Professional Documents

Culture Documents

Manual Comando Control Air Hd2

Uploaded by

Brian SchmidtOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual Comando Control Air Hd2

Uploaded by

Brian SchmidtCopyright:

Available Formats

Bosch Rexroth Corporation, Pneumatics

1953 Mercer Road, Lexington, KY 40511-1021

Tel: 859-254-8031 / Fax: 859-254-4188 or 800-489-4188

Email: pneumatics@boschrexroth-us.com

Web: www.boschrexroth-us.com

HD-2 CONTROLAIR

VALVE

Service Information

Description of Models

The HD-2 Type Controlair Valves are handle oper-

ated 4-way, exhausted center, pressure control

valves.

The typical unit contains two directional control 3-way

side valves and a pressure graduating portion that is

arranged to increase, decrease or maintain air pres-

sure to a separate delivery line. In neutral position,

both 3-way side valves exhaust both delivery lines. A

movement of 10 degrees either side of center posi-

tion opens the appropriate side valve and directs

pressure to the indicated outlet port. Continued

movement past 10 degrees up to full travel, or 46

degrees either side of neutral continues to actuate

the pressure graduating portion to deliver a gradu-

ated pressure according to the valve of the control

spring.

Models

There are six models with similar valve functions, but

different handle operating characteristics.

HD-2-X Controlair Valve -Handle is spring returned

to neutral position from all positions in the handle

travel. Some special models exist. See notes on

Identity schedule on page 7.

HD-2-LX Controlair Valve - Handle is spring re-

turned to neutral position from all positions except at

the maximum pressure setting on both sides of cen-

ter. The handle is held in both extreme positions by

a mechanical detent.

HD-2-FX Controlair Valve - Handle is equipped with

a friction brake that will hold the handle in any posi-

tion selected in the handle travel.

HD-2-XS Controlair Valve - Handle detents in both

maximum pressure positions. The handle is spring

returned to neutral position from all other positions in

the handle travel. Graduated pressure to port (8) is

only delivered in one direction of the handle move-

ment.

HD-2-FXR Controlair Valve - Handle function is

similar to the HD-2-FX Valve. The difference is the

two directional valves are supplied instead of being

exhausted when the handle is in the neutral position,

HD-2-LS Controlair Valve- Handle holds in full

travel, neutral and detent positions.

Table of Contents Page

Description of Models 1

Warnings 2

Technical Data 2

Installation 2

Maintenance and Repair 2

Outline Dimensions 3

Descriptions of Operation 4

Maintenance and Repair 5

Graphical Symbol 6

Identity Schedule 7

Exploded View 8

Part List 9

Repair Kit List 10

Testing

Function 11

Pressure Range 11

Leakage 11

Flow Capacity 11

Response 11

Mechanical Detents 11

Test Setup 11

Test Diagram 12

GENERAL MAINTENANCE AND REPAIR

RECOMMENDATIONS

Maintenance periods should be scheduled in accor-

dance with frequency of use and working environ-

ment of the Controlair Valve.

All valves must be visually inspected for wear and

given an In System operating performance and

leakage test at least once a year. If these visual ob-

servations indicate valve repair is required, the valve

must be removed immediately and repaired.

A major overhaul is recommended at one million

cycles. However, where frequency of use is such

that it would require more than two years to obtain

the one million cycles, the valve must be overhauled

at the two year period.

When it is determined that the Controlair Valve re-

quires a major repair as a result of the one million

cycles, one year routine inspection or the two year

service period has elapsed, the device must be dis-

assembled, cleaned, inspected, parts replaced as

required. The valve then must be tested for leakage

and proper operation prior to installation, refer to the

Major Repair and Maintenance Instructions and test

procedures.

Notice that the operating portion of the valve can be

removed without disturbing the pipe connections by

just removing the (3) screws that hold the pipe

bracket to the valve.

No special tools are required to maintain the Contro-

lair valves, with the exception of internal snap ring

pliers.

One complete Controlair valve should be kept in

stock for every (4) valves in service. During the

maintenance period, replacing the complete valve

with the stand-by unit reduces production down time

and affords inspection and replacement of parts at a

more appropriate time and favorable location.

WARNING: INSTALLATION AND

MOUNTING

The user of these devices must conform to all

applicable electrical, mechanical, piping and

other codes in the installation, operation or re-

pair of these devices.

INSTALLATION! Do not attempt to install,

operate or repair these devices without

proper training in the technique of working

on pneumatic or hydraulic systems and de-

vices, unless under trained supervision.

Compressed air and hydraulic systems con-

tain high levels of stored energy. Do not

attempt to connect, disconnect or repair

these products when a system is under

pressure. Always exhaust or drain the pres-

sure from a system before performing any

service work. Failure to do so can result in

serious personal injury.

MOUNTING! Devices should be mounted

and positioned in such a manner that they

cannot be accidentally operated.

Installation and General Mainte-

nance Recommendations

Before installing the Controlair

Valve, all air

lines in the system should be cleaned to re-

move all dirt, moisture or contamination.

A strainer is furnished on the inlet port to pro-

tect the valve from large particles or foreign

matter in the supply line. To insure long, trou-

ble-free service, a 10 micron or better filter

should be installed in the supply line to the

valve.

The HD-2 Controlair Valve is designed for

panel mounting. The valve less the pipe

bracket can be installed from the top of the

panel. Refer to the installation view for panel

opening dimension. Allow suitable clearance

for installing or removing of the (3) pipe bracket

screws which are 2 1/8 long.

Technical Data:

Max. Operating Pressure 200 PSI (13.8 Bar)

Admissible Mediums Clean & Dry Compressed Air

Operating Temperature -40 to 160 F( - 40 to 71 C)

Hysteresis 1 1/2 Psi

Control Pressure Range Ref. Identity Chart

Pressure Change 1/2 Psi. Increments

Mounting Flanged Plate

Port Size 1/4-18 NPTF

Materials

Controlair Valve

Housing & Body Die Cast Aluminum

Internal Parts Brass, Rubber, Aluminum, Steel,

Plastic and Hytrel

Weight 9 Lb. (4.1 Kgs.)

Installation and General Maintenance Recommendations

Page 2

Page 3

Outline View

HD-2 TYPE CONTROLAIR

VALVE

HD

Note in the diagrammatic view that supply pressure is connected to

port (2) and this supply pressure is directed to the pressure-graduating

portion and the side control valves. The delivery graduating portion is

directed to port (8). The delivery from the side valves is directed to out-

let ports (1) or (3).

With the handle in neutral position both outlet (1) & (3) ports are open

to atmosphere through their respective side valve and port 8 is at mini-

mum pressure.

Movement of the handle through the first 10 degrees of travel from

neutral operates one of the 3 way side valves to connect the supply

pressure from port 2 to the appropriate outlet port (1) or (3), and the

graduating portion to port (8).

Movement of the handle to 10 degrees either side of center position

causes the dual cam to push down on the pressure control plunger

closing the exhaust valve and opening the upper supply valve, which

allows air to flow to port (8) and the upper diaphragm chamber. As the

pressure builds up in the delivery line Port (8) and through the sensing

port orifice it deflects the control diaphragm downward, compressing

the control spring. When sufficient diaphragm deflection is obtained to

allow the upper supply valve in the pressure control portion to close,

the pressure in the delivery line is held to that value.

The value of the pressure delivered to the outlet port is proportional to

the pressure graduating portion plunger movement. This movement in

turn is controlled by the cam contour and is proportional to the handle

travel.

The HD-2 Controlair Valve will automatically compensate for air pres-

sures changes. These air pressure changes can be caused by line

leakage, temperature change or load feedback. If air pressure at port

(8) increases over that called for by the handle position, the diaphragm

in the control portion will deflect downward opening the lower exhaust

valve and exhausting air until the original setting is obtained. If the

pressure drops below that called for by the handle position the de-

creased force on the diaphragm will allow the control spring to force

the diaphragm upward, opening the upper supply valve to restore the

set pressure.

The range of pressure is controlled by the strength of the diaphragm

spring. Various values are available as shown on the Identity Schedule

on page 7.

Description of Operation

For HD-2 Controlair

Valve

Page 4

Page 5

Repair and Maintenance Instructions

Repair and Maintenance Instructions

When it has been determined that the Controlair

Valve re-

quires repairs, the following general instructions are recom-

mended.

Disassembly, Cleaning and Lubrication

Completely disassemble the Controlair valve. Wash all metal

parts in a non-flammable solvent. Rinse each part thoroughly

and blow dry with low pressure air.

Inspect and clean the inlet filter Item #2 and gasket Item #3

(older models had multiple gaskets that are still supplied in the

repair kits). Be sure all passages in the body and pipe bracket

and sensing port orifice in top of the diaphragm chamber are

clean and unrestricted.

To remove cam set screw Item #55 use of an impact wrench

(set soft) will break it loose to remove the cam and shaft form

cam housing.

Examine all parts carefully. Replace all rubber parts and all

worn or damaged parts. The use of repair kits is recom-

mended.

Reassemble

Refer to exploded Parts and Assembly Views.

Valves should always be reassembled using new rubber

parts.

Lubricate all metal to metal wear surfaces with Lubriplate

107 Grease. Lubricate all the rubber parts, except the dia-

phragm with Dow Corning No. 55 Pneumatic Grease.

The exhaust valve and seat if not replaced should be pol-

ished for minimum leakage using a 600 grit lapping compound.

Be sure to clean these parts prior to installing in the valve.

Installing the cam set screw Item #55. The cam set screw

must be fully seated into the drill point location on the cam

shaft, Items #62 or 63. When installing set screw Item #55 use

a thread locker like Loctite TL242.

Installing the handle Item #53, seat the handle into the yoke,

Item #52 before installing the nut, Item #51.

Do not over torque the cap nut, Item #60.

Adjustments

Screw, Item #40 varies the graduated output pressure set-

ting. Screws Item #23 adjust the opening of the side valves

and screw, Item #19 aligns the follower Item #18 with the cam

Item #61. The nut Item #50 adjusts the brake tension on the

HD-2-FX versions.

Side Valve Lever Adjustments

With air supplied to the valve, turn adjusting screw Item #40

in or until the control spring Item #29 is slightly compressed.

Remove the snap rings and screens Item #3. Move the Contro-

lair Valve handle Item #53 back and forth, both sides of the

neutral position, observing the action of the levers Items #20 &

22. The side valves should be fully open after the handle

moves the first 10 degrees of travel.

Move the control handle to a maximum pressure position.

With 3/32 Allen Wrench, back out adjusting screws Items #23

of the operated lever Items #20 or 22 just far enough to crack

the exhaust valve so that gage in the output line starts to show

a drop in pressure. From this point, turn the adjusting screw in

a full three (3) turns. This will open the inlet valve of the side

valve to its maximum capacity.

Move the handle to the other extreme position and repeat

these adjustments on the other side valve lever.

Graduated Output Pressure Adjustments

Adjusting screw Item #40 varies the maximum pressure set-

ting. Turning the adjusting screw in raises the maximum pres-

sure. Turning the screw out decreases the maximum pressure.

The maximum control pressure adjustment should not exceed

the maximum control pressure shown in the Identity Schedule

for that part number. (Control Springs are color coded).

The maximum output pressure rating can be changed by

changing the control spring Item #30.

With air supplied to the valve, move handle from neutral to

full travel position and hold. Adjust graduating valve screw Item

#40 to obtain the maximum control pressure per Identity

schedule. Move handle back to neutral position and note deliv-

ery line is exhausted to zero. Move handle to full travel position

in the opposite direction and the delivery pressure should be

the same as the other side. If the delivery pressure is higher or

lower by 2 to 3 psi it can be corrected by adjusting the cam dog

Item #18 with adjusting screw Item #19. Move the handle back

to neutral position and note delivery line is exhausted to zero.

Cam Dog Adjustment

The eccentric cam dog screw Item #19 aligns the cam fol-

lower Item #18 with the rise in the cam item #61. If the pres-

sure setting is not within 2 to 3 psi from one full handle travel

position to the other, the difference can be compensated for by

turning the eccentric screw Item #19 either clockwise or

counter-clockwise. This adjustment is accessible from the out-

side of the valve through the notch under the panel flange us-

ing a long flat bladed screw driver.

The following procedure is recommended: move the valve

handle to Full Travel in one direction (on detented models

handle should be placed in detent position). Observe the out-

put gage and note the pressure. Move the handle to the oppo-

site position, turn the eccentric cam follower screw Item #19 to

half way between the pressure difference. Continue adjustment

until delivery gages (1 and 3) match within 2 to 3 psi of each

other for related handle position.

Special Preload Setting

This settings calls for a predetermined delivery pressure

when the handle is moved 10 from neutral in either direction.

Place handle 10 from neutral in either direction. Turn adjust-

ing screw Item #40 in until the gage reads the desired preload

pressure. Move the handle to the maximum pressure position.

The delivery gage should read, preload pressure plus the

range value of the control spring within 3 psi. Check handle

setting in the opposite direction.

Force Brake Adjustment

The handle force of the HD-2-FX Controlair Valve can be

varied by adjusting nut Item #50 on the brake shoe holder Item

#47. This adjustment increases or decreases the force re-

quired to move the handle in any position of the handle travel.

This adjustment is normally made on the cam housing por-

tion before assembling to the control portion. Factory setting is

8 lbs.

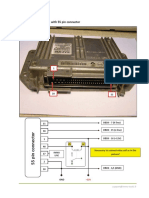

Page 6

DIAGRAMMATIC VIEW

VALVE

SYMBOL

HD-2 CONTROLAIRVALVE

IN

1

2

3

NEUTRAL

FULL TRAVEL

FULL TRAVEL

ADJ USTING SCREW

SIDE VALVE (3-WAY)

8

1

2

3 8

DIAPHRAGM

RANGE CONTROL SPRING

ADJ USTING SCREW

EXHAUST PORT

EXHAUST VALVE

SUPPLY VALVE

INLET & EXHAUST

VALVE UNIT

SIDE VALVE (3-WAY)

ADJ USTING SCREW

DUAL CAM

10 10

SENSING PORT ORIFICE

LEGEND - PIPE BRACKET

2 - SUPPLY-IN

8 - GRADUATED-DELIVERY

1 - SIDE VALVE-DELIVERY

3 - SIDE VALVE-DELIVERY

HD-2 IDENTITY SCHEDULE

Model Complete Part Control Pressure Control Spring & Color Cam Portion Valve Portion Remarks

Number Range (PSI) Code (Ref. #29) *Complete **Complete

P 050973-00001 0 - 65 P55442 Brown 850258 P 055583-00001

P 050973-00002 0 - 100 526749 Yellow 850258 P 055583-00002

HD-2-X

P 050973-00003 0 - 125 540577 Light blue 850258 P 055583-00003

P 050973-00004 0 - 150 P55441 Red 850258 P 055583-00004

P 050973-00005 0 - 15 P60293 White 850258 P 055583-00005

P 050970-00001 0 - 65 P55442 Brown 850260 P 055883-00001

P 050970-00002 0 - 100 526749 Yellow 850260 P 055583-00002

P 050970-00003 0 - 125 540577 Light blue 850260 P 055583-00003

HD-2-FX

P 050970-00004 0 - 150 P55441 Red 850260 P 055583-00004

P 063512-00001 0 - 65 P55442 Brown 850260 P 055583-00001 Note 2

P 063512-00002 0 - 100 540577 Light blue 850260 P 055583-00002 Note 3

P 064924-00017 15 - 70 P60291 Orange 850260 P 055583-00017 Note 4

P 066514-00001 0 - 65 P55442 Brown P66515 P 055583-00003 Note 1

P 068503-00001 0 - 65 P64834 Silver P66515-0001 P 055583-00022 Note 5

P 050972-00001 0 - 65 P55442 Brown 850431 P 055883-00001

HD-2-LX

P 050972-00002 0 - 100 526749 Yellow 850431 P 055583-00002

P 050972-00003 0 - 125 540577 Light blue 850431 P 055583-00003

P 050972-00004 0 - 150 P55441 Red 850431 P 055583-00004

P 055449-00001 0 - 65 P55442 Brown P55592 P 055883-00001

HD-2-LS

P 055449-00003 0 - 125 540577 Light blue P55592 P 055583-00002

P 055449-00004 0 - 150 P55441 Red P55592 P 055583-00015

HD-2-FXR

P 051868-00001 0 - 65 P55442 Brown P51870 P 055883-00001

HD-2-XS P 067556-00001 0 - 65 P55442 Brown P67555 P 055883-00001 Note 6

Cam Portion - less valve portion, pipe bracket, screws and nameplate

** Valve Portion - less pipe bracket, screws and cam portion.

Note 1 - Same as P 050971-00001 except items 38, 52 & 53 are chrome plated (refer to page 8).

Note 2 - Same as P 050971-00001 except external surfaces are painted with black epoxy paint.

Note 3 - Same as P 050971-00003 except external surfaces are painted with black epoxy paint.

Note 4 - Same as P 050970-00000 - type except range setting.

Note 5 - Same as P 050970-00000 - type except pressure setting and cam, Item 61, Pc. No. P 068502-

00000. Special setting 0 psi at clutch and heavy detent at 13 degrees

Note 6 - Same as HD-2-X, Pc. No. P 050973-00001, except cam and escutcheon plate, Item 61 & 67

Pc. No.'s P 067554-00001 & P 048348-00000 respectively. (no graduated pressure at delivery line (8)

when handle is moved in direction towards pipe bracket.)

Page 7

EXPLODED VIEW

Page 8

HD-2-X CONTROLAIR

HD-2-LX CONTROLAIR

HD-2-LS CONTROLAIR

HD-2-XS CONTROLAIR

HD-2-FX CONTROLAIR

HD-2-FXR CONTROLAIR

NOTE:

1. SEE PAGE 9 FOR PART NUMBERS

2. SEE PAGE 10 FOR REPAIR KITS

3. MATCHED / LAPPED SET OF ITEM 34

& 42 ARE IN KIT, P/N P 055687-00000

60

60

63

59

58

57

58 56

65 64 62

47

48

49

50

54

53

52

51

67

66

38

61

55

44

46

45

P/N - P 066890-K0000

Pipe Bracket Portion

Complete (Ref. 1,2,3, 4)

41

Stainless

Steel

Handle

37

36

25

30

31

32

5

68

69

35

34

35

29

39

42

4

1

2

3

7

15

16

17

22

24

21

23

18

19

20

28 27

40

33

Ref. Qty. Description HD-2-X HD-2-LX HD-2-LS HD-2-XS HD-2-FX HD-2-FXR

Complete Device P-50973-000X P-50972-000X P-55446-000X P67556-000X P50970-000X P-51868-000X

1 1 Pipe Bracket P66812-0006 P66812-0006 P66812-0006 P66812-0006 P66812-0006 P66812-0006

2 **1 Filter P66849 P66849 P66849 P66849 P66849 P66849

3 **1 Gasket P66823 P66823 P66823 P66823 P66823 P66823

4 3 Screws P49902-0048 P49902-0048 P49902-0048 P49902-0048 P49902-0048 P49902-0048

5 1

Complete Bottom P55583-000X P55583-000X P55583-000X P55583-000X P55583-000X P55583-000X

Portion includes items 5 thru 33 Must specify spring range, same as last digit on val ve

6 1 Complete Body Bushed w/item 7 P51112-0001 P51112-0001 P51112-0001 P51112-0001 P51112-0001 P51112-0001

7 1 Cartridge Valve See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits

8 2 Side Cartridge Valve w/2 "0" rings P55474-0002 P55474-0002 P55474-0002 P55474-0002 P55474-0002 P55474-0002

8A 2 Side Cartridge Vlv w/2 0rings including P57094-0001 P57094-0001 P57094-0001 P57094-0001 P57094-0001 P57094-0001

4 Snap rings See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits

2 Screens See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits

16 2 Screen See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits

17 2 Snap Ring See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits

18 **1 Cam Dog P52835 P52835 P52835 P52835 P52835 P52835

19 1 Cam Dog Pin P51856 P51856 P51856 P51856 P51856 P51856

20 1 Left Lever,includes Items 21, 23 & 24 P58978-0001 P58978-0001 P58978-0001 P58978-0001 P58978-0001 P58978-0001

21 1 Roller included with lever

22 1 Rt. Lever, includes items 21, 23 & 24 P58979-0001 P58979-0001 P58979-0001 P58979-0001 P58979-0001

23 1 Adjusting screw included with lever

24 1 Pin included with lever

25 *1 Nut See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits

27 1 Lever Pin P50686-0007 P50686-0007 P50686-0007 P50686-0007 P50686-0007 P50686-0007

28 2 Cotter Pins P49913-0001 P49913-0001 P49913-0001 P49913-0001 P49913-0001 P49913-0001

29 *3 Exhaust Valve Spring See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits

30 1 Control Springs See page 6 See page 6 See page 6 See page 6 See page 6 See page 6

31 1 Spring Seat 526347 526347 526347 526347 526347 526347

32 1 Spring Housing P66488-0002 P66488-0002 P66488-0002 P66488-0002 P66488-0002 P66488-0002

33 4 Mounting Nuts P49901-0020 P49901-0020 P49901-0020 P49901-0020 P49901-0020 P49901-0020

34 *1

Graduating Valve includes items 21 &

22

See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits

35 *2 3/4" "O"Rings See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits

36 *1 Washer See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits

1 Complete Top Portion 850258 850258 P55592 P67555 850260 P55583-1

37 *1 Diaphragm See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits

1

Complete Cam Housing includes Items

38,39,40,41,42,63 & 64

P51284 P51205 P51205 P51284-0001 P51205 P51205

38 *1 Cam Housing with bushing P50851-0002 P50851-0002 P50851-0002 P50851-0002 P50851-0002 P50851-0002

39 *1 "O" Ring See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits

40 1 Adjusting screw P66209 P66209 P66209 P66209 P66209 P66209

41 2 Studs P49906-0014 P49906-0014 P49906-0014 P49906-0014 P49906-0014 P49906-0014

42 *1 Exhaust Valve Seat See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits

43 1

Brake Assembly includes items 47,

48, 49, 50 & 65

850187 850187

44 1 Latch See Repair Kits See Repair Kits See Repair Kits See Repair Kits

45 1 Latch Spring See Repair Kits See Repair Kits See Repair Kits See Repair Kits

46 2 Rivets See Repair Kits See Repair Kits See Repair Kits See Repair Kits

47 1 Brake Shoe & Holder See Repair Kits See Repair Kits

48 1 Brake Spring See Repair Kits See Repair Kits

49 1 Washer See Repair Kits See Repair Kits

50 1 Nut See Repair Kits See Repair Kits

51 1 Nut See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits

52 1 Yoke See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits

53 1 Handle Shaft See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits

54 1 Ball See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits

55 1 Stop Pin included with cam #61

56 1 Arbor 850254 850254 850254 850254

57 1 Spacer Washer See Repair Kits See Repair Kits See Repair Kits See Repair Kits

58 2 Return Springs See Repair Kits See Repair Kits See Repair Kits See Repair Kits

59 1 Arbor See Repair Kits See Repair Kits See Repair Kits See Repair Kits

60 1 End Cap Nut P55465 P55465 P55465 P55465 P55465 P55465

61 1 Cam w/Stop Pin P50878-0003 P50878-0003 P50878-0012 P67554-0001 P63994 P51867

62 1 Cam Shaft See Repair Kits See Repair Kits

63 1 Cam Shaft See Repair Kits See Repair Kits See Repair Kits See Repair Kits

64 1 Woodruff Key P49767-0003 P49767-0003

65 1 Brake Drum See Repair Kits See Repair Kits

66 4 Screws P49987-0002 P49987-0002 P49987-0002 P49987-0002 P49987-0002 P49987-0002

67 1 Escutcheon Plate 536565-1 536565-1 536565-1 P48348-1 536565-1 536565-1

68 2 Tooth Washers P49898-0009 P49898-0009 P49898-0009 P49898-0009 P49898-0009 P49898-0009

69 2 Mounting Nuts P49901-0020 P49901-0020 P49901-0020 P49901-0020 P49901-0020 P49901-0020

15 2 Snap Ring See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits See Repair Kits

HD-2 Controlair

Valve Parts List

* These items are in the a minor repair kit for graduating section

** These items are in the major repair kit for graduating section.

Page 9

See Page 10

For Repair Kits

Repair Kits for HD-2 Controlair

Valves

Quantity

Description

per valve

P -055687-00000 1 Minor Graduating Valve Portion-Repair Kit

Note 1 includes items 25, 29, 34, 35, 36, 37, 39 & 42

P -057136-00000 1 Major Graduating Valve Portion-Repair Kit

Note 1 includes items 2,3 & 18 and kit P55687

P -055474-00002 2 Minor Side Valve Portion-Repair Kit

includes item 7 cartridge with "O" Rings

P -057094-00001 2 Major Side Valve Portion-Repair Kit

includes snap ring, screen and kit P -055474-00002

P -064894-00002 1 Complete Repair Kit for Control Portion -

Notes 1,2,3 & 4 includes (1) kit P -055687-00000,

(2) kits P -057094-00001, items 2, 3, 16 & 17

P -064421-00001 1 Spring Latch Kit for LX, LS, FX and FXR Models

Note 5 includes items 44, 45 & 46

850187-00000 1 Friction Brake Kit for FX & FXR Models

Note 5 includes items 47, 48, 49, 50 & 65

P -064421-00004 1 Cam Shaft Kit for FX &FXR Models

Note 5 includes items 51, 52, 53, 54 & 62

P -064421-00005 1 Cam Shaft Kit for X, LX, LS & XS Models

Note 5 includes items 51, 52, 53, 54 & 63

P -064421-00009 1 Return Spring and Arbor Kit for X, LX, LS & XS Models

Note 5 includes items 57, 58 & 59

Piece Number

P 066890-K0000 1 Pipe Bracket Portion Kit for all Models

includes items 1, 2, 3 & 4

NOTES:

1. The inlet and exhaust valve unit Item 34 and exhaust valve seat Item 42 are lapped together to form

a matched set. Kits that contain these items from the factory include matched sets.

2. Select replacement range control spring from identity schedule on page 7.

3. All kits above include small tubes of the recommended lubricants.

4. Valve portion kits listed above contain the seals and other parts that are needed to repair the valve

portion.

5. Replace all worn or damaged components, especially in the mechanical portions of the valve. The

mechanical parts are listed on pages 7, 8 and 9.

Page 10

Item 38 Item 52 Item 53

Model Complete Part Number Cam Housing Yoke Handle Shaft

Part Number Part Number Part Number

HD-2-FX P 066514-00001 P 051025-00001 P 066852-00001 P 050979-00001

HD-2-FX P 064924-00017 P 051025-00000 P 066852-00000 850460-00000

Chrome plated HD-2 Controlair Valves

with chrome plated parts for item numbers listed

(See Note 1 -- Page 6)

Testing and Test Set-Up

Testing

After any repair or adjustments, the HD-2 Controlair Valve

should be tested using the following procedures and test ar-

rangements described in this section.

Pressure control valves need to be tested for the following:

1. Function 4. Flow Capacity

2. Pressure Range 5. Response

3. Leakage 6. Mechanical Detents

The adjustments affecting these points were described in the

previous sections.

General instructions for accomplishing these tests are listed be-

low.

1. Function: The HD-2 Controlair valve is a 4 way exhausted

center valve capable of graduating pressure in one or the

other delivery lines. This function must be checked using the

test arrangement to insure that only one volume is charged

in either direction of handle travel.

2. Pressure Range: The minimum and maximum pressure

range generated in the delivery lines (1) and (3) is specified

by the control spring in use. See the graduated output pres-

sure setting Adjustment Section. After the valve is adjusted,

confirm that the minimum and maximum pressure ranges

are generated in the delivery lines (1) and (3) as per the

Identity Schedule by moving the handle from neutral to first

10 then to the full travel position on both sides of center.

3. Leakage: Set supply pressure to 20 psi above maximum

delivery pressure of the valve being tested. Using a soap

and water solution, coat the valve at the pipe bracket and

spring housing parting lines. No leakage is permitted in any

handle position.

A. Port (1)

1. On all valves with spring ranges less than 90 psi, set

supply line pressure to 100 psi handle to full travel posi-

tion and hold (detent position on detented valves).

Close valve in supply line to port (2) and valve in deliv-

ery line (1) to isolate graduating valve. Observe delivery

pressure gage in line (1). A pressure drop of no more

than 2 psi in 30 seconds is permitted.

2. On all valve with spring ranges of 100 psi and above,

set supply line pressure to 100 psi. Move valve handle

to deliver 95 psi to delivery line (1) and hold in that posi-

tion. Close valve in supply line to port (2) and valve and

valve in port (1) delivery line to isolate the graduating

valve. Observe the delivery gage in line (1). A pressure

drop of no more than 2 psi in 30 seconds is permitted.

B. Port (3)

1. Repeat test A-1 for valves with 90 psi or less in oppo-

site direction of the handle travel.

2. Repeat test A-2 for valves with 100 psi or more in

opposite direction of the handle travel.

4. Flow Capacity: Set supply line pressure to 100 psi regard-

less of the control spring rating. Moving the handle from

neutral position in either direction to full travel position. The

delivery volume (1) or (3) should start to fill within the time

limits shown in Table 1.

Move the handle quickly from full travel position to back to

neutral position. This should exhaust volume (1) or (3)

within the time limits shown on table 1.

Note valve with less than 0 to 35 psi or less rated

springs require an additional volume as shown in test

arrangement diagram.

5. Response

A. Port (1) Move valve handle to the full travel position and

hold. Fully open the valve at test volume (1) so that that

the air exhausts through the choke plug. Observe the

delivery pressure gage at volume (1). A pressure drop

of no more than 3 psi permitted.

B. Port (3) Repeat test 5A for opposite direction of handle

travel.

6. Mechanical Detent (HD-2-LX or SX Models only): Move

handle to extreme detent position. Connect a spring scale

just under the knob Item #54. The force required to pull the

handle out of detent position should be at least 12 lbs.

Check detent hold in both extreme handle positions.

Valve

Range

Fill Psi Maximum

Time-Sec

Exhaust

Psi

Max.

Time

Test

Vol.

0 to15

psi

0 to 15

psi

2 sec

15 to 5

psi

2 sec.

450

cu.in.

0 to20

psi

0 to 15

psi

2 sec

15 to 5

psi

2 sec.

450

cu.in.

0 to25

psi

0 to 15

psi

2 sec

15 to 5

psi

2 sec.

450

cu.in.

0 to30

psi

0 to 15

psi

2 sec

15 to 5

psi

2 sec.

450

cu.in.

0 to 35

psi

0 to 15

psi

2 sec

15 to 5

psi

2 sec.

450

cu.in.

0 to 65

psi

0 to 50

psi

2 sec.

50 to 10

psi

2 sec.

225

cu. In.

0 to 100

psi

0 to 50

psi

2 sec.

50 to 10

psi

2 sec.

225

cu. In.

0 to 125

psi

0 to 50

psi

2 sec.

50 to 10

psi

2 sec.

225

cu. In.

0 to 150

psi

0 to 50

psi

2 sec.

50 to 10

psi

2 sec.

225

cu. In.

0 to 65

psi

0 to 15

psi

2 sec.

50 to 10

psi

2 sec.

225

cu. In.

35 to 85

psi

35 to 70

psi

2 sec.

70 to 40

psi

2 sec.

225

cu. In.

Flow Capacity Tests- Ports 1 & 3

Test Ranges & Times

Page 11

Notes:

1. Rexroth Taskmaster

Timing Volumes, part number TM058887-00225 can be used for the

volumes indicated.

2. The supply air line to the valve and the delivery lines must be full size as shown. Line must not

exceed 3 Ft. between the supply valve and port (2), or between ports (1) & (3).

3. It is recommended that as large a gage as practical be used on the delivery lines. A 6 gage is

recommended.

SM-800.6508

(Supercedes B4-65.0800)

September 2004

Page 12

Test Arrangement Diagram

Pressure

Gage

IN

Clean, dry, chemical free air supply 200 PSIG

maximum (or 20 PSIG above maximum delivery

pressure of any valve to be tested).

OPTIONAL:

Required for low spring range valves only.

1

8

3

2

225 in

3

225 in

3

225 in

3

225 in

3

Choke Plug .032

Delivery Pressure Gages

1/4 Pipe Schedule 40

Or

3/8 O.D. Tubing

Or

#6 Single Braid Hose

LEGEND - PIPE BRACKET

2 - SUPPLY-IN

8 - GRADUATED-DELIVERY

1 - SIDE VALVE-DELIVERY

3 - SIDE VALVE-DELIVERY

REXROTH

P/N PD-020031-00191

PR-7816-10

You might also like

- Manual Sany MantenimientoDocument681 pagesManual Sany MantenimientoJuan Carlos Bermudez Cardenas94% (88)

- 2019 Ford Warranty and Policy ManualDocument256 pages2019 Ford Warranty and Policy ManualRay50% (2)

- ECU Sagem Safir 2 ConectionsDocument1 pageECU Sagem Safir 2 ConectionsBrian Schmidt77% (13)

- TFE 731 Chap 72Document38 pagesTFE 731 Chap 72Egor85100% (1)

- Timing Fuel Syst Setting ToolDocument20 pagesTiming Fuel Syst Setting ToolSaid Touhami100% (2)

- Marine Engine: SpecificationsDocument4 pagesMarine Engine: SpecificationsSiding BarroNo ratings yet

- DETROIT - 6-71 - (Maintenance)Document204 pagesDETROIT - 6-71 - (Maintenance)Farlen Bulsoni100% (2)

- PZ Service ManualDocument40 pagesPZ Service Manualjulioramca100% (5)

- 3512C HD TDC For No 1 PistonDocument3 pages3512C HD TDC For No 1 Pistonharikrishnanpd3327100% (1)

- Caterpillar C15 FTH000001Document3 pagesCaterpillar C15 FTH000001Hendra MechanicNo ratings yet

- 06R0862362+6067MK62 Piezas Comunes PDFDocument2 pages06R0862362+6067MK62 Piezas Comunes PDFAlexis SanchezNo ratings yet

- OPI600 FE Parts ManualDocument50 pagesOPI600 FE Parts ManualActivos Fijos0% (1)

- 12T1600 Mud Pump Clearance Check FormDocument1 page12T1600 Mud Pump Clearance Check FormMoataz Nazeem100% (1)

- Detroit 8.2 v8Document25 pagesDetroit 8.2 v8Jose Juan Davila100% (3)

- Mud Pump Gardner Denver Maintenance Doc - SchlumbergerDocument9 pagesMud Pump Gardner Denver Maintenance Doc - SchlumbergerGlen AshwellNo ratings yet

- Detroit Diesel - 2ngines V-71 Operators Manual: Downloaded From Manuals Search EngineDocument174 pagesDetroit Diesel - 2ngines V-71 Operators Manual: Downloaded From Manuals Search EngineAlexNo ratings yet

- Connections RenaultDocument16 pagesConnections RenaultBrian SchmidtNo ratings yet

- Hdpe FieldDocument44 pagesHdpe Fieldwesqui100% (1)

- Increse Valve de PeriaDocument18 pagesIncrese Valve de Periarony adonay sandovalNo ratings yet

- Bomba Demay Hd500 - AxonDocument34 pagesBomba Demay Hd500 - AxonOSCAR PABA100% (1)

- SS815Document24 pagesSS815Adel Ahmed100% (1)

- Type "S" Relay Valve (Volume Booster) : Service ManualDocument6 pagesType "S" Relay Valve (Volume Booster) : Service Manualayman akrabNo ratings yet

- Detroit V71 Service Manual Parte 2Document319 pagesDetroit V71 Service Manual Parte 2Elisio Marques100% (3)

- 7838 Brake Care and OperationDocument54 pages7838 Brake Care and OperationMarutpal Mukherjee100% (1)

- National Oilwell: Installation, Operation and Maintenance Instructions For Baylor Eddy Current Brake, Model 7838Document51 pagesNational Oilwell: Installation, Operation and Maintenance Instructions For Baylor Eddy Current Brake, Model 7838sorangel_123100% (1)

- Detroit Engine Service Manual DD S V 71 SerDocument12 pagesDetroit Engine Service Manual DD S V 71 SerAndrey PomazanovNo ratings yet

- Liner ProtrusionDocument8 pagesLiner Protrusionsidhu100% (1)

- JGC JGD JGF enDocument145 pagesJGC JGD JGF enKarlosant MJ100% (2)

- Maintenance Interval Schedule: When RequiredDocument3 pagesMaintenance Interval Schedule: When Requiredsxturbo100% (1)

- DENISON - Bomba Hidraulica P16 & 260 CDocument52 pagesDENISON - Bomba Hidraulica P16 & 260 Chebert perezNo ratings yet

- Detroit V71 Service Manual Parte 1Document322 pagesDetroit V71 Service Manual Parte 1Elisio Marques100% (4)

- Novatech Catalog Guide: - All Rights ReservedDocument20 pagesNovatech Catalog Guide: - All Rights ReservedJovianto Prisila100% (1)

- Compresor TuFlo 750-RepDocument40 pagesCompresor TuFlo 750-RepRimbert100% (1)

- 3512C 2365 BHP - SpecDocument4 pages3512C 2365 BHP - SpecJoseramirezjlrt100% (1)

- CAT 3208 Mrine Engine SpecificationDocument4 pagesCAT 3208 Mrine Engine SpecificationCher Wee67% (3)

- Wichita Clutch Spring Set BrakesDocument12 pagesWichita Clutch Spring Set Brakesayman akrab100% (1)

- Yanmar Engine Type 6CXM-GTE2Document2 pagesYanmar Engine Type 6CXM-GTE2Yoga_DMNo ratings yet

- Ds Pf12v71nDocument2 pagesDs Pf12v71nashirogimuto0% (1)

- Detroit Diesel Engine Serial NumbersDocument1 pageDetroit Diesel Engine Serial NumbersLes1011100% (1)

- Detroit Series 60 Service Manual - Vibratoare Seismice - 19-60-00aDocument20 pagesDetroit Series 60 Service Manual - Vibratoare Seismice - 19-60-00anguynthanhlongNo ratings yet

- Automatic Timing Advance 7FB1-Up, 4MG1-4MG3599Document10 pagesAutomatic Timing Advance 7FB1-Up, 4MG1-4MG3599EdivaldoVeronese100% (1)

- Valve Lash - AdjustDocument4 pagesValve Lash - AdjustHugo Cipriani100% (1)

- Compresor Bendix Ba-921 P Detroit PDFDocument36 pagesCompresor Bendix Ba-921 P Detroit PDFDenis HernandezNo ratings yet

- YG110 Hook Block Operation InstructionDocument10 pagesYG110 Hook Block Operation InstructionLuzmary Maiz de BetancourtNo ratings yet

- 3512 Engine Shutoff ValveDocument2 pages3512 Engine Shutoff Valveกัญญารัตน์ พูลทองNo ratings yet

- 12-P-160 Triplex Mud Pump: With Forged CrankshaftDocument14 pages12-P-160 Triplex Mud Pump: With Forged CrankshaftRICHARD100% (1)

- Oem Gardner Denver Pz-11Document8 pagesOem Gardner Denver Pz-11caballero_tigre100% (1)

- PZH (PZ-8) Pump Parts List AF 19002011Document25 pagesPZH (PZ-8) Pump Parts List AF 19002011mantilla7No ratings yet

- CAT - 361 Marine & Generation 645Document314 pagesCAT - 361 Marine & Generation 645david14d100% (1)

- Calibracion de Valvulas D399Document82 pagesCalibracion de Valvulas D399Reynol Rivas80% (5)

- InternationalDocument40 pagesInternationalayman akrabNo ratings yet

- Serva PumpDocument72 pagesServa Pumppengepul rosok100% (1)

- Operator'S Manual For Models: JG, Jga, JGM, JGP: Heavy Duty Balanced Opposed CompressorsDocument70 pagesOperator'S Manual For Models: JG, Jga, JGM, JGP: Heavy Duty Balanced Opposed CompressorsDjebali MouradNo ratings yet

- JWS 400Document2 pagesJWS 400николайNo ratings yet

- Eight Position Cylinders Service Information: Warnings-Installation and MountingDocument10 pagesEight Position Cylinders Service Information: Warnings-Installation and MountingyelmustafaaliNo ratings yet

- Ingersoll Rand SS815 Parts ManualDocument36 pagesIngersoll Rand SS815 Parts ManualSergei KurpishNo ratings yet

- SC-700-800 Valvulas de Convercion de AireDocument100 pagesSC-700-800 Valvulas de Convercion de AireFlorencio MaximilianoNo ratings yet

- Fabco PTO 180 PTO 180 23 Parts ManualDocument27 pagesFabco PTO 180 PTO 180 23 Parts Manualeliseo cardosoNo ratings yet

- RexrothDocument14 pagesRexrothWilson CendalesNo ratings yet

- H-2 Controlair Valve: Service InformationDocument18 pagesH-2 Controlair Valve: Service InformationRonald LlerenaNo ratings yet

- Rexroth ValveDocument20 pagesRexroth ValvesatriaNo ratings yet

- R431002626 AventicsH 3Controlair®ValveswithRollerDocument2 pagesR431002626 AventicsH 3Controlair®ValveswithRollerHamza ChenakerNo ratings yet

- Super Choke BasicsDocument10 pagesSuper Choke Basicsel_guariquenoNo ratings yet

- Super Choke BasicsDocument10 pagesSuper Choke BasicsTg TarroNo ratings yet

- Amico Regulador de Manifold Planos PDFDocument52 pagesAmico Regulador de Manifold Planos PDFLopez ClaudioNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Lowrance Simrad Dealer Install - ProgramDocument3 pagesLowrance Simrad Dealer Install - ProgramBrian SchmidtNo ratings yet

- Portable Boring MachineDocument6 pagesPortable Boring MachineBrian SchmidtNo ratings yet

- Baypren BroschureDocument16 pagesBaypren BroschureDevender KumarNo ratings yet

- How To Perform Data Mover Failover and FailbackDocument2 pagesHow To Perform Data Mover Failover and FailbackMalyaj ShankerNo ratings yet

- CV Oil and GasDocument6 pagesCV Oil and Gaszameer malikNo ratings yet

- Equipment Design Rubric-WrittenDocument2 pagesEquipment Design Rubric-WrittenSam Denielle TugaoenNo ratings yet

- PLC Based Elevator Model Collage Project 2006Document4 pagesPLC Based Elevator Model Collage Project 2006Pawan D BarondeNo ratings yet

- Lecture 4.1Document31 pagesLecture 4.1VershiyiLambertNo ratings yet

- ADS Summer 2022 Market Monitor vF2Document14 pagesADS Summer 2022 Market Monitor vF2Nadja Josefine GavrilukNo ratings yet

- Bell Crank White PaperDocument9 pagesBell Crank White PaperagniflameNo ratings yet

- 011 - CAR Corrective Action ReportDocument4 pages011 - CAR Corrective Action ReportRocky BisNo ratings yet

- Legends: L-Lecture T - Tutorial/Teacher Guided Theory Practice P - Practical C - Credit, CADocument7 pagesLegends: L-Lecture T - Tutorial/Teacher Guided Theory Practice P - Practical C - Credit, CAMohammed FaizNo ratings yet

- Mini Assignment 1 (Given)Document4 pagesMini Assignment 1 (Given)pobox0210No ratings yet

- An Introduction To PlatinumDocument102 pagesAn Introduction To PlatinumMarcelo G.100% (1)

- Bolts and NutsDocument18 pagesBolts and NutsKhaled SalemNo ratings yet

- CP Carrillo HardwareDocument23 pagesCP Carrillo HardwarePaul ZiddyNo ratings yet

- Executive Office Assistant Group Managing Director Job Description May12Document1 pageExecutive Office Assistant Group Managing Director Job Description May12cdarshakNo ratings yet

- Excavator: TerminologyDocument8 pagesExcavator: TerminologySenna KesavanNo ratings yet

- Toyota Motor Corporation and TPSDocument5 pagesToyota Motor Corporation and TPSMaitri BiswadharaNo ratings yet

- 02 HummingbirdDocument36 pages02 Hummingbirdantenr100% (1)

- Risk Assessment DAWRA001R4 Loading Unloading Vehicles 090621Document2 pagesRisk Assessment DAWRA001R4 Loading Unloading Vehicles 090621Danny100% (1)

- Distribution Channel of CSR Forging Pvt. Ltd.Document33 pagesDistribution Channel of CSR Forging Pvt. Ltd.Dheeraj SinghalNo ratings yet

- WWW Guru99 ComDocument22 pagesWWW Guru99 ComAbu Nilu Mostofa JamalNo ratings yet

- Input Rate (Unit/hr) Throughput Rate Output Rate (Unit/hr) Min (Demand, Capacity)Document3 pagesInput Rate (Unit/hr) Throughput Rate Output Rate (Unit/hr) Min (Demand, Capacity)Tanvi S PurohitNo ratings yet

- Tronox LP Eng GesichertDocument3 pagesTronox LP Eng GesichertForeverNo ratings yet

- Financial Statement and Ratio Analysis of Tata MotorsDocument120 pagesFinancial Statement and Ratio Analysis of Tata MotorsAMIT K SINGH100% (1)

- Chapter 9 MacroDocument52 pagesChapter 9 MacroRusselle AdrianoNo ratings yet

- Rubber Buffer SpringDocument14 pagesRubber Buffer SpringmailbkraoNo ratings yet