o n

s i g n a l

T h e b c o n t a c t o f r e v e r s e m o v e m e n t o u t p u t .

U n c l a m p i n t h i s e x a m p l e .

b c o n t a c t

S t a r t

W o r k c l a m p

W e l d e n d

Wo r k u n c l a m p

C y c l e e n d

O N

O F F

C o m p l e t i o n m e m o r y

Y1

Work clamp

Work unclamp

Y2

Y2

Y1

Not using this domain

22

Head down

support

Head up

support

Y

Y

Auto

Manu Manu

A

Head lower

M3 M4

Lacth-in lower

A Auto

Manu

Head up

Head upper

LS

M4 M3

Lacth-in upper

M3

M4

Y4

Y3

Head down

Head up

LS

sw

Manu sw

Control of 3 position double solenoid use supporting memory.

Output does on/off in this memory.

(3) Start/stop of process.

Refer to clause (4-2) Start condition(M101)

Auto run(CR A)

Refer(4-3) Start reset (M102)

( M103 Supply PP

Run memory

Start

Reset

1 cycle

complete

auto

run Start condition

M101 (M111)

M101

23

4 4 2 Auto running program of process. (Used MC/JP)

Supply lower LS

M106

M105

( M105 Sequence start

Supply down

Start condition

M105

M101

Chuck close Ls

M107

M106

Supply up Ls

M108

M107

Supply frontLS

M109

M108

Supply low Ls

M110

M109

Chuck open Ls

M111

M110

upperLS

M112

M111

Back LS

M112

M103

MC

K1

( MC K1

( M106 down end

chuck close

(

M107 Close end

supply up

(

M108 UP end

supply forward

( M109 forward end

srdpply down

( M110 supply lower

chuck open/

( M111 chuck open end

supply up

( M112 supply UP end

supply back

( M113 supply finih

supply complete

( MCR K1

M116

M117

M113

24

* NOTE

Step trigger takes in the sensor input as much as possible.

When the time ON of M105 to give down instruction. Supply P&P will down

accordingly,when the time receive the lower LS signal,turn off M105 by M106

to off the circuit.

When time of movement stability is necessary, Insert timer.

Cf. chart below.

The circuit which delays completion signal of chuck close.

The circuit which delays timing of chuck.

Chuck close LS

M108

M107

Supply lower LS M107

M106

( M106 Supply down end

Chuck close

M105

( T100

Chuck close delay

0.2sec

( M107

Chuck close end

supply up

K2

M106

T100

Supply lower LS M107

M107

( T100 Lower LS Stability.

0.2sec

( M106 Lower LS Stability

chuck close

K2

M105

T100

25

ORG return program of process.

When there is all once ORG return memory in main program

Put it program of process like chart below.

NOTE

Consider ORG return condition,start condition,stop/reset condition

ORG return

SW

Supply PP

Drive/run

All ORG return

instruction

( M120 supply PP

ORG return

Manu

mode

26

Interface program.

If movement of turntable is completed, supply P&P starts.

Off the start condition of turntable by M120 upon completion of supply.

When a work does not come in supply P&P, a turntable steps in the cycle.

Interlock assumes that automatic & manual operation is common.

Trouble detection program of process.

Gather a trouble to detect by each process.

Start

( M120

Turntable

Prohibit start

M112

Supply backward LS

( M121 supply P&P/Turntable

Not interaction

turntable

Move complet

Turntable ORG

( M200

turntable supplyP&P

Start signal

Supply P&P

start

M105 M103

M120

Supply upper LS

M105

M200

27

Actuator drive program

Solenoid valve

Cf. Chart below.

A state of actuator is maintained even if change a mode.

If interlock is complete by manual operation, it is all right even if there is a

mistake in an automatic program.

( Y00

Chuck down

down

SW

M105 M103

M109

Y0

M107 M111 M10 Y01

manu

P&P backward

LS

table

ORG

manu

PP forward

LS

UP manu

SW

Return ORG

(

Y01

Chuck up

UP

SW

M107 M103

M111

Y1

M105 M109 M10 Y00

Manu

PP backward

LS

Table

ORG

Manu

PP forward LS Down manu

SW

Return ORG

Interlock

28

MOTOR

Chart below is a circuit of turntable. (Table 1 cycle at motor 1 round.)

Manual mode.

If manu SW keep on, a motor stop 1 round.

( M300 Motor ORG sensor

OFF detect.

( M301 Motor 1 round memo

( Y10 Turntable ON

M301

M301

M301

MOTOR ORG

PLS

Auto run

Turn signal

Turn

SW

Manu

Motor ORG

Auto run

Turn signal

Turn

SW Manu

Interlock

Cam drive Inching 1 round stop

Auto program Y

MM1

MM1

ORG sensor

Manu PB

Auto SS

Cam motor

Interlock

MM1

ORG OFF Memo

ORG sensor

29

6 Other circuit

1) Flip-Flop circuit

Used 1 timer.

T T

A B

B

B

A

T

A

B

30

2 Shift circuit * Note* Write it from a last step.

Shift timing

Shift PB

Shift timing

Shift PB

Shift PLS

MM20

MM10

Shift reset PB

MM20

MM

(N-1)

MM

N

MM

(N+1)

MM

(N+1)

MM2

MM3

MM1

MM2

MM1

Work detect sensor

MM1

MM3

MM2

(3)

(2)

(1)

MM

(N-1)

MM

N

MM10

MM20

Auto

MM10

Auto

MM20

(N-1)

(N)

MM20

31

Sample program

1 : Main program

T1

( TO Flicker ON timer

0.5sec

(

M1 Flicker ON

K5

( MO Dummy anyoff

MO

( T2 Initial timer

O.2sec

K3

( M2 Initial PLS

PLS

( M3 Trouble reset

( M7 PLC OK

( M8 E-STOP

( M9 air pressure down

T0

MO

T2

( T1 Flicker OFF timer

O.3sec

K3

M50

Run Reset

PB

I/O

Unit error

Self-che

error

CPU run

1 scan ON T2

M8

reset

E-STOP

Air pressure sensor

Reset

Drive prepare

PB

PC OK E-STOP Air pressure down

M9

M10

M7 M8 M9

( M10 drive prepare ON

32

T3

( M11 auto mode

( Y auto lamp

( T3

M10

( M12 Manu mode

( Y Manu lamp

M10

T4

auto manu

M12

M50

auto manu

M11

( T4

M70 M120 M170

supply

Unit ORG

Take out

Unit ORG

turntable

ORG

( M20 All ORG

M107

M117

M157

M167

M190

Supply P&P

trouble

Supply C/V

trouble

Take out P&P

trouble

Take out C/V

trouble

Turntable

trouble

( M30 Trouble

M108

M118

M158

M168

M191

Supply P&P

trouble

Supply C/V

trouble

Take out P&P

Trouble

Take out c/V

trouble

turntable

trouble

( M31 Trouble 2

33

( M41 Stop

( M42 Stop OK

( M50 Auto start

( Y Auto start lamp

( Y Stop lamp

( M60 All return ORG

( T61

M50 M11

M35 M30

M31

M41

M40

M50

M42 M11

M50

M12 M10 M35 T61

M60 M20

Stop

Auto Run

Erch process stop

Auto Manu

Start condition Start PB Stop OK

Return ORG

SW

Manu

Drive prepare ON

Process stop

All ORG

Trouble 1

Trouble 2

34

1-1 : PROCESS 1 PROGRAM (Supply P&P)

( M73 supply run

( T70

M50

M73

M72 M81

K1

Auto run Run condition

Start reset

( T71 supply down

( M76 Lower deray

Supply lower LS

M76

M77

T71

( M77 Supply UP

Chuck open LS

M77

M78

( M78 forward

M78

M79

( M72 Start reset

(

M71 supply unit run

( M70 supply PP

ORG

BWD LS UP LS

Chuck open LS

M40

M40

M40

Supply unit ORG

Work arrival

PR

Table work

Find PR

table

complete

Cycle stop

Supply unit run

M11

M107

M10

Auto mode

Time over

prepare

M71

Supply P&P cycle end

K200

M73

( MC K1

Start condition

M71 M76

M75

M75

M76

( M75 supply start

Supply UP LS

M77

condition

35

( T72 Supply FWD delay

( M81 Supply UP

Lower LS

M80

M81

T72

( M80 Supply chuck close

Chuck close LS

M81

M82

( M82 Supply BWD

M82

M83

M79

M80

Supply UP LS

M81

( M79 Supply down

Supply FWD LS

M79

M80 M78

M83

Supply lower LS

M82

M60

M73

ORG return

SW

M12

Manu mode Supply run

All ORG return

K2

( M83 cycle end

( MCR K1

( M90 Supply P&P

ORG return

36

( T72 Supply lower delay

( M81 Supply UP

Supply lower LS

M80

M81

T72

( M80 Chuck open

Chuck open LS

M81

M82

( M82 Supply BWD

M82

M83

M79

M80

Supply upper LS

M81

( M79 supply down

Supply FWD LS

M79

M80 M78

M83

Supply lower LS

M82

M60

M73

ORG return

SW

M12

Manu mode Supply run

Org return start

K2

( M83 Supply cycle end

( MCR K1

( M90 Supply P&P

ORG return

37

1-2 : Interface between processes

( M96 Prohibit table start

Suplly BWD LS

M96

M73 M82 M75

(

M97 Supply P&P--Table

interlock

( M98 Prohibit C/V start

M98

M73 M78 M75

Supply upper LS

(

M99 Supply P&P

Turntable

Interlock

Supply UP LS

Supply FWD LS

38

1-3 : Trouble detection program

M78

M100

M101 M3

M80

M102

M103 M3

T70

M107 M3

M101

M103

M0

M107

M108

M109

Work arrival LS

Turntable

Work detect PR

(

PLS M100 chuck error

Detect timing

( M101 chuck error

Trouble 2

( PLS M102 work fall

Detect timing

( M103 Work fall error

Trouble 2

( M107 Supply P&P error

Trouble 1

(

M108 Supply P&P error

Trouble 2

( M109 Supply P&P error

Trouble 3

( Y

Supply trouble lamp

39

1-4 : Actuator drive program

( Y Supply UP/DOWN

Down

M75 M73 M77 Y M81

Supply UP

Manu PB

Turntable

Work detect LS

Supply FWD LS

Supply BWD LS M12

Manu mode

M75

Supply

Down PB

Manu mode

M12

Y

M77 M73 M75 M79

M81

M90

Y

Supply

Down PB

Manu

M12

M12

Manu mode

Supply down

(

Y supply UP/DOWN

UP

M90 M90

M12 M12

Manu mode Manu mode

Supply up LS

Supply FWD

PB

Y

( Y Supply FWD

M82 M73

M90

Y

Manu mode

M12 M12

Manu mode

Supply FWD

PB

Supply up LS

Supply BWD

PB

( Y Supply BWD

Supply BWD

PB

Y

40

M76 M73 M80

Y

Manu mode

M12 M12

Manu mode

Chuck open

Supply upper

LS

chuck

close PB

( Y Chuck close

M82 M73 M76

M90

Y

Manu mode

M12 M12

Manu mode

Chuck close

PB

Supply up LS

Chuck open

PB

( Y Chuck open

M90

Lower LS

Lower LS

41

1-4 : Process 2 program (Supply C/V)

( M110 Supply C/V start

( T110 Lack of work

( M117 Trouble 1

Supply P&P

Prohibit C/V

M98 M107

Trouble 1

Work detect

PR

M50

M0

M0

T110

M110

M50 M99

M12

Run

Supply interlock

manu

C/V ON

PB

K300

( M118 Trouble 2

( M119 Trouble 3

(Lack of work)

( Y trouble Lamp

( Y Supply C/V ON

condition

42

2-1 : Process 3 program (Take out P&P)

BWD LS

Upper LS Chuck open

( M120 Take out P&P

ORG

ORG

M120

M41

M123

Take out

Work detect

Table

Work detect

Table

Complet

Cycle stop Take out run

M11 M10

Auto mode

Trouble 1

Drive prepare

(

M121 Take out P&P

Start condition

(

M122 Take out

Run reset

M50 M121

M122 M131

Auto run

Start condition

Take out P&P

Start reset Cycle END

M123

( M123 Take out RUN

( T120

K300

K2

M121

M125

Start condition

( M125 Take out start

Take out

M125

M126

M127

T121

( T121 Take out lower

Delay

(

M126 Take out

Chuck close

K2

( M127 Take out up

Chuck close LS

M126 M128

M127

Upper LS

M127

M129

M128

( M128 take out FWD

MC K2

Run reset

Lower LS

43

(

M129 Take out down

FWD LS

M126

M130

M129

( T122 Take out lower

delay

Lower LS M129 M131

M130

( M131 Take out UP

Chuck close

M130 M132

M131

( M132 Take out BWD

Upper LS

M131

M132

M131

( M133 Take out

Cycle end

Lower LS M132

M133

( M140 Take out P&P

Return ORG

ORG

Return SW

M12

M123

M60

M122

( M130 Take out

Chuck close

K2

( MCR K2

Manu mode

Run

All ORG return SW

LS

44

( M146 Turn table

Start prohibition

M126

M123

M146

( M147 Take out P&P

Turn table interface

FWD LS

M126

M130

( Y Take out P&P

Down

M125

M123

M127 M140 M131

Take out

UP SW

Take out c/v

Work detect

Take out

FWD LS

Take out

BWD LS M12

Manu mode

M129

Take out

Down SW

Manu mode

M12

Y

M127 M123 M125

M129

M131

M140

Take out

UP SW

Manu mode

M12

M12

Manu mode

Take out

Down SW

M128 M123 M132

M140

M12 M12

Manu mode

Take out

Take out

FWD SW

Y

( Y Take out P&P

FWD

M125

Upper LS

( Y Take out P&P

UP

Y

Take out

BWD PB

Take out

Take out

Manu mode

Upper LS

45

M132

M123

M128

Take out

FWD SW

( Y Take out P&P

BWD

M126

M123

M130

M140 FWD LS

Chuck

Close PB

Y

Take out P&P

Chuck close SW

M130

M101 M126

FWD LS

chuck

Open SW

M140

Take out P&P

Chuck close SW

Manu mode

M12

Take out

BWD SW

M140

Y

( Y Take out P&P

Chuck close

BWD LS

( Y Take out P&P

chuck open

LS

Y

Manu mode

M12

Manu mode

M12

Manu mode

M12

Manu mode

M12

Manu mode

M12

46

Trouble Detection Program.

M150

M3

Table work

Detect PR

( M151 Chuck error

M151

M152

M3

Take out c/v work

Detect PR

( M153 Take out work drop

M153

M3

( M157 Take out P&P

Trouble

M157

M153

M157

M158

M159

M0

M128

(

PLS M150

Chuck error timing

(

PLS M152 Take out work

drop detect timing

( M158 Take out P&P

Trouble 2

( M159 Take out P&P

Trouble 3

( Y Take out

Trouble lamp

M130

T120

M151

47

Process 4 program ( Take out C/V)

M3

Take out

Trouble 1

(

M167 Take out C/V trouble 1

(Take out C/v full

M163

M0

MO

M160 M50

Take out c/v

Manu SW M12

Manu mode

T160

M167

( M160 Take out C/V start condition

(

T160 Take out work full

( Y Full Lamp

( M168 Take out C/V trouble 2

( M169 Take out trouble 3

( Y Take out C/V ON

Work detect

48

Process 5 program (Turn table)

Table OPRG

M170

M41

M123

Take out

Work LS

Inter lock Cycle stop

Table start

M11

M10

Auto mode

Trouble.1

Prepare

(

M171 Turn table

Start condition

( M172 Turn table

Start reset

M171

M172 M176

Table start

condition

Table start

Reset

Table

Cycle END

M173

(

M172 Turn table start

( M170

K300

M176

M178

( M178 Table turn END

Supply start

M125

M179

ORG LS

M96 M146

M30

M50

Auto start

( M170 Table ORG

ORG LS

M176

M175 M173

ORG LS

Table ON

Manu SW

M12

Manu mode

M180

Return ORG

( M175 ORG OFF

( M176 1 turn memo

M75

ORG LS

M176

ORG LS

( M179 Table turn END

Take out start

M12

M60

Turn table

Start

( M180 Table Return ORG

M173

Manu mode

ORG return

Manu SW

All ORG

Return Start

49

Reference of mode setting. (push button SW).

Principle

When it is auto running, selecting is not possible.

M50

M50

Auto PB

( M11 Auto mode

M11

Manu PB

OFF line PB

Auto start

M10

Prepare

M50

M50

Off line PB

( M12 ON line mode

M12

Auto PB

Manu PB

M10

Prepare

M50

Manu PB

( M11 Manu mode

M13

AUTO PB

ON Line PB

M10

Prerare

50

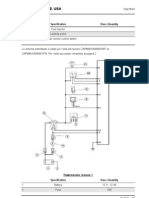

NEC

M71

(M71

M72

(M73

M74

T70 K200

(CJ P0

MC K1

LS LS LS

M70

No.1

M10

M11

M50

M71

P&P

M81

M90

M12

M73

M73

P&P

M72

M12

M73 M74

M73

M41 M73

M107

51

M75

M70 K2

M76

M77

M78

M79

T171 K2

M80

M81

M82

M71 M76

M75

LS

M75 M77

M76 T100

LS

M76

M78

LS

M77

M77 M79

M78

LS M78 M80

M79

LS

M79 M80

M80 T71

M82 M80

LS

M81

LS M8 M83

M82

52

LS

M82

M83

P0 No.

SW

M12

M74

M80

M83

MCR K1

(M90 P&P

LS LS LS

1000

1003

No.1

1001

P&P

10121

1003

1003

1000

1001

1002

1003

53

(1200

(JMP 00

OFF

1004

1005

1004

(T100

(1011

(1012

1003 1002

PP

1003 1200

1003

(IL

1003

1001

1004 1200 1006

T100

LS

1005

LS 1010 1012

1011

LS 1010

1012

(ILC

1005

K2

54

(1100 PP

SW

(JME 00

55

Re-try program example of supply P&P.

Supply

ORG

M20 M41

M88

C/V

Work detevtLS

Table

Work detect

Table

Moved end

RUN

prohibi

P.P

2

M60 M73

(

M60 Supply

Run condition

M50 M11

P.P

1

M61

( M61

( T60

K300

MC

K1

(M63

LS

M64

K2

M64

M65

M66

LS

M65

M66

M67

LS

M66

M67

M63

LS

M143

Run

Moved

M61

M61

( MC K1

M60 M64

M63

C69 M80 M67

LS

M63 M65

T61

(T61

0.2

(M64

(M65

(M66

(M67

M68

M68 M71

56

M66

M68

M67

LS

(M68 OK

M69

M68

M69

M70

LS

(M69

M69

M70

M71

LS

(M70

(M71

LS M72

M71

M80 M67

M71

M72

M73

LS

(M72

M72

M73

LS

(M73

M70

(MCR K1

M63

(PLS M75

57

M67

M80

(M80

20N

M61 M72 M63

M76

M75

M58

M80

M2

C69

M3

ON

OK

R

CK

K2

C69

(M76

ON

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Manual For EOT CranesDocument39 pagesManual For EOT CranesManish Jha67% (12)

- ADR131 AmDocument53 pagesADR131 Amapi-3728789100% (2)

- Protective RelaysDocument51 pagesProtective RelaysAkash SinghNo ratings yet

- Vbuilder Manual PDFDocument303 pagesVbuilder Manual PDFantoniocastaedaNo ratings yet

- Electrical SwitchgearsDocument63 pagesElectrical Switchgearsmuaz_aminu142292% (12)

- Introduction To Power System ProtectionDocument52 pagesIntroduction To Power System ProtectionHuzaifa WasimNo ratings yet

- Radial Feeder ProtectionDocument26 pagesRadial Feeder ProtectionLeo GaghanNo ratings yet

- English Mains 2000Document6 pagesEnglish Mains 2000Prasad TlnsNo ratings yet

- Civils Prilims 2000 PaperDocument16 pagesCivils Prilims 2000 PaperPrasad TlnsNo ratings yet

- Enlish Mains 1998Document12 pagesEnlish Mains 1998Prasad TlnsNo ratings yet

- English Mains 1997Document11 pagesEnglish Mains 1997Prasad TlnsNo ratings yet

- Ias Exam PatternDocument2 pagesIas Exam PatternPrasad TlnsNo ratings yet

- English Civils Paper 2002Document3 pagesEnglish Civils Paper 2002Prasad TlnsNo ratings yet

- Preliminary Examinations: 2. Main ExaminationDocument3 pagesPreliminary Examinations: 2. Main ExaminationSagar B LukhiNo ratings yet

- Gs Test 1 Indian Polity Constituion Current Affairs 2010 Vision Ias Module I II III IV VDocument4 pagesGs Test 1 Indian Polity Constituion Current Affairs 2010 Vision Ias Module I II III IV VPrasad TlnsNo ratings yet

- Syluubus All Subjects For IasDocument2 pagesSyluubus All Subjects For IasPrasad TlnsNo ratings yet

- Syllubus of Ias For Electrical Enginnering PrelimsDocument5 pagesSyllubus of Ias For Electrical Enginnering PrelimsPrasad TlnsNo ratings yet

- Civil Services Main Examination Timetable 2009Document1 pageCivil Services Main Examination Timetable 2009Prasad TlnsNo ratings yet

- An Introduction To Computer - 2Document48 pagesAn Introduction To Computer - 2Prasad TlnsNo ratings yet

- IES MarksDocument4 pagesIES MarksSupersittu SittuNo ratings yet

- 4.wave GuideDocument54 pages4.wave GuidePrasad TlnsNo ratings yet

- Fuse Box Diagram Mercedes-Benz C-Class (W203 2000-2007) MiniDocument6 pagesFuse Box Diagram Mercedes-Benz C-Class (W203 2000-2007) Minimitoloj410No ratings yet

- Wired Start Circuit Test Points (11-2010)Document2 pagesWired Start Circuit Test Points (11-2010)agvassNo ratings yet

- WECON LX3V ModulesDocument8 pagesWECON LX3V ModulesJorriqueNo ratings yet

- 3gts250 Workshop Manual-3Document109 pages3gts250 Workshop Manual-3Fernando MattinaNo ratings yet

- 1SFA898112R7000 pstx210 600 70 SoftstarterDocument4 pages1SFA898112R7000 pstx210 600 70 SoftstarterRaul EirisNo ratings yet

- 4.5" Dial Temperature Swichgage SPL and 45TE SeriesDocument4 pages4.5" Dial Temperature Swichgage SPL and 45TE SeriesAlejandroMuñozNo ratings yet

- Siprotec: Communication Module DNP 3.0 Bus Mapping / Point ListsDocument36 pagesSiprotec: Communication Module DNP 3.0 Bus Mapping / Point ListsChomsaniNo ratings yet

- Aux Boiler Dosing Pump (New)Document112 pagesAux Boiler Dosing Pump (New)Panait TibiNo ratings yet

- GAM900/GAM900S: Acceleration Precisely Measured and Safely MonitoredDocument8 pagesGAM900/GAM900S: Acceleration Precisely Measured and Safely MonitoredrrNo ratings yet

- Report On Industrial TrainingDocument60 pagesReport On Industrial TrainingAnish Sarkar100% (1)

- 7SR11 and 7SR12 Argus Catalogue SheetDocument24 pages7SR11 and 7SR12 Argus Catalogue SheetIsai Soledad CervantesNo ratings yet

- Mechanical Relay-Type PDFDocument17 pagesMechanical Relay-Type PDFSaleCvetkovicNo ratings yet

- Self Powered Relay-CGI14SEnglishDocument16 pagesSelf Powered Relay-CGI14SEnglishjoydip.dgp2152100% (2)

- Wizard 900/900E Digital Readout Operations ManualDocument198 pagesWizard 900/900E Digital Readout Operations ManualnorbertNo ratings yet

- Sensor Based Energy Conservation System For Corporate Computers and Lighting SystemDocument43 pagesSensor Based Energy Conservation System For Corporate Computers and Lighting SystemSaravanan ViswakarmaNo ratings yet

- Arrancadores Con EnvolventeDocument16 pagesArrancadores Con Envolventediego martinezNo ratings yet

- 1TLS gd2Document6 pages1TLS gd2Constantin MoldoNo ratings yet

- Chapter 1 - Ladder Diagram FundamentalsDocument5 pagesChapter 1 - Ladder Diagram FundamentalsRitesh SharmaNo ratings yet

- C-9 Heui System Power SuppliesDocument14 pagesC-9 Heui System Power SuppliesJean-Jacques OuandaogoNo ratings yet

- Schneider MiCOM P442 E0 Line User Manual ENUDocument6 pagesSchneider MiCOM P442 E0 Line User Manual ENURaúlEmirGutiérrezLópezNo ratings yet

- Lock - Out Relay PDFDocument4 pagesLock - Out Relay PDFFatholla SalehiNo ratings yet

- GE Fuji Drives USA: Adjustable Frequency DriveDocument2 pagesGE Fuji Drives USA: Adjustable Frequency DriveJosé Luis Torres GNo ratings yet

- Delta Wiring GuidelinesDocument62 pagesDelta Wiring GuidelinesLeonardo MartinsNo ratings yet